¶ What it is

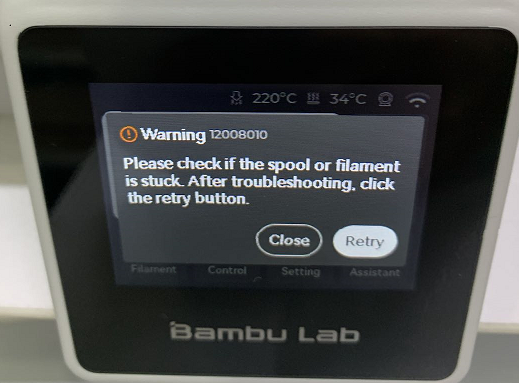

- If the prompt pops up on the screen, as shown below, please refer to steps of solution 1.

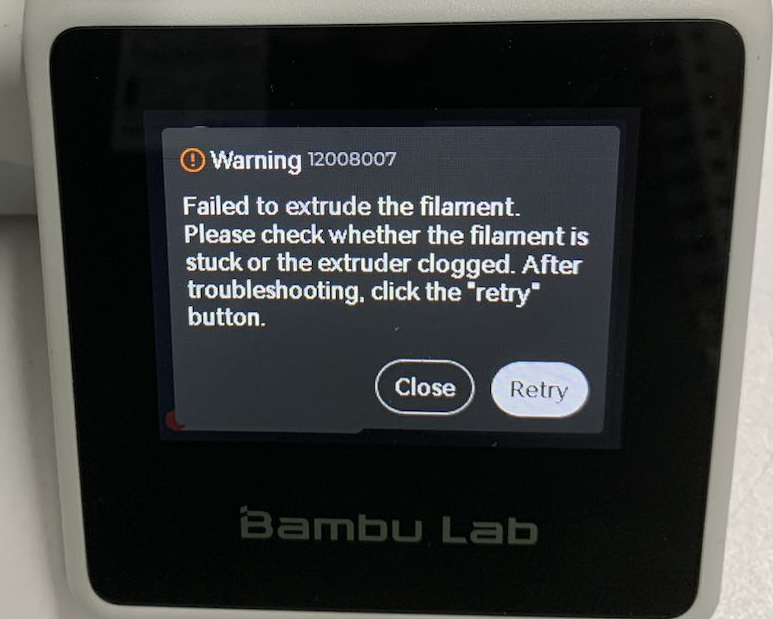

- If the prompt pops up on the screen, as shown below, please refer to steps of solution 2.

¶ Filament tangle detection

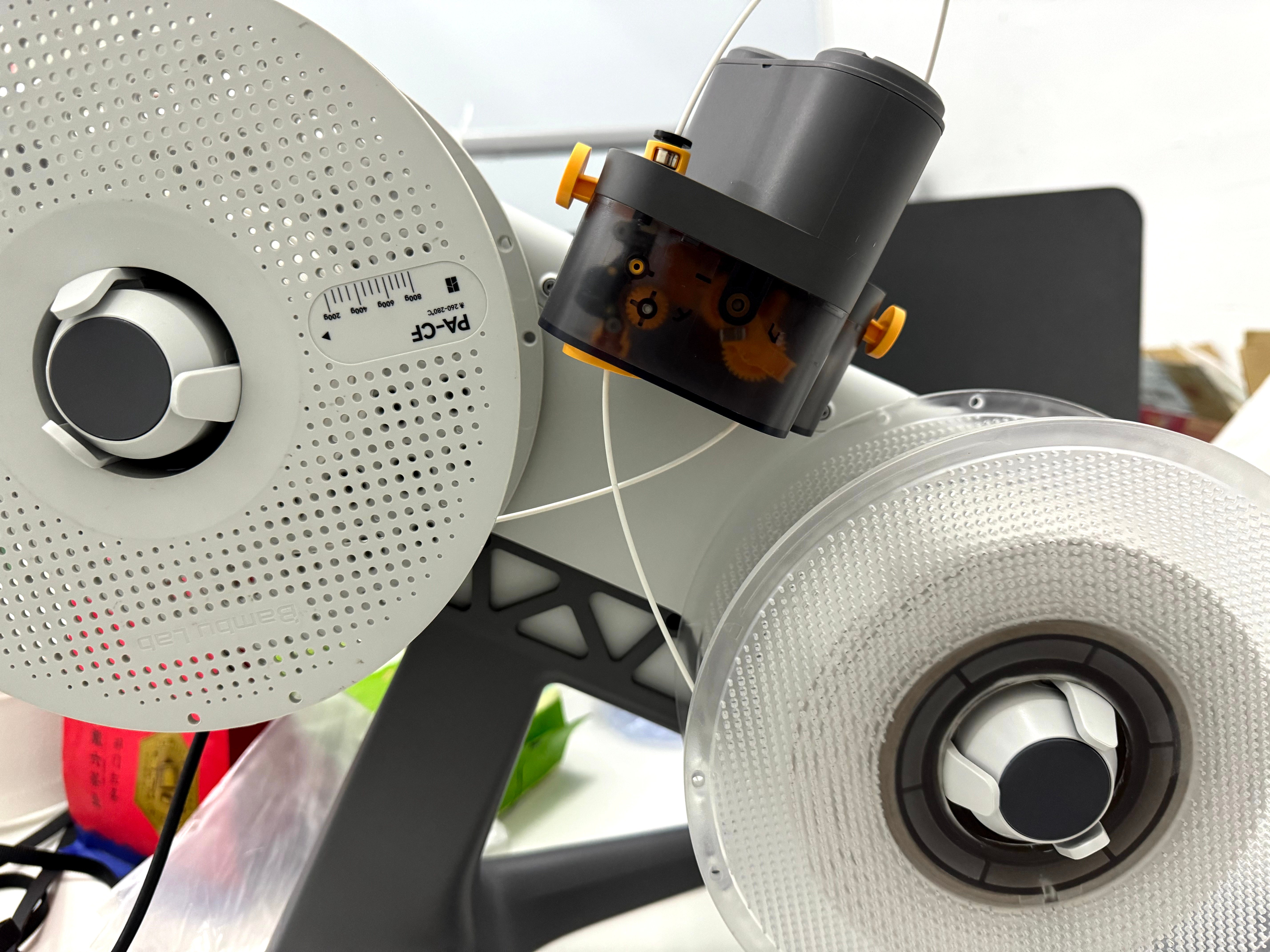

There is a tangle detection module above the tool head. When the resistance of the AMS feed is too high, the tangle detection module will be pressed down to trigger the Hall sensor inside the tool head, and the printer will determine that the feed resistance is too high. The comparison between the normal feeding and detected tangle status of the tangle detection module is as follows:

- During the printing process, when the tangle detection module is triggered, the printer will automatically cut the filament and pull back the filament, pause, and report an error. Once the tangle problem is resolved, please click “Retry” to continue printing.

- During the process of feeding new filament into the extruder(including filament exchange), the extruder will extrude a section of filament to ensure the filament is grabbed successfully, when the tangle detection module is triggered, the printer will pause and report an error. Please refer to Solution 2 below for troubleshooting. Once the tangle problem is resolved, please click “Retry” to continue printing.

The tangle detection function does not apply to all types of filament, please refer to this wiki for more details: Introduction to filament tangle monitoring | Bambu Lab Wiki

¶ Solution1

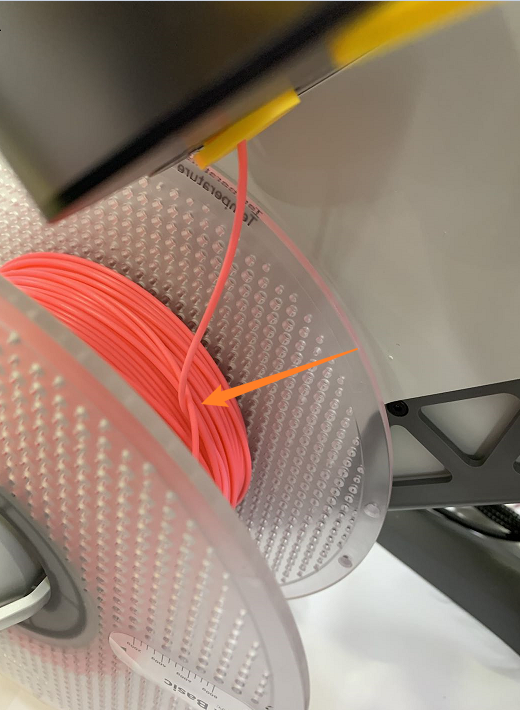

1. Check the filament on the spool for entanglement. If it gets tangled, manually rearrange the filament, insert it into the AMS slot, and click the “Retry” button.

2. Sometimes the filament may be caught on the edge of the spool and cannot be sent out. Please pull it out and try again.

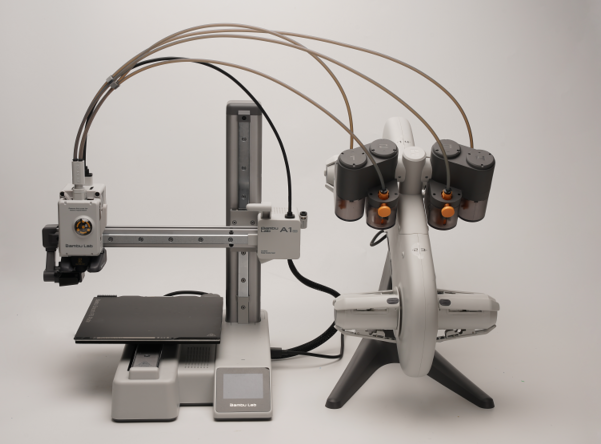

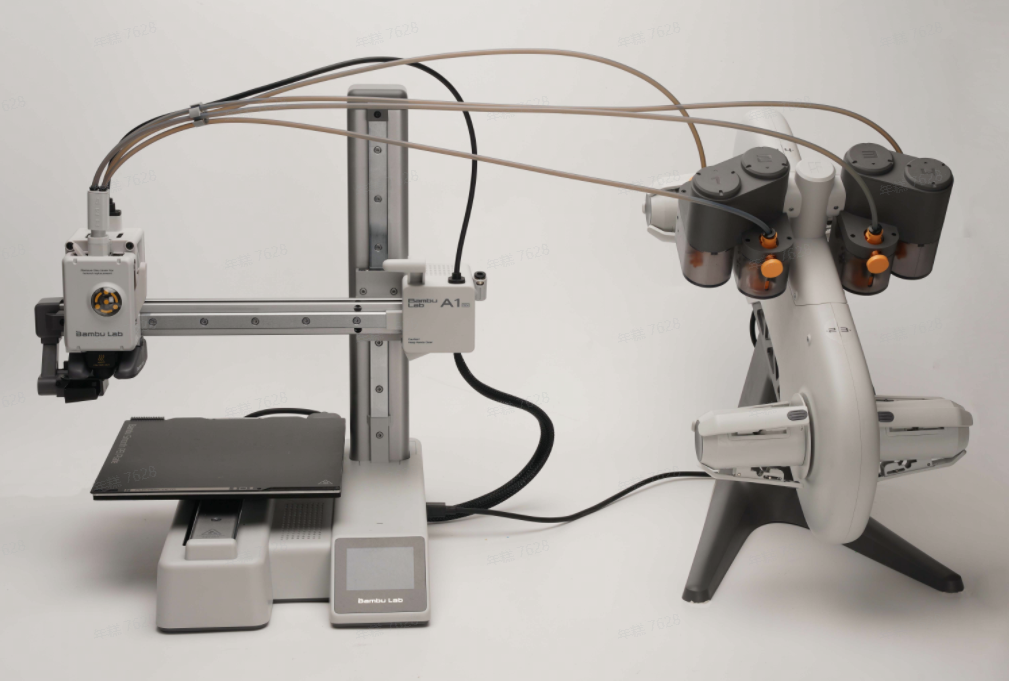

3. If there is no tangle or sink problem, please check if the PTFE tube of this slot is bent too much or too long, which can also cause excessive resistance in the feeding path. The standard length of the PTFE tube is 580mm for slot 1 and slot 2, and 700mm for slot 3 and 4. The optimal placement of the printer and AMS is shown in the following figure 1. If the printer and AMS are placed far apart, the PTFE tube will be pulled and bent, resulting in high feed resistance, as shown in the following figure 2.

4. Check if there are any residual chips on the extrusion wheel of the corresponding slot of AMS lite. Please clean them and click the retry button.

5. Please confirm whether the filament is inserted into the wrong slot, for example, the filament of slot 1 is inserted into the feeder of slot 2 by mistake, as shown in the following picture:

6. If you cannot solve the problem through the above steps, please submit a support ticket to contact our support team.

¶ Solution2

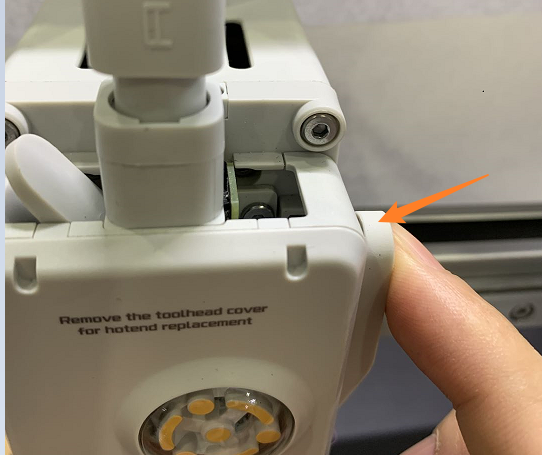

- First check whether the filament on the spool is tangled or sunk, and whether the PTFE tube is installed incorrectly or the AMS Lite is placed too far away from the printer, as shown in solution 1. If not, please manually press the tool head cutter to cut off the filament.

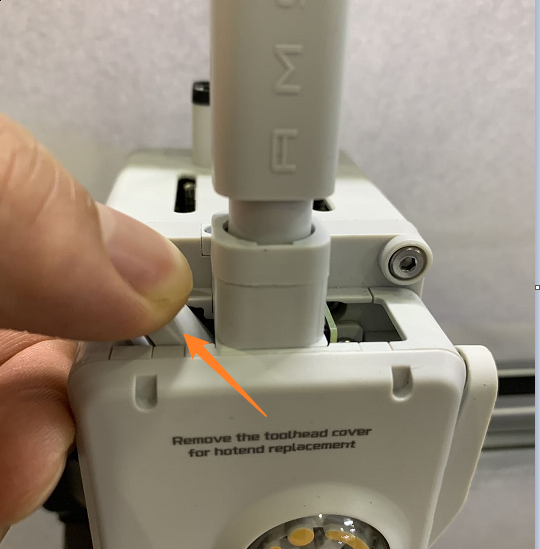

2. Manually press the drive wheel holder of the tool head and pull the filament from the feeder side.

|

|

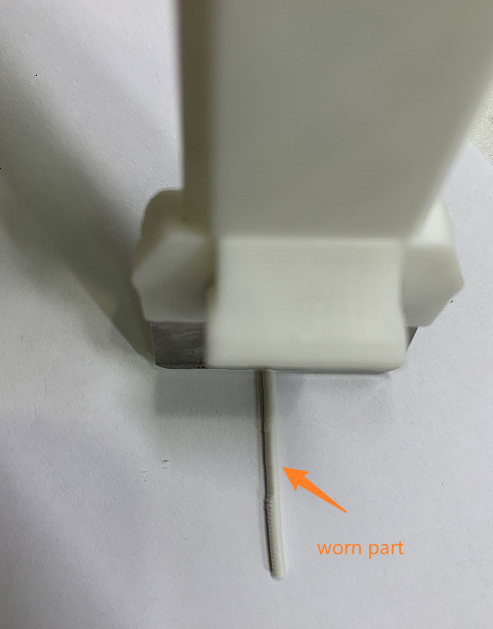

3. After pulling out the filament, check if there are any signs of wear on the filament. If so, cut the worn part, then insert the filament into the corresponding slot and retry.

4. If the problem still exists, please check whether the extruder or hot end is clogged, if the nozzle and extruder are not clogged, you can check whether the filament is too thin, whether the filament is slipping with the extruder gear, etc., you can also replace a roll of filament and try again. If multiple rolls of material will encounter this problem, it may also be that the extruder gear is abnormal, and can not successfully grab the filament.

5. If you are still unable to resolve the problem through the above steps, please submit a support ticket to contact the after-sales support team.

¶ Error message

HMS_1201-8000-0002-0001: AMS2 Slot1 filament may be tangled or stuck.

HMS_1201-8100-0002-0001: AMS2 Slot2 filament may be tangled or stuck.

HMS_1201-8200-0002-0001: AMS2 Slot3 filament may be tangled or stuck.

HMS_1201-8300-0002-0001: AMS2 Slot4 filament may be tangled or stuck.

HMS_1202-8000-0002-0001: AMS3 Slot1 filament may be tangled or stuck.

HMS_1202-8100-0002-0001: AMS3 Slot2 filament may be tangled or stuck.

HMS_1202-8200-0002-0001: AMS3 Slot3 filament may be tangled or stuck.

HMS_1202-8300-0002-0001: AMS3 Slot4 filament may be tangled or stuck.

HMS_1203-8000-0002-0001: AMS4 Slot1 filament may be tangled or stuck.

HMS_1203-8100-0002-0001: AMS4 Slot2 filament may be tangled or stuck.

HMS_1203-8200-0002-0001: AMS4 Slot3 filament may be tangled or stuck.

HMS_1203-8300-0002-0001: AMS4 Slot4 filament may be tangled or stuck.

HMS_1200-8000-0002-0001: AMS1 Slot1 filament may be tangled or stuck.

HMS_1200-8100-0002-0001: AMS1 Slot2 filament may be tangled or stuck.

HMS_1200-8200-0002-0001: AMS1 Slot3 filament may be tangled or stuck.

HMS_1200-8300-0002-0001: AMS1 Slot4 filament may be tangled or stuck.

¶ End notes

We hope our guide was helpful. If you have any questions or concerns about the process, please contact our customer service team. We're here to assist you.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.