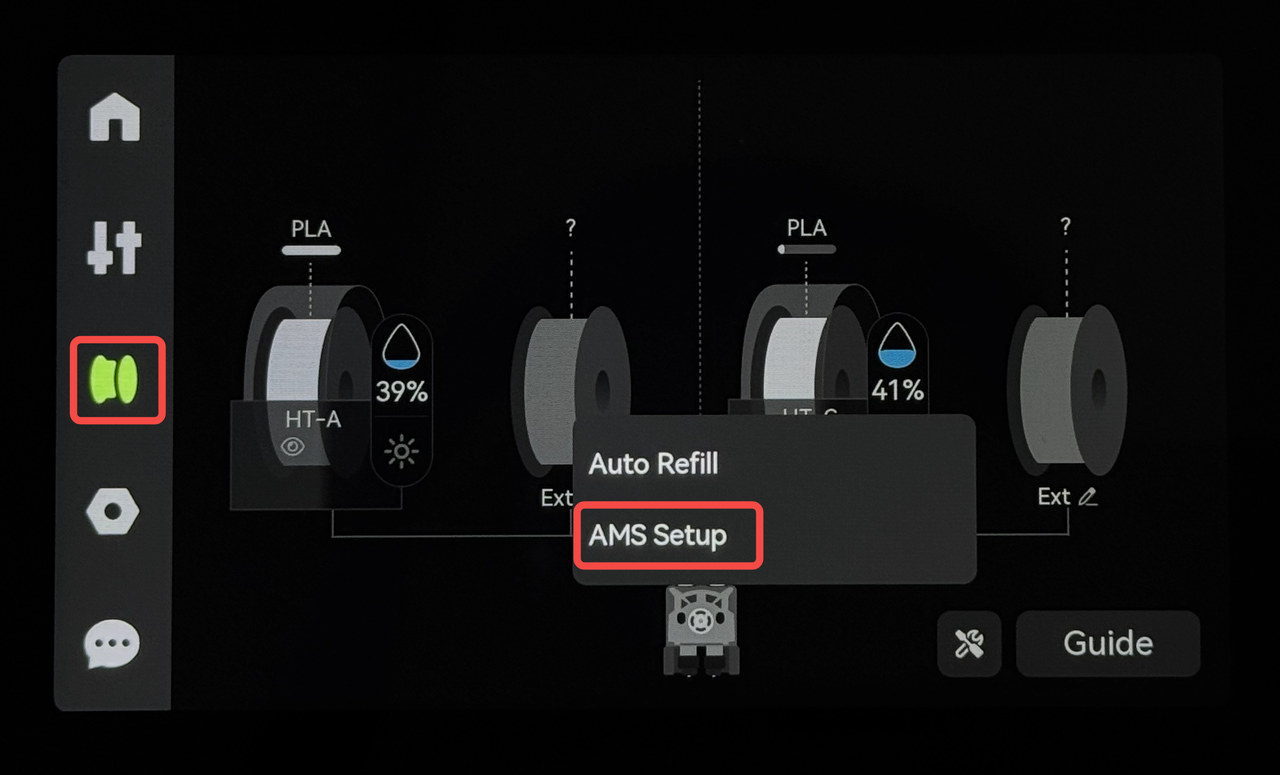

¶ AMS Setup

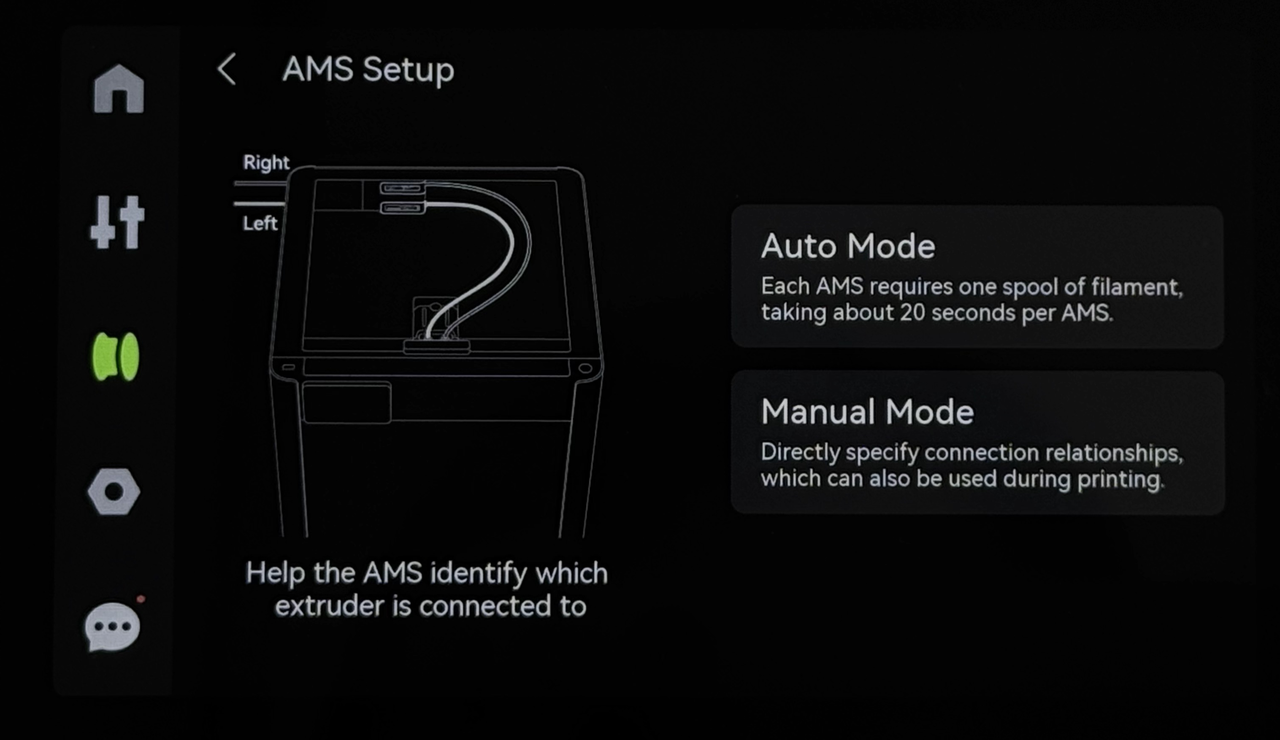

When connecting AMS HT to an H2D printer for the first time, you need to perform an initialization. Because H2D is equipped with dual extruders, this step aims to detect which side of the extruder AMS is connected to. On the "Filament" Page - "AMS Setup", select "Auto Mode" or "Manual Mode" to start the AMS setup.

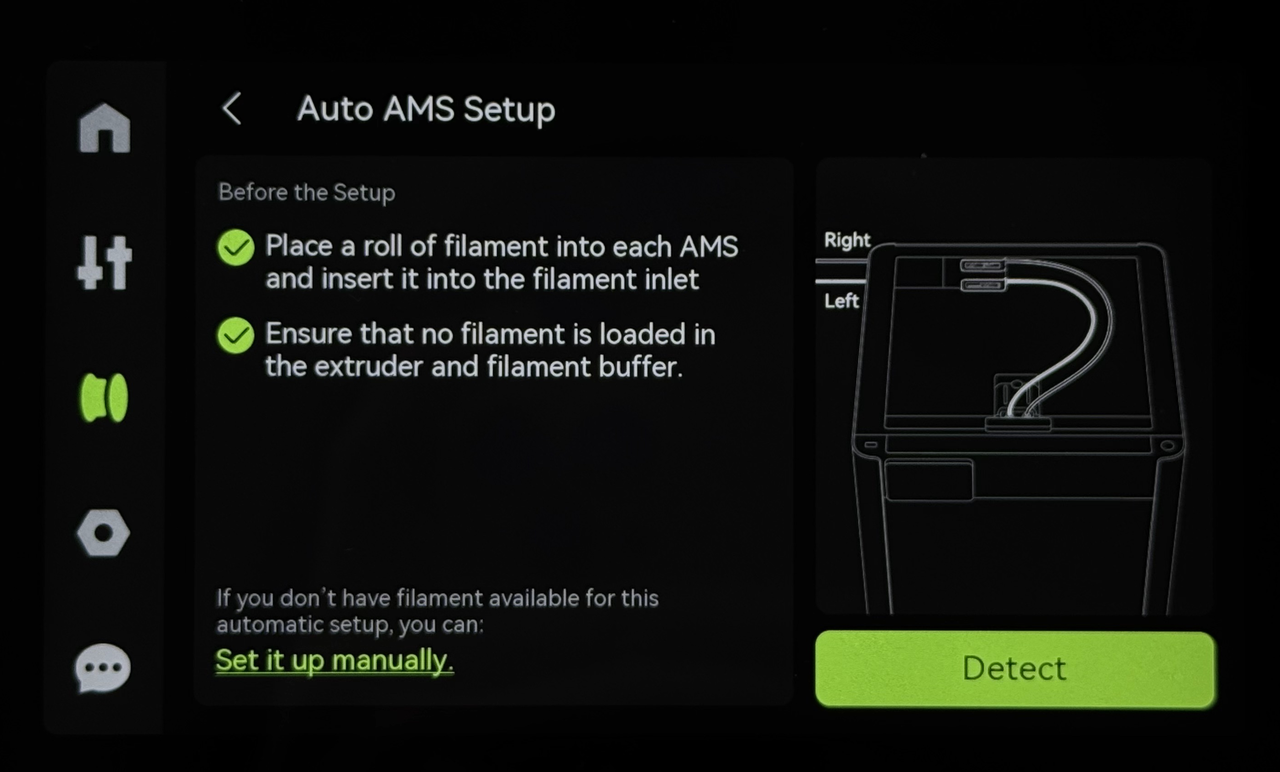

¶ Auto Mode

Operation steps:

Enter the printer screen "Filament" → "AMS Steup" → select "Auto Mode";

The system automatically detects the extruder (left/right) to which the AMS is connected.

Note:

Ensure that the filament is inserted into AMS HT.

The loaded filament must be unloaded in advance.

Ensure that there is no residual filament inside the filament buffer (to avoid leftover filament inside).

Working principle:

AMS sends the filament to the extruder. Each left and right extruder is equipped with a Hall sensor. The signal triggered by the Hall sensor is used to determine which extruder AMS is paired with.

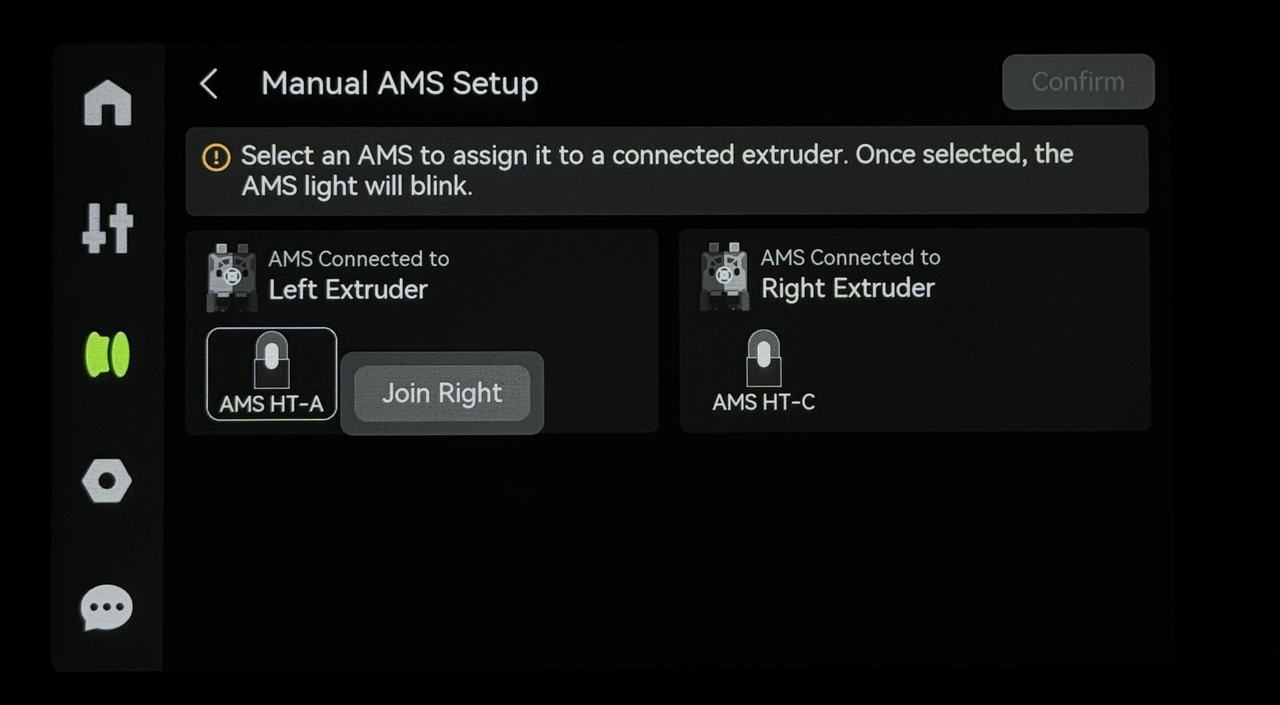

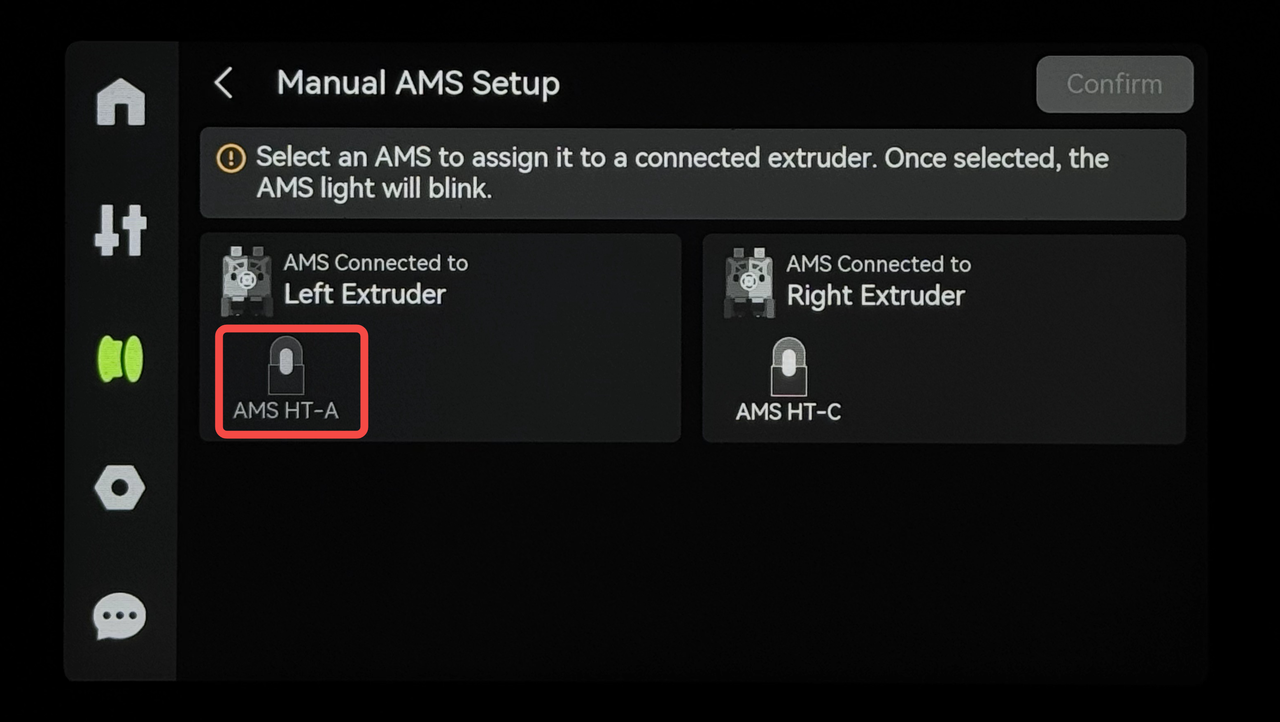

¶ Manual Mode

Applicable scenarios: Manually adjust the pairing relationship between AMS and extruder when there is no filament in AMS.

Operation steps:

Enter "Filament" → "AMS Setup" → select "Manual Mode";

Manually specify the extruder side (left/right) to which AMS is connected.

Restrictions:

- When an AMS has sent the filament to the extruder, the AMS icon will be gray and the pairing relationship with the extruder cannot be changed.

¶ AMS Features

¶ Pre-loading

Function: Tighten the filament roll on the spool to ensure that the filament on the spool is not loose, and provide interactive feedback when inserting.

Trigger method: When the AMS HT is idle, insert the filament into the feeder → automatic pre-loading (the assist motor sends the filament to the Hall sensor at the rear of the AMS and then pulls it back).

Insertion assistance function: Click the empty slot icon → the internal assist motor starts to rotate, which can be used to assist in inserting.

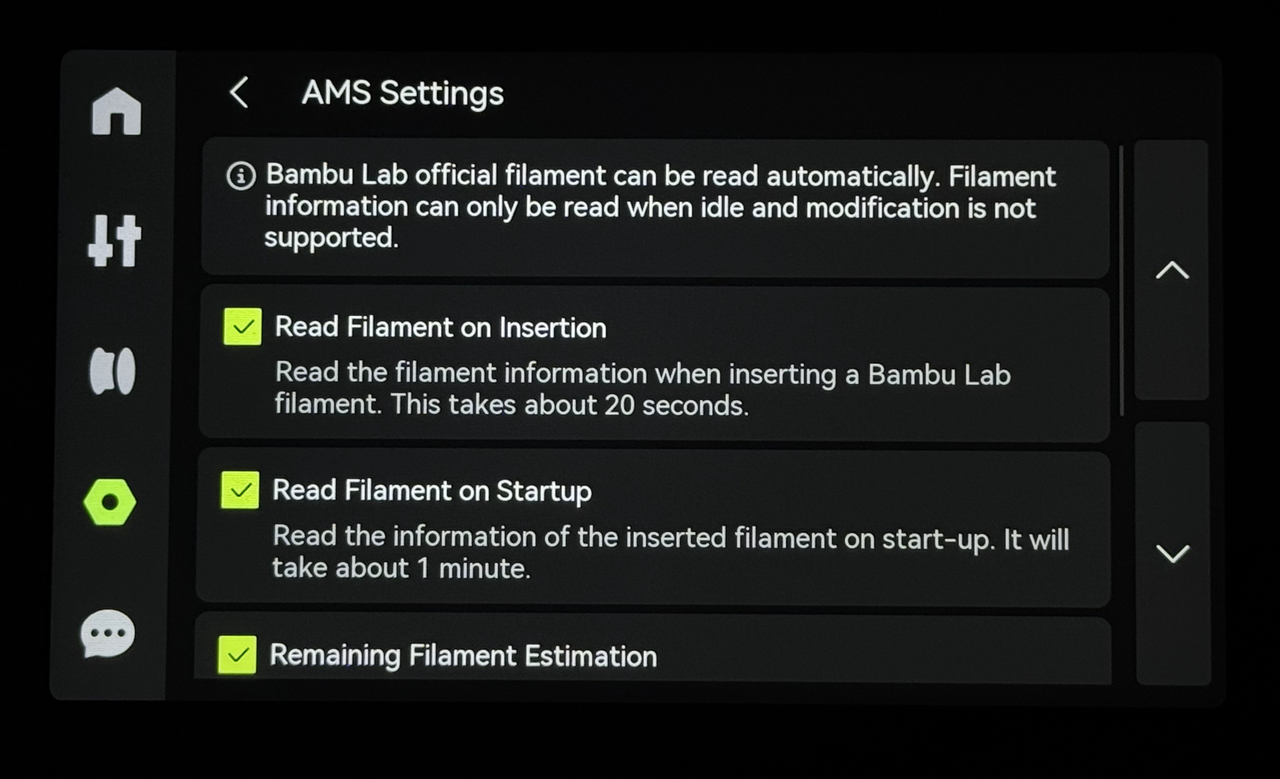

¶ Reading RFID

Mode settings:

You can set the Reading RFID function in the screen "Settings" - "AMS Options".

Read Filament on Insertion: automatically read RFID after inserting the filament;

Read Filament on Startup: automatically read the RFID information of the inserted filament after restarting AMS;

- Manual read: click the corresponding slot → "Re-Read" to re-read the RFID of the slot.

|

|

|---|

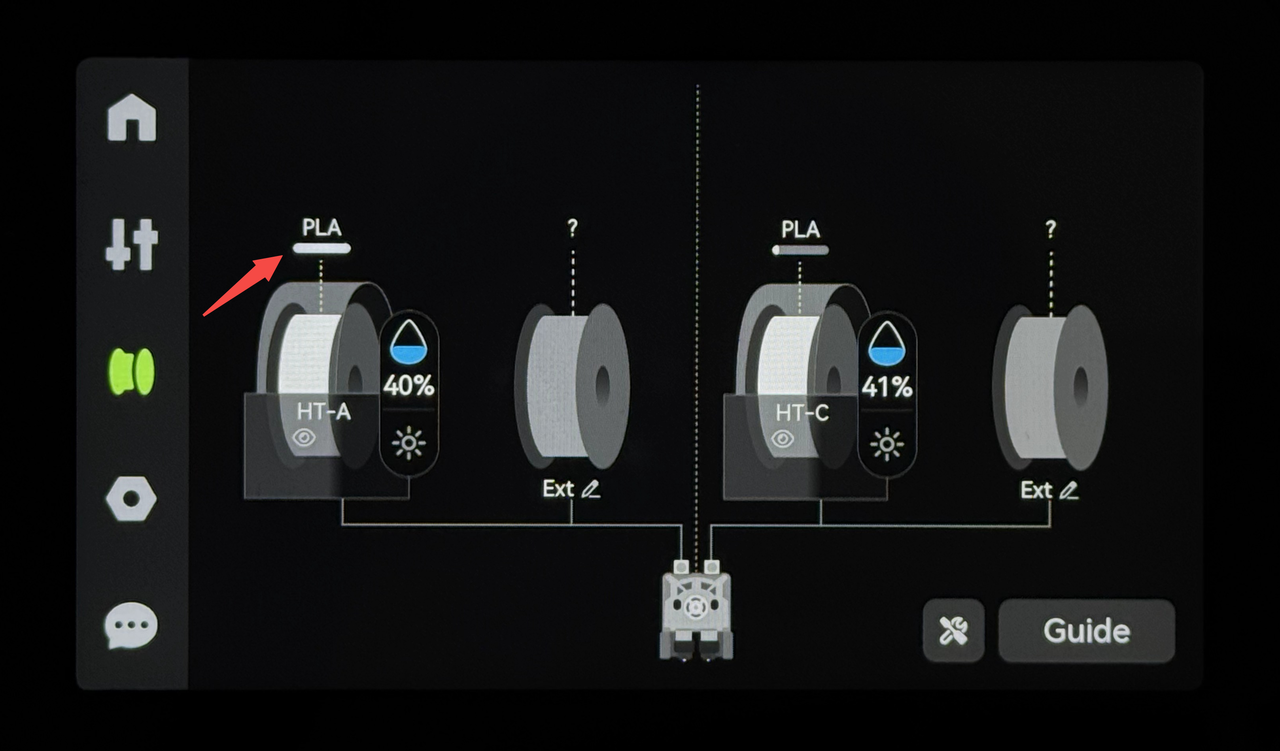

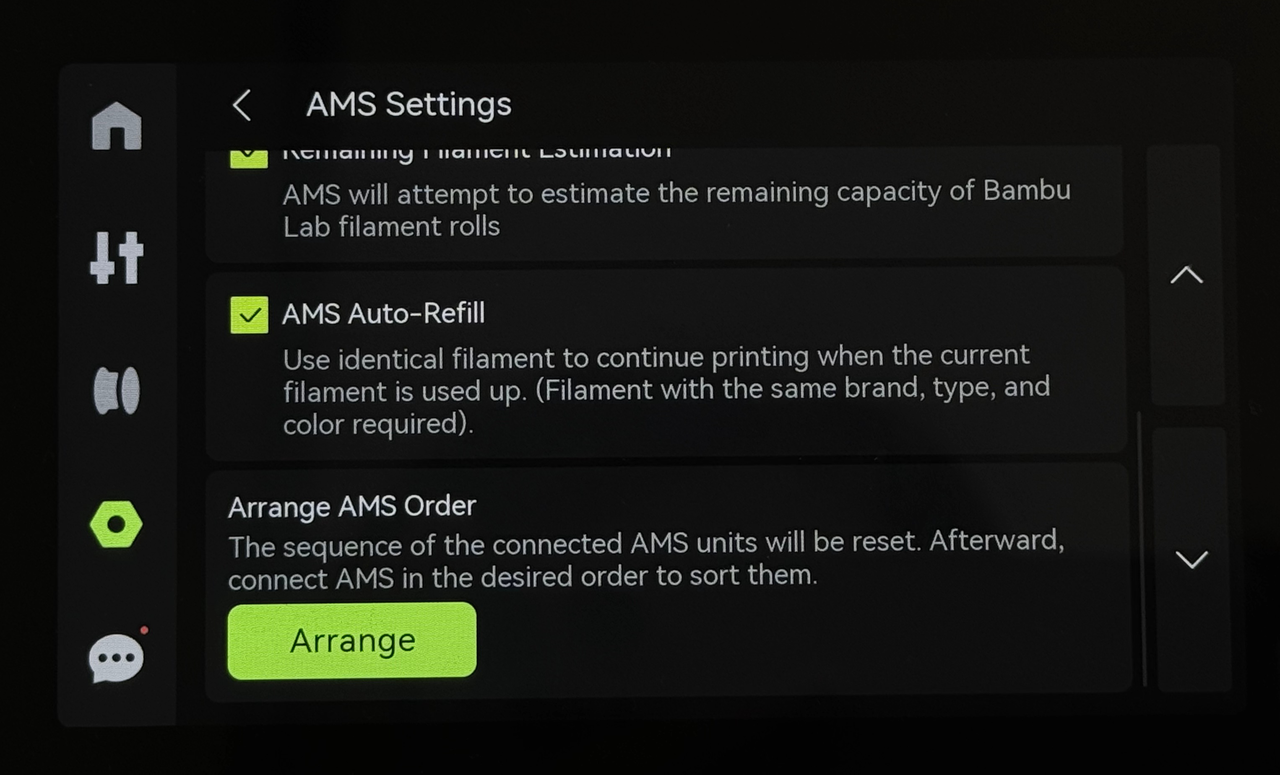

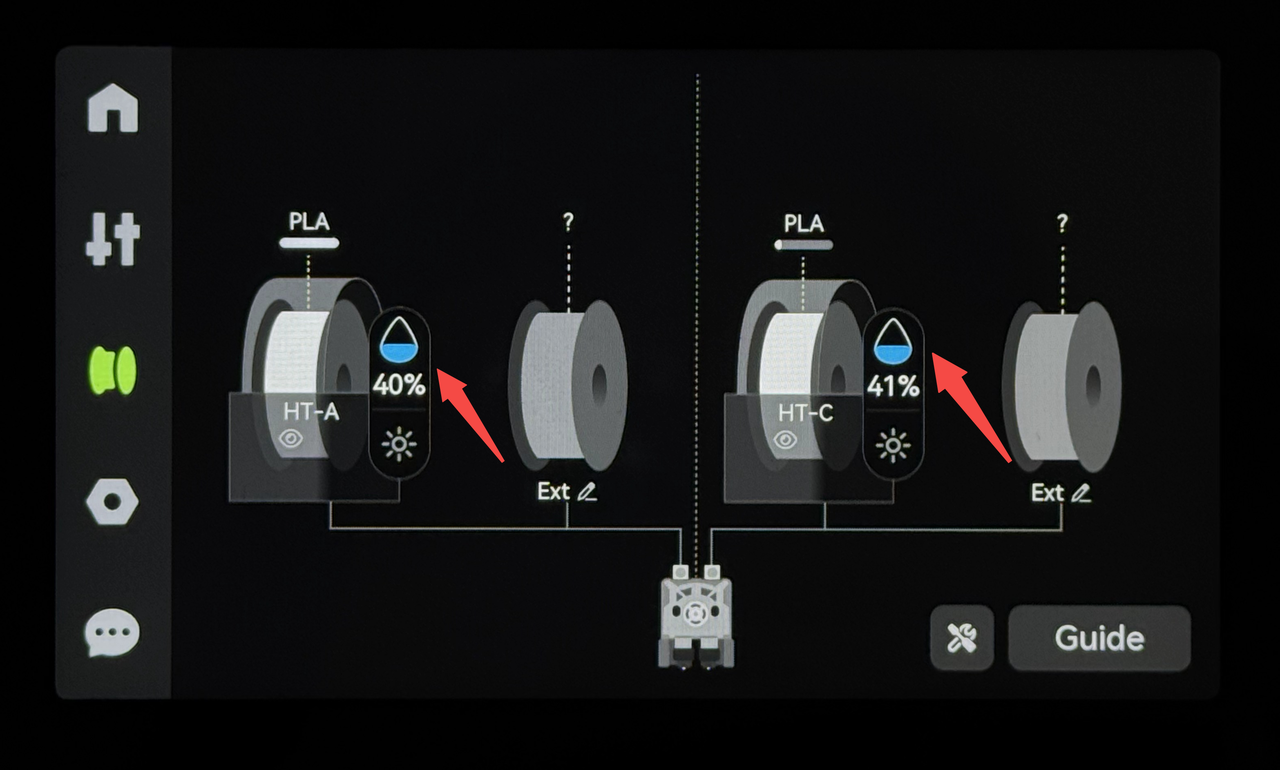

¶ Remaining Filament Estimation

Working principle: The remaining filament is estimated by the length of the filament fed out by the RFID tag after one rotation (the complete 1kg filament roll is 100% capacity by default). If this function is enabled, the RFID reading process will be carried out twice, the first time reading the filament information and the second time estimating the remaining capacity.

Display location: The small horizontal bar below the filament name shows the estimated remaining filaments.

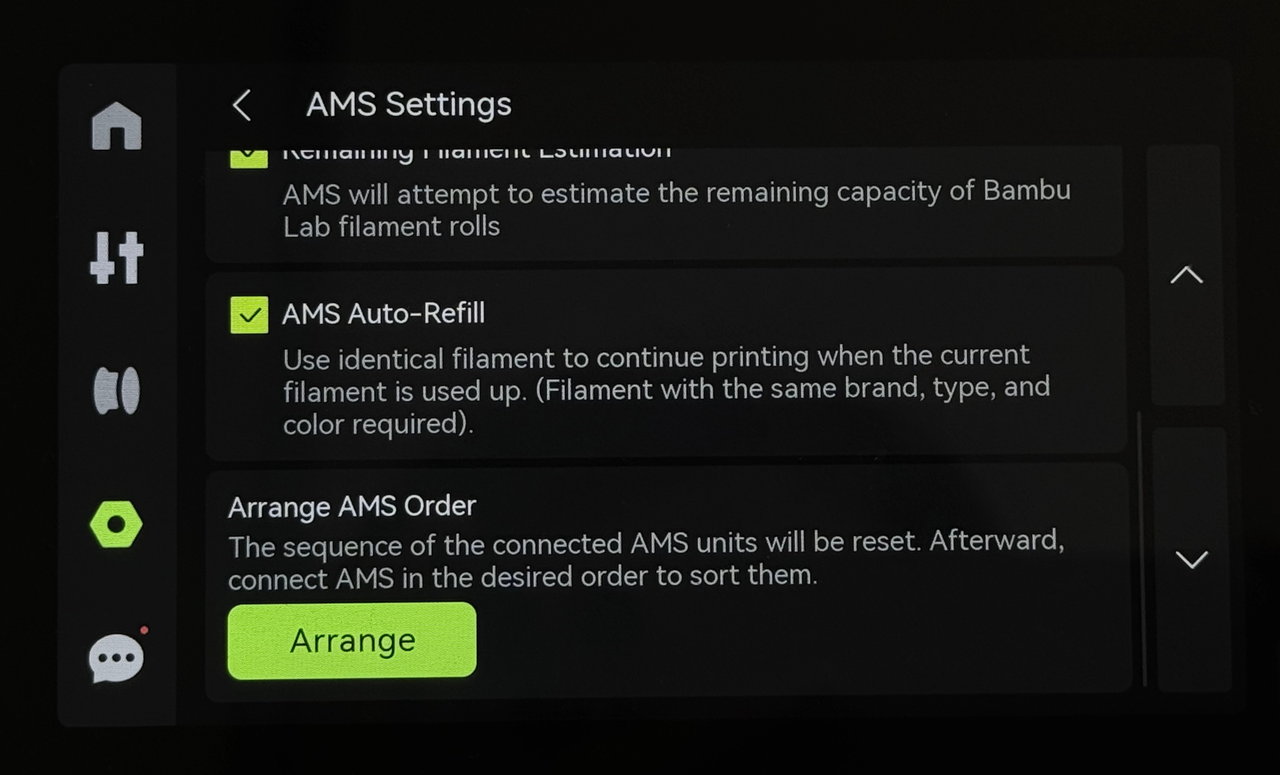

¶ Arrange AMS Order

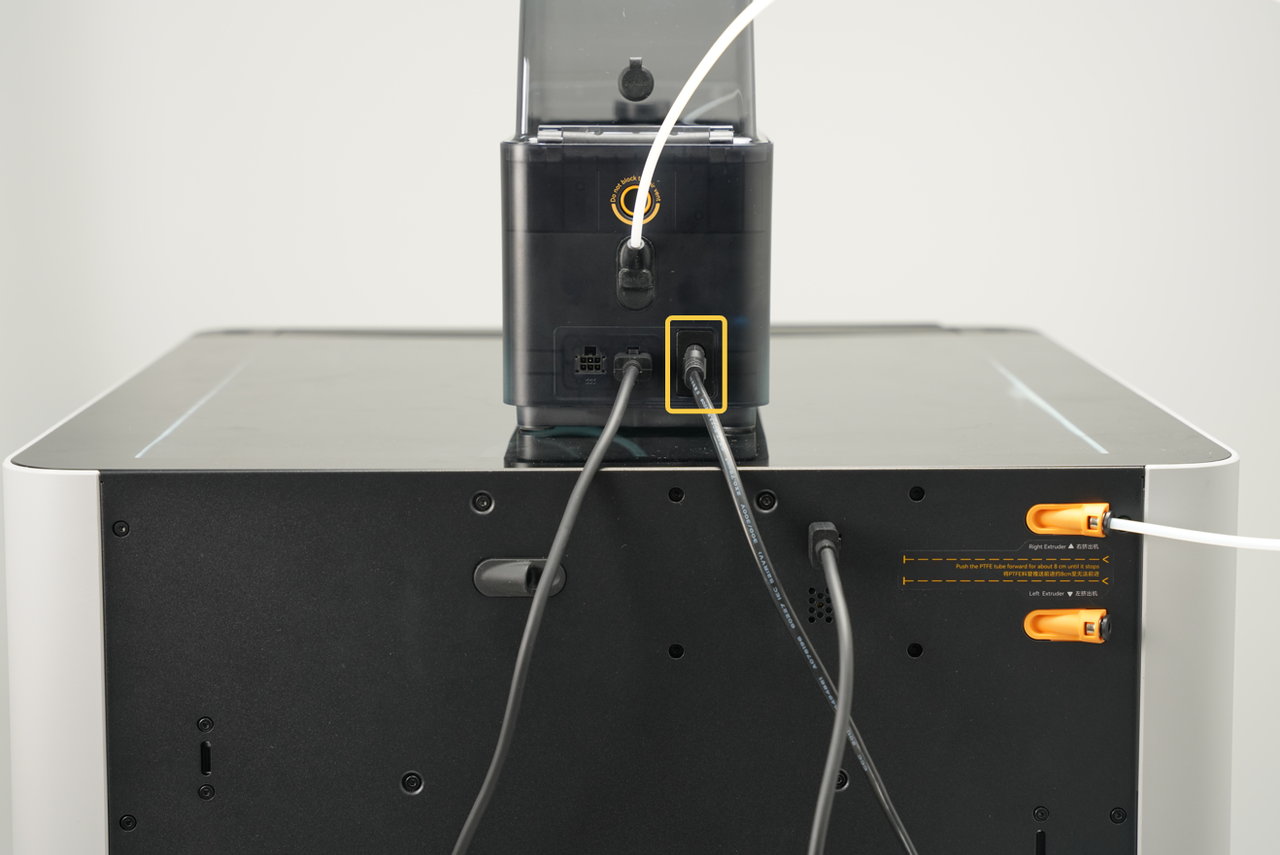

Default order logic: Each AMS will be assigned an order and displayed on the screen. Directly connected to the printer via a 6-pin cable is AMS A, and the cascaded ones are B, C, and D;

Manual reset: Click "Arrange" → Reconnect AMS as needed.

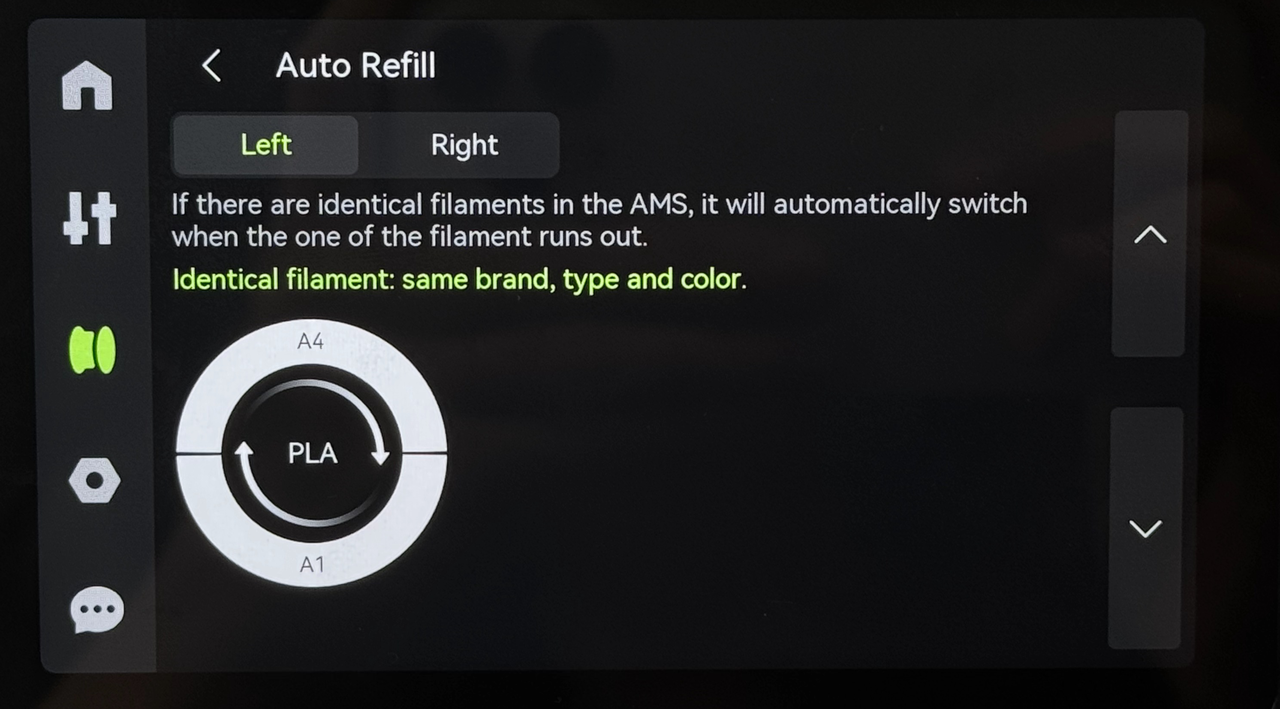

¶ AMS Auto-Refill

Enable conditions:

The filament properties are exactly the same (brand, type and color) to form a refill relationship.

The filaments must be located in the AMS connected to the same extruder (left to left, right to right).

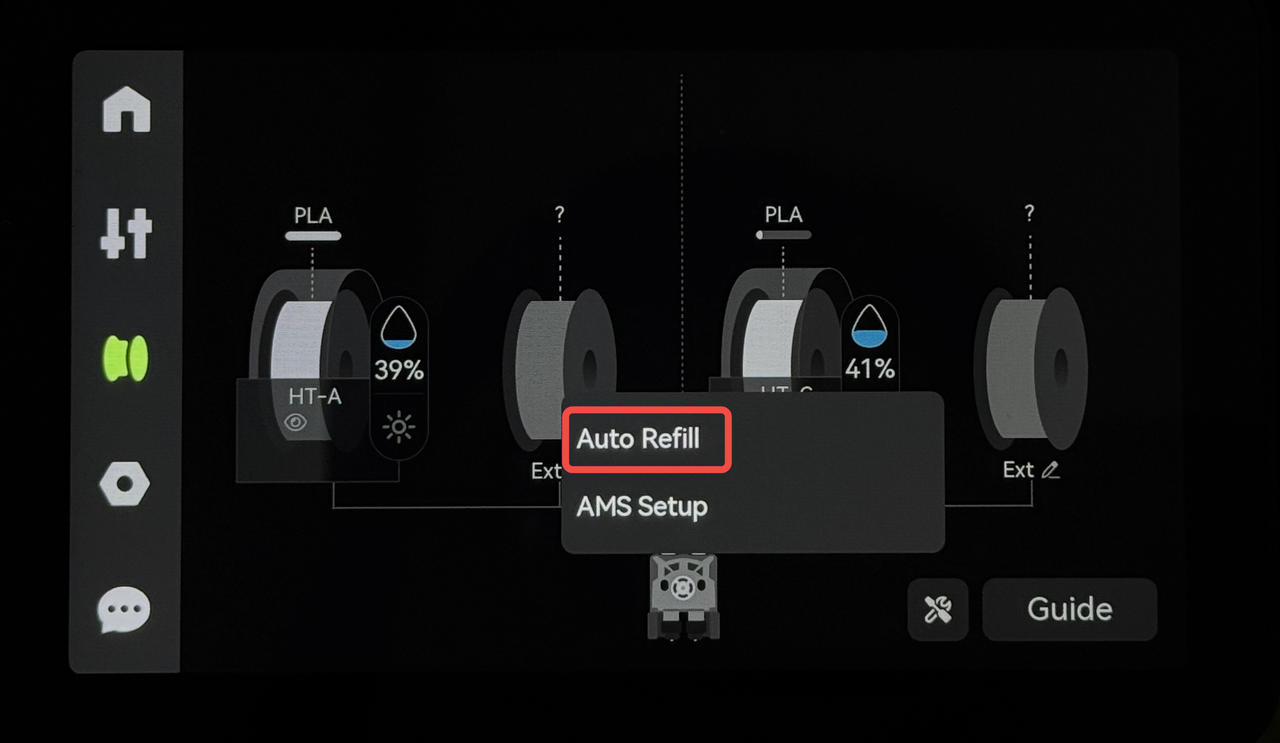

Operation steps:

- "Settings" → "AMS Options" → Select "AMS Auto-Refill" to enable the auto refill function.

- "Filament" → "Auto Refill" → View the refill relationship on the left and right extruder pages.

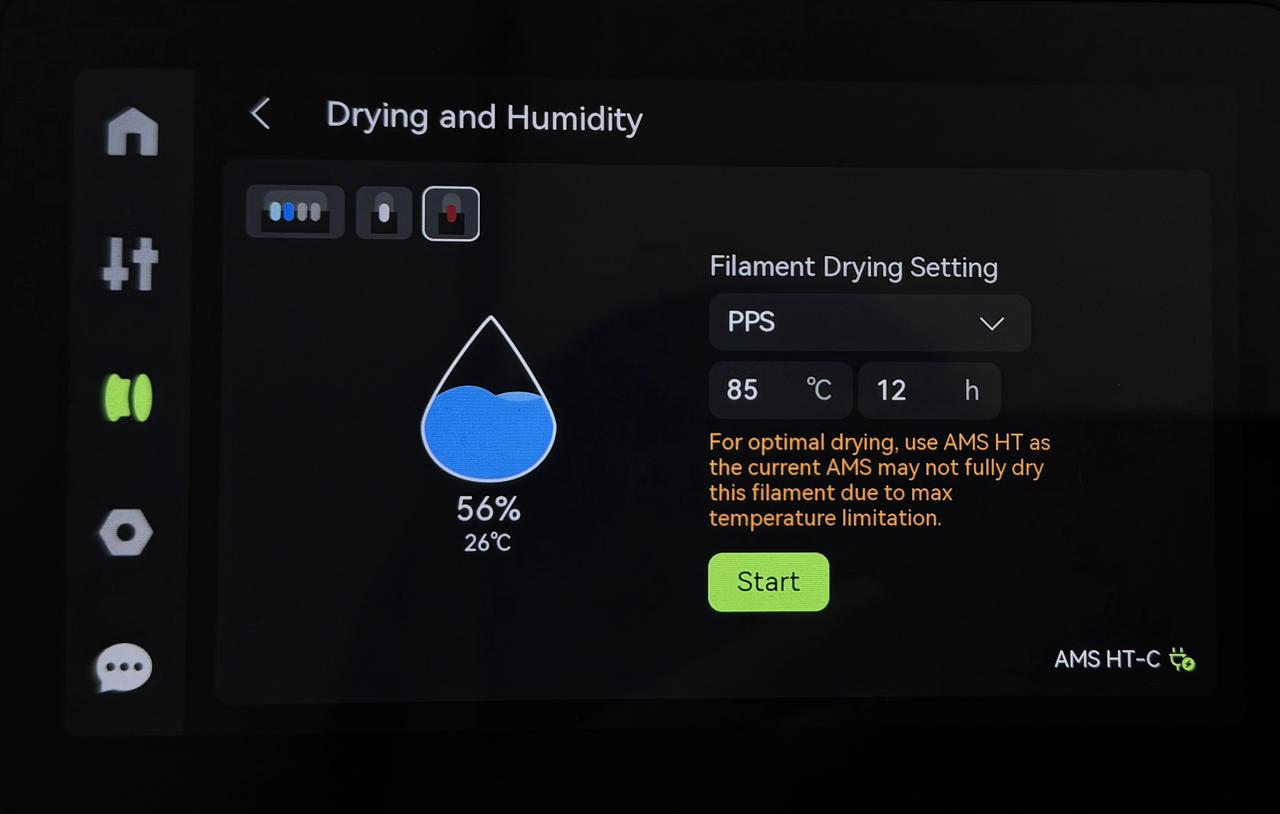

¶ Drying filament

¶ Function Overview

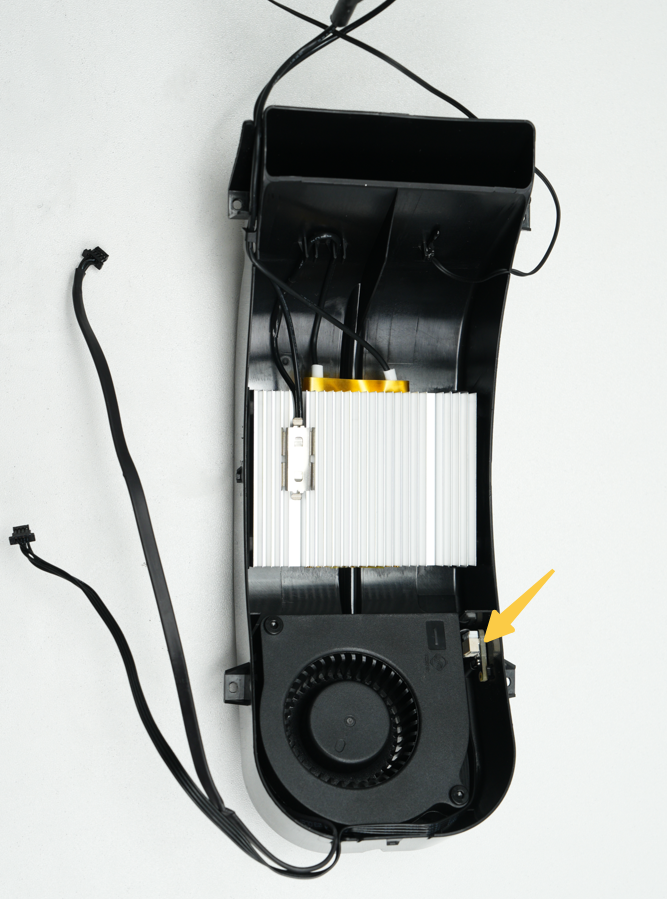

- Hardware configuration: AMS HT features a built-in heating and drying module (located below the middle frame), with a maximum drying temperature of 85°C;

- Applicable scenarios: If the filament is damp, you can use the drying function to dry it. All filaments can be dried using AMS, but some filaments require a drying temperature higher than 85°C and may not be completely dried, such as PPS, PPA.

¶ Operation Guide

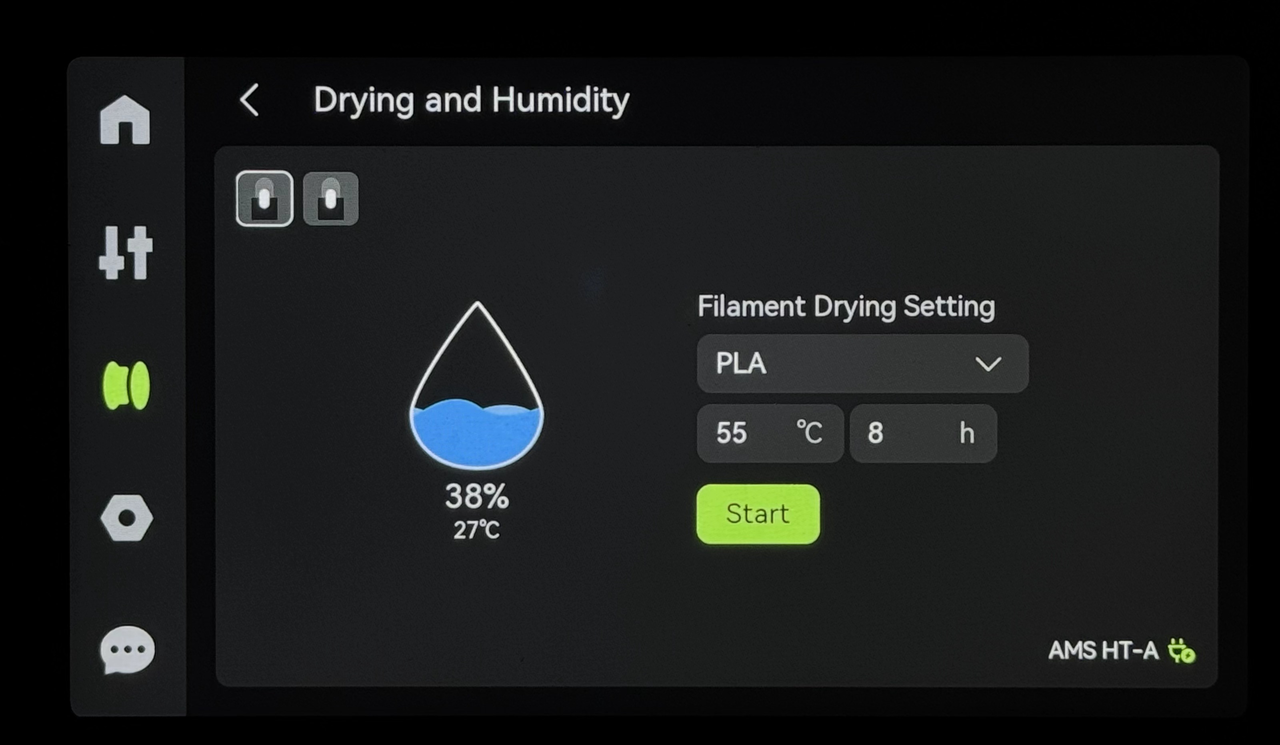

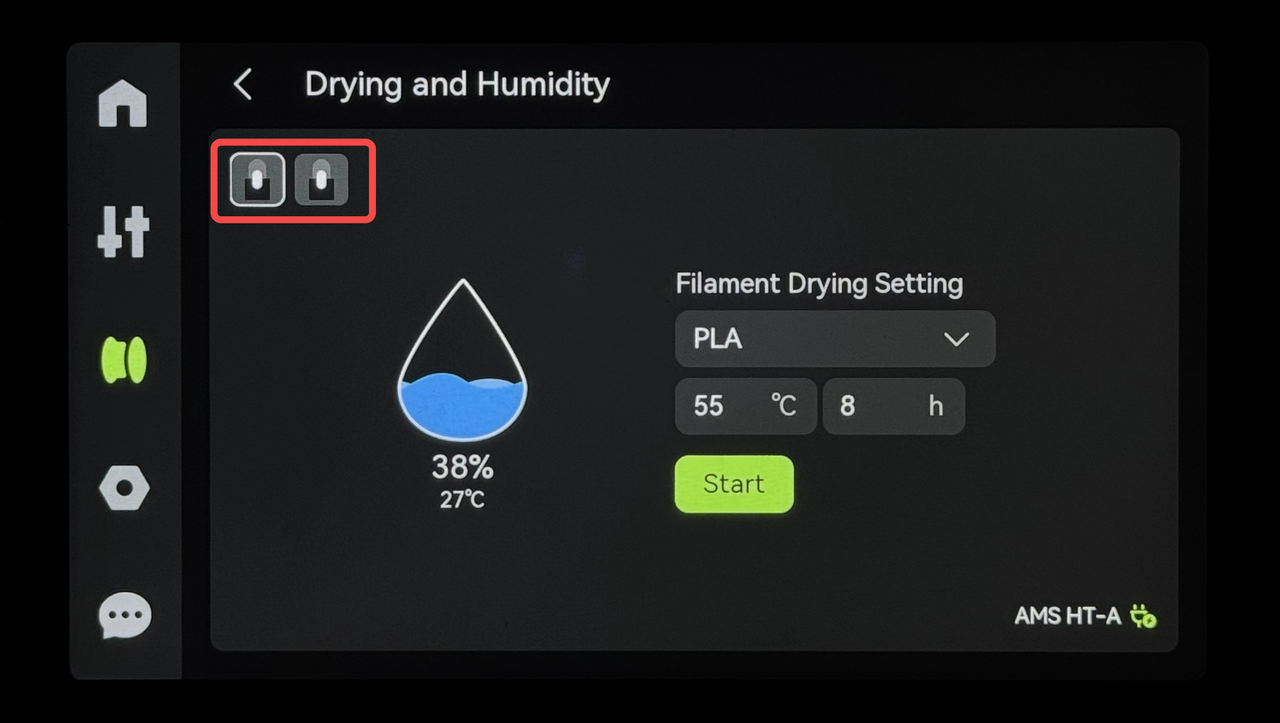

Drying process:

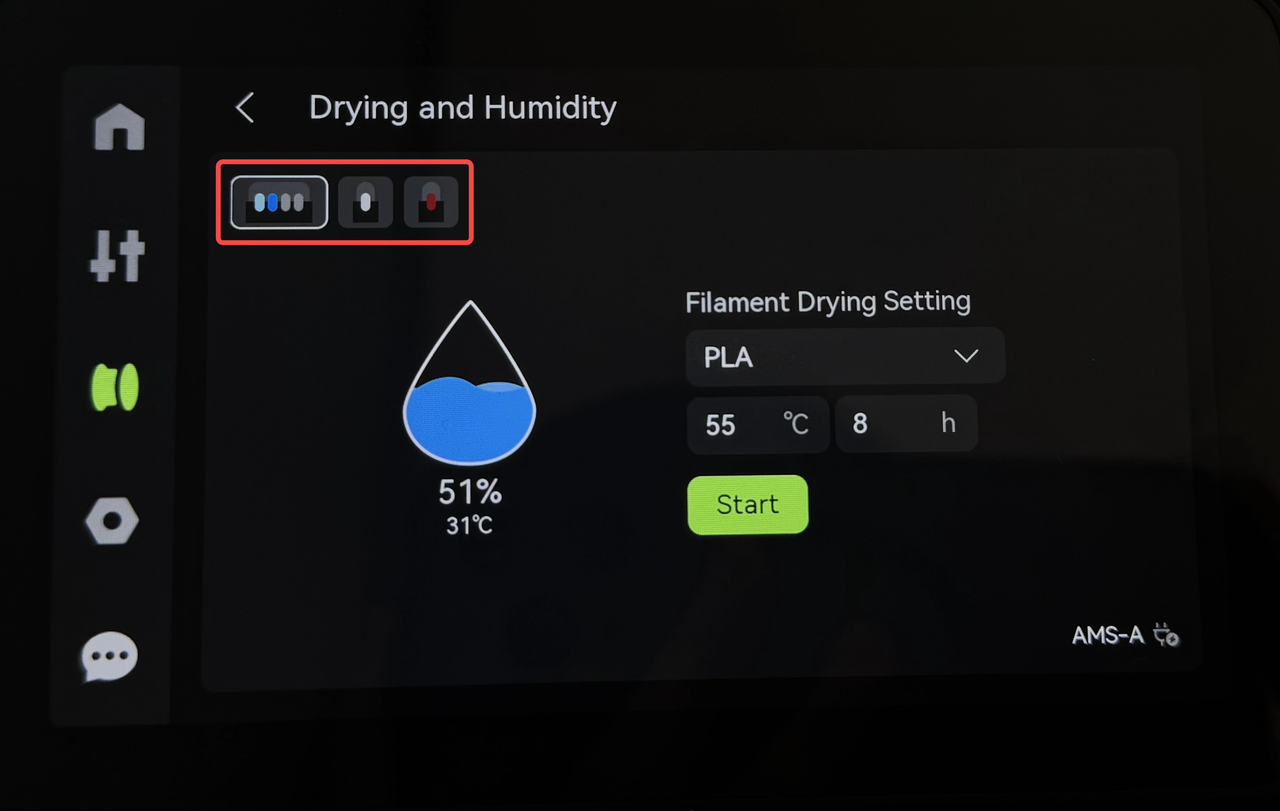

Close the AMS HT top cover → enter the "Drying and Humidity" page;

Select the filament to be dried → set the temperature and duration → start drying. When connecting multiple AMS, you can switch devices one by one to start drying through the "Filament" page, or switch AMS in the upper left corner of the drying page.

¶ Note

- Power requirements: Must be powered independently using the standard power cable (the printer cannot power the drying function of the AMS HT);

Status indication:

Not connected to power → The power icon in the lower right corner of the page is grayed out, and the drying process cannot be started;

Connected to power → The power icon in the lower right corner of the page turns green.

Due to the limited internal space of the AMS HT, when drying highly moisture-saturated filament (such as fully water-absorbed PVA), condensation may form inside. If you notice water droplets, please open the AMS HT lid briefly to release the steam and prevent potential short circuits.

¶ Drying method description

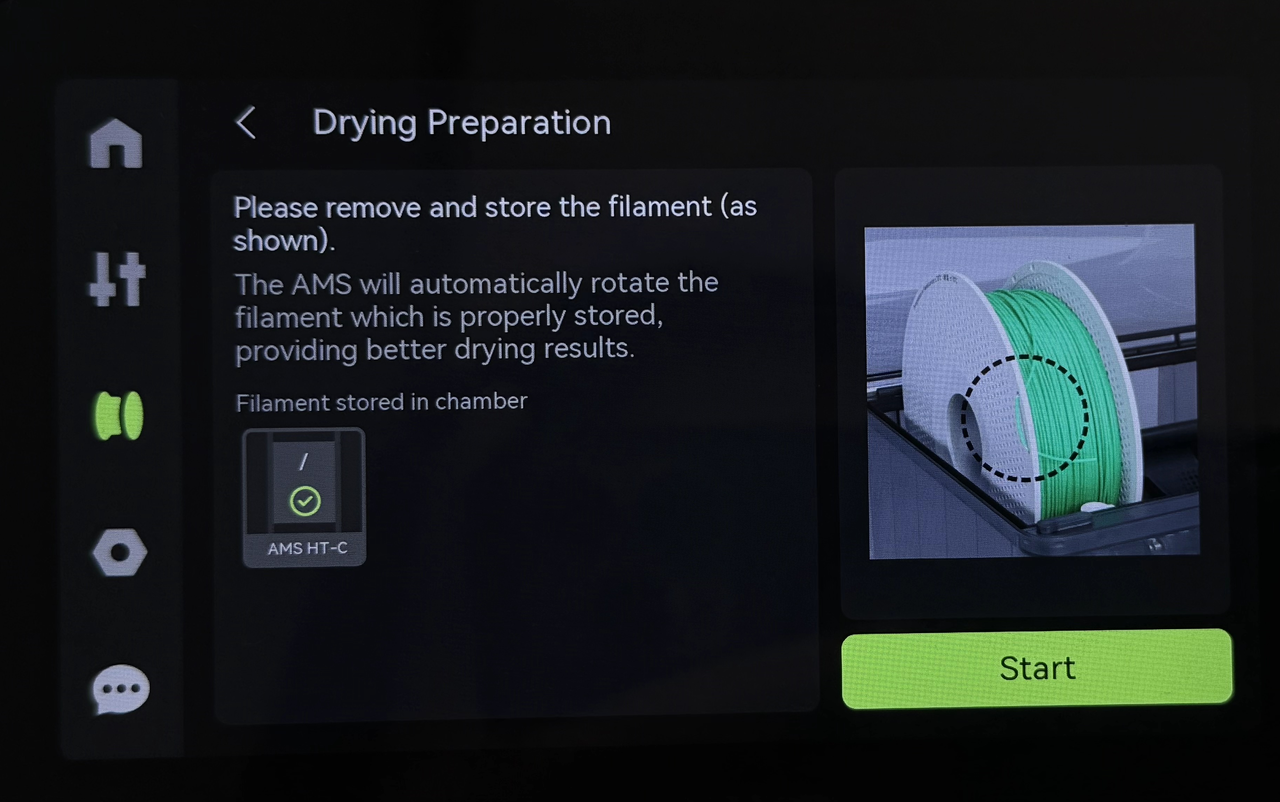

Mode 1: Rotating drying

Method: Pull out the filament from the feeder and store it in the spool;

Spool Rotation rule: Rotate 30° every 5 minutes for uniform drying.

Mode 2: Static drying

Not applicable to filaments: Filaments with softening temperature < drying temperature (such as PLA, PVA, Support for PLA/PETG and TPU);

Method: Insert the filament into the feeder;

Principle: The spool is fixed and only relies on hot air circulation for drying.

¶ Air Intake and vent control

Function:

AMS HT features active air intake and vent. During drying, AMS will open the air intake and vent to discharge moisture through external circulation.

Working logic:

Non-drying state: The air intake and vent is closed to prevent humid air from entering;

Start drying: The air intake and vent opens and closes once, prompting the user to start drying and performing self-test at the same time;

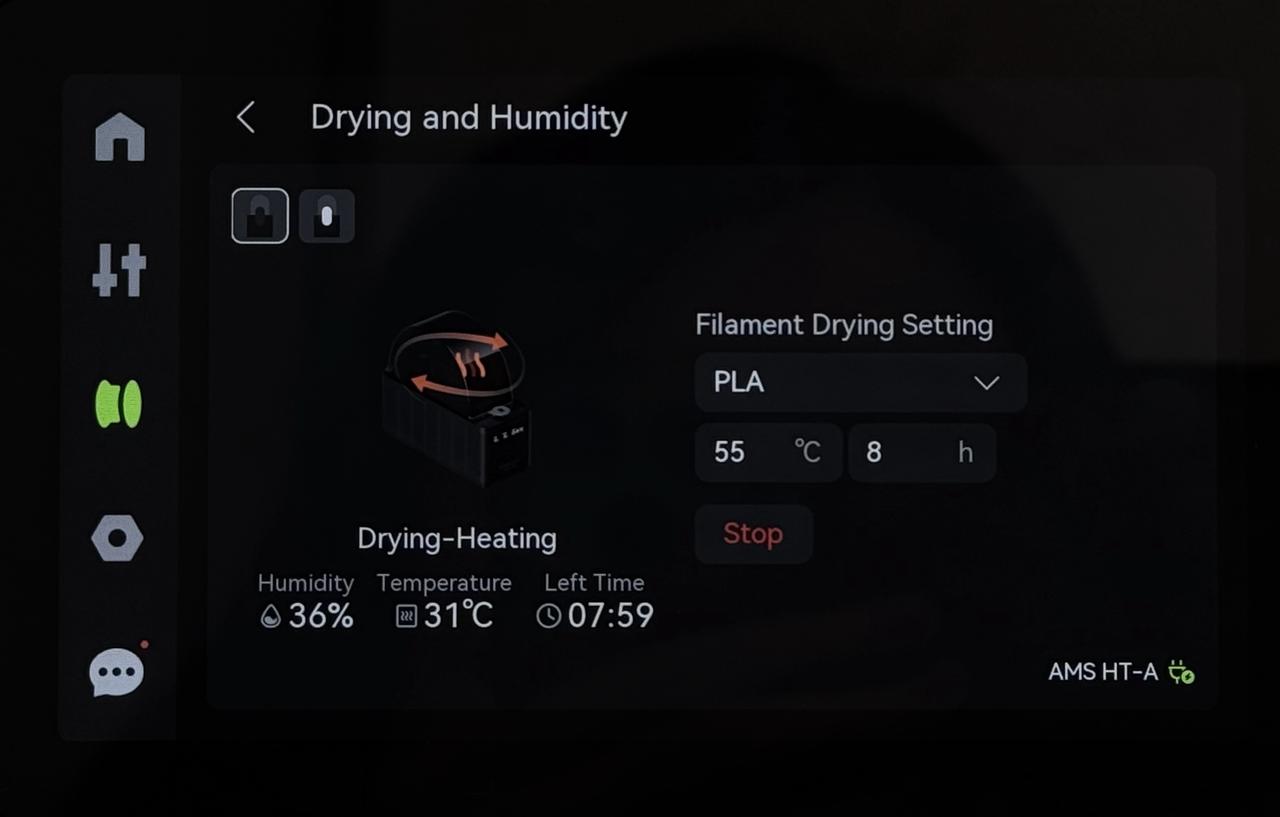

The chamber temperature is less than the target value during the drying process: The air intake and vent is closed to quickly increase the chamber temperature;

The chamber temperature reaches the target value during the drying process: The air intake and vent opens to exclude the humid air in the chamber;

Inspection before feeding: Before AMS starts feeding, if the chamber temperature is higher than the softening temperature of the filament to be loaded, the fan will be turned on for a period of cooling, and feeding will not start until the chamber temperature drops.

| Drying-Heating | Drying-Dehumidifying |

|---|---|

|

|

¶ Humidity monitoring

The AMS HT has a sensor in the drying module that can be used to detect humidity and temperature inside the AMS.

- View path: "Filament" → Click the AMS humidity icon → Enter the "Drying and Humidity" page;

- Display content: Click the icon in the upper left corner to switch between different devices and view the real-time humidity and temperature data of each AMS.

¶ Auto arrange

When initiating a multi-color printing task, the most efficient dual extruder printing scheme will be automatically assigned. You can also customize the filament selection in the window for sending print tasks. For details, please refer to: Introduction to Filament Grouping Strategy for Dual Nozzle Printers

¶ AMS Workflow

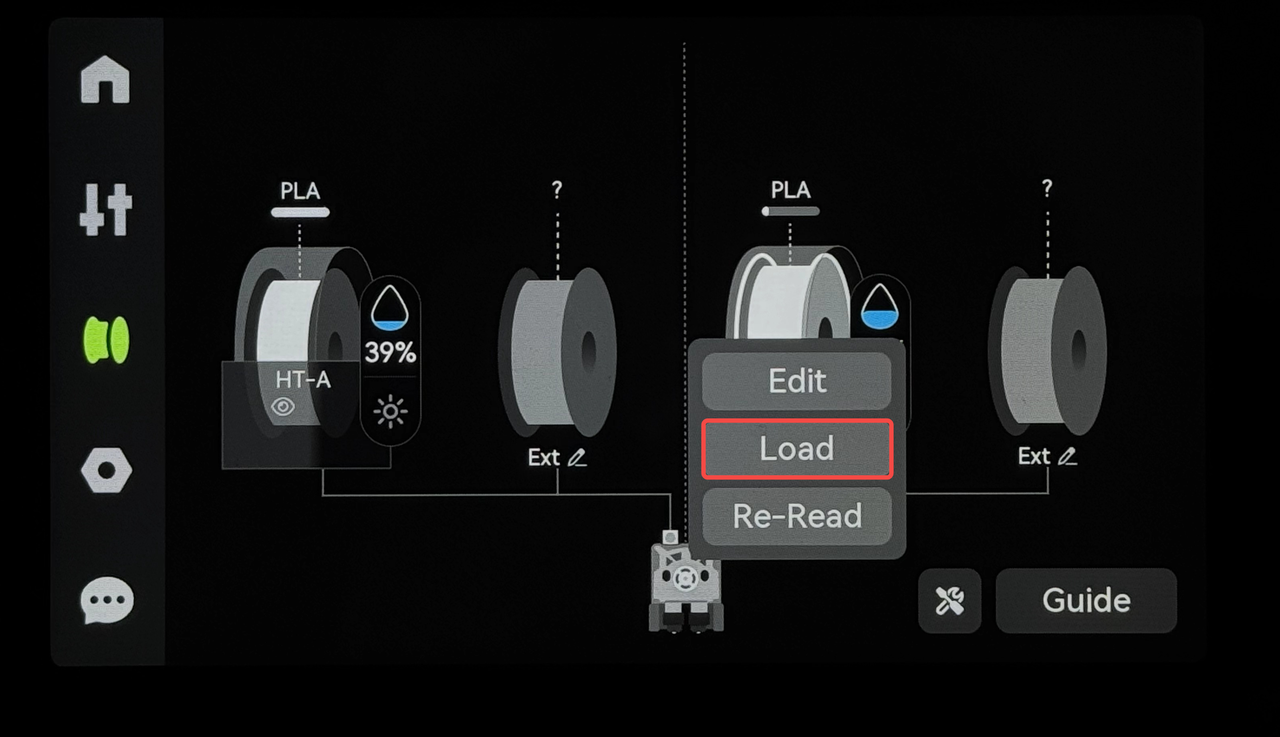

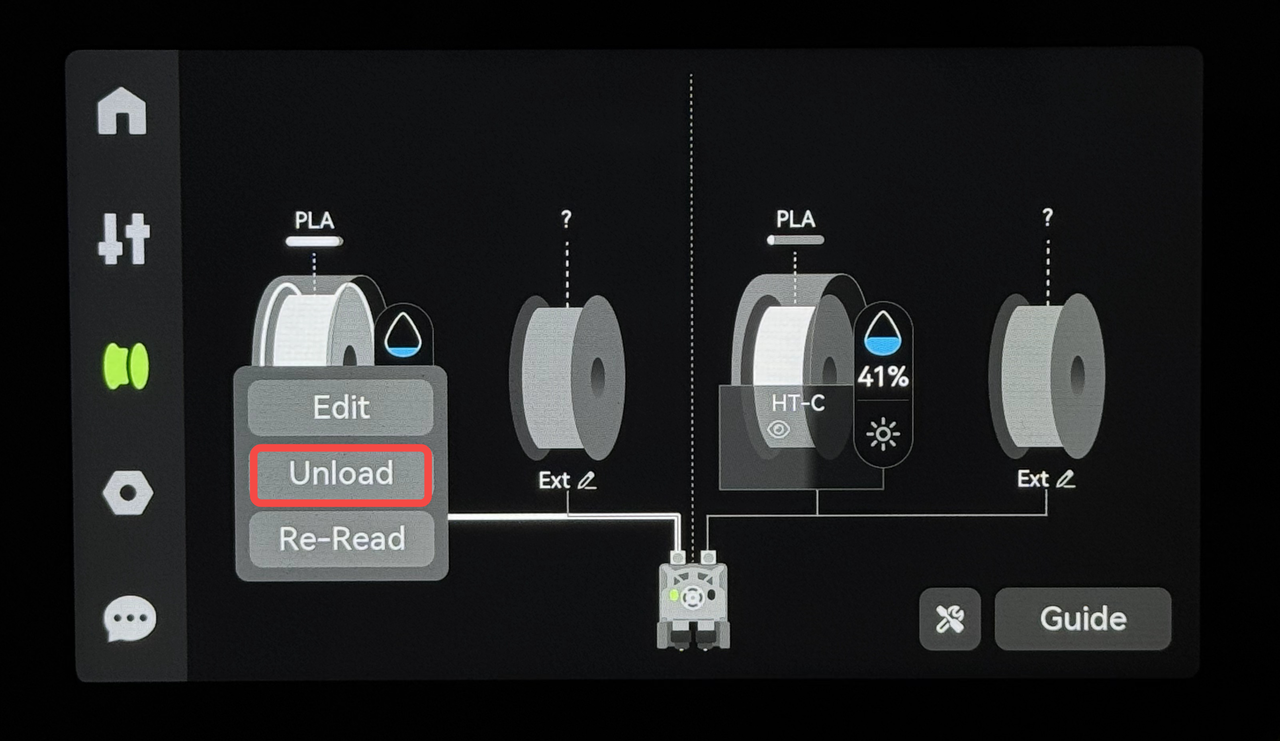

¶ Load/Unload

Load: Select a slot → click the "Load" button, or send a print task and AMS HT will load the filament automatically.

Unload: The slot has been loaded→ Click "Unload" to automatically eject the filament. The filament will also be automatically ejected at the end of printing, but it will not be automatically ejected if the print task is manually terminated. During the unloading process, the feeder and filament motor work simultaneously. The feeder is responsible for driving the spool to rotate, and the filament Hub motor pulls back the filament until it returns to the inside of AMS.

¶ tart multi-color printing task

You can refer to the wiki to initiate a multi-color printing task: H2D Combo First Print

¶ Feed Assist Mode

When printing, AMS assists feeding or retracting according to the signal from the buffer (slider position feedback resistance status);

AMS will switch to feed assist mode after the filament is sent to the extruder and return to the idle mode after restarting. The feed assist mode only determines whether to continue feeding according to the signal feedback of the buffer, regardless of whether it is printing or not.

¶ LED Status

| NO. | LED Status | AMS HT Status |

| Error status (red light) | ||

| 1 | Red light flashing | AMS communication is abnormal, and AMS cannot be detected by the printer. |

| 2 | Red light breathing |

1. No filaments were inserted into the corresponding slots when printing start. It will return to normal after inserting the filament into the feeder; 2. Abnormal state during drying; |

| 3 | Red light keeps on | The filament is not detected by the feeder, but by the Filament Hub. It is possible that the filament is broken inside the Filament Hub. |

| 4 | Red light single flashing | It may be that the slot failed to feed the filament, and the filament is detected by the feeder but not by the filament Hub. The filament is inside the AMS. Need to check whether the feeder is working properly. |

| Normal condition (white light) | ||

| 1 | White light flashes in turn | When AMS is powered on and initialized, the white lights will flash in sequence, and after initialization is complete, the four slots will remain on. |

| 2 | White light keeps on |

1. After AMS is powered on and initialized, or when the screen is awakened, all four slots have filaments inserted (the LED in the slot with filaments inserted will light up when the screen is awakened) 2. In the process of pre-loading, reading RFID or printing (including loading and unloading). |

| 3 | White light is not on | 1. After the screen is turned off, there is no pre-loading, reading RFID or printing (including loading and unloading) in the slot within 15 minutes, and the white light is turned off; 2. When pre-loading or reading RFID, the white light will light up again, and the white light will be extinguished 10 seconds after the action ends; 3. After the AMS power-on initialization is complete, there is no pre-loading, reading RFID, or printing (including loading and unloading) action within 20 minutes, and the white light is off. |

| 4 | White light is breathing at the same time | Normal drying status |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!