¶ AMS feeding system introduction

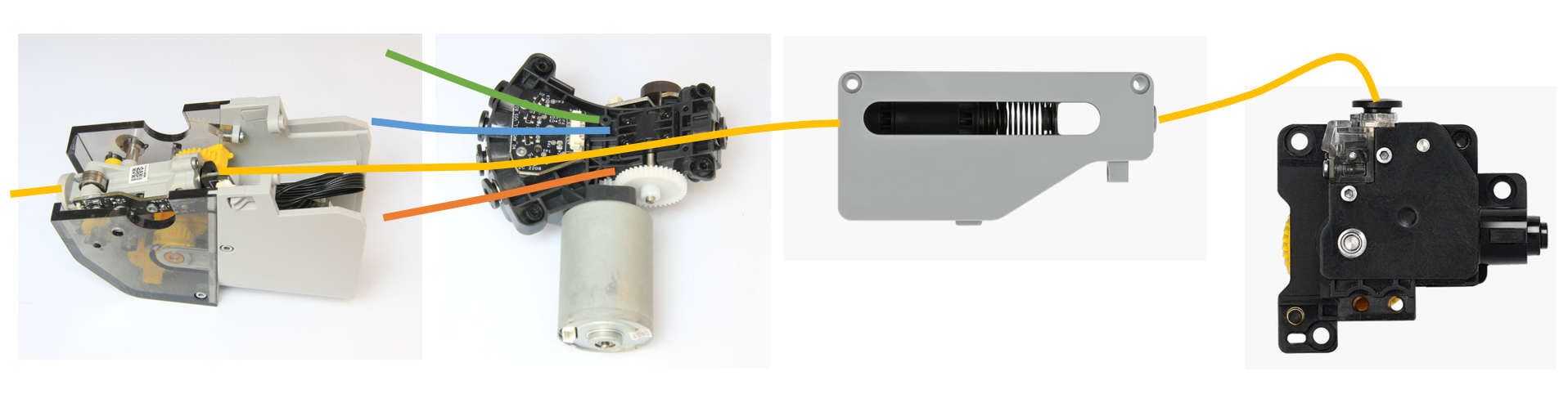

The AMS feeding system can be divided into two main parts:

1. First stage feeder + Filament hub + Buffer

2. Extruder (Cutter sensor + Filament detection sensor)

AMS feeding path diagram

The feeder and filament Hub can detect the filament and load and unload the filament. The buffer feeds the signal back to the AMS and printer to control the feed speed. There is a cutter sensor and filament detection sensor inside the extruder, and the sensor signals will also be fed back to AMS to judge whether the filament can be fed normally. In short, the AMS and printer rely on signal feedback from each sensor to ensure a smooth feed process.

¶ First stage feeder

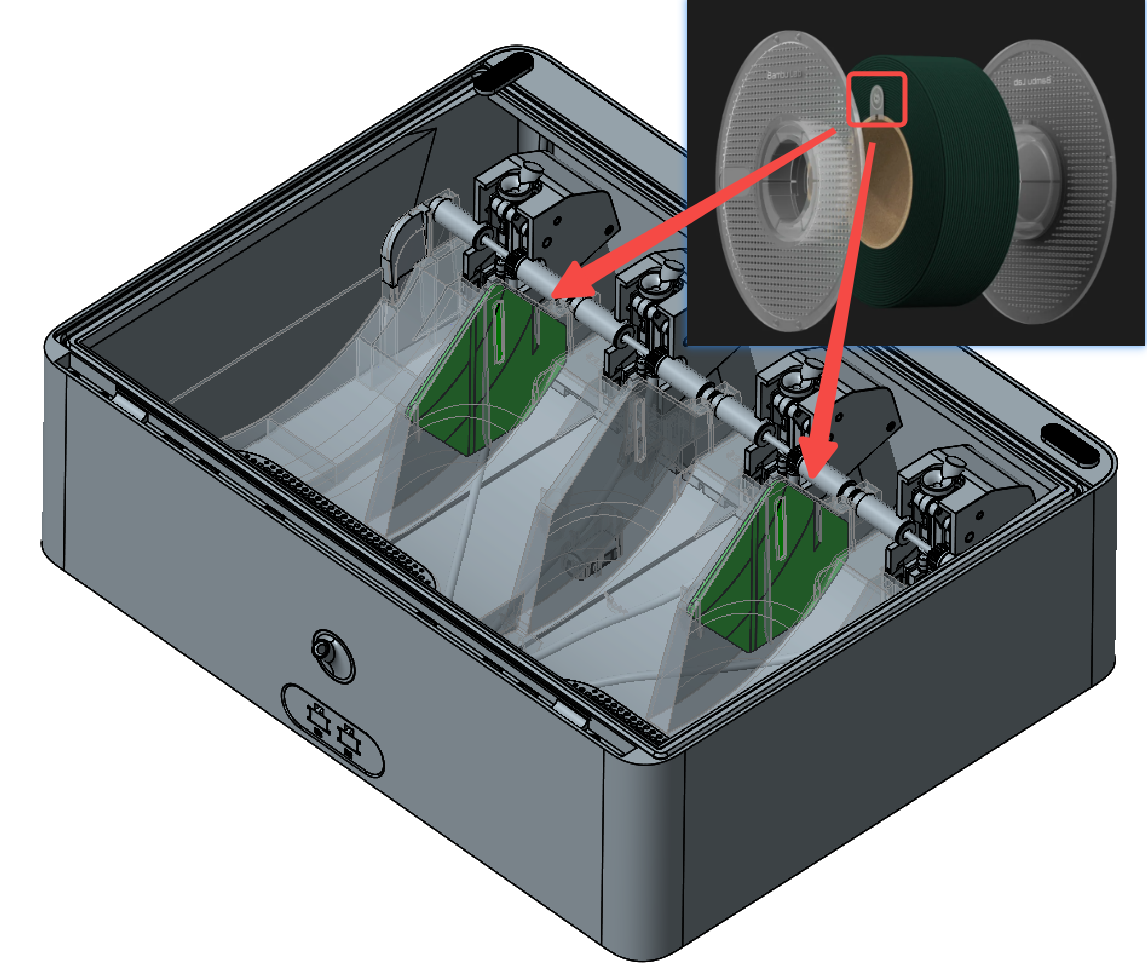

There are four feeders on the AMS, which pull the filament into the AMS. It also drives the Black sleeve unit to rotate the spool when unloading the filament.

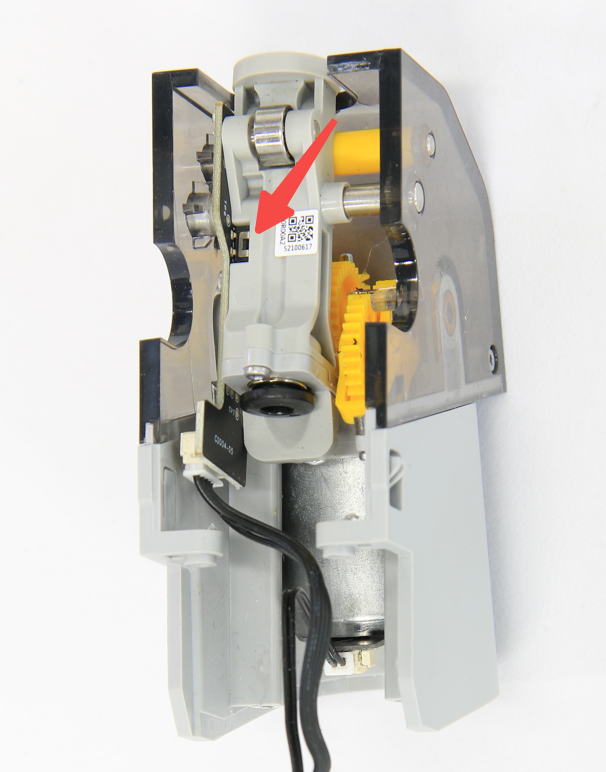

The feeder has a filament detection sensor. When it detects the insertion of the filament, its motor will start to work and automatically pull in the filament for pre-loading. The position of the detection sensor is shown below:

¶ Filament hub

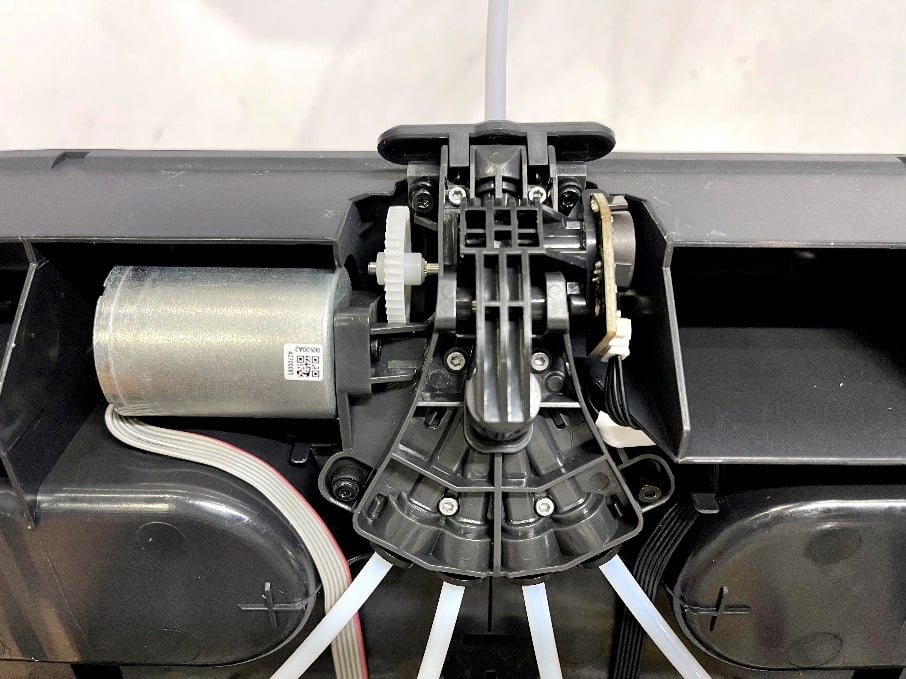

The filament Hub is located at the rear of the AMS and consists of four sensors, an odometer, and a motor. It combines four feeding paths into one. After the sensor detects that the filament is being fed into the filament hub from the feeder, the motor is activated to provide a second driving force for the filament to be sent to the extruder.

The position of the filament detection sensor and odometer of the filament Hub is shown in the figure below. When the filament enters and leaves the filament Hub, the signal of the sensor will change so that AMS can judge whether the filament is sent to the filament hub. You can refer to the wiki for the internal structure of the filament Hub: Dismantling and cleaning the AMS filaments hub | Bambu Lab Wiki

The odometer is used to determine whether the filament has been sent out of the AMS, and can also be used to calculate the length of the filament sent out.

Filament sensors and odometer

¶ Buffer(AMS Hub)

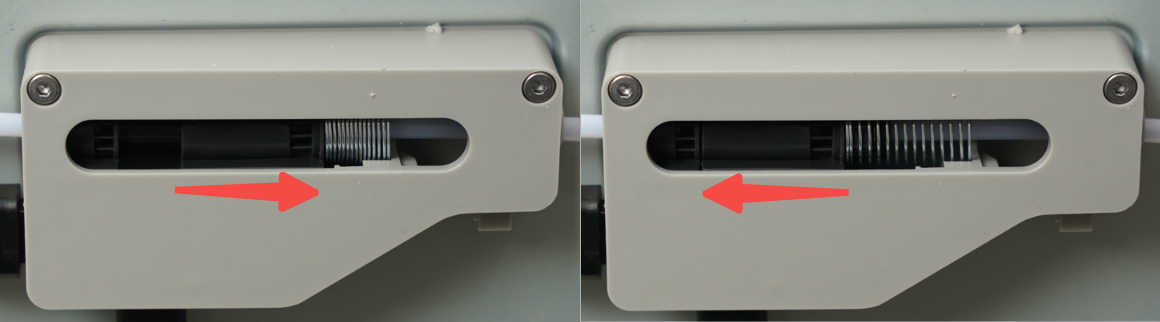

The buffer is used between the AMS and the printer (the AMS hub is used when multiple AMS are connected) and consists of a slider, spring, and sensor. when the AMS pushes the filament into the tool head extruder, the pressure of the filament feed pushes the slider to the right and stores a small section of filament in the buffer. When the extruder consumes the filament in the buffer, the slider returns to the left. The position of the slider is detected by sensors and fed back to the AMS and printer to adjust the feed speed.

¶ Extruder

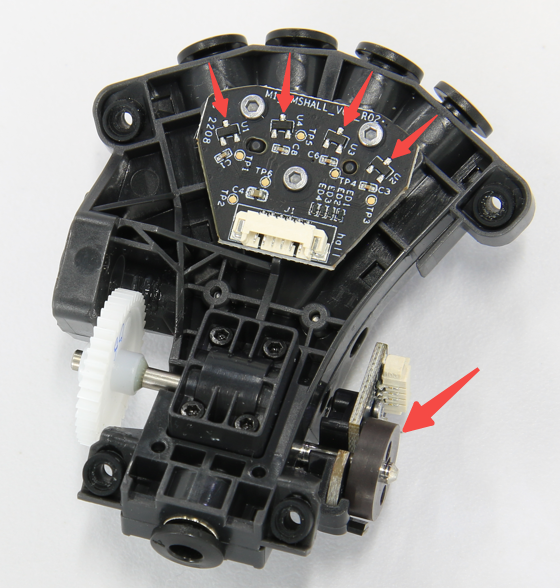

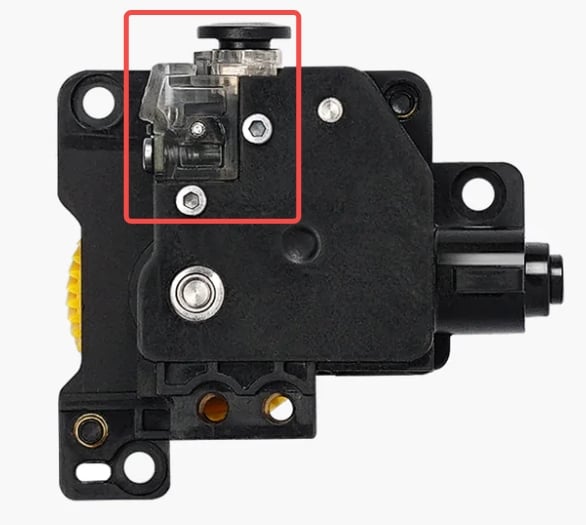

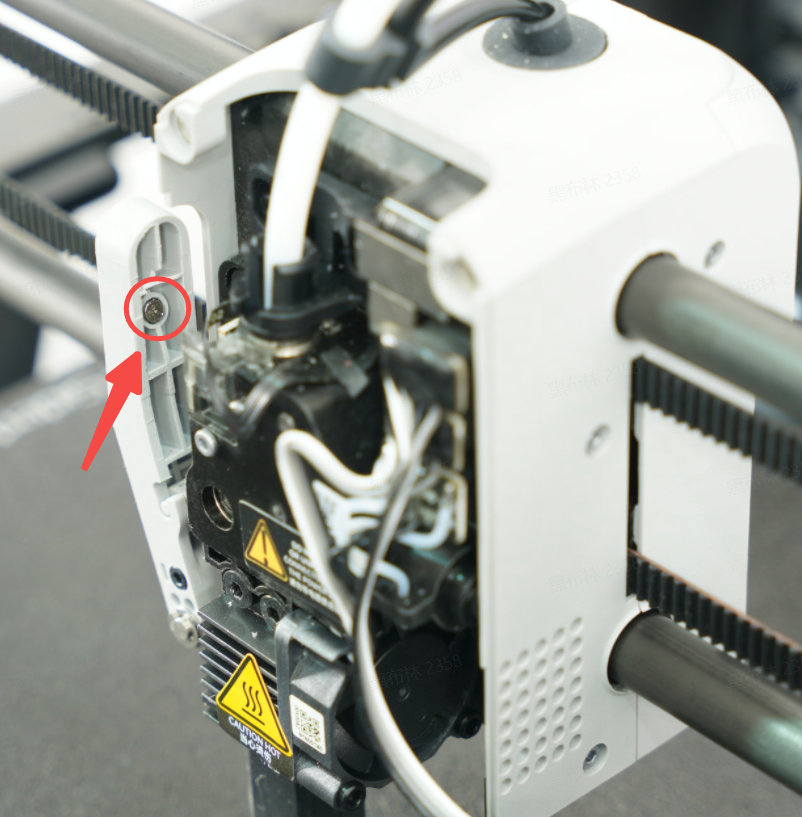

The extruder is used to extrude the filament for printing. It has a filament detection sensor and a cutter detection sensor inside, as shown in the figure below:

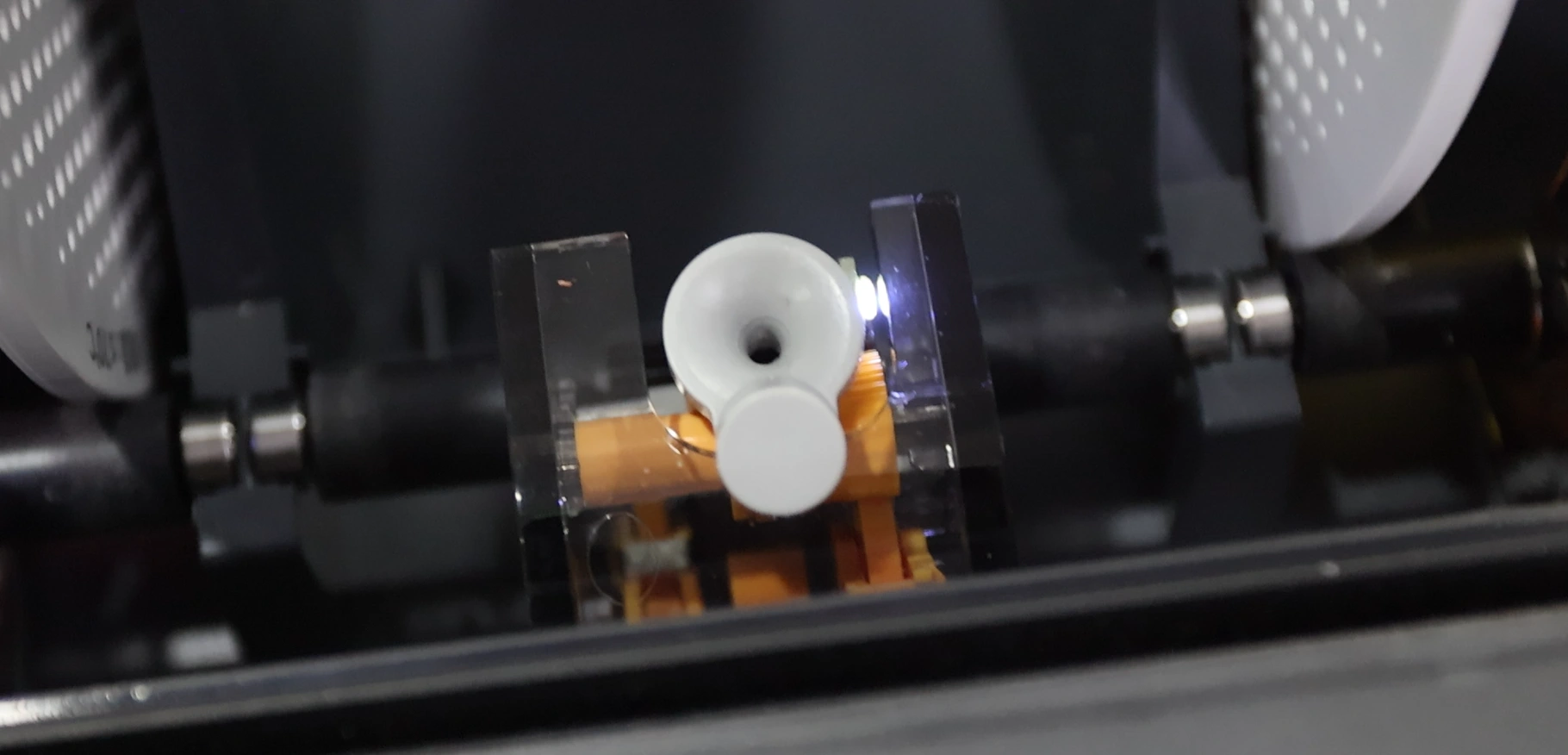

¶ Filament detection sensor

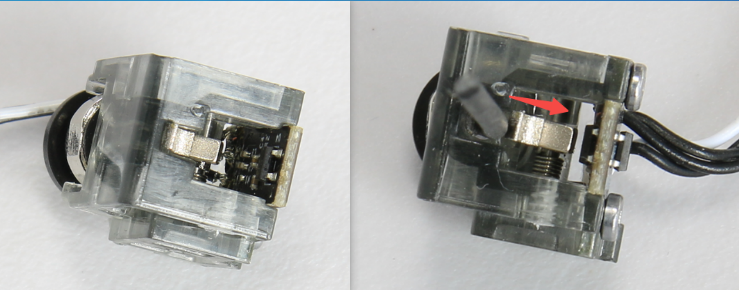

The filament detection switch, as shown below, consists of a magnet and a Hall sensor. When the filament is inserted, the magnet moves closer to the Hall sensor; When there is no filament, the magnet will automatically spring back. The printer determines whether there is a filament inside the extruder according to the detected Hall value.

When the filament is inserted it pushes the magnet closer to the sensor

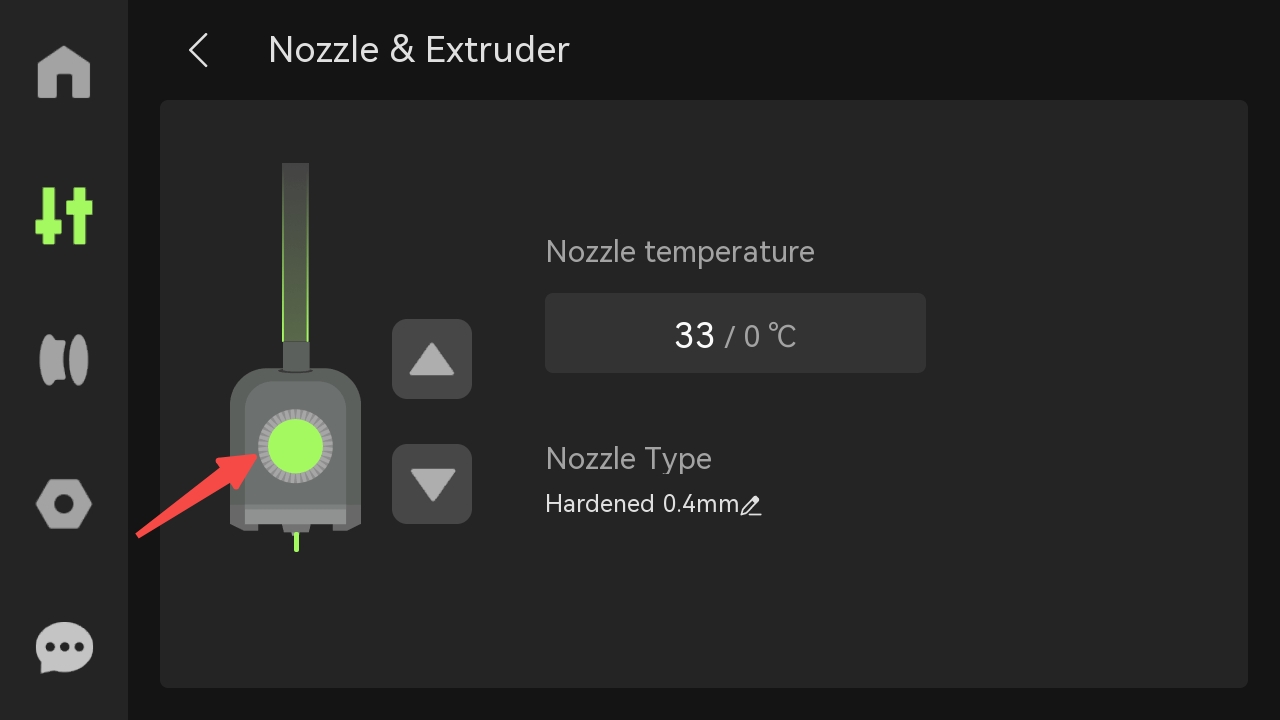

When the filament is detected, the display will show a green dot:

¶ Cutter sensor

The following figure shows the Hall sensor of the cutter. The cutter has a magnet on its handle. When the cutter cuts the filament, the magnet will be close to the Hall sensor; When the cutting is finished, the cutter will spring back and the Hall value will change throughout the process. Based on the detected Hall value, the printer can determine whether the cutter is stuck and whether the cutting has been successful.

¶ The main functions of AMS

¶ Pre-loading

When AMS is idle, inserting the filament into the feeder, the feeder will send it to the filament Hub and pull it back a bit until the filament Hub sensor detects it. This process is pre-loading. In addition to providing the user with interactive feedback when inserting the filament, pre-loading can also tighten the filament roll on the spool to ensure that the filament on the spool is not loose.

Insertion assistance function: Before pre-loading, you can tap the empty slot icon on the display screen, and the motor and gears of the feeder will start to rotate, making it easier to insert filaments through assistance.

¶ Reading RFID

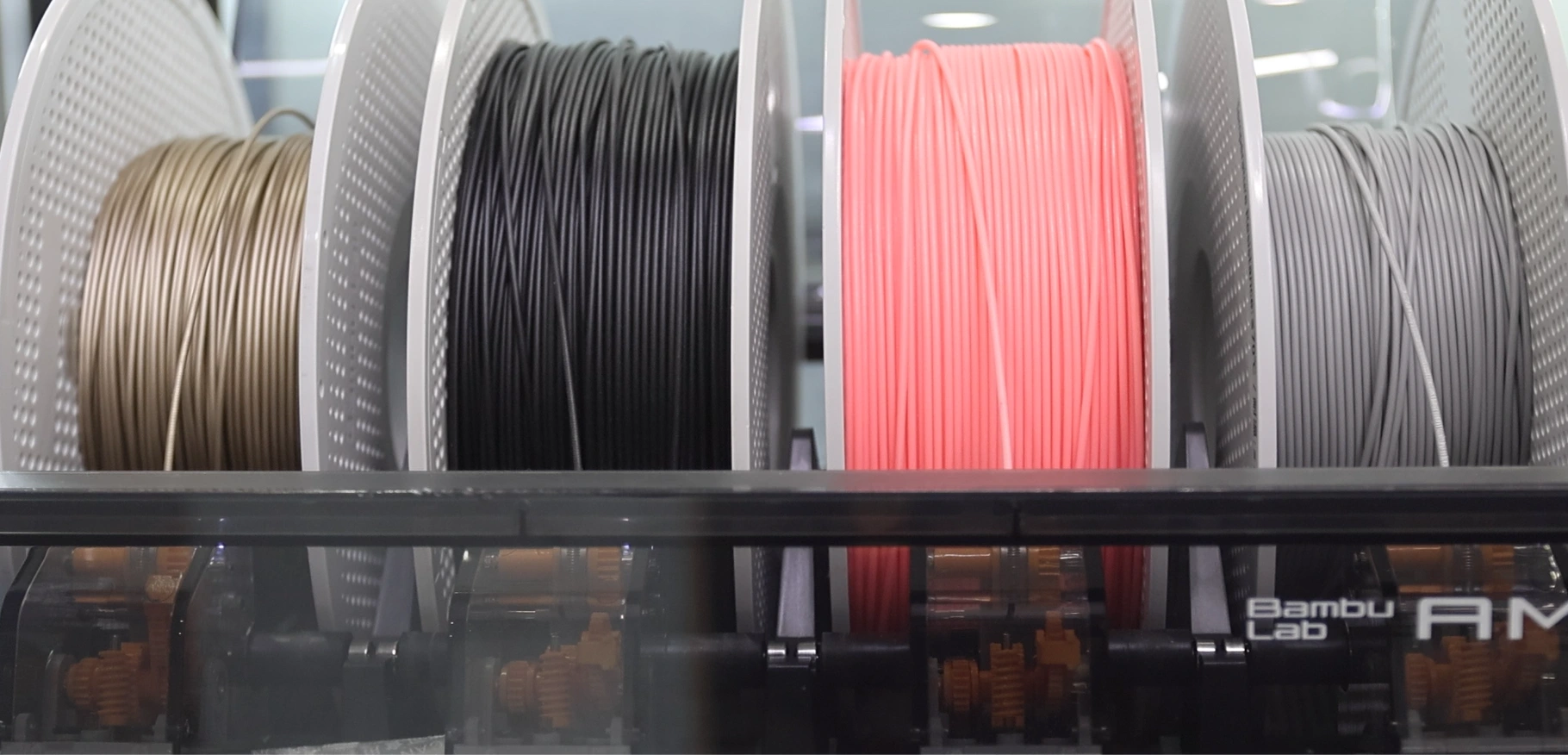

Bambu's official filament roll has RFID tags on both sides, and on AMS there are two RFID-reading circuit boards that can read the filament information.

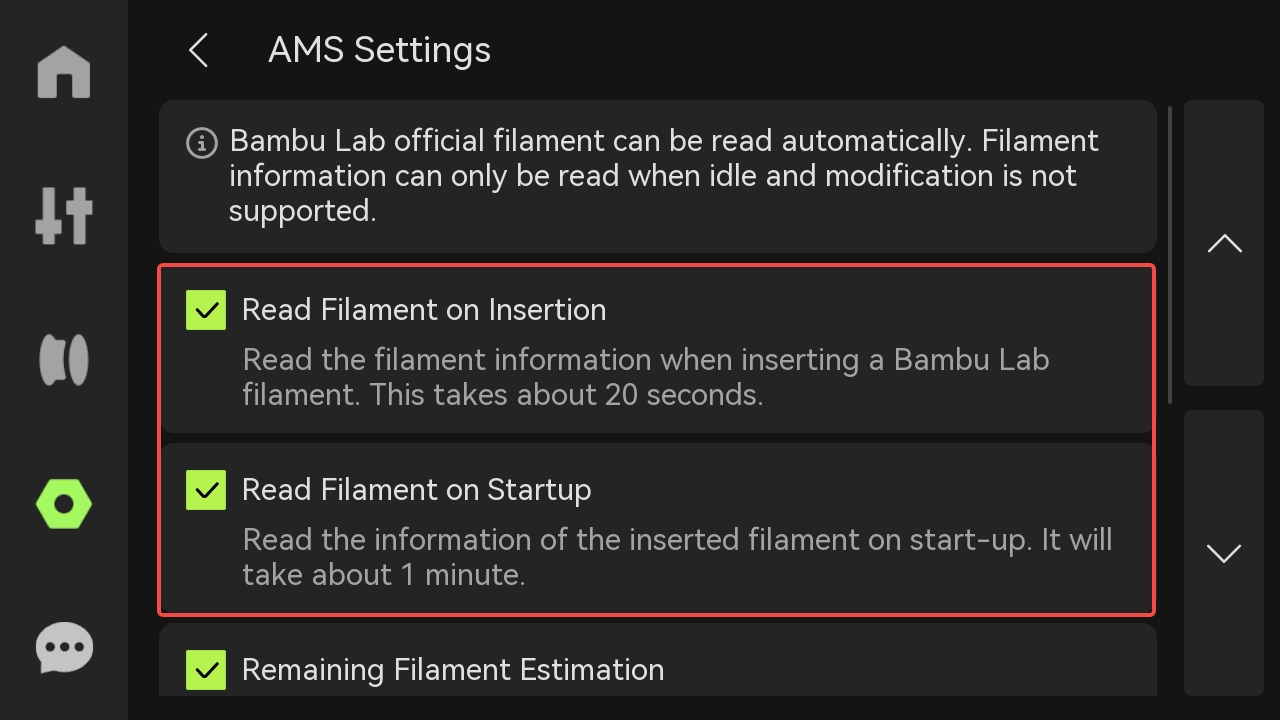

RFID reading function can be set on the screen for updates on insertion/startup. If “Read Filament on Insertion” is enabled, AMS starts to read the filament RFID after pre-loading. Similarly, with "Read Filament on Startup" enabled, after each restart of the printer, it will also start reading the RFID of each slot filament in turn.

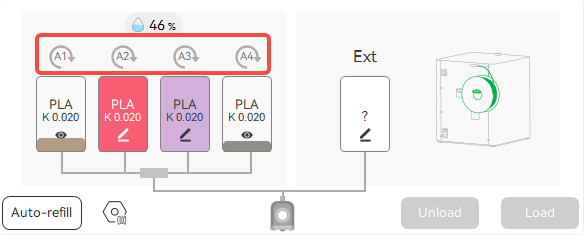

You can also manually click the icon above each slot on the screen/slicer for RFID reading.

Click to read RFID

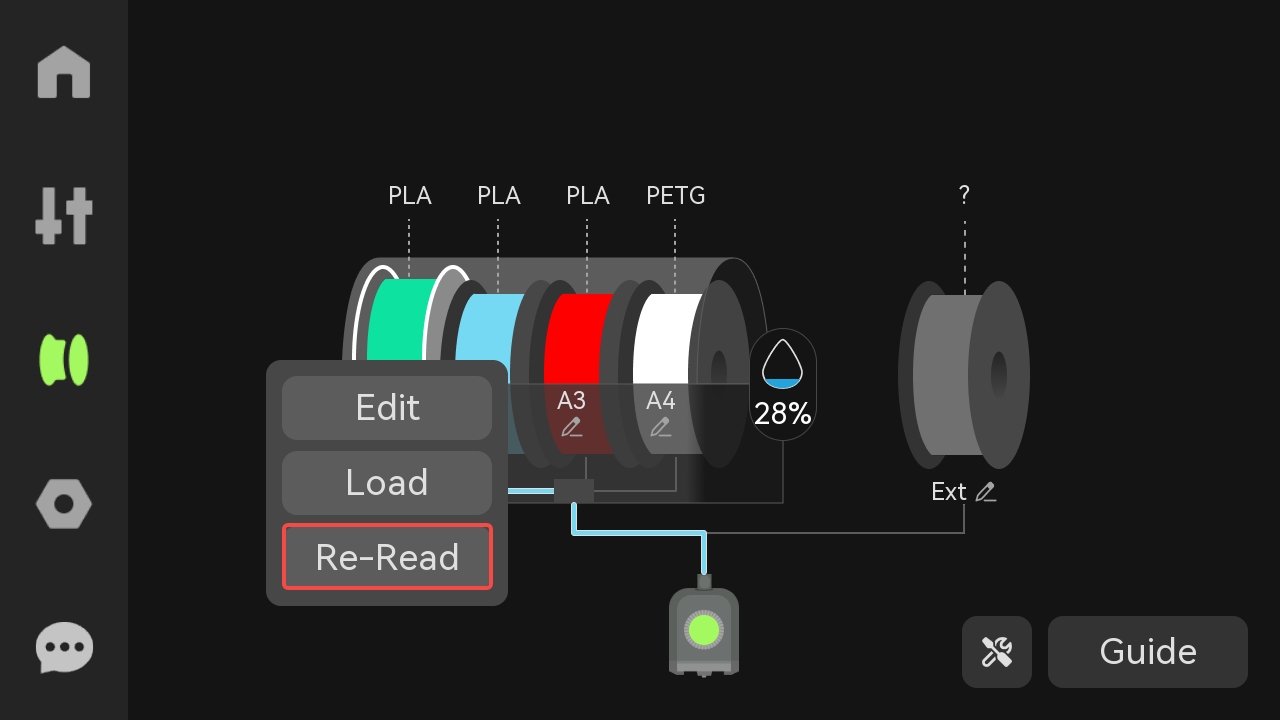

Select the spool and click Re-Read to reread the RFID.

When AMS reads the RFID, it will preload first to tighten the spool. It then sends the filament out of AMS a section to turn the spool, allowing the circuit board to scan the RFID tag and read the RFID information.

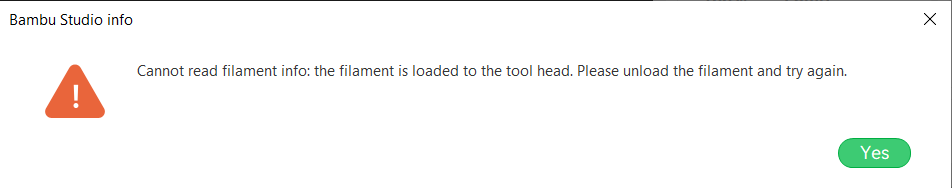

When the filament in a slot has been sent out to AMS, or the extruder detects that there is a filament inside, the RFID reading function cannot be used. Click to read will show that AMS is busy and cannot read the filament information.

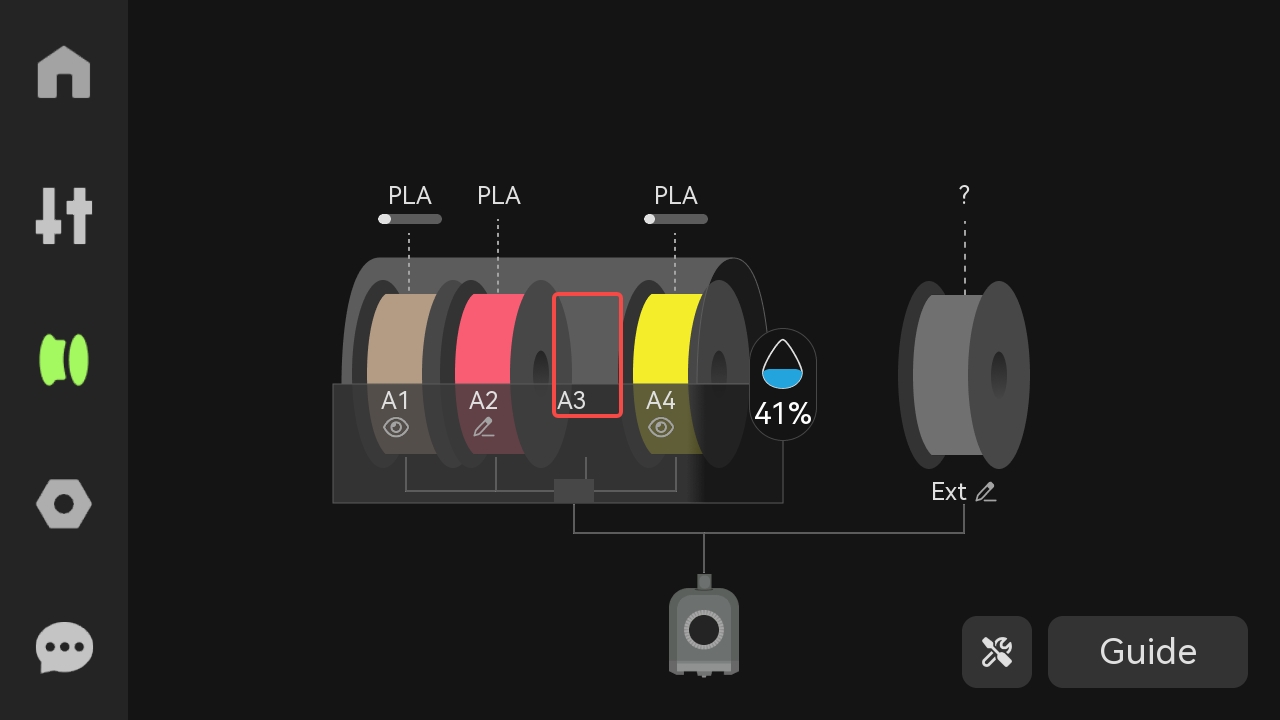

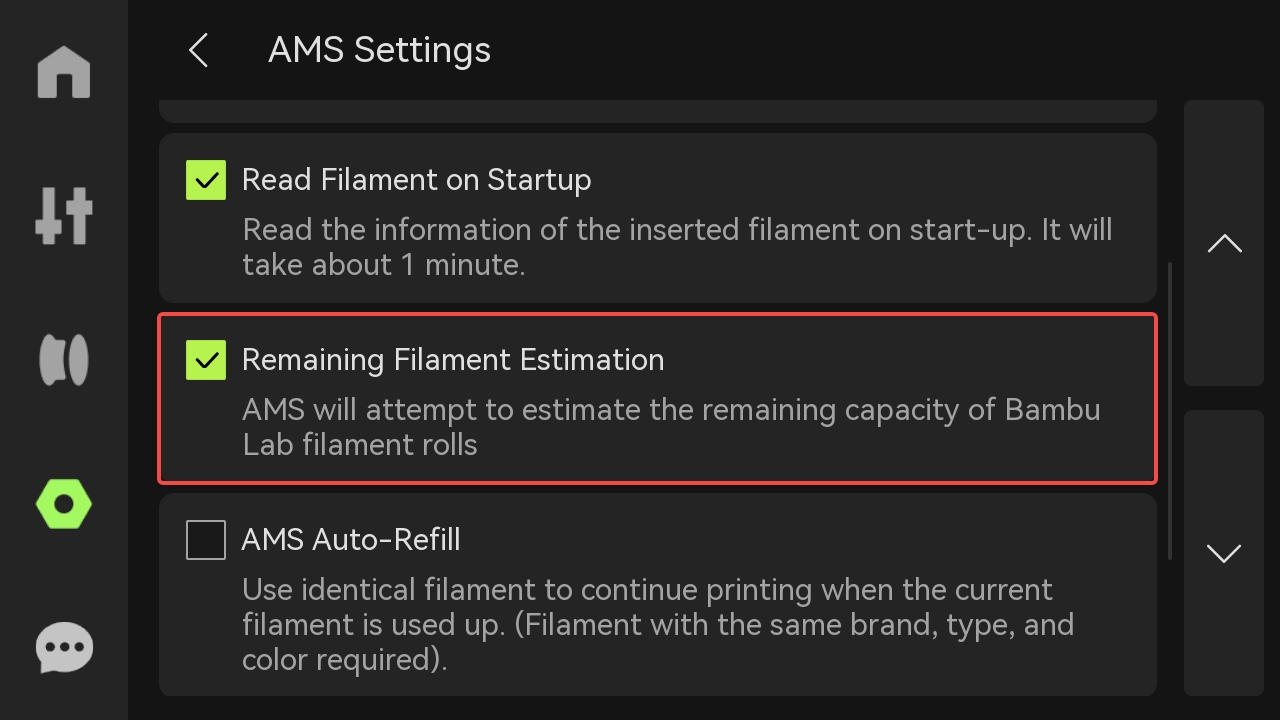

¶ Remaining Filament Estimation

The RFID reading process can also be used to estimate the remaining filament. The working principle is to estimate the percentage of the remaining filament on the spool by the length of the filament sent out after the RFID tag on the spool rotates a full circle. The complete 1kg filament roll is 100% capacity by default.

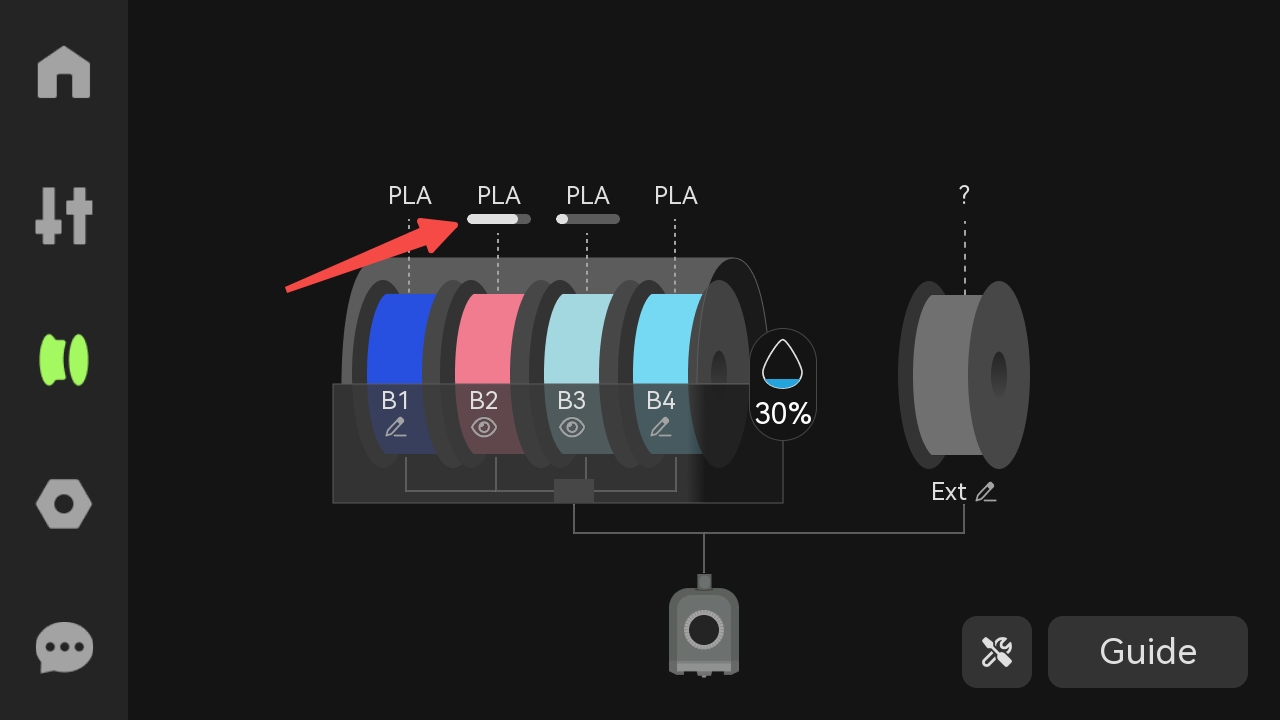

The small horizontal bar below the filament type shows the estimated remaining filaments.

For the P1 series, after enabling the 'Update remaining capacity' feature, please check it in Bambu Studio or Bambu Handy.

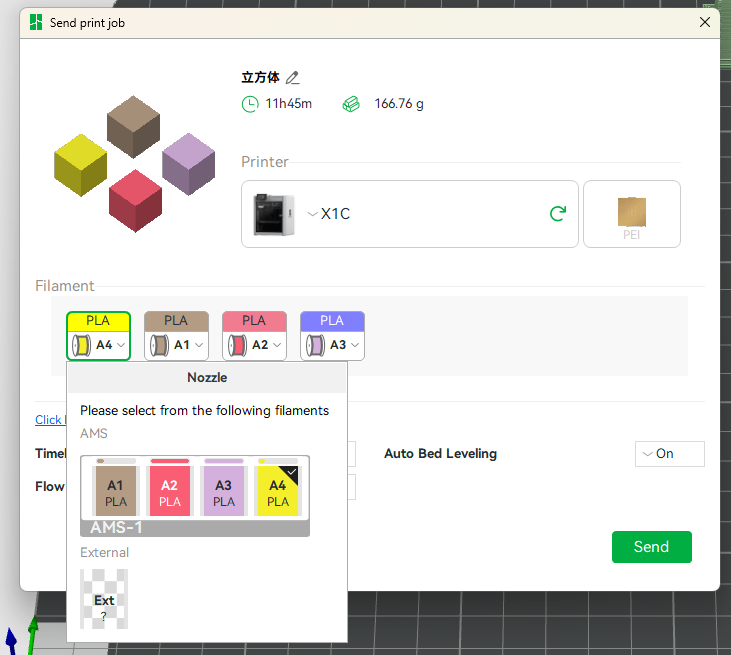

¶ Automatic mapping function

When you send a multi-color print task in the slicer, the model is automatically matched to the closest color filament in the AMS slots. You can also customize the filaments in the window.

¶ Filament run-out detection and auto-refill function

When you use AMS printing, it still has the filament run-out detection function, which can be divided into the following two cases:

1. Single filament printing: the same filament run-out detection logic as when printing without AMS. When the toolhead detects that the filament runs out, it will report that the filament runs out and a new filament needs to be inserted.

2. Multi-filament printing: There is a special case of multi-filament printing, that is, the last section of filament has been detached from the spool, at this time if the filament needs to be switched in the middle of printing, as the filament can no longer be pulled back, it will directly flush the remaining filament, and then switch to another slot of filament to continue printing after the flushing is completed. The screen will indicate that the filament has run out, please wait while the old filament is purged.

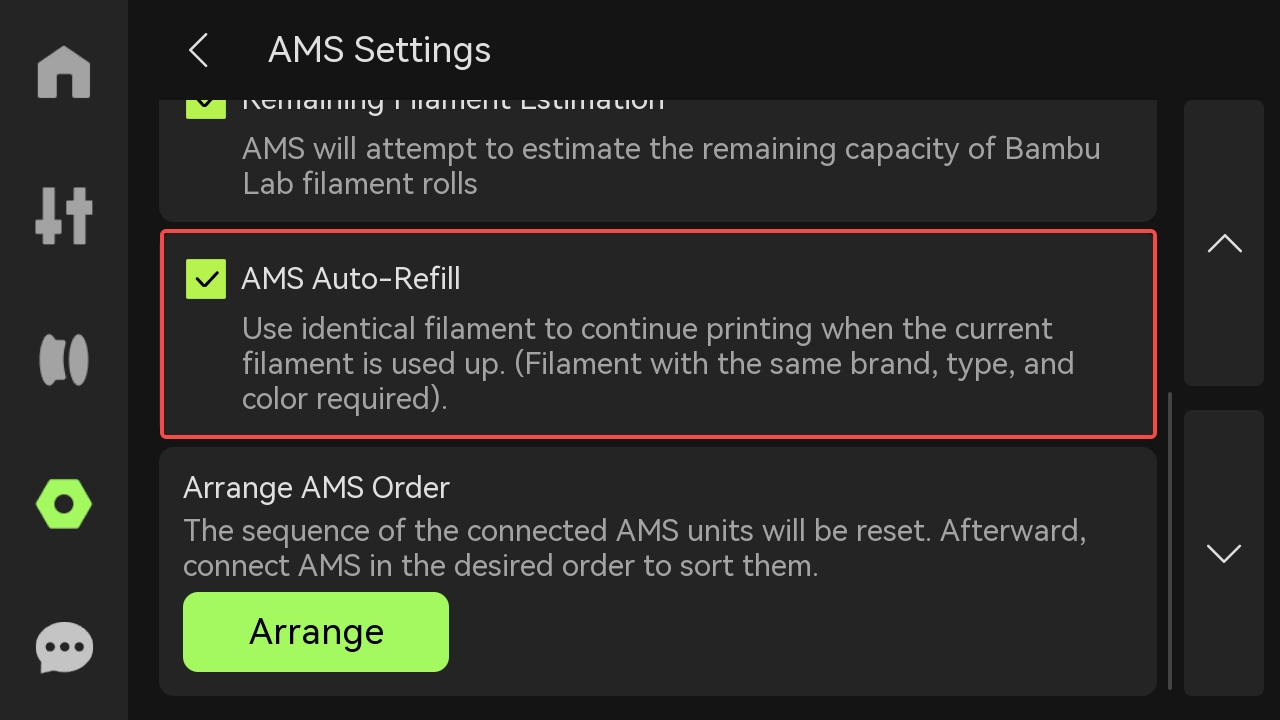

3. AMS Auto-Refill: the AMS will switch to another spool with the same filament properties automatically when the current filament runs out. To enable this feature, please check "AMS Auto-Refill" on the AMS settings page.

- This function requires filaments with exactly the same properties. These filament properties include brand, type, color, and nozzle temperature.

- If the AMS cannot find the same filament, it will display a prompt that the current slot has run out.

- It is recommended that Bambu filament be used as a replacement for Bambu filament and non-Bambu filament be used as a replacement for non-Bambu filament.

Note: Please avoid pausing and unloading during a print process, as unloading may disrupt the filament backup function, switching to feeding from the external spool.

¶ AMS Workflow

¶ Loading & Unloading

During the loading process, the feeder sends the filament to the filament hub. When the odometer of the filament hub calculates a short length of the filament sent out of AMS, the feeder stops working, and then the filament is fed into the tool head by the filament hub motor.

During the unloading process, the feeder and filament motor work simultaneously. The feeder is responsible for driving the spool to rotate, and the filament Hub motor pulls back the filament.

The left and right rocker gears of the feeder control the feeding and unloading actions respectively. The right rocker arm lifts the gear to pull the filament to feed, while the left rocker arm lifts the gear to drive the black roller to rotate the spool to unload the filament, as shown in the following figure.

¶ Feed Assist Mode

When the AMS sends the filament to the extruder and successfully extrudes, the AMS will switch to the feed assist mode. AMS assists in feeding or retracting according to the feedback value of the buffer. The filament hub motor determines whether to continue feeding forward based on the position of the slider: When the feeding process encounters resistance, the slider in the buffer will be pushed to the right. When the filament is consumed by the extruder, the slider will return to the left. When the filament is about to run out, when the last section of filament is sent out through the filament hub, the filament hub motor will continue to run until the extruder detects that the filament is completely exhausted and pauses printing, and then the motor will stop rotating.

The entire process is as follows:

AMS will switch to feed assist mode after the filament is sent to the extruder, and switch back to idle mode after the filament is pulled back to AMS or the machine is rebooted. In the feed assist mode, AMS only determines whether to continue feeding according to the signal feedback of the buffer, regardless of whether it is printing or not.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!