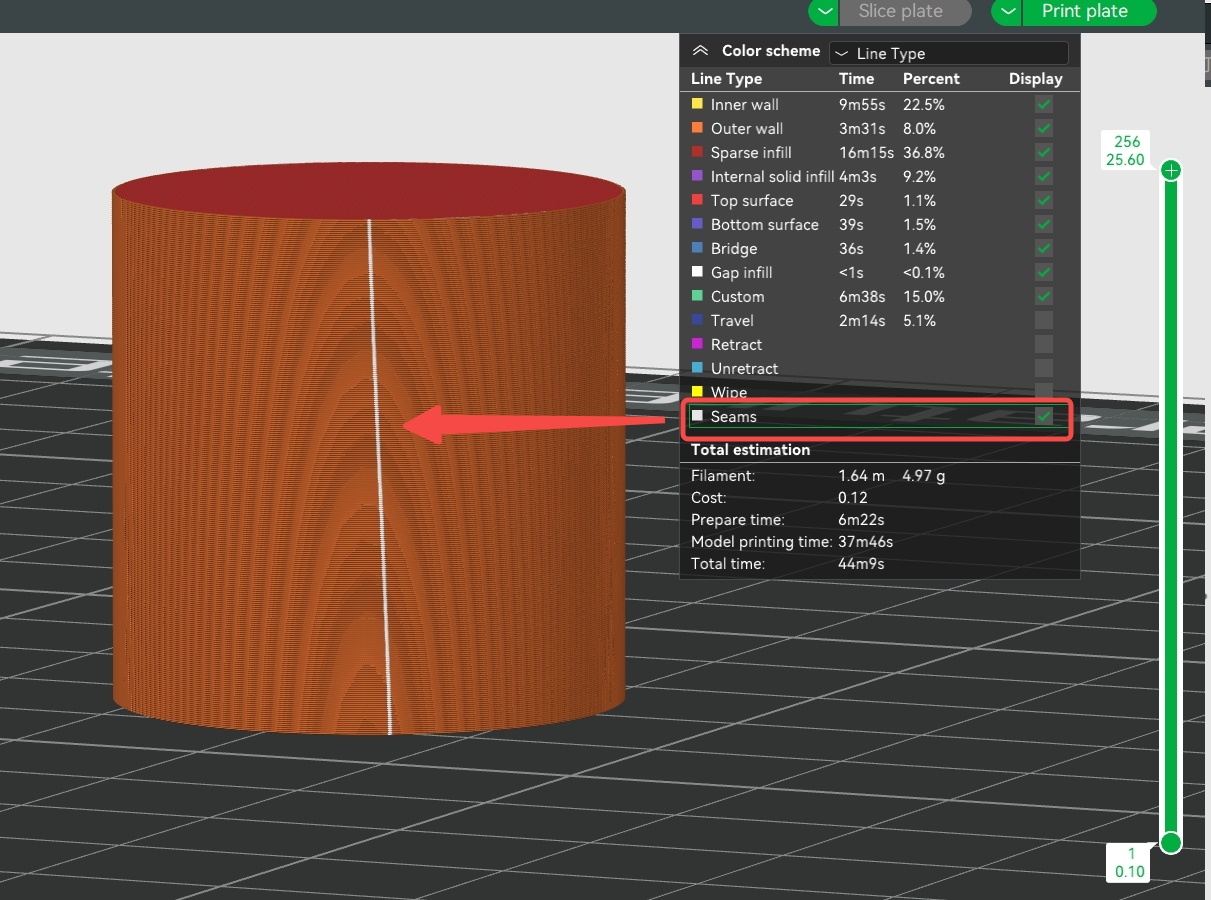

¶ Seam

In FDM 3D printing, a seam is formed at the junction of the starting point and the end point of each layer of printing, which is a normal phenomenon. To learn more about seams, refer to this wiki: Seam | Bambu Lab Wiki。

You can use the following methods to properly improve the quality of the seam:

1. Set the number of wall loops to 3;

2. Try to avoid printing multiple models on one plate to reduce tool head travel;

3. Appropriately raise the nozzle temperature and reduce the printing speed of the outer wall;

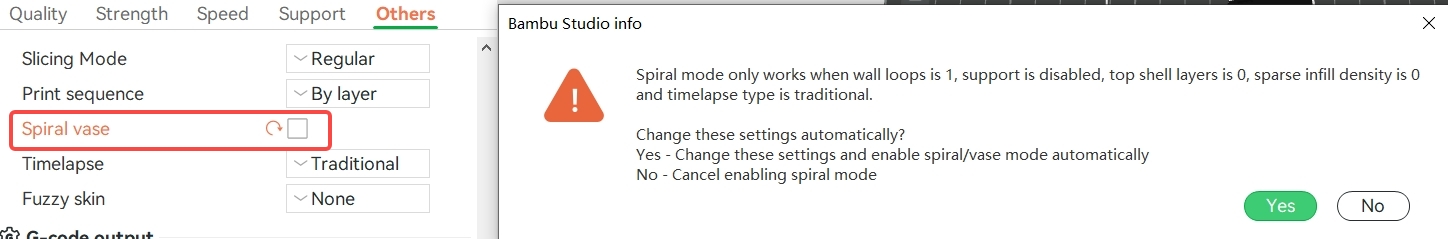

4. For some special models, you can enable the “Spiral vase” mode. When the "Spiral Vase" mode is enabled, the model will be printed in a linear spiral, and the seams will only appear on the bottom shell ayers , and not on the outer walls at all. Note: The model printed by this mode has only a single outer wall, no infill and top shell, and only applies to some simple models (complex models cannot be completed with a single line, resulting in some suspended sections when slicing). Please refer to this wiki for more details: Spiral Vase | Bambu Lab Wiki。