¶ 1. The pattern is not cut through or not completely cut through

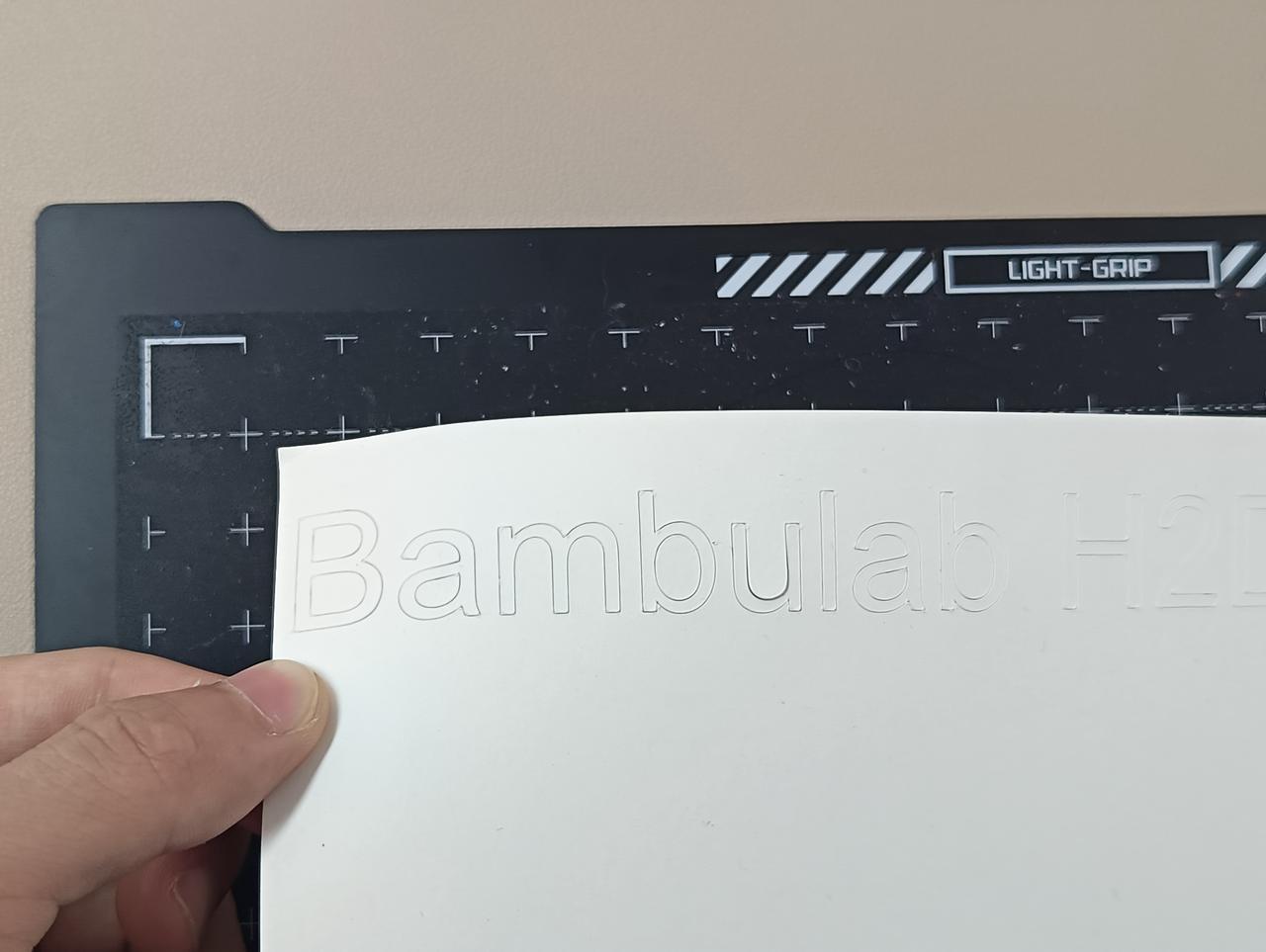

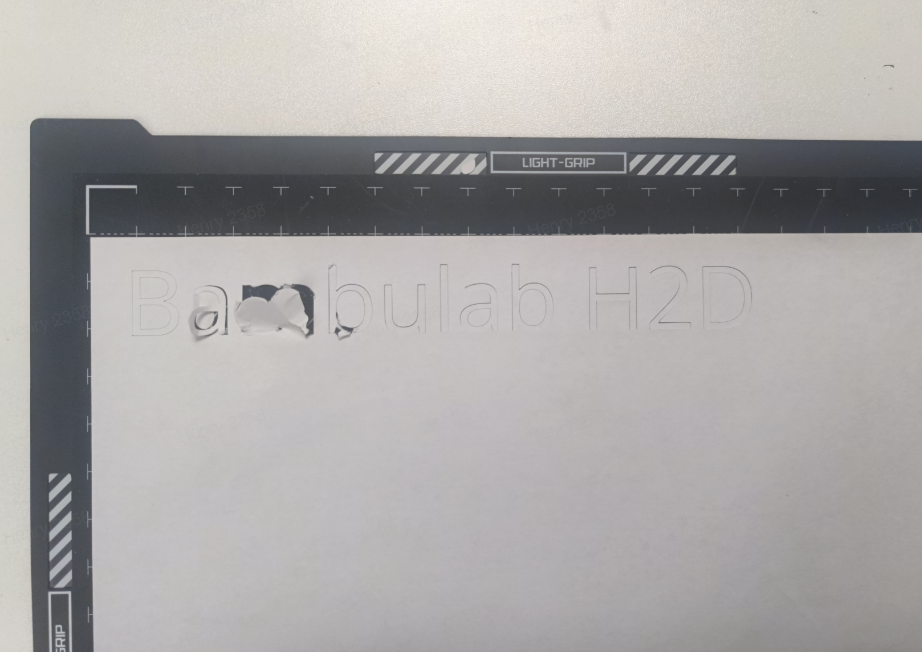

¶ Phenomenon:

After the cutting process, the pattern cannot be cut through or partially cannot be cut through, as shown in the following figures:

¶ Troubleshooting:

-

Perform cut pressure calibration on the cut material and increase the cut pressure appropriately. You can refer to this wiki for detailed operation steps: Bambu Suite Material Parameter Calibration and Machining Optimization Guide.

-

Check if the cutting module on the tool head is stable. You can manually check if there is any obvious shaking. If it is unstable, tighten the screw on the wrench appropriately. The loose wrench screw can cause the cutting module to be unable to be securely fixed, and there is a possibility of shaking during the processing, which can affect the processing quality.

-

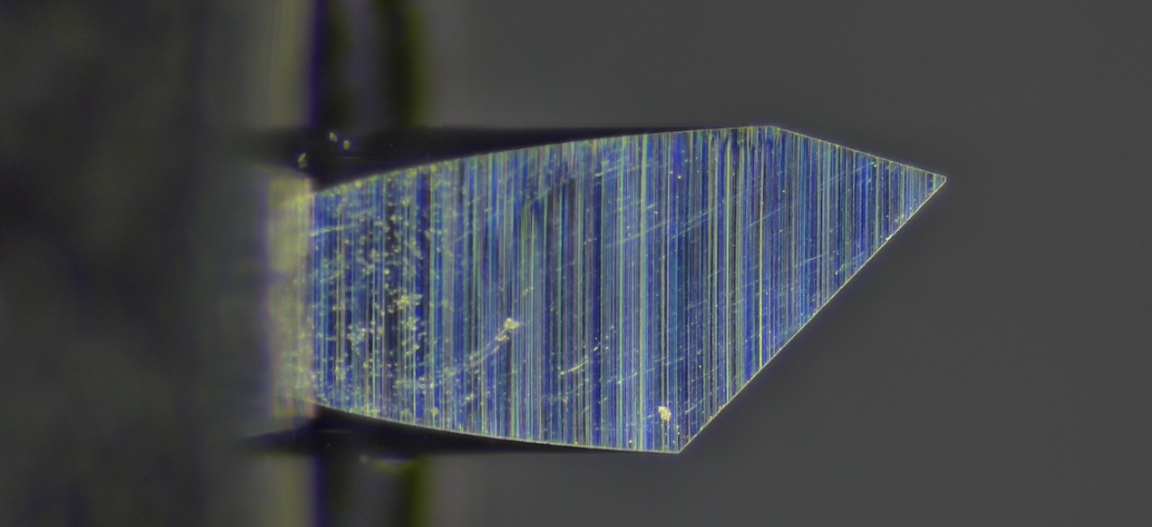

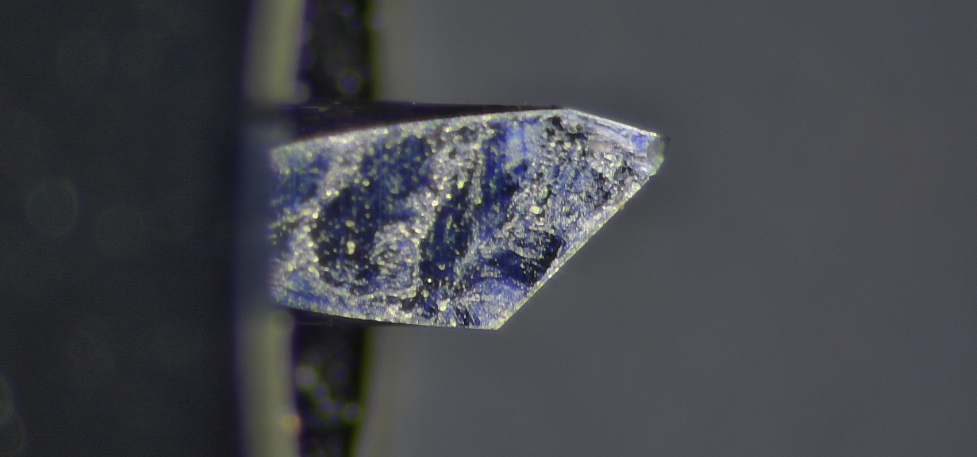

Observe whether the blade tip is broken or worn, and replace it with a new blade if it is damaged. (You can compare it with a new blade using a magnifying glass)

Good blade tip:

Worn blade tip:

Broken blade tip:

-

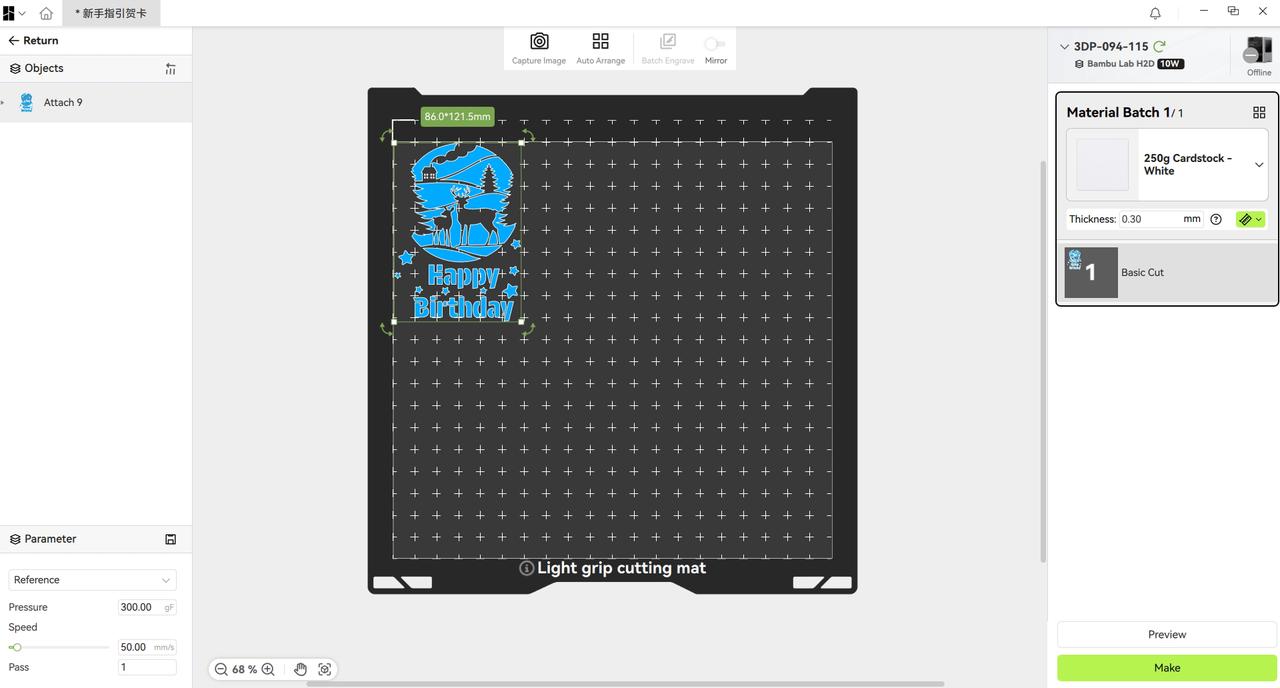

Confirm that the material placed on the cutting platform is consistent with the material selected in the software. If the materials are inconsistent, it is possible to use mismatched cutting pressure for processing, resulting in the inability to cut through.

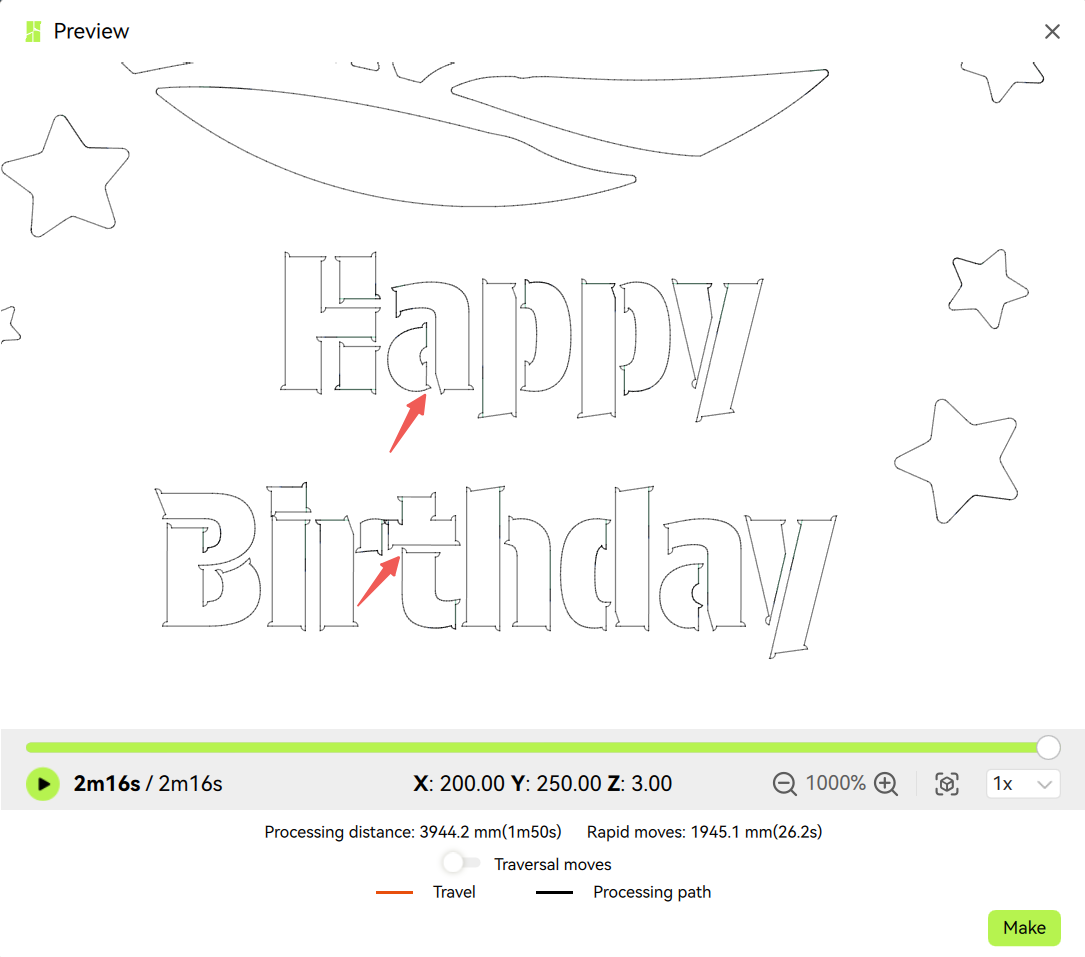

¶ 2. The blade tip scratches the paper

¶ Phenomenon:

During the cutting process, the blade scrapes the paper, as shown in the following figure.

¶ Troubleshooting:

-

Check if the cutting module on the tool head is stable. You can manually check if there is any obvious shaking. If it is unstable, tighten the screw on the wrench appropriately. The loose wrench screw can cause the cutting module to be unable to be securely fixed, and there is a possibility of shaking during the processing, which can affect the processing quality.

-

Observe whether the blade tip is broken or worn, and replace it with a new blade if it is damaged. (You can compare it with a new blade using a magnifying glass)

-

Check the adhesion of the cutting platform and whether there are any foreign objects on its surface. Make sure the paper is flat on the platform. You can use a roller to press the paper properly. If the material is not completely adhered to the platform's surface, the blade will likely scrape it during processing.

-

If it is found that the paper scraping path is caused by redundant lines in the original pattern, please delete the redundant lines in Bambu Suite.

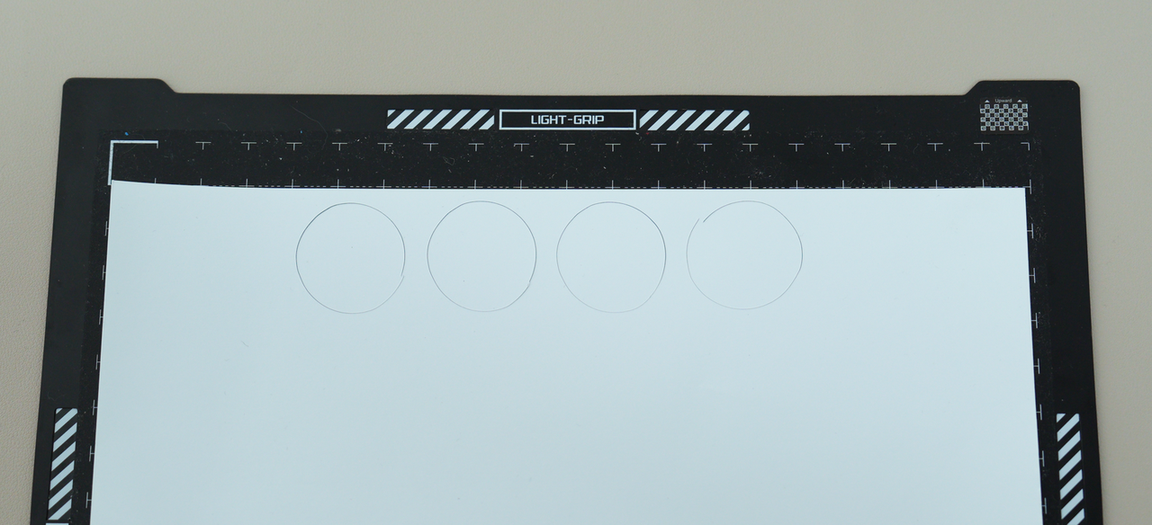

¶ 3. Corner adhesion of cutting patterns

¶ Phenomenon:

Some of the cut patterns have adhesions at the corners and have not been completely cut through, as shown in the following picture.

¶ Troubleshooting:

To better protect the blade during gradual leading and at the corners of the path, some slight adhesion is allowed. Usually, at the corners and starting positions of a cutting path, a smaller cut pressure is used to lead in or rotate the blade to reduce the wear of the blade tip. Therefore, the cutting pattern may have some adhesion at these positions, which is a normal phenomenon.

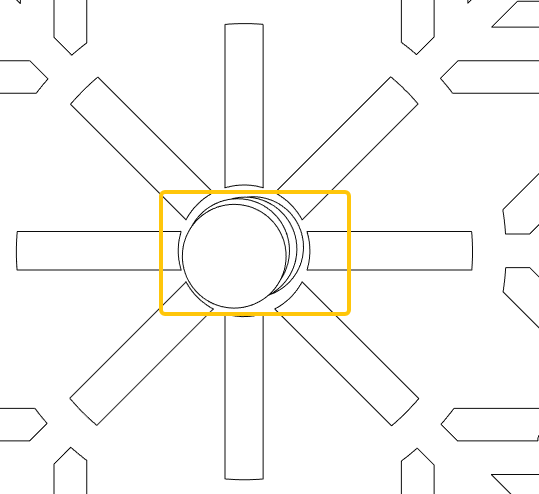

¶ 4. The processed pattern has deformed

¶ Phenomenon:

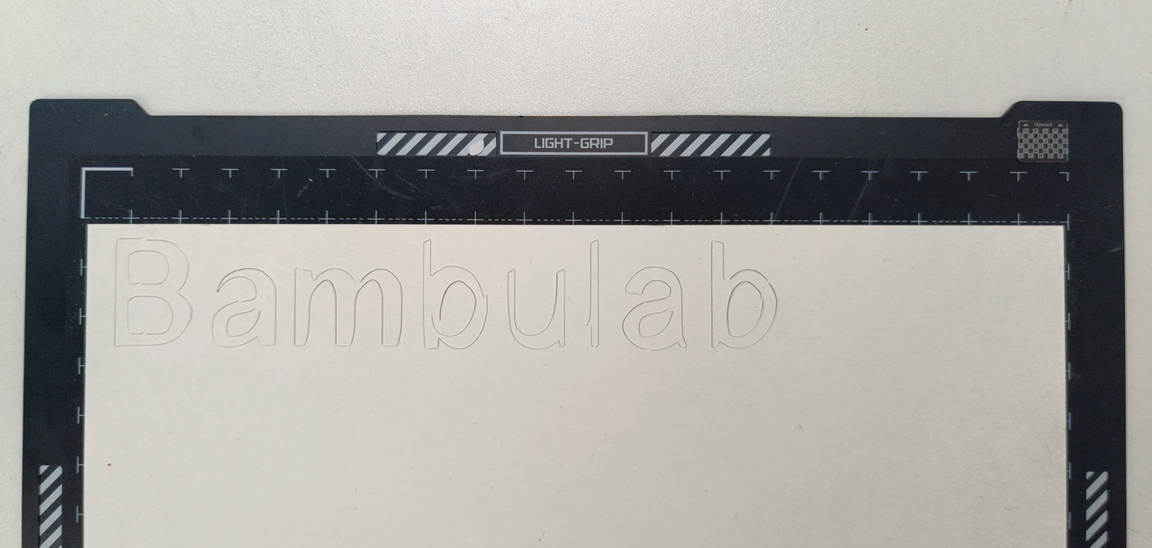

The pattern processed by cutting or drawing is significantly deformed. For example, the circle cut (drawn) is obviously not round enough, the pattern or text is obviously distorted, broken, etc., as shown in the following figures:

¶ Troubleshooting

Check if the cutting module on the tool head is stable. You can manually check if there is any obvious shaking. If it is unstable, tighten the screw on the wrench appropriately. The loose wrench screw can cause the cutting module to be unable to be securely fixed, and there is a possibility of shaking during the processing, which can affect the processing quality.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!