¶ Preface

Ensuring a clean and unobstructed nozzle is crucial during the 3D printing process, as it directly affects print quality and performance. Due to the H2D intelligent extruder motor, we have developed a practical feature that enables users to efficiently clean the nozzle. We strongly recommend incorporating this function into your routine maintenance to effectively extend the nozzle's lifespan.

Here are some scenarios where cold pull maintenance is necessary:

-

Frequent Extruder Motor Overload Errors: If the extruder motor frequently reports overload errors under normal printing flow conditions, it indicates excessive nozzle resistance and requires immediate cleaning.

-

Before Switching to TPU Filament: TPU is highly sensitive to nozzle resistance. If other materials have been previously used, we recommend performing a cold pull before printing with TPU to ensure smooth extrusion.

Note: If the nozzle is completely clogged and cannot be cleaned using the standard flushing procedure, please refer to the Hotend Unclogging Procedure first. After clearing the clog, proceed with the cold pull operation.

Test Criteria for Complete Nozzle Clogging:

After assembling the nozzle on the extruder and heating it steadily to 250°C, perform a feeding test using PLA or PETG filament. If no molten material is extruded from the nozzle tip or the extrusion is significantly lower than normal, the nozzle is considered completely clogged.

¶ Selection of Cold Pull Parameters

Through a series of tests, we have determined that PLA and PETG perform excellently in the cold pull process. Other filaments showed poor performance during cold pulling, as they are prone to tearing, leaving residue inside the nozzle. For cleaning filaments produced by third-party manufacturers, please carefully read the instructions before use and ensure they are used under appropriate conditions. The following is a guide for selecting parameters during the cold pull process:

¶ Extruder Selection

Both left and right extruders support automatic cold pull functions. If you are performing a cold pull on an HF nozzle, we recommend using the right extruder to significantly improve the cold pull success rate.

¶ Nozzle Selection

Here, you need to enter the parameters for the nozzle you wish to cold pull. Due to differences in the geometric parameters of various nozzles, we have preset corresponding parameters for each type of nozzle.

¶ Cold Pull Filament Selection

Cold pull filaments need to fulfill three core functions:

-

Perform flushing based on the flushing temperature to remove any residual filament inside the nozzle.

-

Refill the nozzle chamber based on the filament's printing temperature.

-

Cool down to the cold pull temperature and use cold pulling to remove internal impurities. Different nozzle models may require different cold pull filaments:

-

SF Nozzle: PLA or PETG is recommended as the cold pull filament.

-

HF Nozzle: PETG is preferred for cold pulling due to its better extensibility.

¶ Flushing Temperature Selection

You can choose the appropriate flushing temperature based on the highest temperature filament the nozzle has previously used:

-

250°C: Suitable for low-temperature filaments such as PLA, PETG, TPU, PVA, etc.

-

290°C: Suitable for high-temperature filaments such as ABS, ASA, PA, PC, PET, etc.

-

320°C: Suitable for ultra-high-temperature filaments such as PPS, PPA, etc.

If you are unsure which temperature to choose, you can base your flushing temperature on the highest usage temperature of the filaments you have.

¶ Cold Pull Temperature Selection

Cold pulling works by precisely controlling the nozzle temperature (recommended to be set 20-30°C above the filament's glass transition temperature) and using the material's viscoelasticity to physically strip contaminants from the nozzle wall. H2D has pre-configured parameter tables for you, but you can adjust them flexibly based on cold pull effectiveness and success rate. The suggested adjustment increment is 5°C. Specific adjustment directions are as follows:

-

If you encounter significant resistance and the filament breaks easily during cold pulling, it is recommended to increase the cold pull temperature.

-

If the filament breaks with minimal resistance during cold pulling, it is recommended to lower the cold pull temperature.

¶ Cold Pull Process

¶ Function Entry:

¶ Parameter Selection Operation:

For example, performing a cold pull operation using the right extruder with a 0.4 standard flow (SF) nozzle and PLA filament:

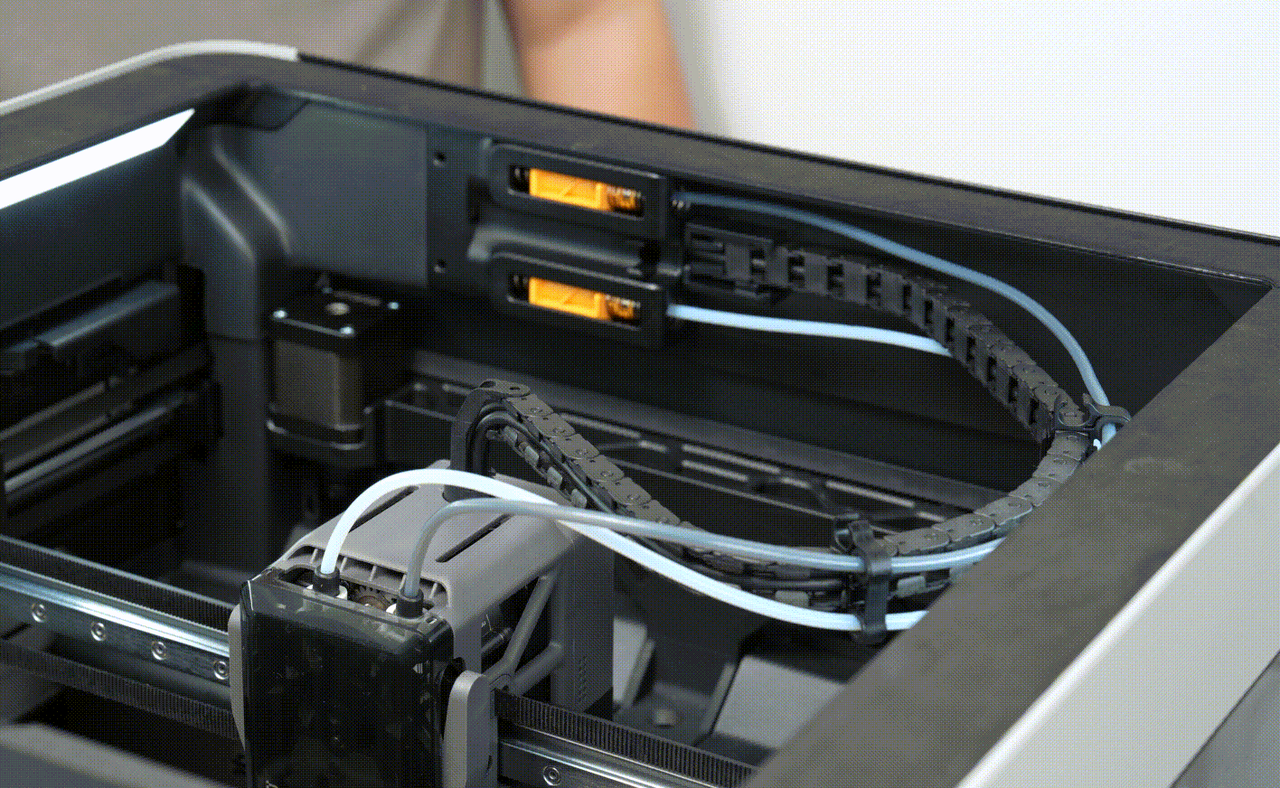

¶ Disassembling the PTFE Tube:

This guide uses the right hotend cleaning as an example, so you only need the right-side PTFE tube.

¶ Automatic Flushing and Cold Pulling:

After the toolhead and heatbed move to the designated positions, please cut at least 30 cm of filament and load it into the corresponding hotend.

.gif)

During this process, the machine will automatically perform flushing and filament refilling actions. Once the temperature drops to the cold pull setting, the extruder will automatically and slowly cold pull the filament until it reaches the extrusion machine at the filament's neck. You will then need to perform the subsequent filament removal operation.

Note:

After the machine enters the automatic process, the nozzle will heat up. Do not touch the nozzle to avoid burns.

During the machine's automatic flushing and cold pulling process, smoke may be generated due to the high flushing temperature. Please close the machine's front and top covers, and wait for the flushing to complete before opening them.

¶ User-Performed Cold Pull:

During the cold pull, the nozzle temperature will remain at the cold pull temperature you set. Avoid direct contact with the nozzle to prevent burns.

After the machine prompts you to perform a manual cold pull, grip the filament above the extruder and slowly pull the filament upward. During the cold pull process, pull the filament slowly; excessive speed or an incorrect angle may cause the filament to break.

¶ Evaluating the Cold Pull Effect:

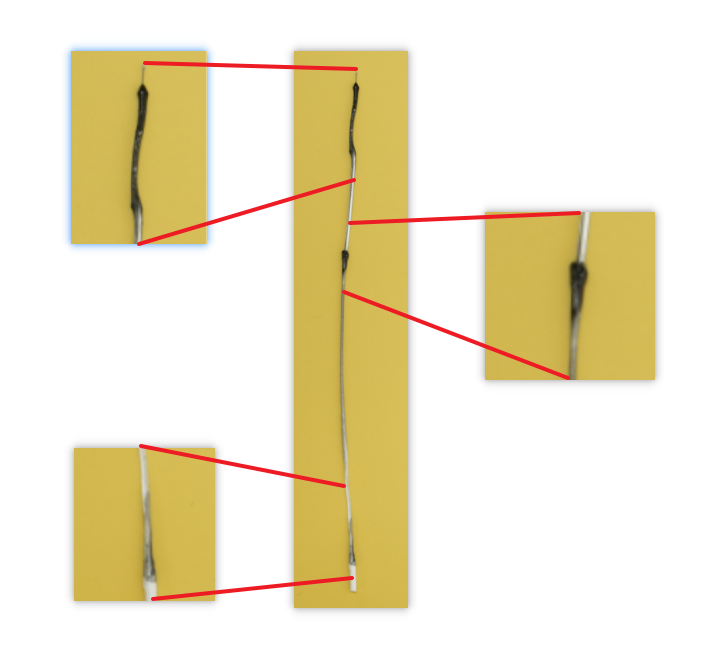

At the end of the pulled filament (The following image shows the HF Nozzle), focus on the following quality indicators:

-

Color Consistency: The pulled filament should not contain any foreign color impurities or carbonized deposits.

-

Surface Cleanliness: The surface of the pulled filament should display a homogeneous molten state, with no granular sintered material attached.

We strongly recommend repeating the cold pull multiple times until the extruded filament shows a clean surface with no abnormal residue (The following image shows the HF Nozzle).

¶ Reinstalling the PTFE Tube:

This guide uses the right hotend cleaning as an example. Since only the right-side PTFE tube was removed, you only need to reconnect the right-side PTFE tube.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!