¶ Heatbed Unit

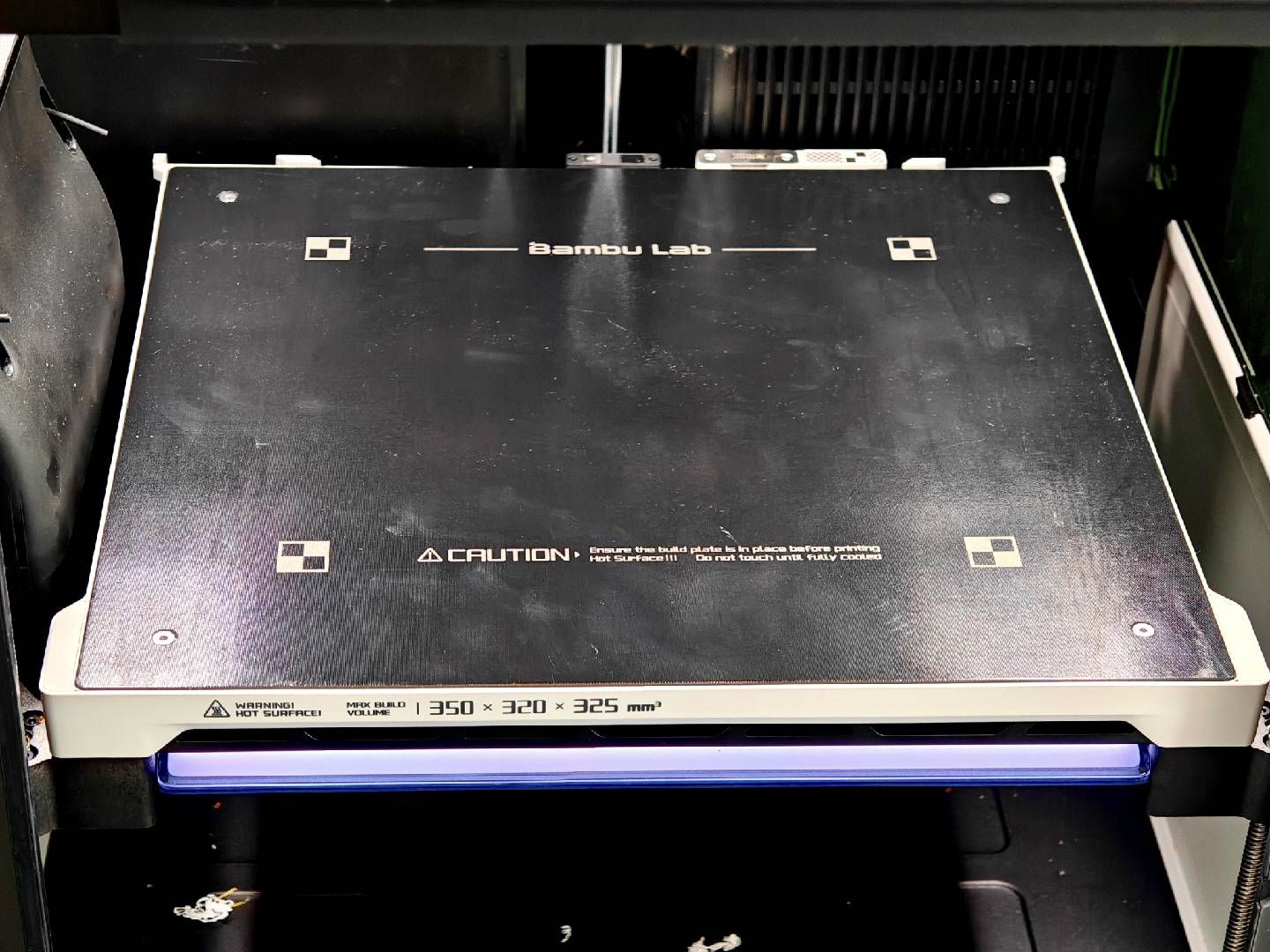

The printer’s heatbed is installed inside the printer chamber and can move up and down along the Z-axis. It heats up according to the user's set temperature to ensure proper adhesion of the model to the build plate and prevent warping.

The spare parts for the heatbed unit include the following:

-

Heatbed (pre-installed with H2D status light and nozzle offset calibration sensor connector) * 1

-

M3x8 screws (for fixing the heatbed to the Z-axis slider) * 6

-

M2x5 screws (for fixing the nozzle offset calibration sensor to the heatbed) * 2

-

Silicone plugs * 2

-

STW3x5 screw (for fixing the heatbed ground wire) * 1

¶ When to Use

-

The heatbed fails to heat up, and troubleshooting confirms it is faulty.

-

Physical damage or noticeable deformation affecting functionality.

-

Confirmation by Bambu Lab official technical support that the heatbed needs replacement.

¶ Tools and Materials Needed

-

New heatbed unit

-

H2.0 Allen key

-

H1.5 Allen key

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, we recommend submitting a technical ticket regarding your issue and we will do our best to respond promptly and provide the assistance you need.

¶ Remove the Heatbed

¶ Step 1: Remove the status indicator and nozzle offset calibration coil

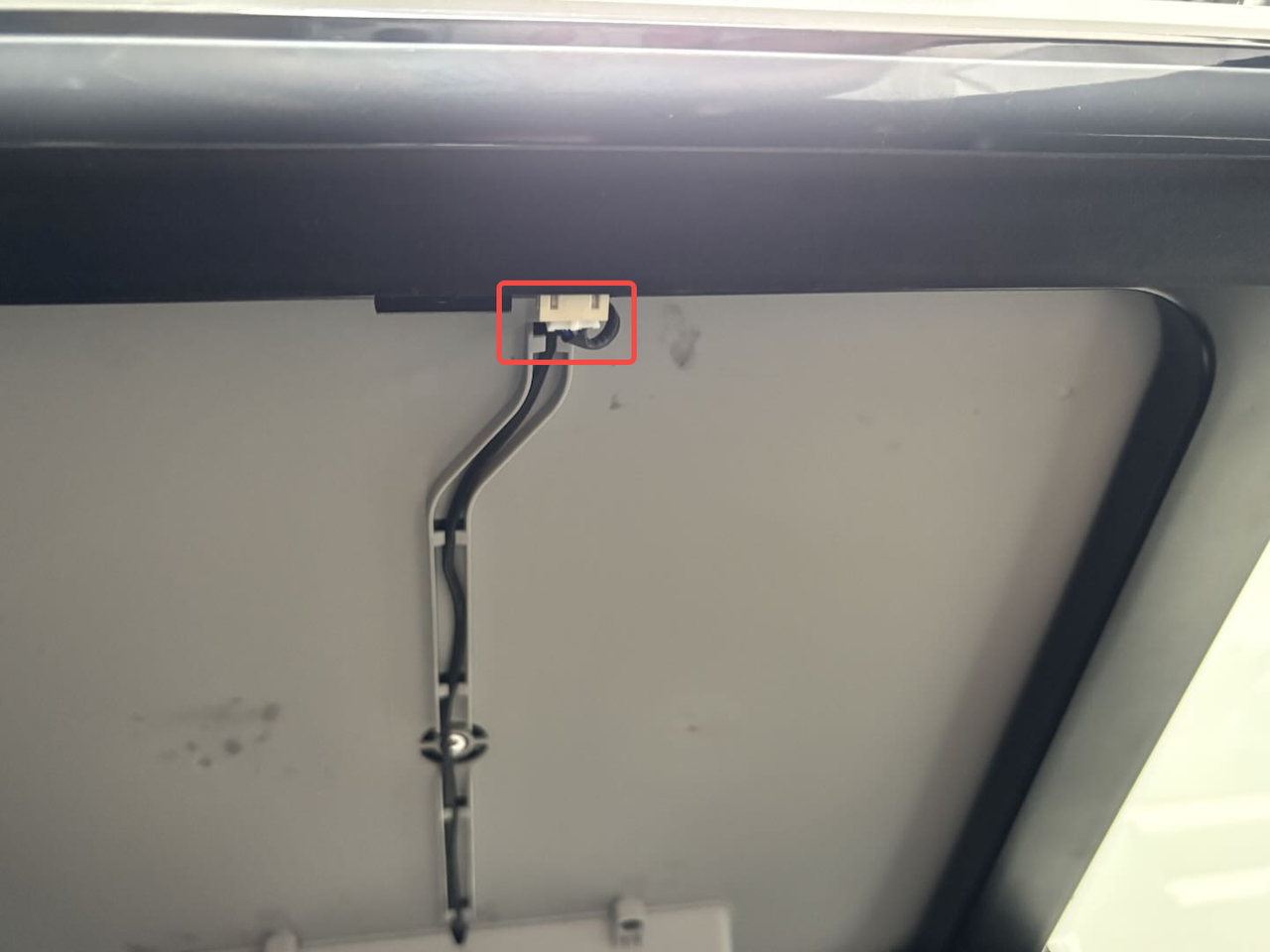

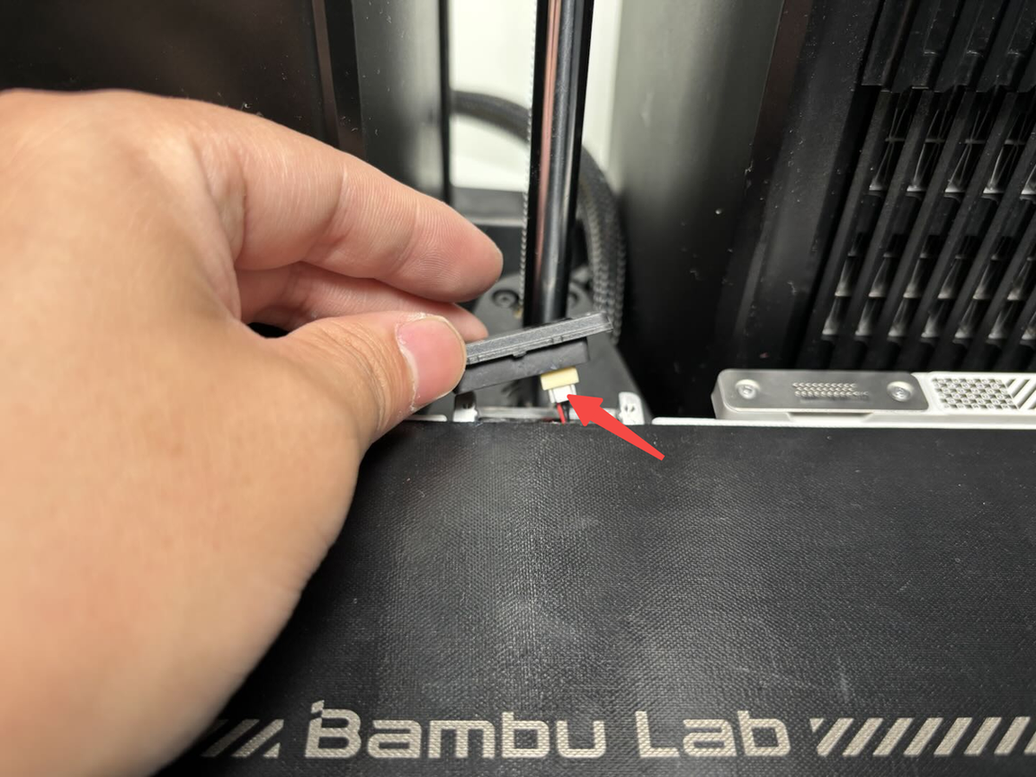

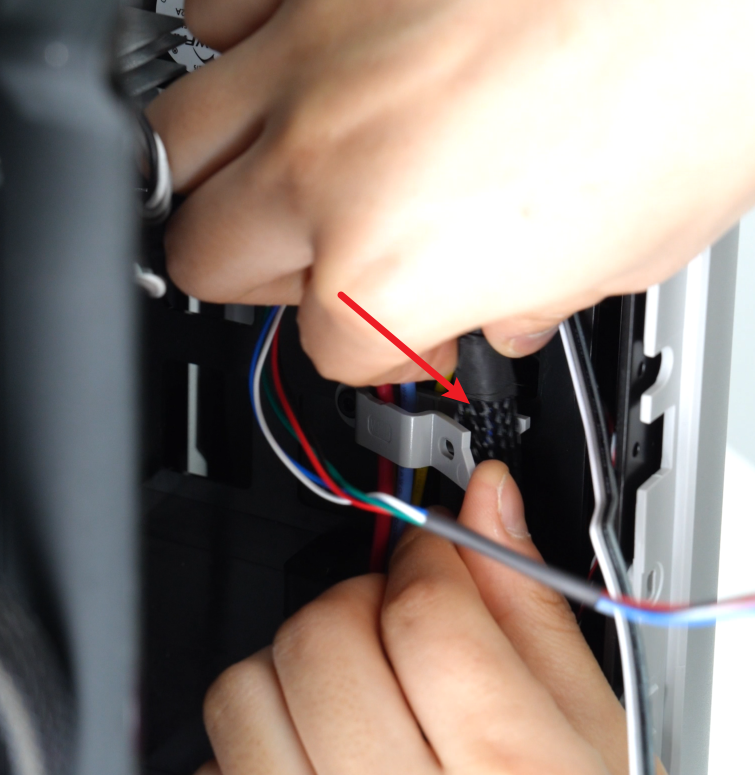

- The status indicator is fixed to the heatbed with clips. First, disconnect the status indicator connector. Then, hold the status indicator and firmly push from the back to release the rear clip. Once the rear clip is unlocked, push the status indicator backward to release the front clip and remove it.

|

|

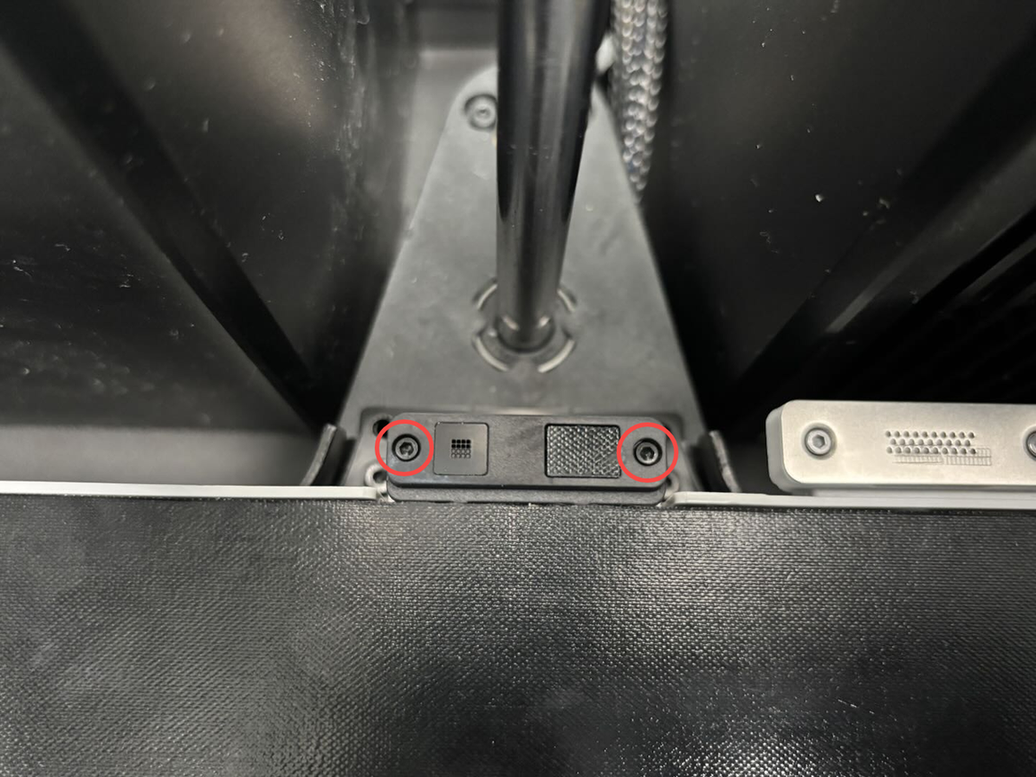

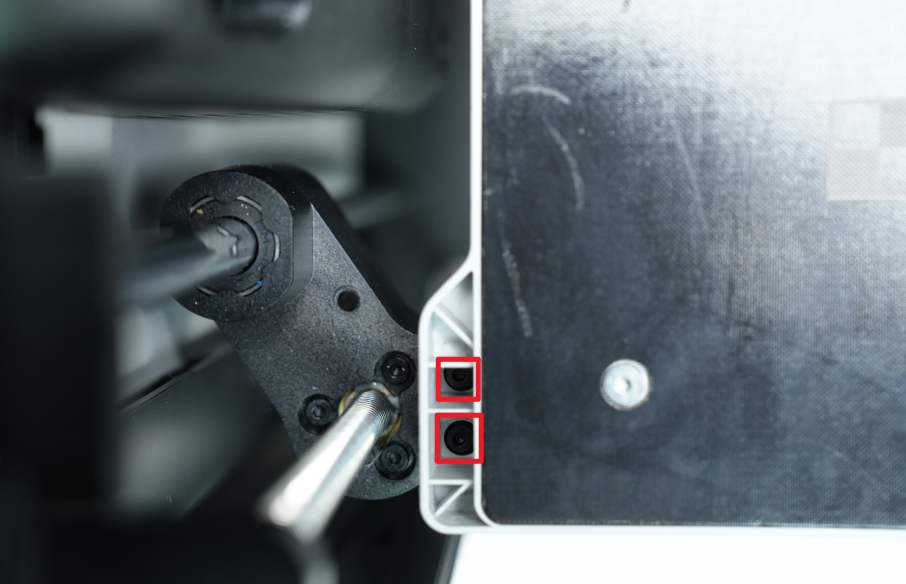

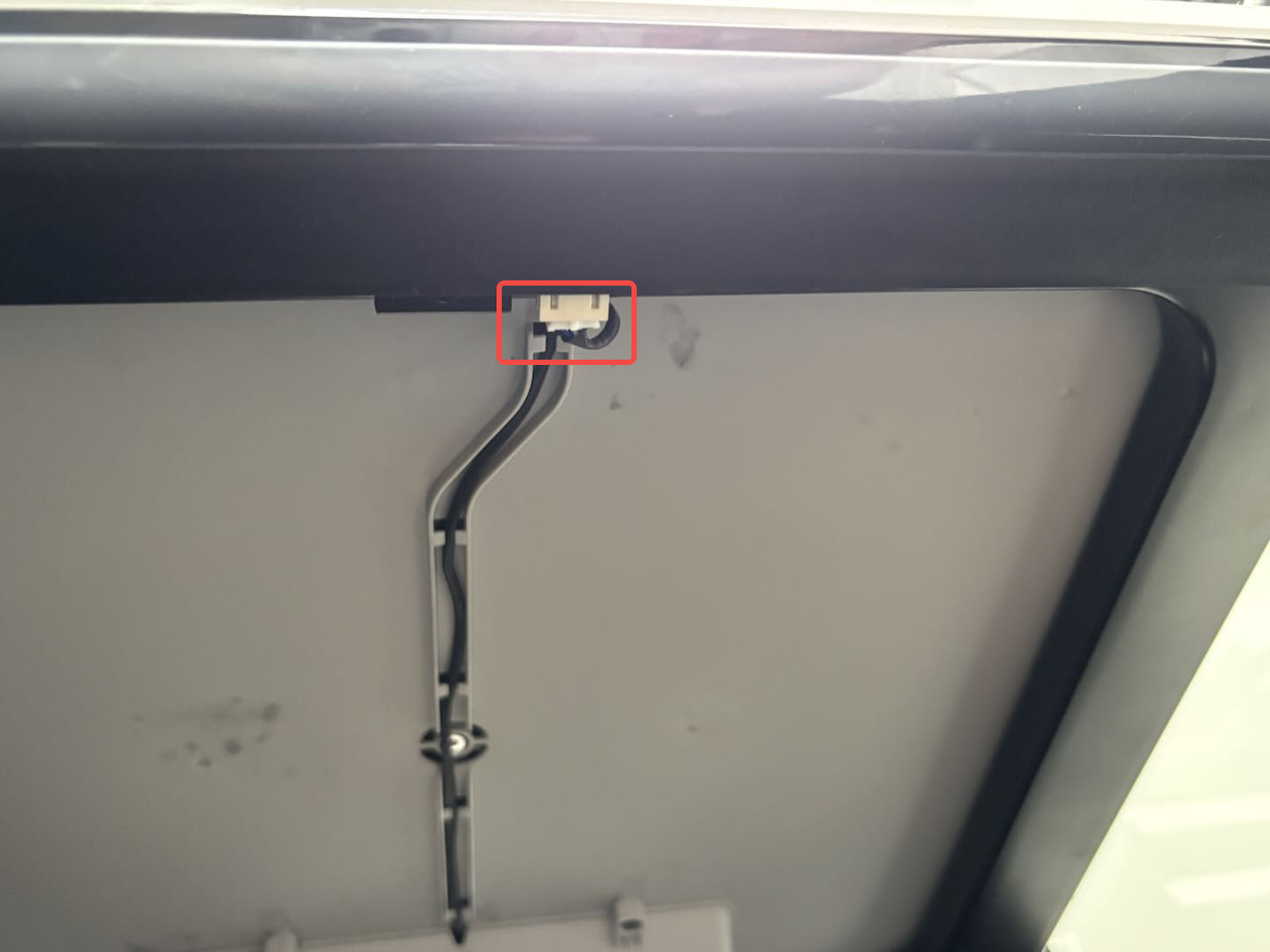

- Use an H1.5 Allen key to remove the two fixing screws (M2x5) securing the nozzle offset calibration coil. Lift the calibration coil upward and disconnect its connector.

¶ Step 2: Remove the rear panel, purge chute, and AC board cover

Refer to this Wiki Replace H2D AC Board/AC board Cover to remove the following in sequence:

-

Rear panel

-

Purge chute

-

AC board cover

Since replacing the heatbed does not involve the AC board, you can skip the steps related to AC board removal.

¶ Step 3: Disconnect heatbed cable

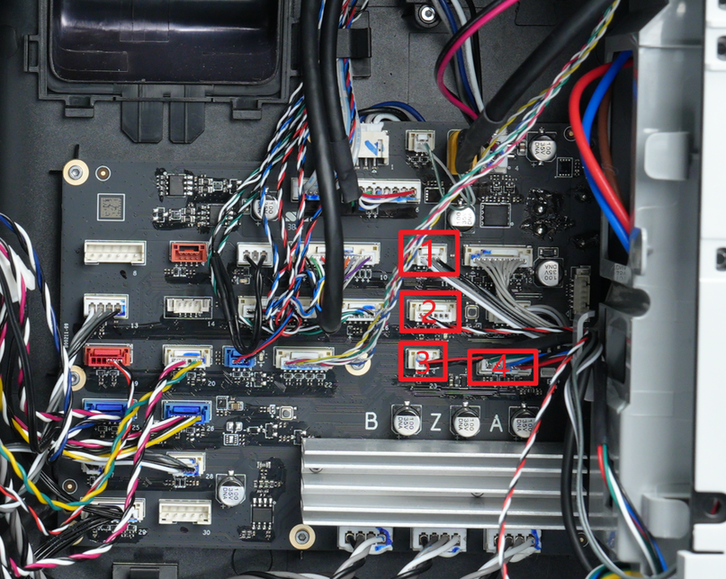

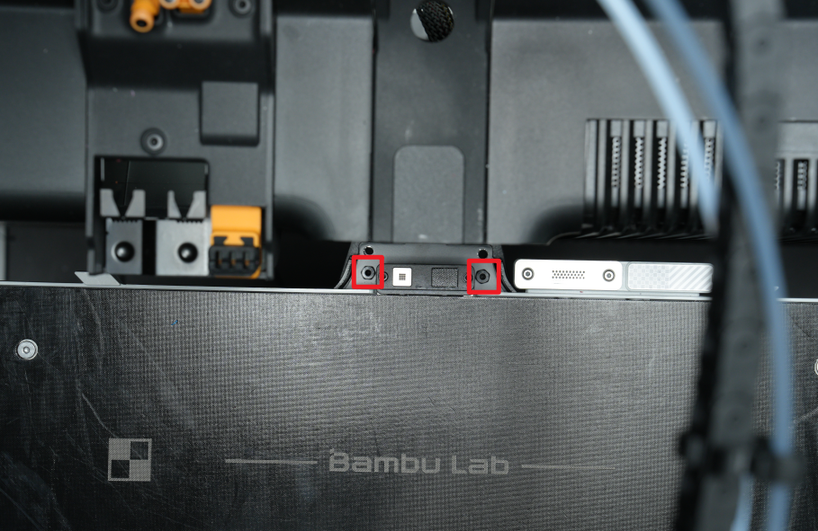

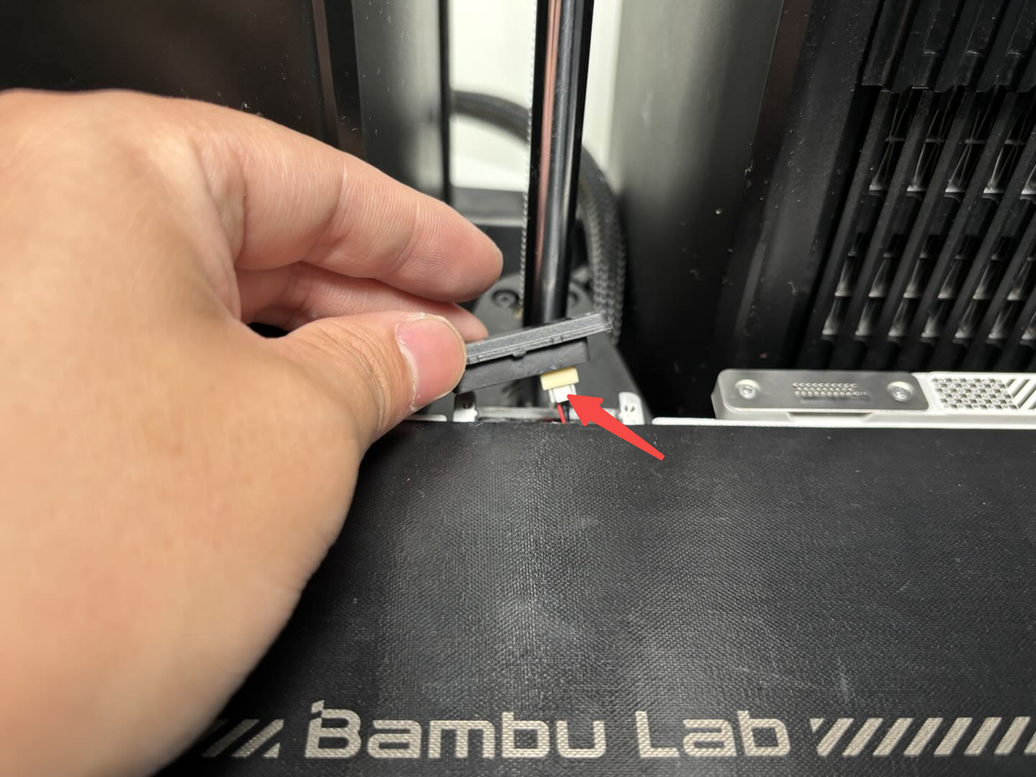

- Since the two cables connecting the heatbed to the MC board were already removed in Step 2, you can skip this step. The two cables are:

-

3: H2D status indicator connector

-

4: Heatbed signal cable

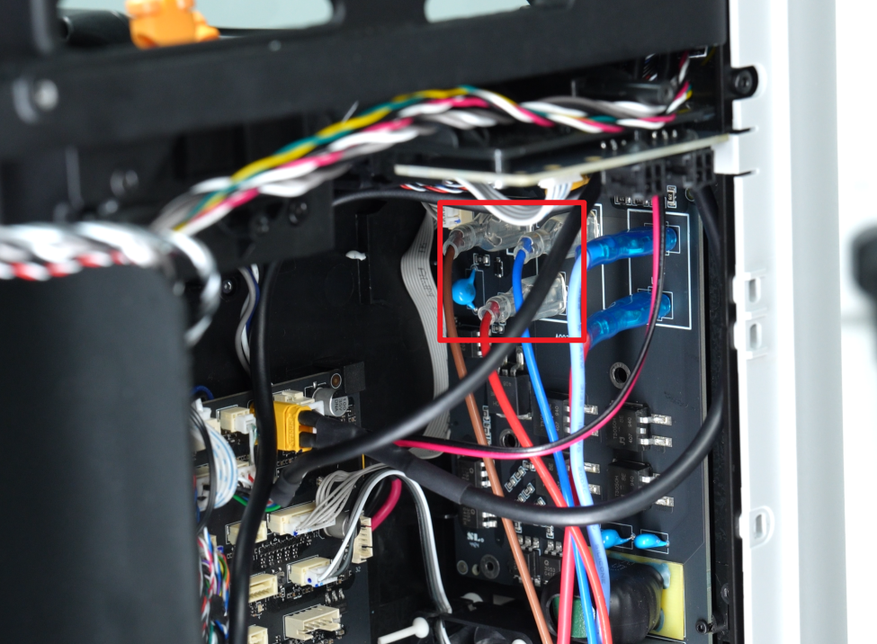

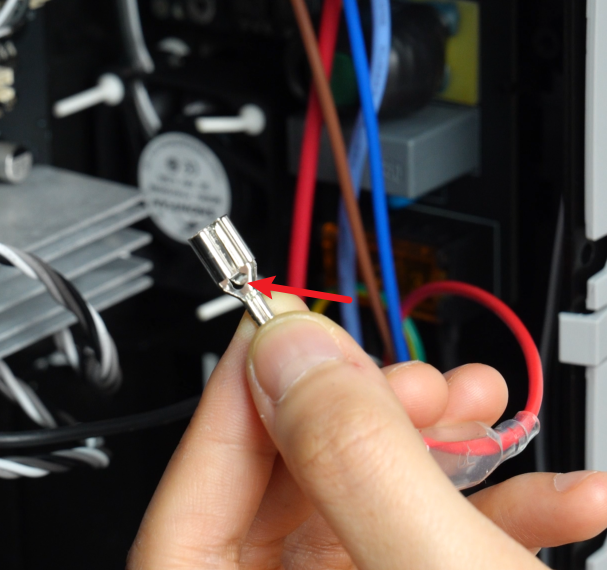

- After removing the heating module power cables, use tweezers to press the clip on the heatbed power cable connector and remove the power cables. Remove the 3 power cables one by one.

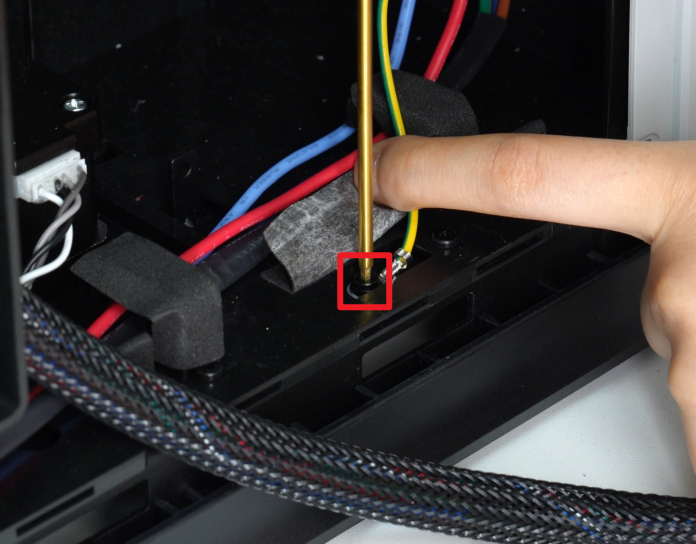

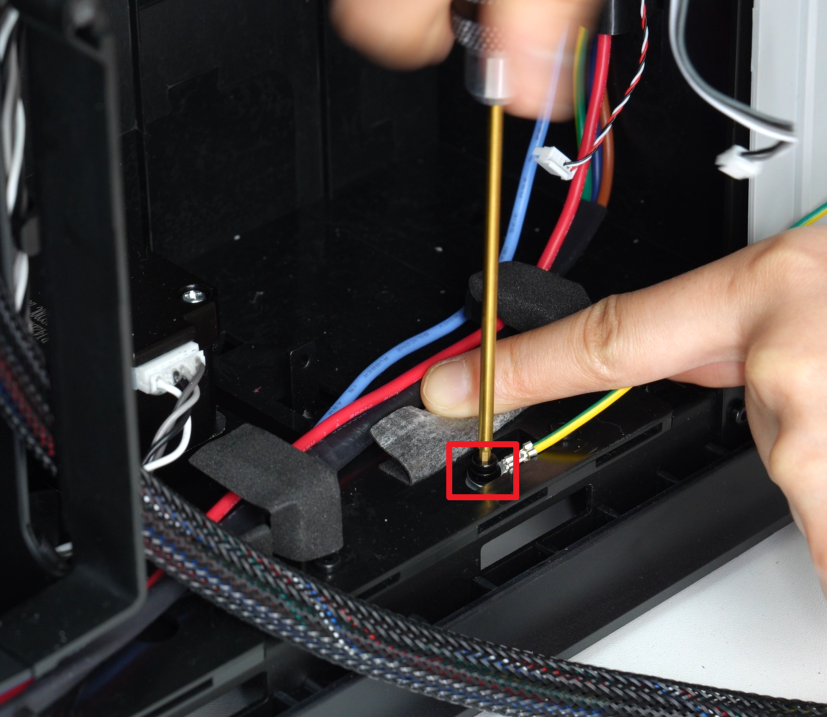

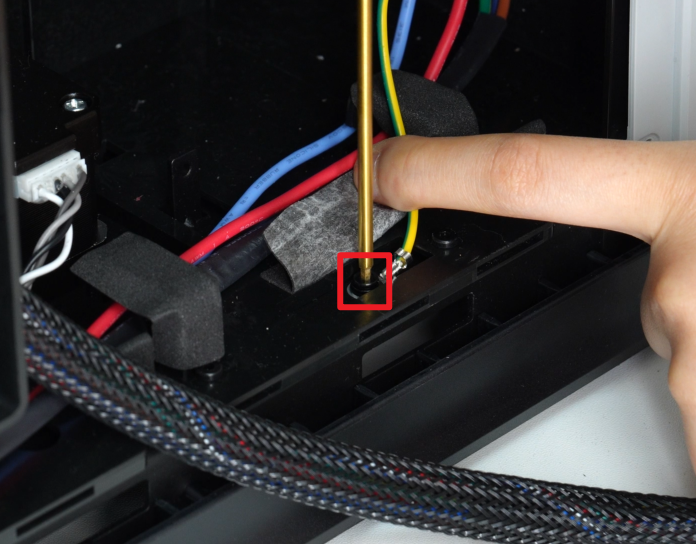

- Remove the heatbed ground wire from the clip and peel off the foam. Use an H2.0 Allen key to loosen the heatbed ground fixing screw (STW3x5) and release the ground wire.

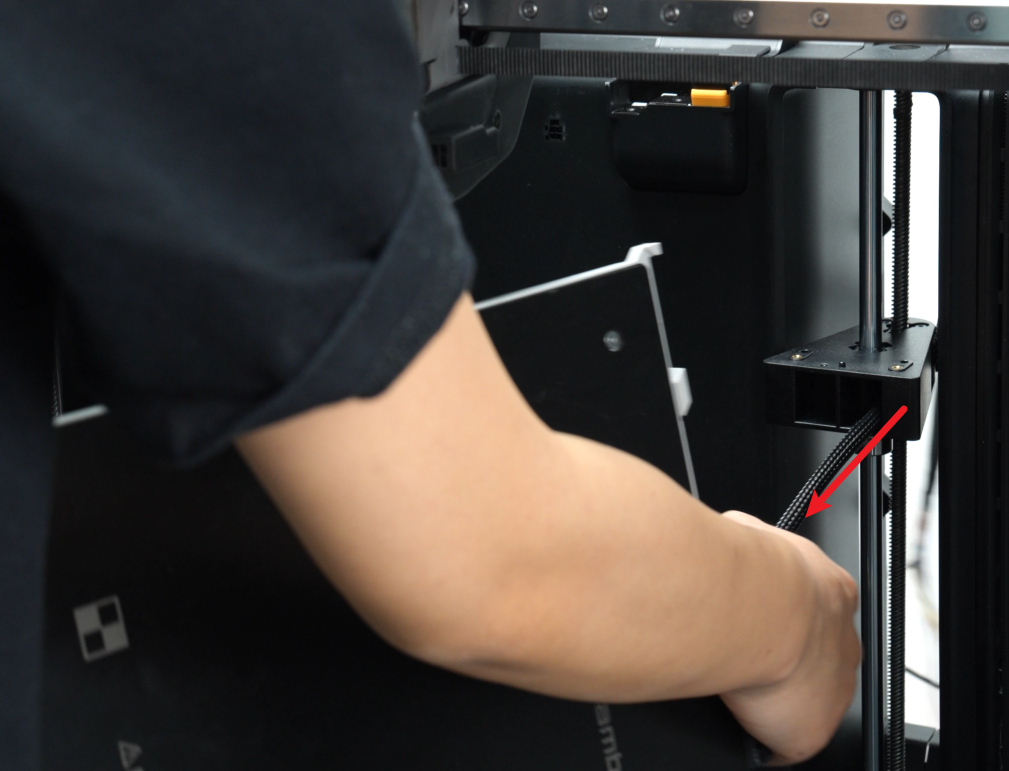

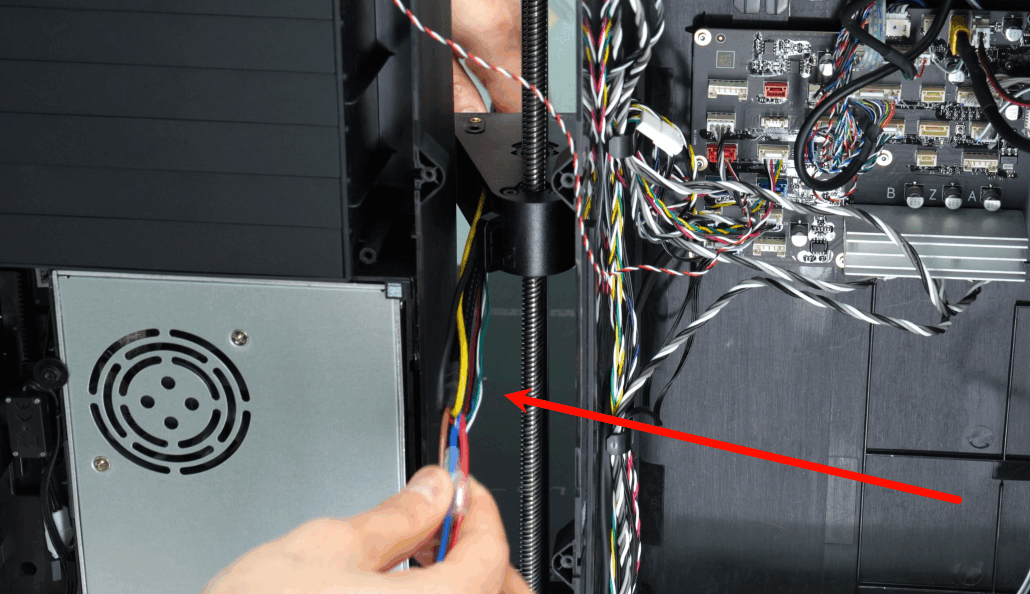

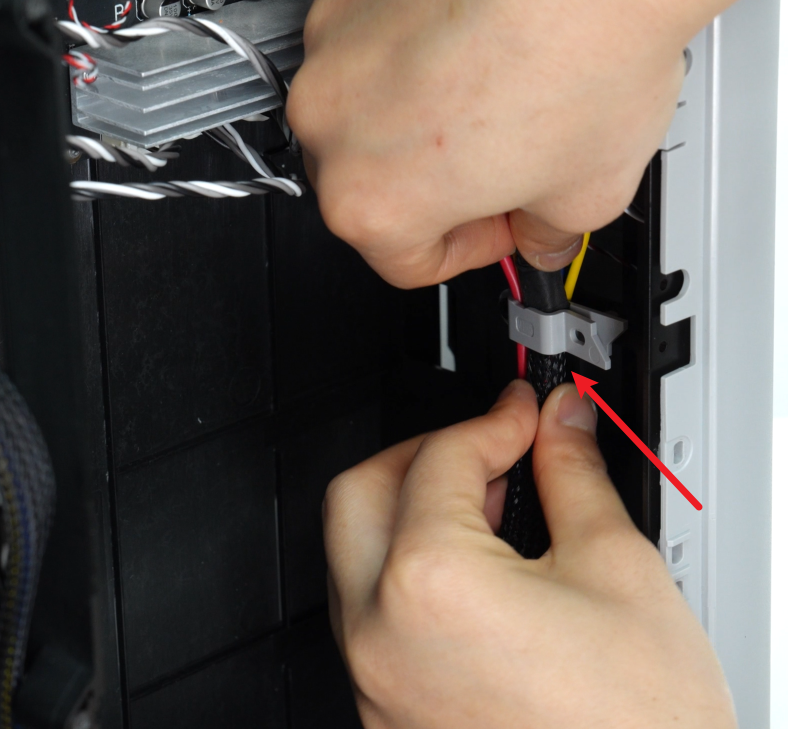

- Use an H2.0 Allen key to loosen one cable clip fixing screw (BT3x12), open the clip, and pull out the heatbed cables. Then, extract the cables from the side lining gap and remove them from the clip behind the Z-axis slider.

¶ Step 4: Remove the heatbed

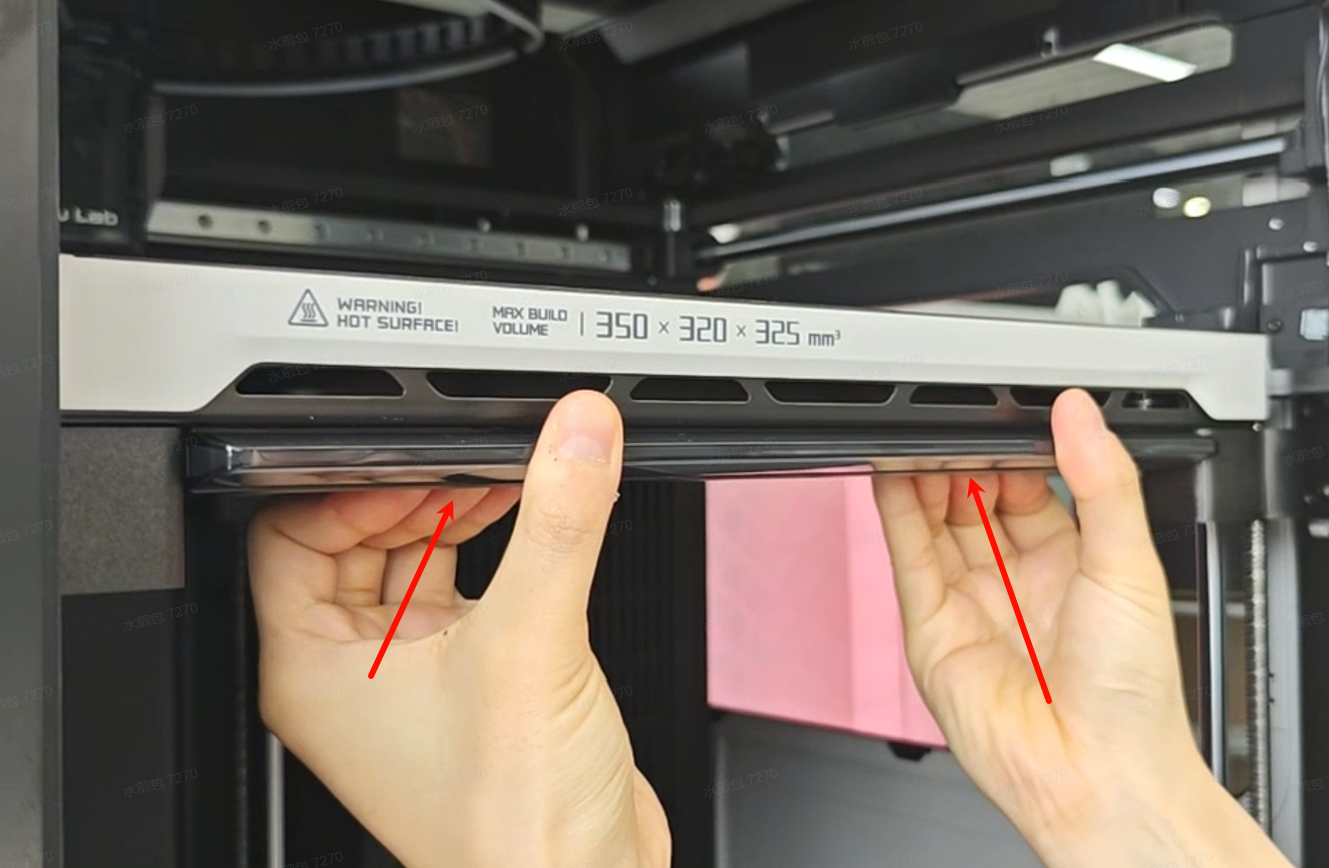

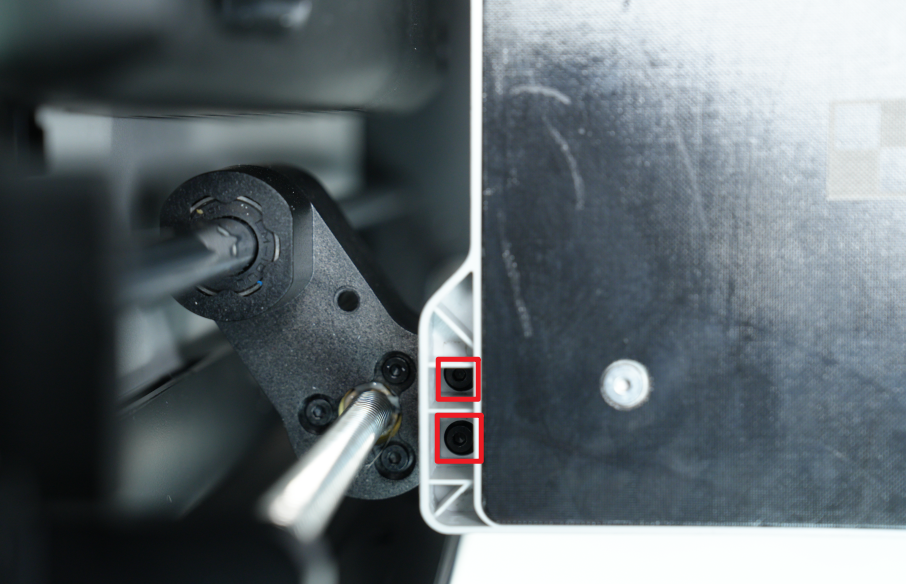

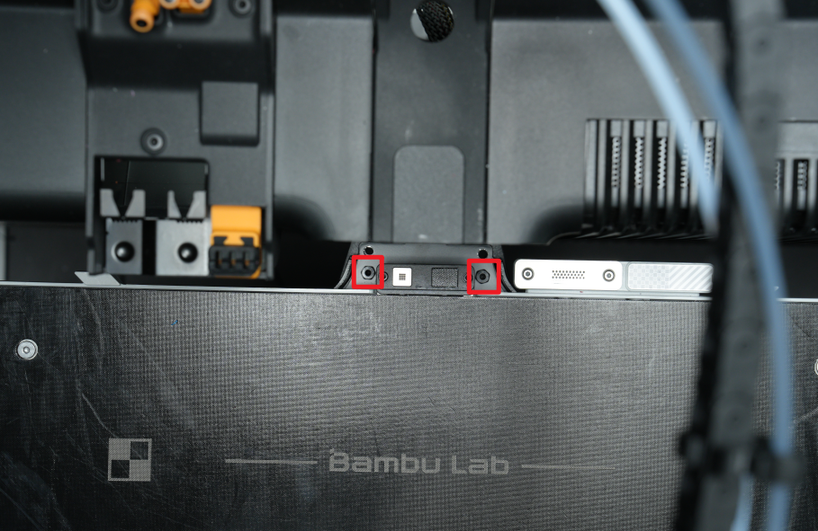

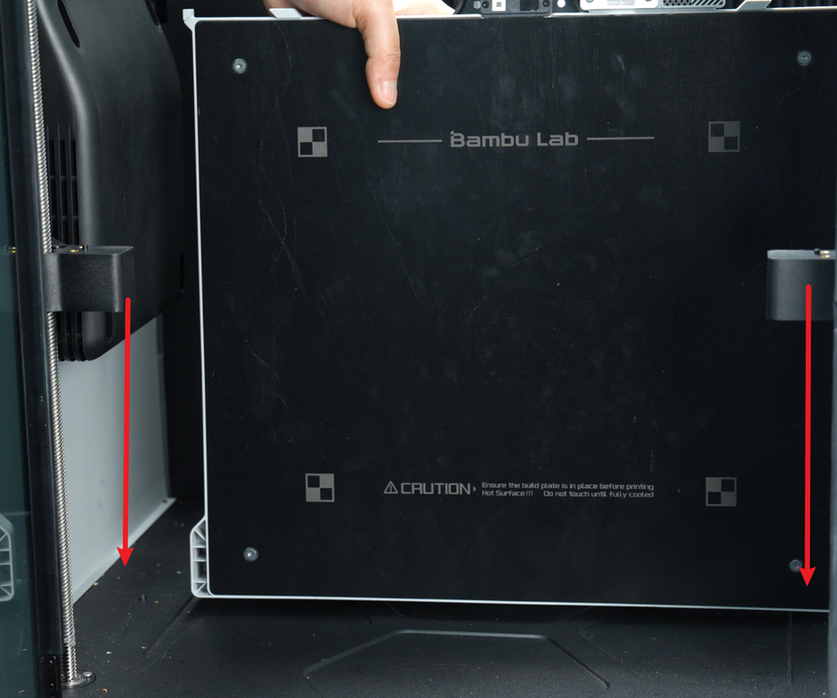

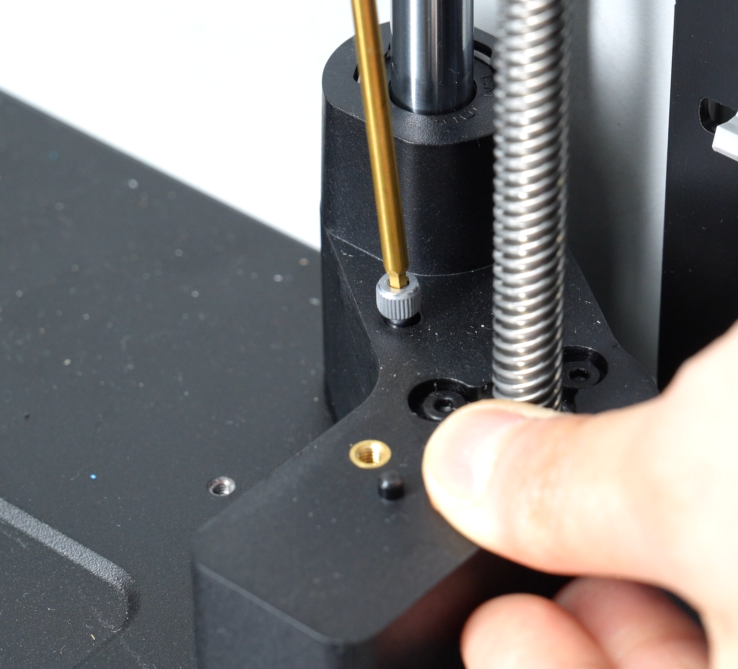

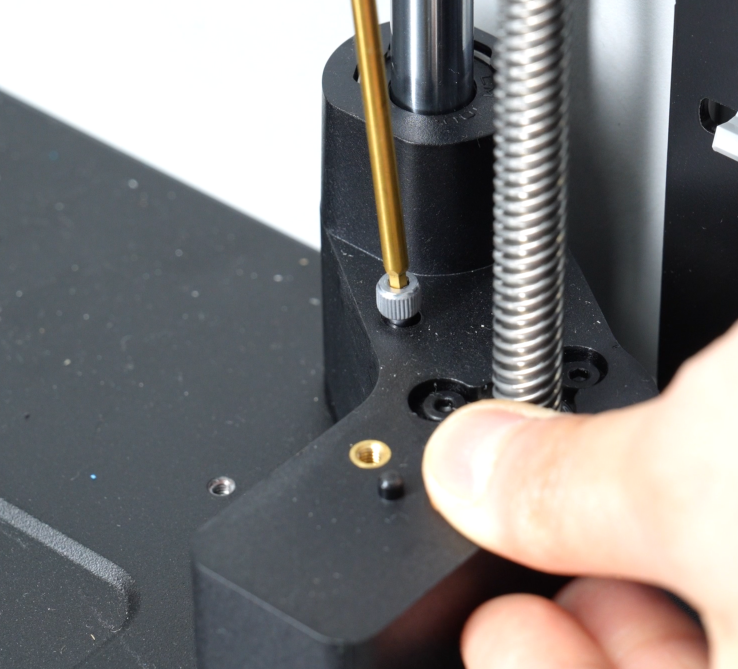

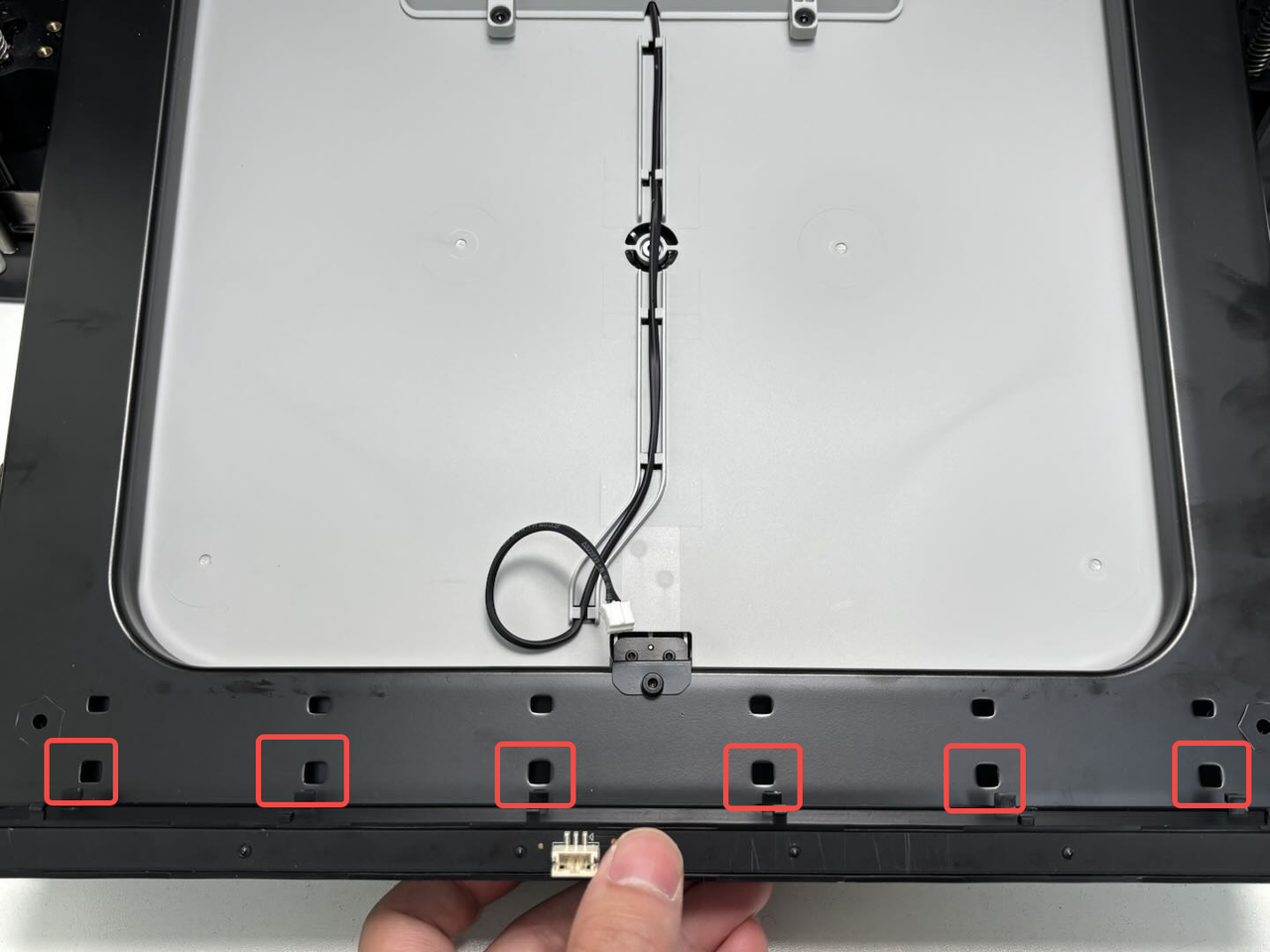

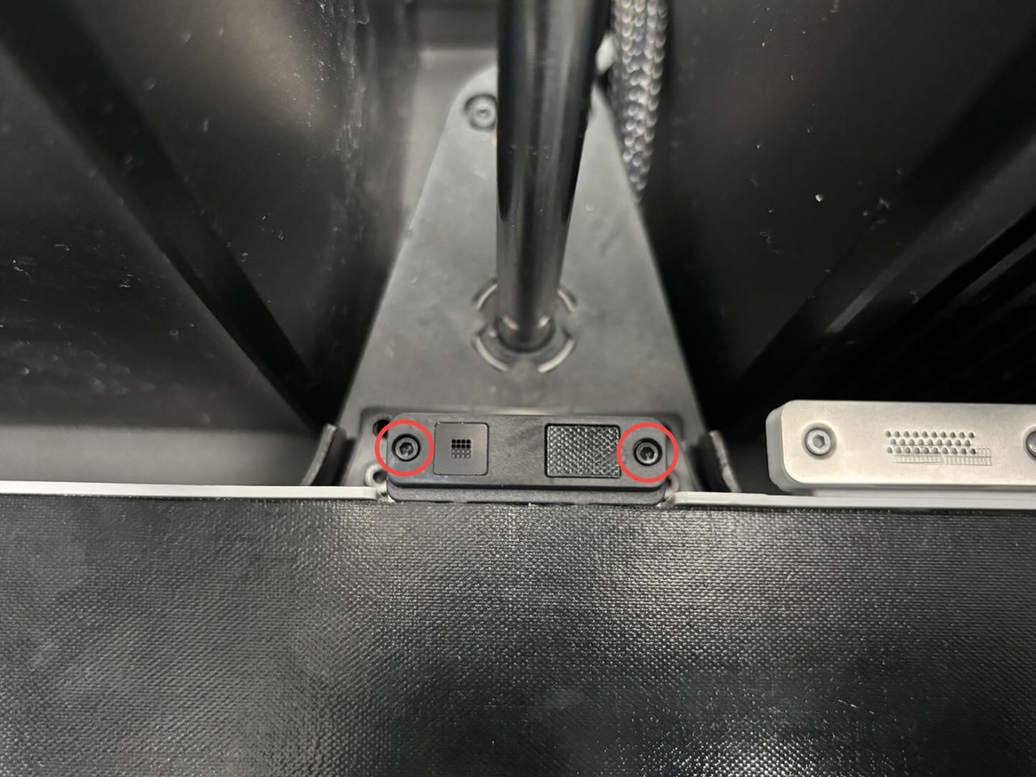

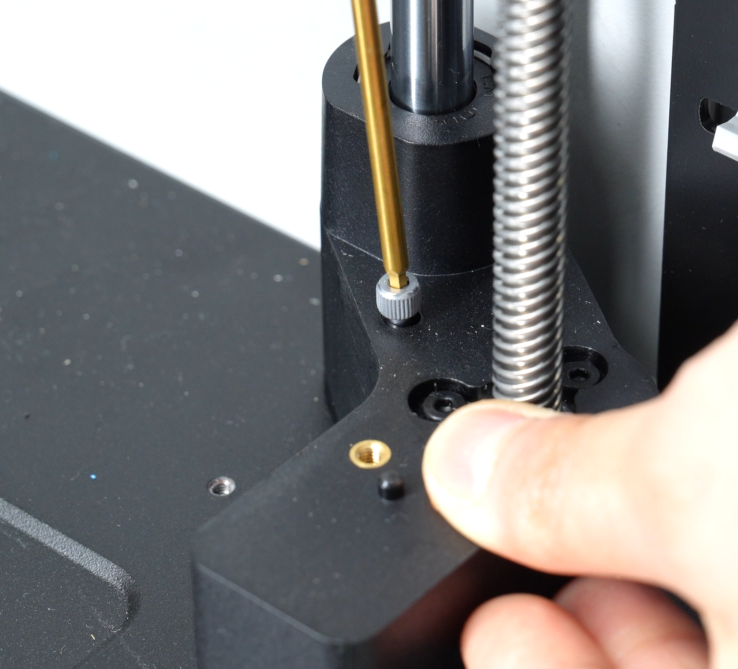

- Use an H2.0 Allen key or tweezers to remove the two silicone plugs on the left and right sides of the heatbed. Then, use the H2.0 Allen key to loosen the 6 screws (M3x8) shown in the images.

- After removing all cables and loosening the screws, lift the heatbed slightly and extract the heatbed cables from the Z-axis slider. Remove the cables from the nylon ties one by one to prevent interference due to the small slider gap.

¶ Install the heatbed

¶ Step 1: Install the heatbed

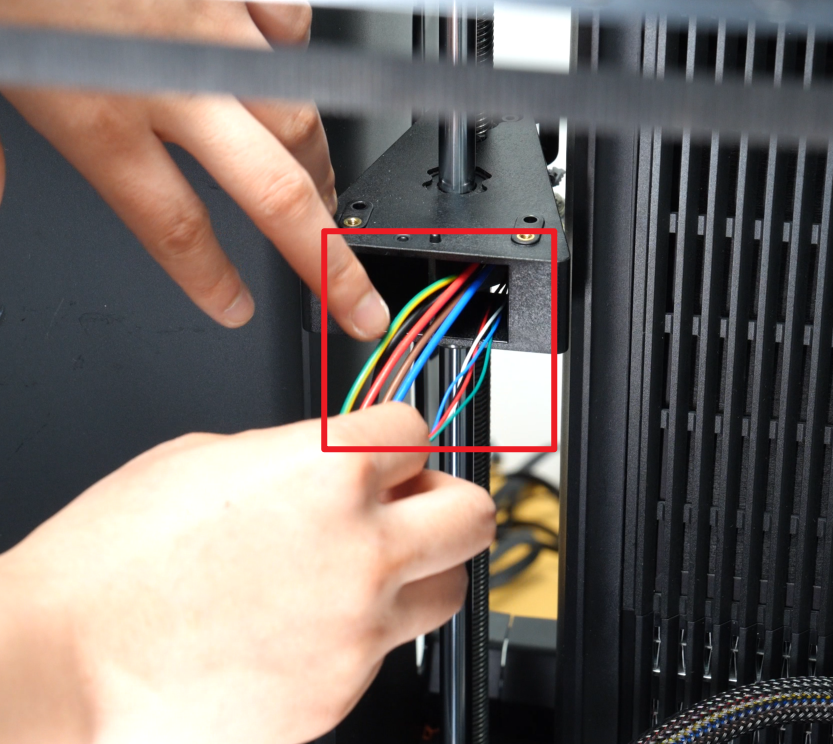

- Thread the heatbed cables through the small holes in the Z-axis slider. First, pass the cables connected to the AC board, then fold the remaining cables and pull them through.

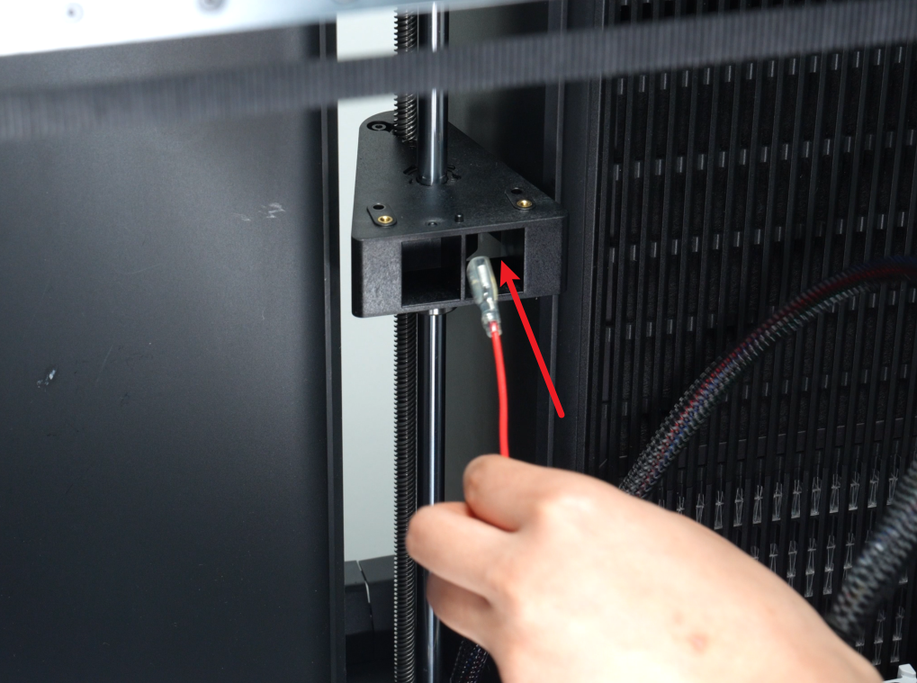

First, you can pass the red cable through.

|

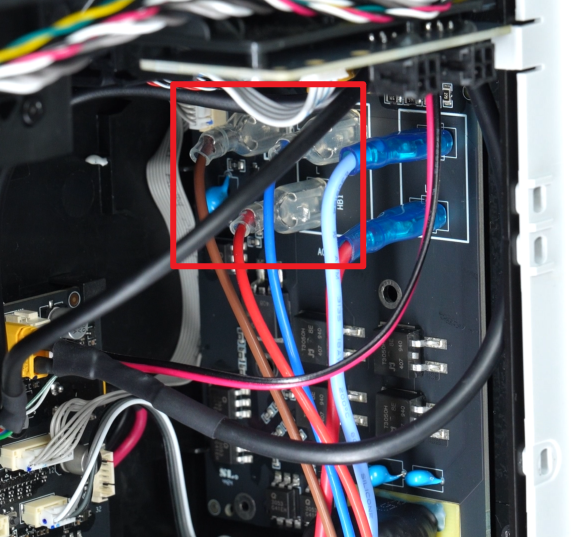

|

Due to the narrowness of the hole, it is necessary to peel off the silicone covers of two blue and brown cables respectively, and then pass them through the small hole one by one.

|

|

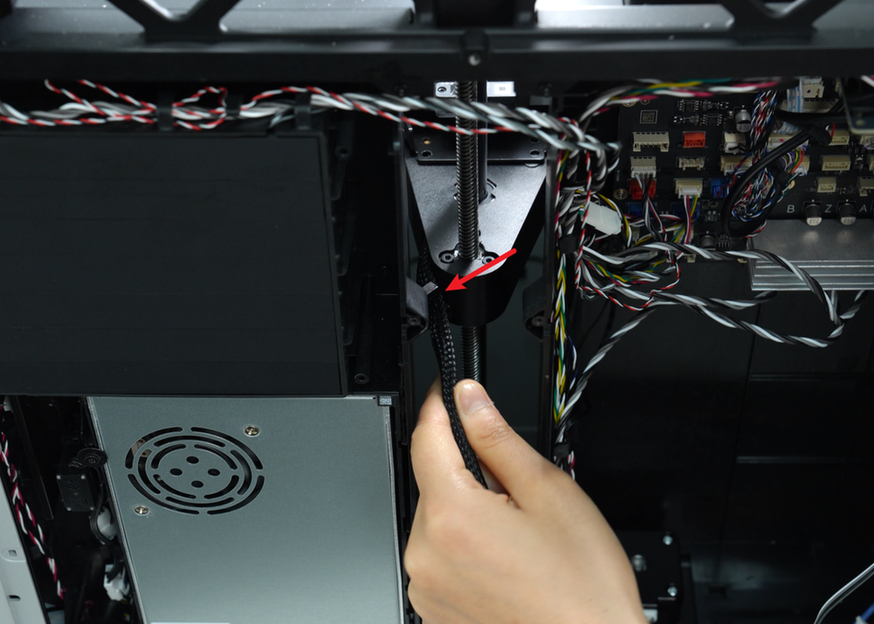

After threading the red, blue and brown cables through, bend the remaining cables and insert them into the small hole, then pull them out from the other end.

|

|

The final state is shown in the following figure.

- Slightly tilt or lift the printer (please hold the printer steady to avoid it falling and causing damage) and manually pull the belt to lower the 3 Z-axis sliders to the bottom. Keep the heatbed upright to avoid interference with the sliders.

Note: Pull the belt back and forth to confirm the downward direction.

Gradually lower the Z-sliders until they reach their lowest position.

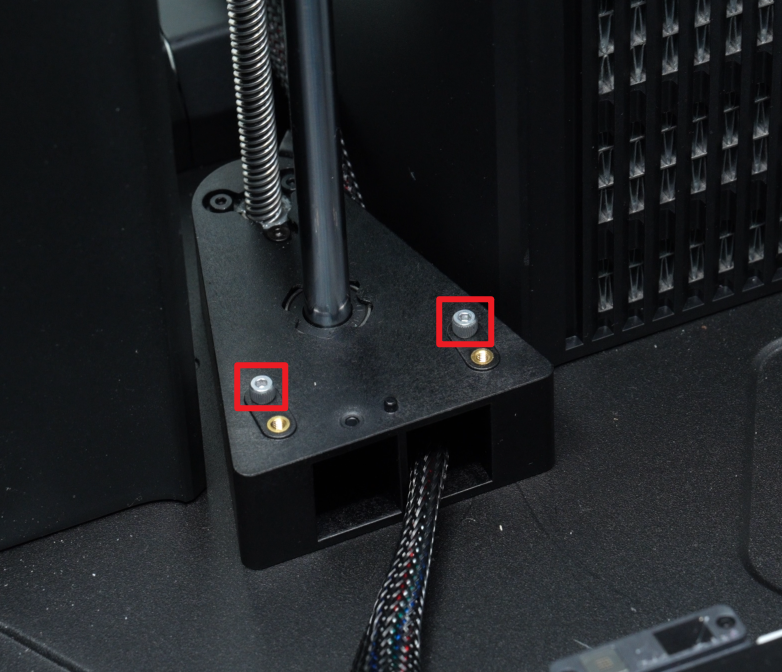

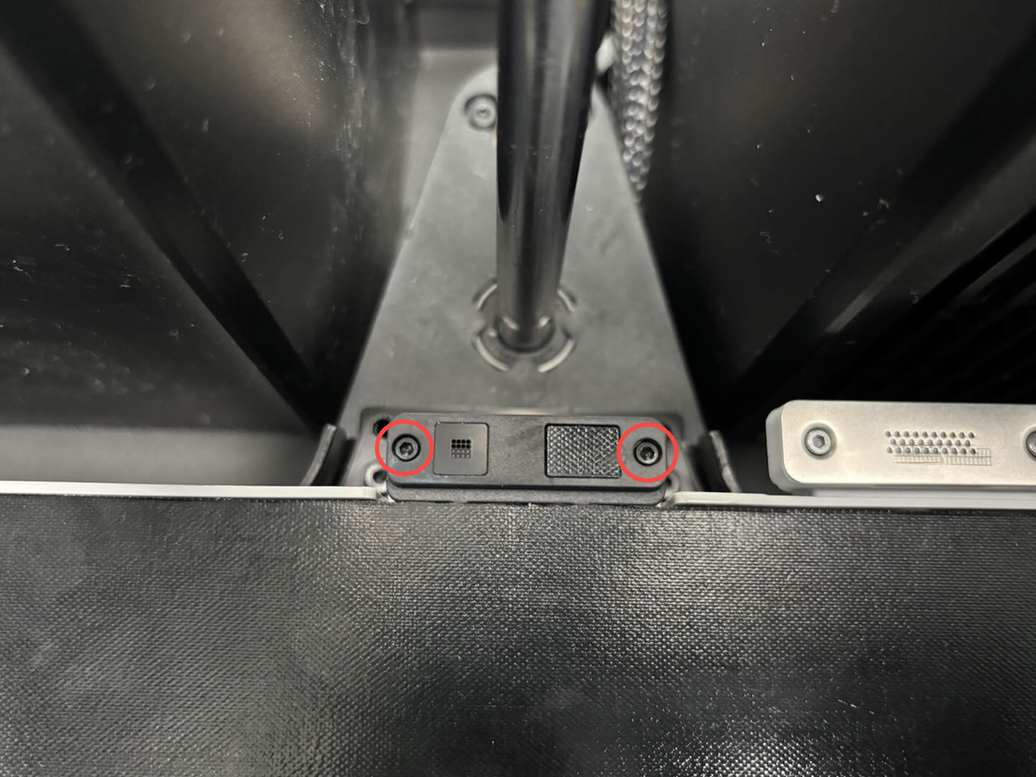

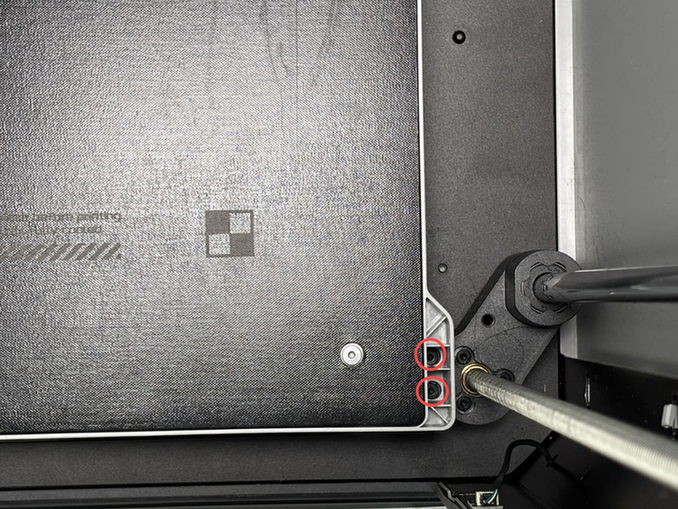

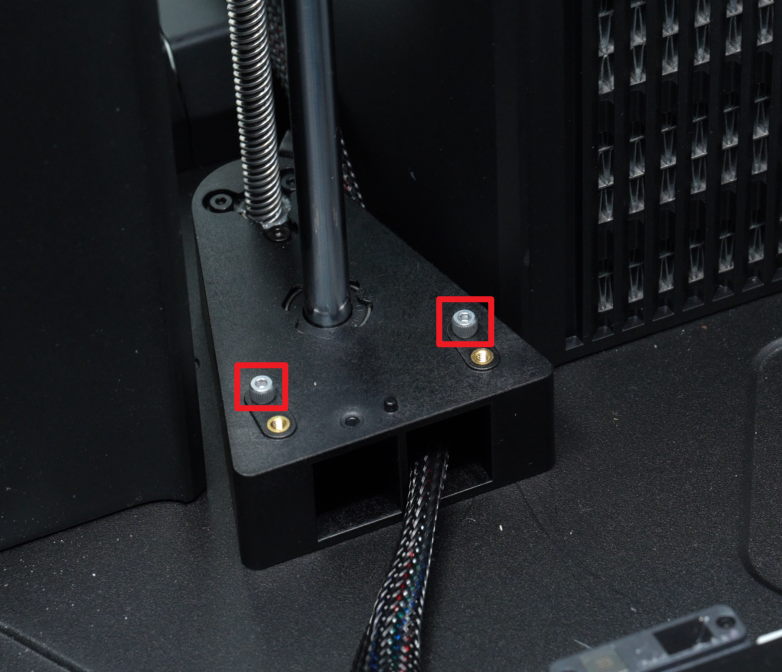

- Use an H2.0 Allen key to tighten the two Z-axis slider fixing screws (M3x35x8) present on the right and left Z-axis sliders.

- Fully thread the heatbed cable through the Z-axis slider, align the heatbed with the 3 Z-axis sliders, and tighten the 6 fixing screws (M3x8).

- Reinstall the silicone covers on the front Z-axis Z sliders.

¶ Step 2: Remove the Z-axis slider fixing screws and lift the bed

- Use an H2.0 Allen key to remove the 4 Z-axis slider fixing screws (M3x35x8).

- Slightly tilt or lift the printer (please hold the printer steady to avoid it falling and causing damage) and manually pull the belt to lift the 3 Z-axis sliders to the middle of the machine. Keep the heatbed upright to avoid interference with the sliders.

Note: Pull the belt back and forth to confirm the upwards direction.

¶ Step 3: Connect heatbed cables

- Place the heatbed cables into the cable clip and use an H2.0 Allen key to tighten the clip fixing screw (ST3x12).

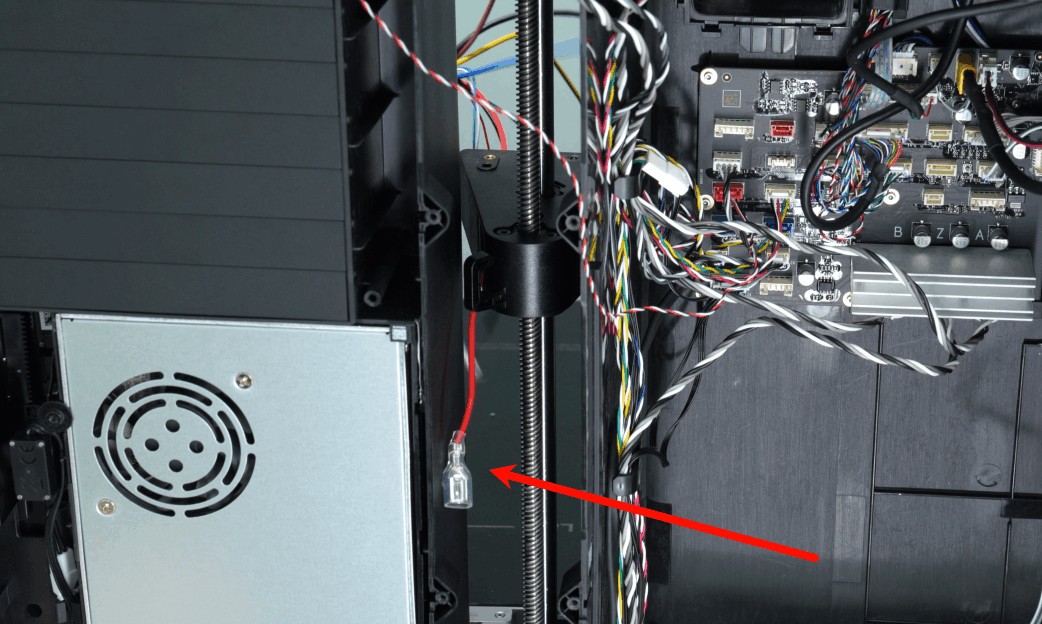

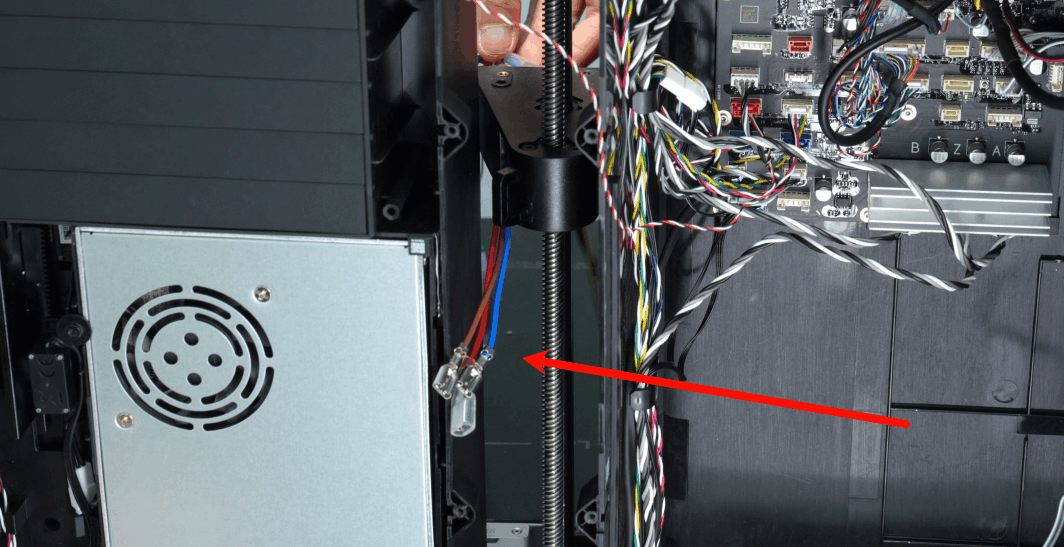

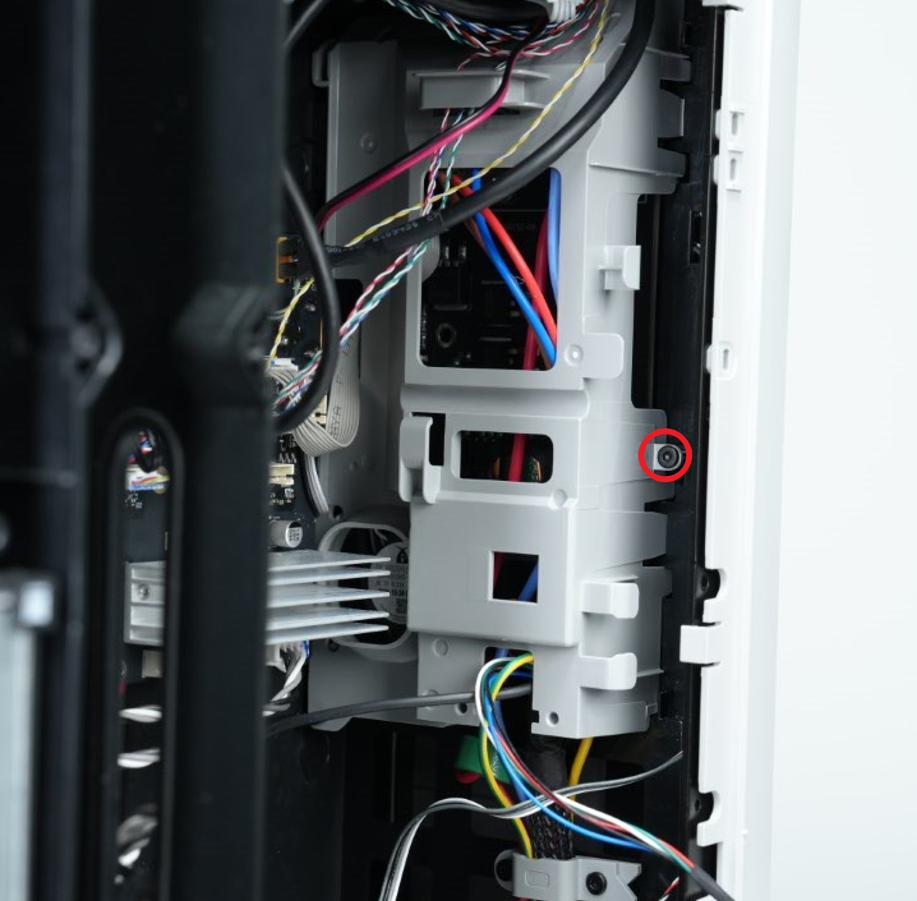

- Connect the 3 power cables (brown, blue, and red) to the AC board with the clip side facing outward.

Refer to the image for the correct connections: top left is brown, top right is blue, and bottom is red.

- Thread the ground wire through the screw hole, use an H2.0 Allen key to fix the heatbed to the printer base, secure the ground wire in the lining clip, and reapply the foam.

- The heatbed signal cable and status indicator connector will be installed in Step 4.

¶ Step 4: Install the AC board cable cover, purge chute, and rear panel

Refer to this Wiki to install the following in sequence:

-

AC board cover

-

Purge chute

-

Rear panel

Replace H2D AC Board/AC board Cover

¶ Step 5: Install the status indicator and nozzle offset calibration coil

- The status indicator has two rows of clips. Align the longer front row of clips with the heatbed holes, insert them, and pull forward to lock them in place. Then, push the status indicator upward to lock the rear clips and reconnect the connector.

- Ensure the nozzle offset calibration coil is connected to the heatbed connector and use an H1.5 Allen key to tighten the 2 fixing screws (M2x5).

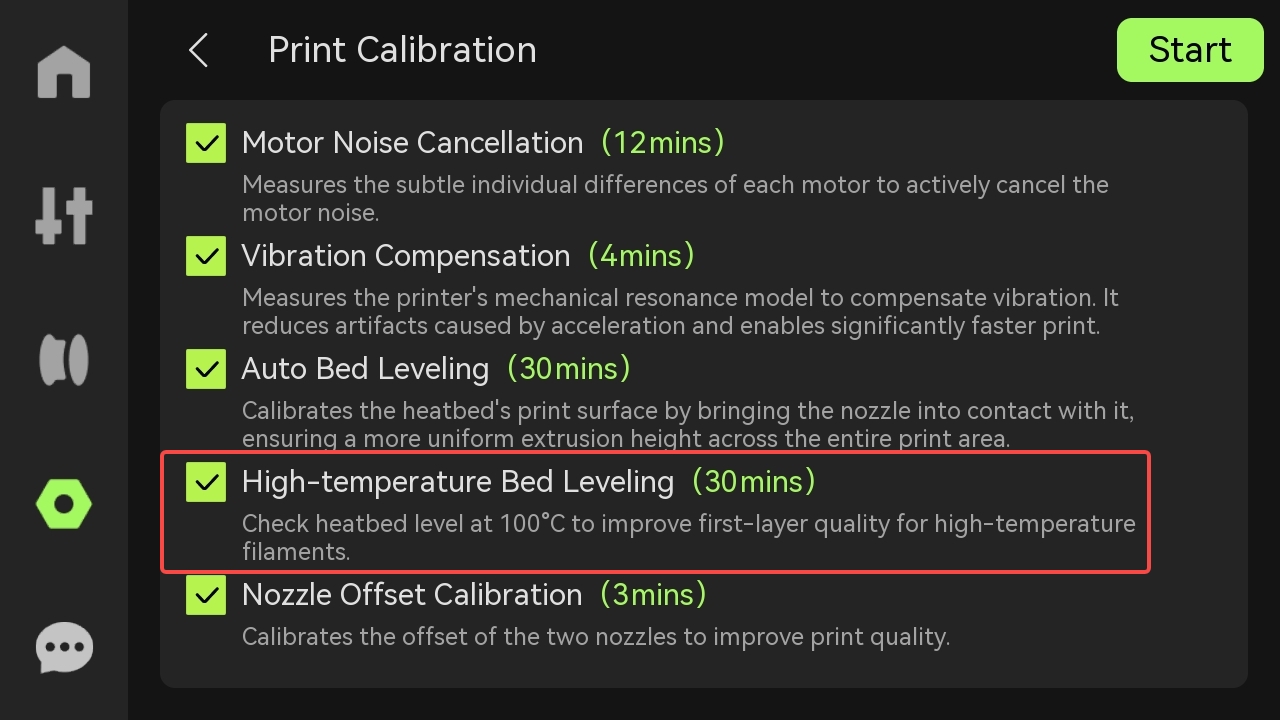

¶ Step 6: High-temperature Bed Leveling

After replacing the heatbed, to prevent any abnormal printer operation, it is necessary to perform a high-temperature bed leveling. Please tap on the screen "Settings" > "Calibration" > "Print Calibration", check "High-temperature Bed Leveling", and start the calibration process.

¶ Verify the Functionality

Connect the power cable and turn on the power, initiate a print, and confirm whether the heatbed function is normal.

¶ Screw specifications and quantities

Specifications and quantities of screws involved in replacing the H2D heatbed (it is recommended to keep the removed screws properly to avoid loss):

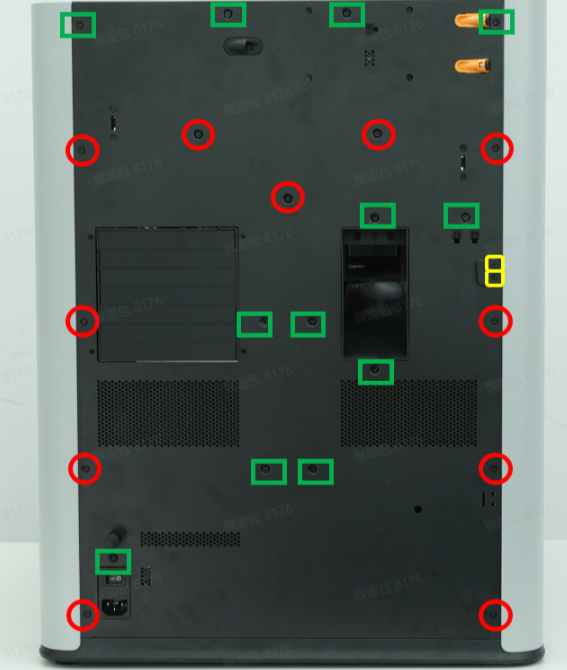

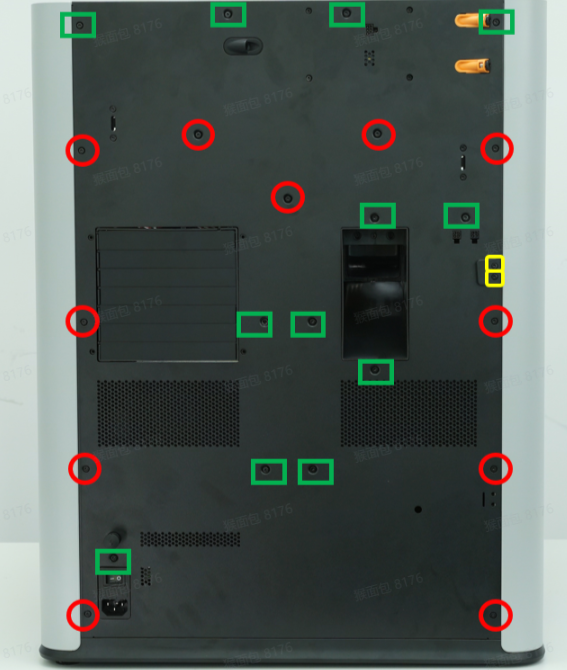

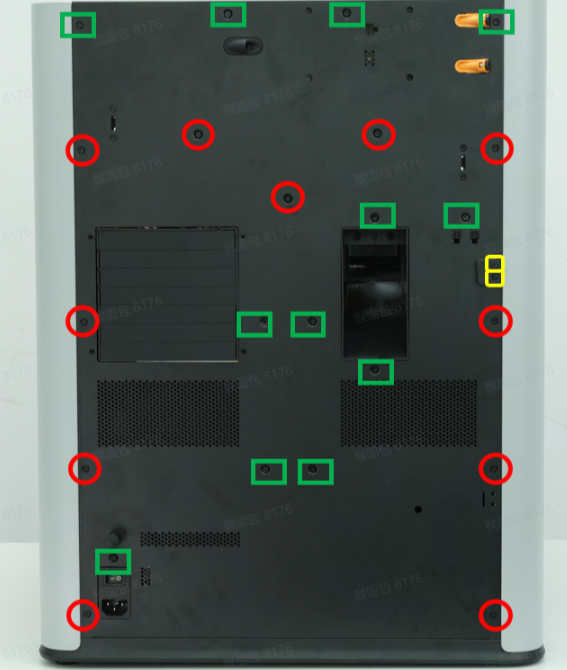

| Specification | Image | Use | Position | Quantity | |

|---|---|---|---|---|---|

| BT3x8 | Fix the rear panel (marked by the green square) |  |

12 | ||

| Fix the purge chute |  |

1 | |||

| Fix the AC board cover |  |

1 | |||

| ST3x8 | Fix the rear panel (marked by the red circle) |  |

11 | ||

| ST3x12 | Fix the spool holder bracket (marked by the yellow square) |  |

2 | ||

| BT3x12 | Fix the cable clip |  |

1 | ||

| STW3x5 | Fix the ground wire |  |

1 | ||

| M2x5 | Fix the nozzle offset calibration coil |  |

2 | ||

| M3x6 | Fix the heatbed |    |

6 | ||

| M3x35x8 | Fix the Z-axis slider |    |

4 |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!