¶ XY Belt Tensioner and Idler Pulley

The XY belt tensioner and idler pulley is mounted on the back of the printer and is secured to the XY tensioner with a single screw.

The spare parts for the XY belt tensioner and idler pulley include the following:

-

Idler pulley * 1

-

Graphite washer - For mounting idler pulleys on frame only * 2

-

Regular idler pulley - For mounting idler pulleys on frame only * 1

-

Tensioner idler shaft - For mounting idler pulleys on frame only * 1

¶ When to use

-

The belt is rubbing against the edge of the idler pulley, causing abnormal noise.

-

The idler pulley is damaged.

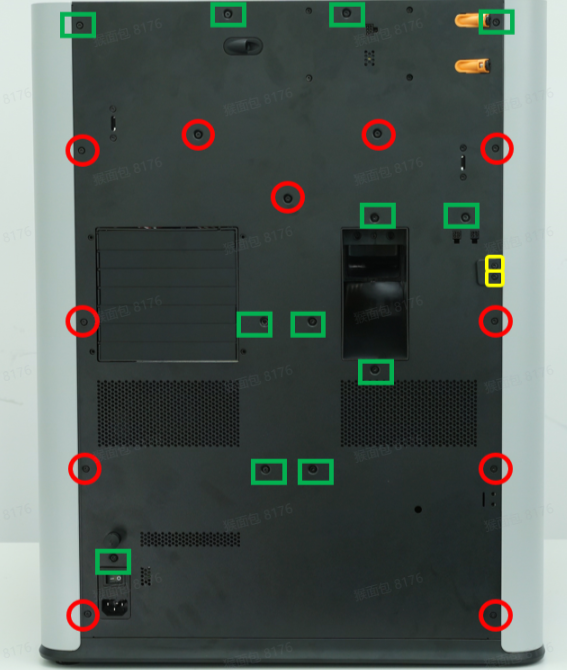

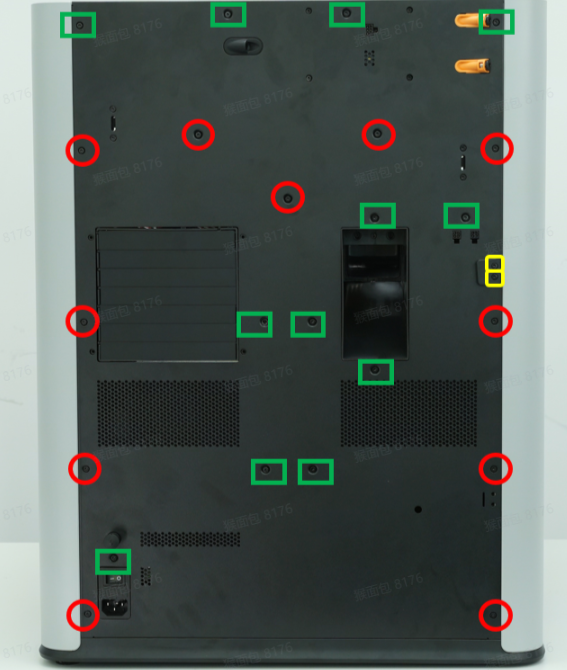

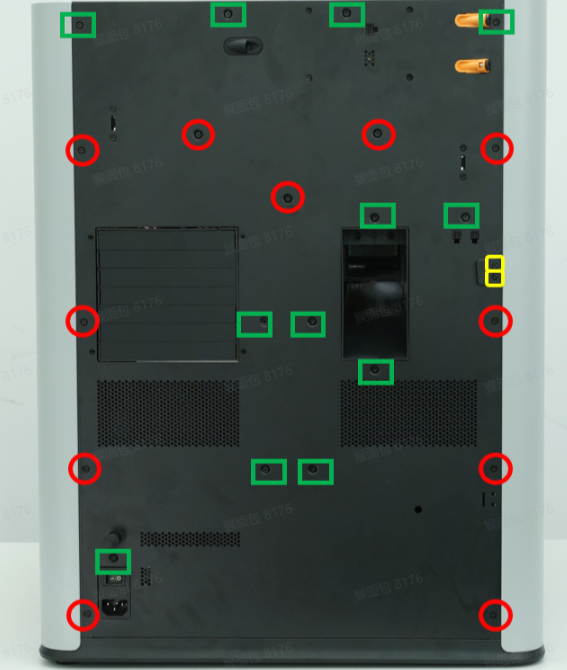

Specifications and quantities of screws involved in replacing the H2D XY belt tensioner and idler pulley (it is recommended to keep the removed screws properly to avoid loss):

| Specification | Image | Use | Position | Quantity | |

|---|---|---|---|---|---|

| BT3x8 | Fix the rear panel (marked by the green square) |  |

12 | ||

| ST3x8 | Fix the rear panel (marked by the red circle) |  |

11 | ||

| ST3x12 | Fix the spool holder bracket (marked by the yellow square) |  |

2 | ||

| M3x6 | Fix the XY tensioner pressure plate and tensioner bracket |  |

4 |

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, we recommend submitting a technical ticket regarding your issue and we will do our best to respond promptly and provide the assistance you need.

¶ Replace the XY Belt Tensioner and Idler Pulley

¶ Step 1: Remove the rear panel

Refer to the following Wiki for instructions on removing the rear panel:

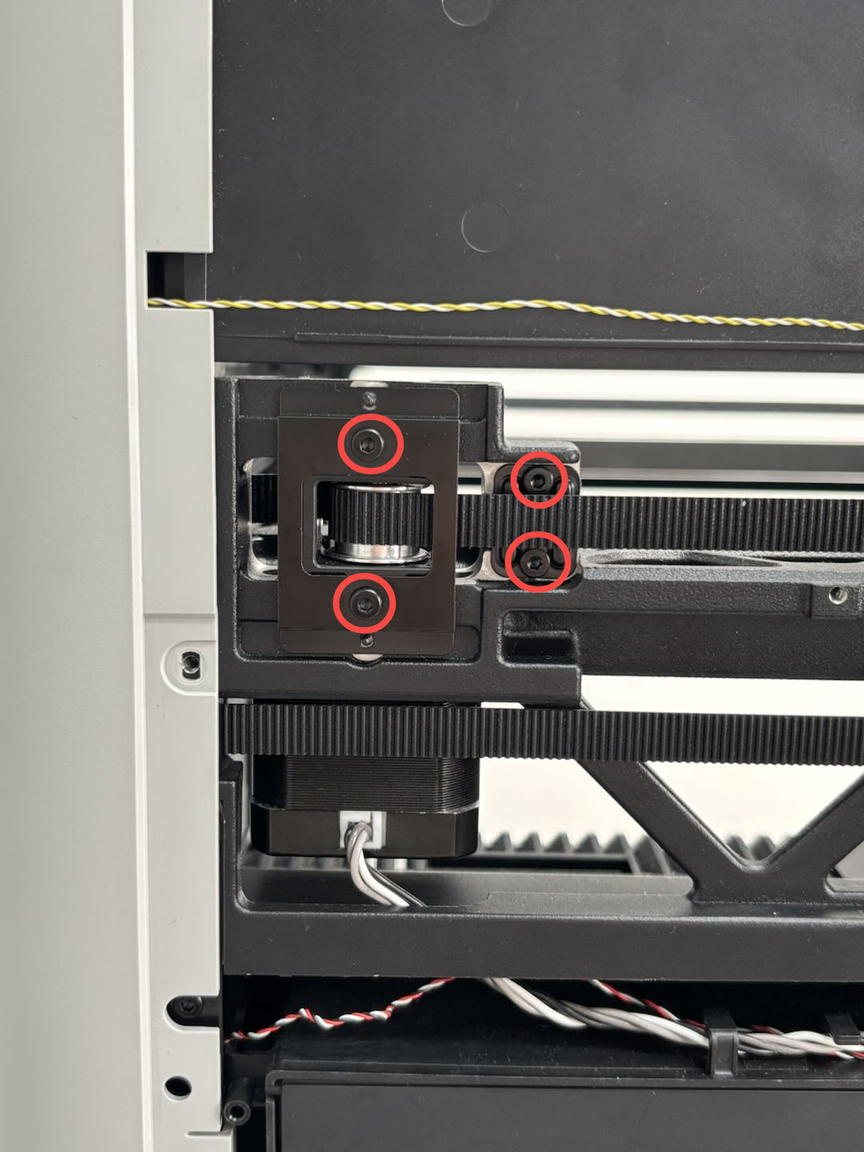

¶ Step 2: Remove the tensioner pressure plate

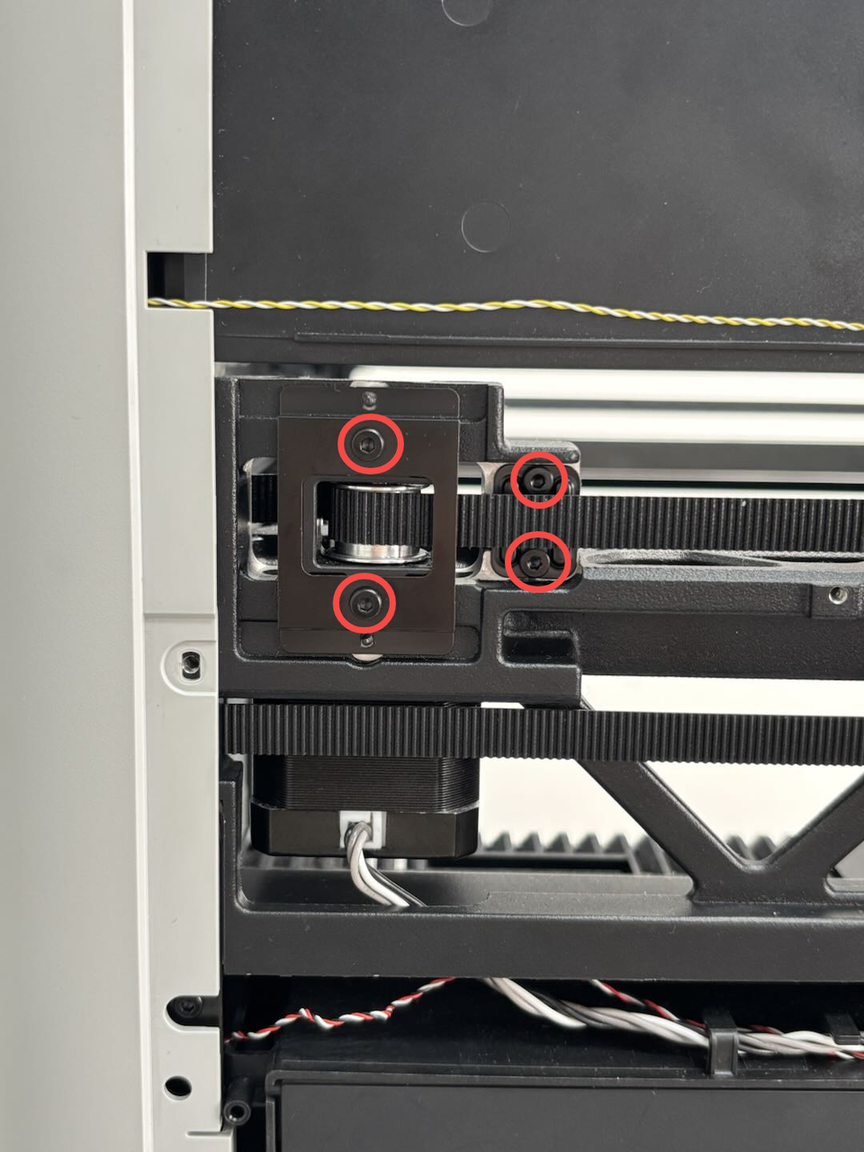

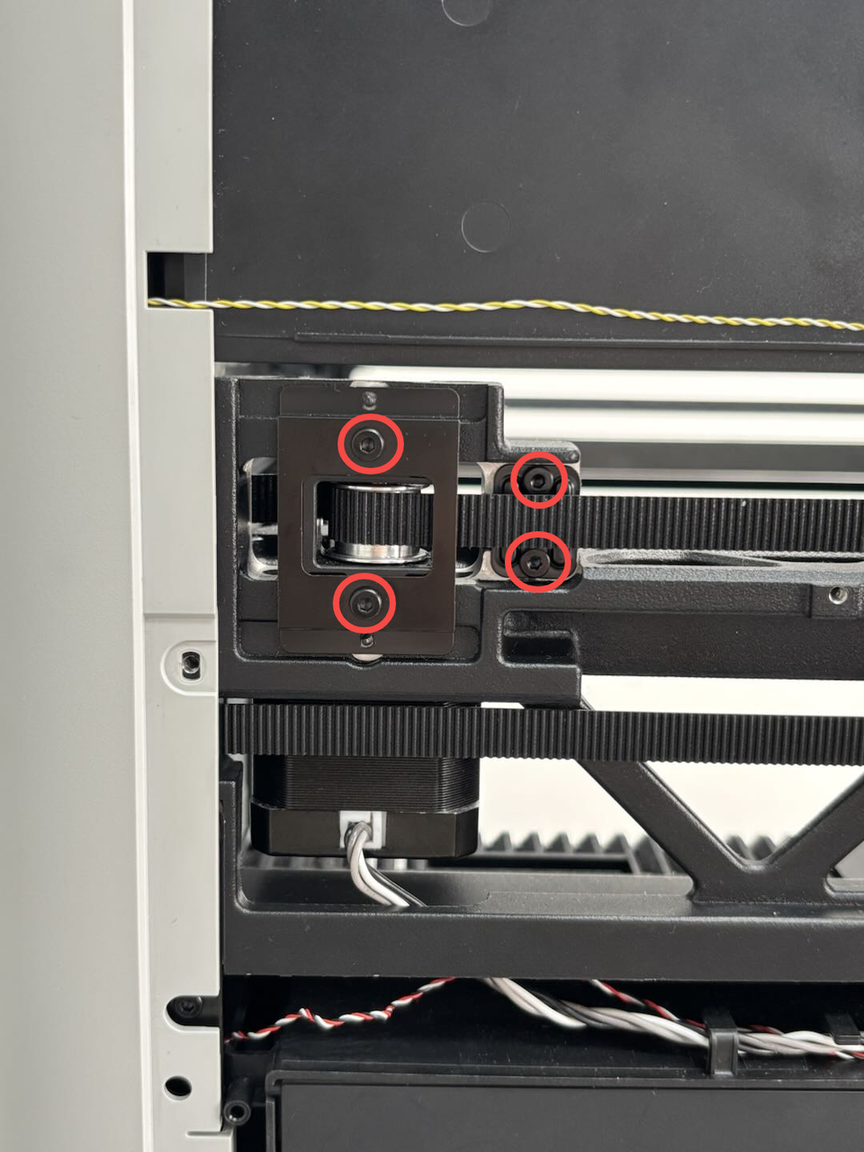

Use an H2.0 Allen key to remove 2 screws (M3x6) securing the tensioner pressure plate and two screws (M3x6) securing the tensioner bracket.

There are 2 tensioner idler pulleys on the back (one on each side). Replace only the idler pulley that needs to be replaced.

¶ Step 3: Remove the XY belt tensioner

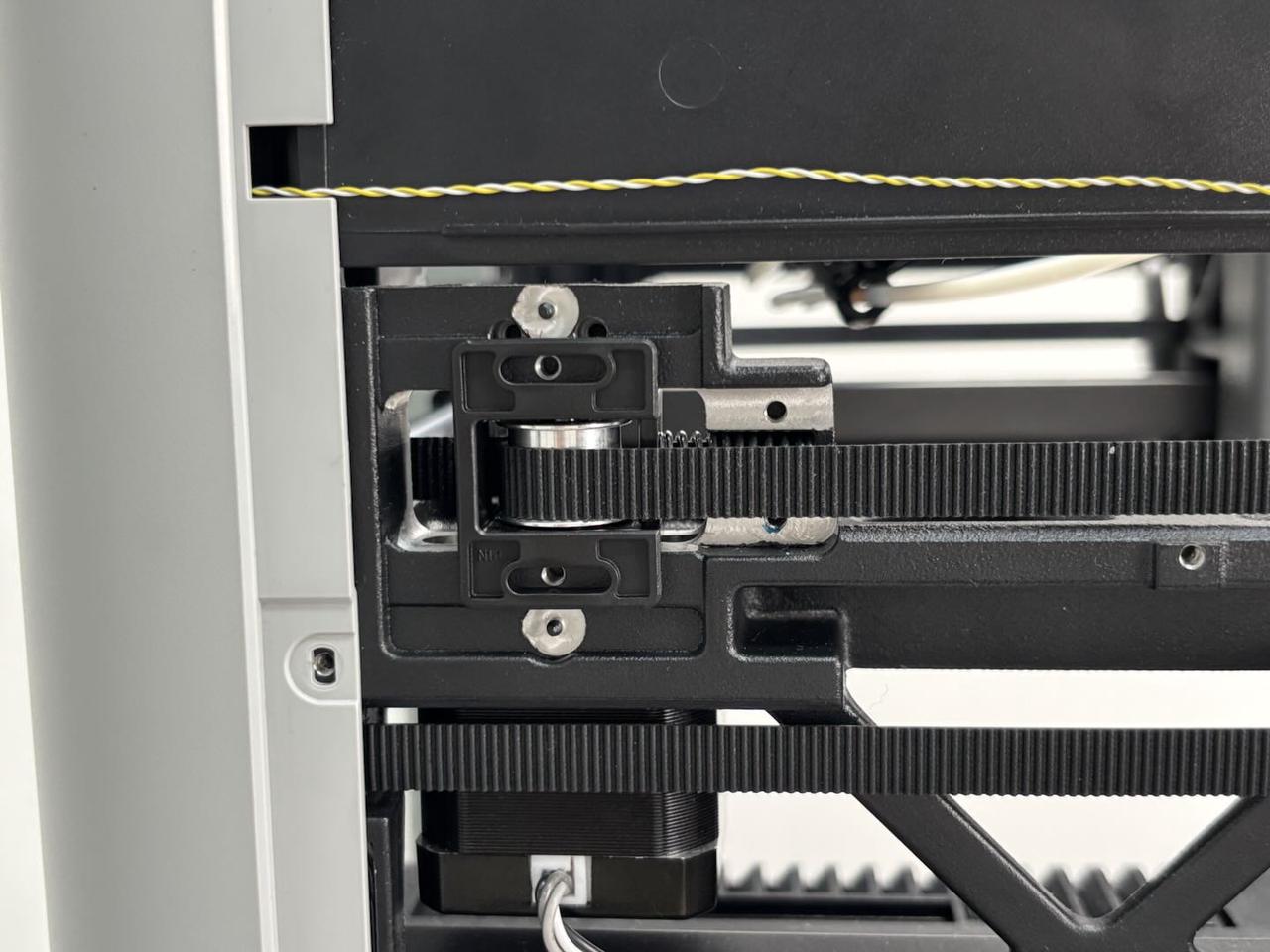

Use your fingers to push the left side of the XY belt tensioner and tilt it outward to remove it. If the tensioner is stuck, avoid using excessive force to prevent damage.

Some force is required for this step.

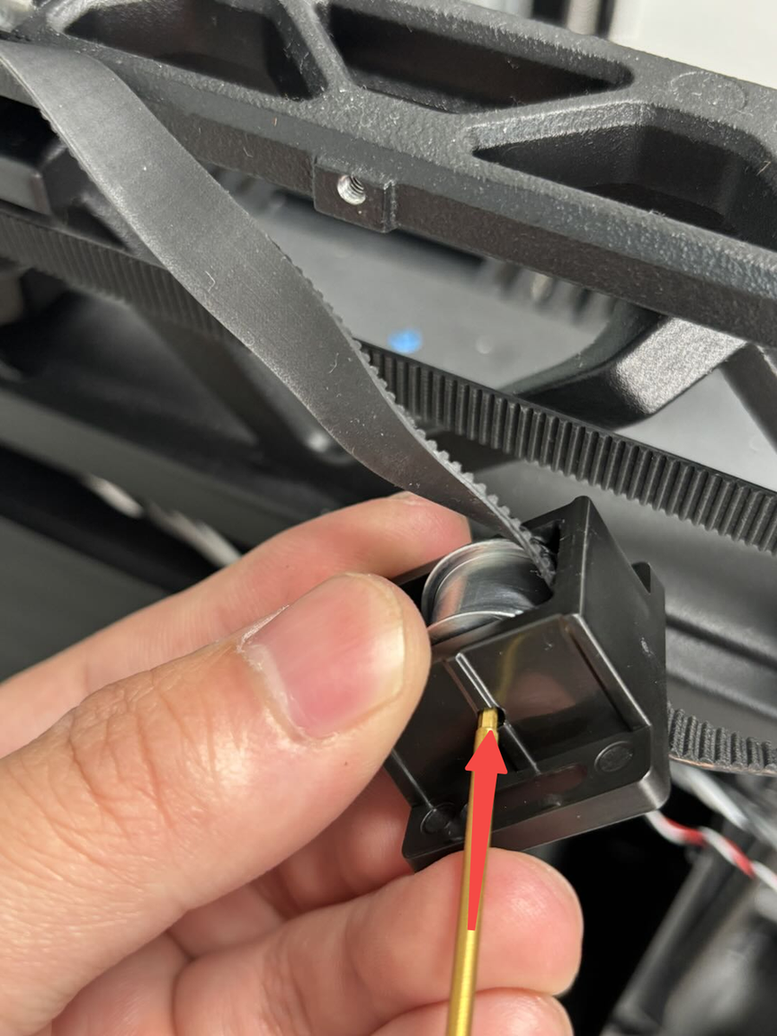

¶ Step 4: Remove the XY belt tensioner and idler pulley

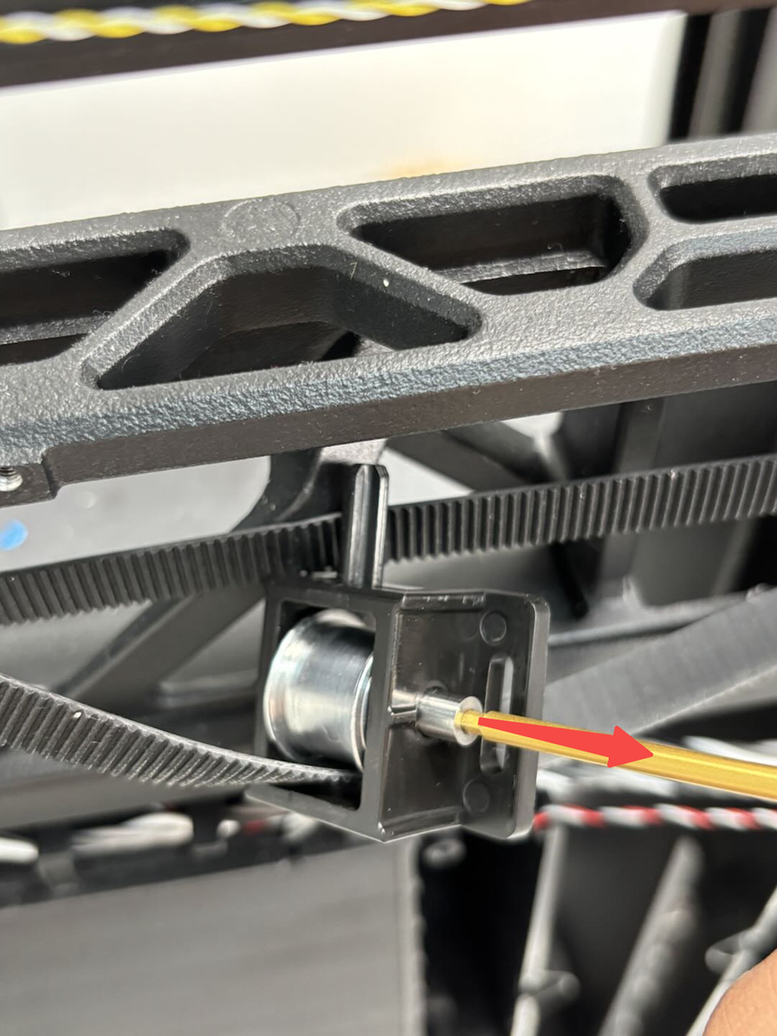

Use an H2.0 Allen key to loosen the idler pulley shaft, then remove the shaft. You can lift the shaft out while loosening it using the Allen key. If it still cannot be removed, push the idler pulley upward from the bottom of the tensioner.

¶ Install the XY Belt Tensioner and Idler Pulley

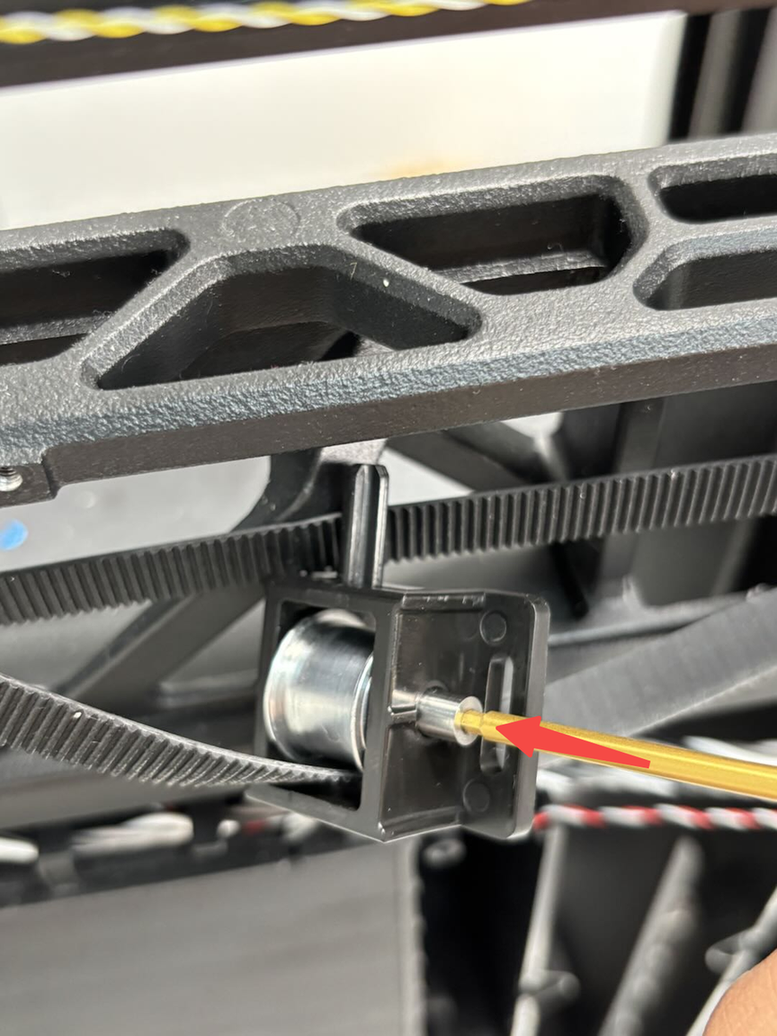

¶ Step 1: Install the XY belt tensioner and idler pulley

Place the new XY belt tensioner and idler pulley into the XY belt tensioner, insert the idler pulley shaft, and tighten it using an H2.0 Allen key.

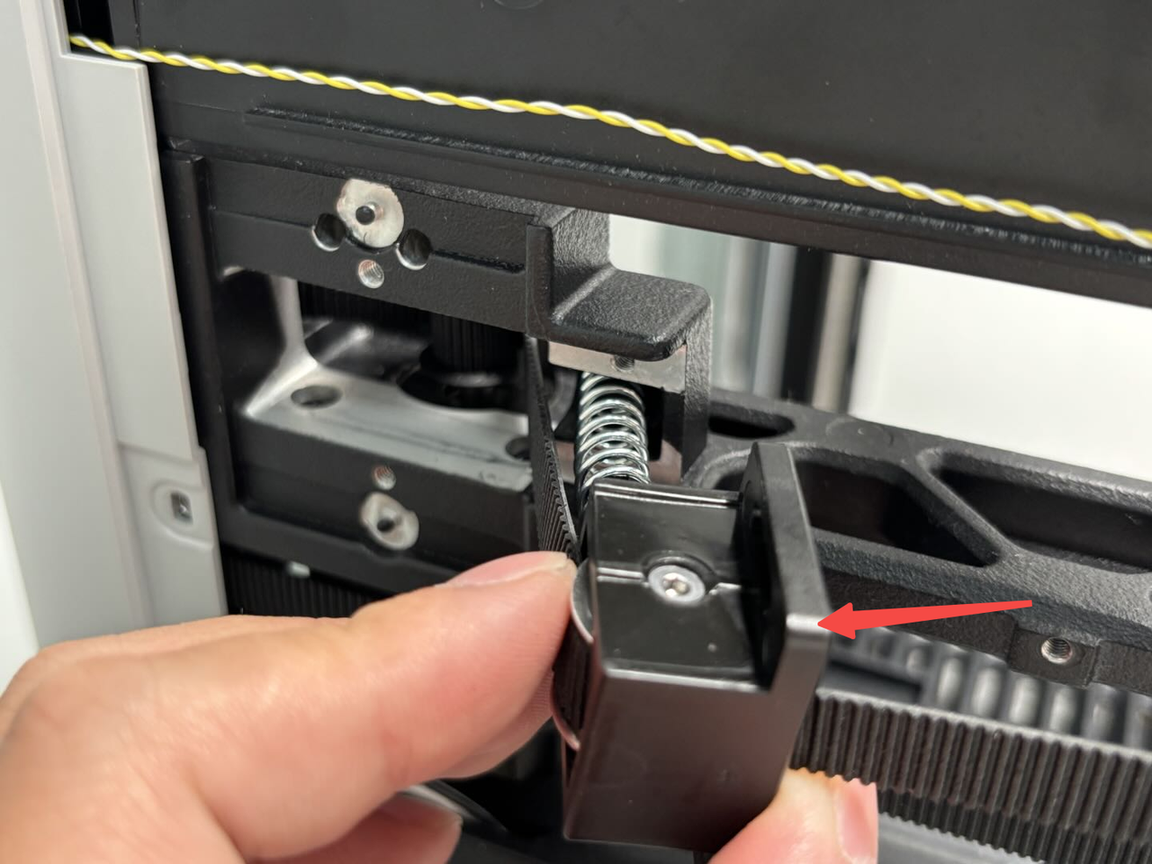

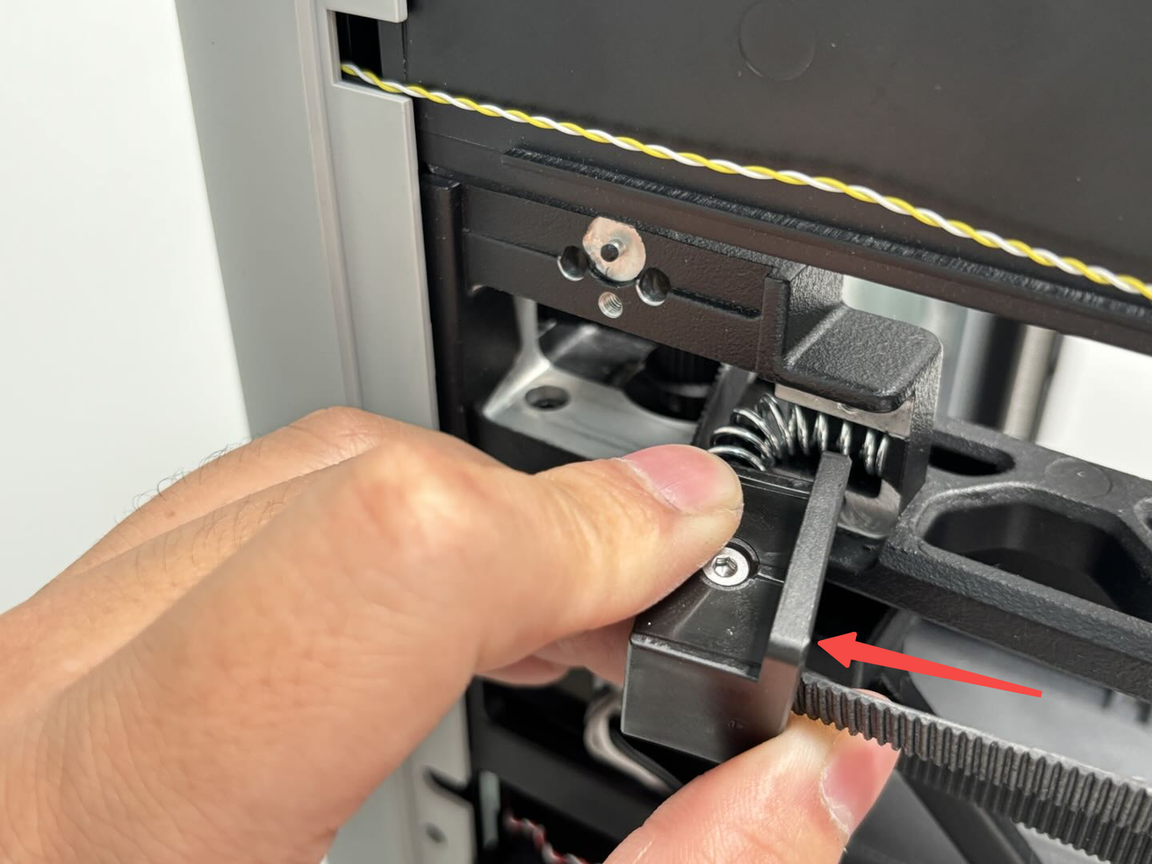

¶ Step 2: Install the XY belt tensioner on the printer

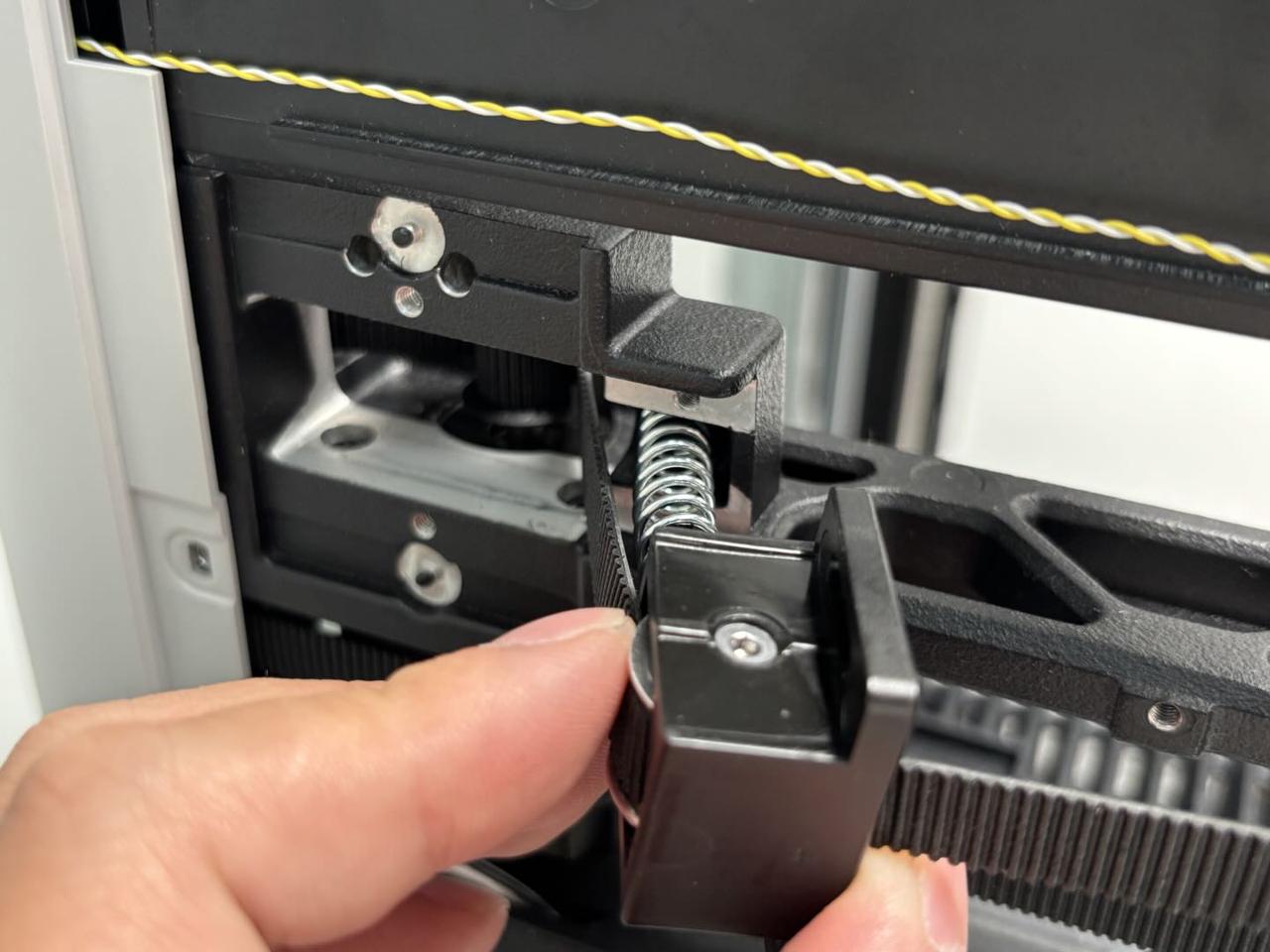

Insert the spring into the shaft of the tensioner bracket, then vertically insert the spring into the printer frame. Push the tensioner to the left with force to secure it into the printer.

¶ Step 3: Install the tensioner bracket and puressure plate

After aligning the tensioner pressure plate with the screw holes, use an H2.0 Allen key to tighten the 2 pressure plate fixing screws (M3x6) and the 2 tensioner bracket fixing screws (M3x6).

¶ Step 4: Install the rear panel

Refer to the following Wiki for instructions on installing the printer rear panel:

¶ Verify the Functionality

The toolhead can move normally, the tensioner idler pulley rotates without abnormal noise, and there is no error message indicating abnormal/low belt resonance frequency.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!