¶ Z Belt/Z Belt Timing Pulley/Z-Axis Tensioner

The Z belt is a closed-loop belt installed at the bottom of the printer, with a length of 1444mm and a width of 6mm. It connects the Z motor and the Z belt timing pulley, driving the heatbed to move in the Z direction.

The spare parts for the Z belt include:

-

Z belt × 1

-

Z belt timing pulley × 1

-

Z belt timing pulley cover × 1

-

M3x6 Screw (used to secure the Z belt timing pulley cover to the Z belt timing pulley) × 1

-

M3x35 Screw (used to fix the heatbed) × 4

The spare parts for Z-axis tensioner assembly include:

-

Z-axis tensioner (includes nut) × 1

-

Z-axis tensioner cover × 1

-

Torsion spring × 1

-

Silver screw (used to fix the Z-axis tensioner cover) × 3

-

Black screw (used to fix the Z-axis tensioner) × 1

¶ When to Use

-

Z belt wear

-

Z belt breakage

-

Z belt timing pulley damage

¶ Tools and Materials Needed

-

New Z belt spare parts

-

H2.0 Allen Key

-

H1.5 Allen Key

Specifications and quantities of screws involved in replacing the H2D Z motor (it is recommended to keep the removed screws properly to avoid loss):

| Specification | Image | Use | Position | Quantity | |

|---|---|---|---|---|---|

| M3x6 | Fix the Z-axis tensioner slider |  |

1 | ||

| M3x6 (Nut diameter 10mm) | Fix the Z belt timing pulley cover |  |

1 | ||

| M3x35x8 | Fix the Z-axis slider | 4 |

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, we recommend submitting a technical ticket regarding your issue and we will do our best to respond promptly and provide the assistance you need.

¶ Remove the Z belt/Z belt timing pulley

¶ Step 1: Clean the printer base

Remove any debris from the printer base, especially residues near the linear rod.

¶ Step 2: Secure the heatbed/Z-axis sliders

- If the belt/timing pulley is functional:

Control the heatbed through the screen and lower it to the bottom of the printer.

After lowering the heatbed, turn off the printer and disconnect the power.

- If the belt/timing pulley is non-functional:

-

Turn off the printer, disconnect the power, remove the 6 heatbed screws, and detach the heatbed from the Z-axis sliders. Refer to this Wiki for instructions: Replace the Heatbed Unit;

-

Tilt the printer, manually rotate the timing pulley to lower the Z-axis sliders to the bottom, and then secure the sliders with screws.

Note: Rotate the timing pulley left and right to confirm the direction of lowering.

¶ Step 3: Remove the glass cover plate and lay the printer down

Remove the top glass cover plate and carefully lay the printer on its side on a stable surface.

Given the printer's weight, it is recommended that two people work together to avoid potential damage.

¶ Step 4: Remove the Z-axis tensioner assembly

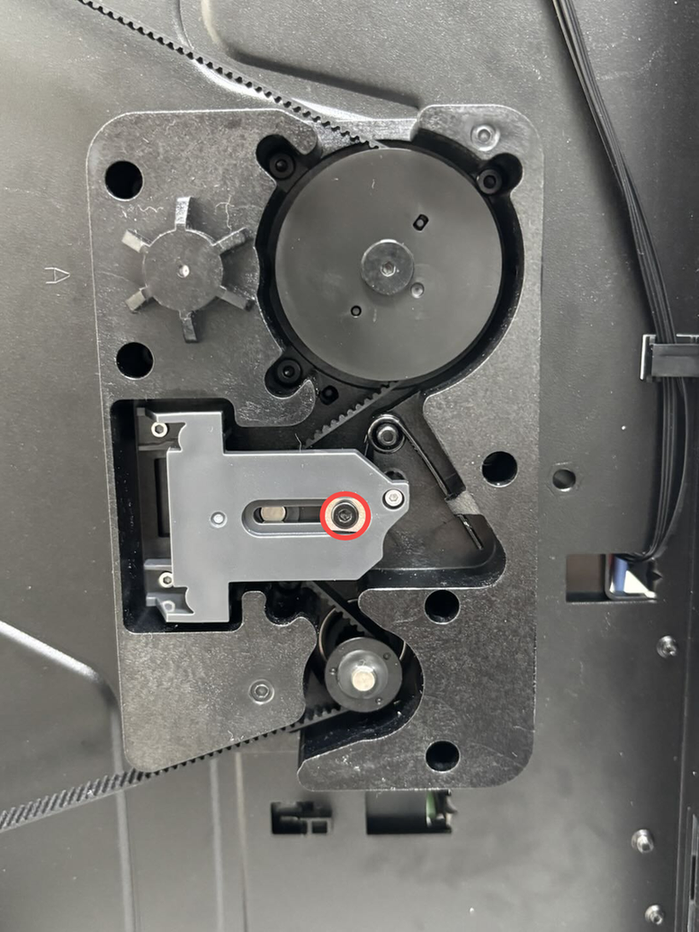

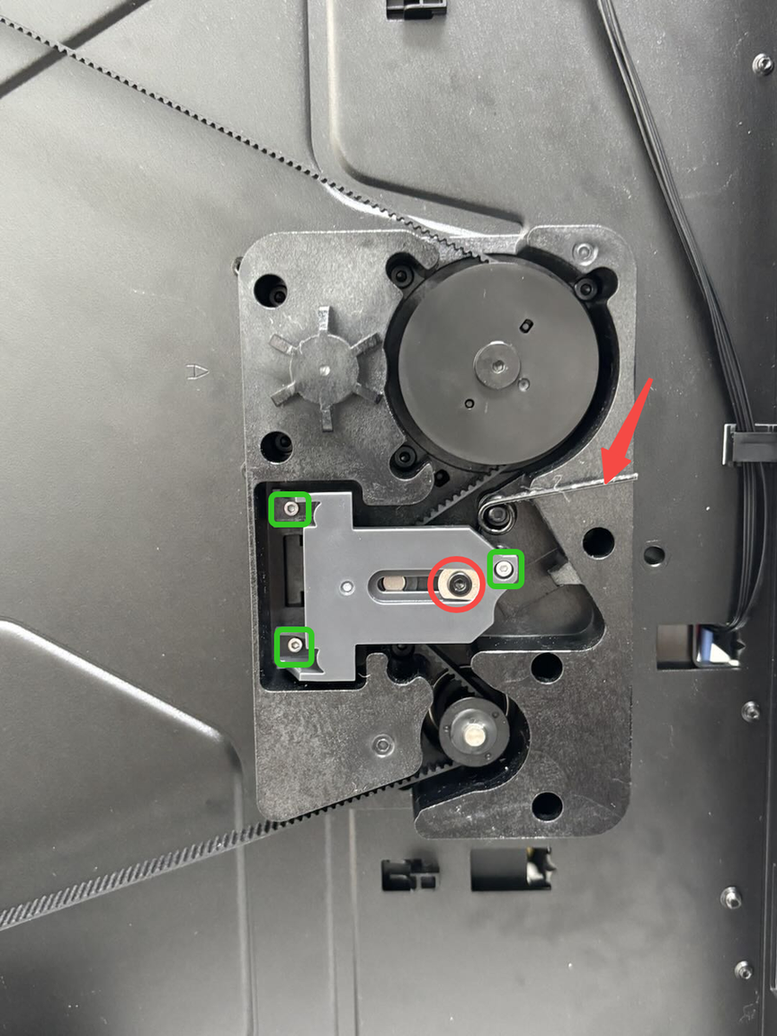

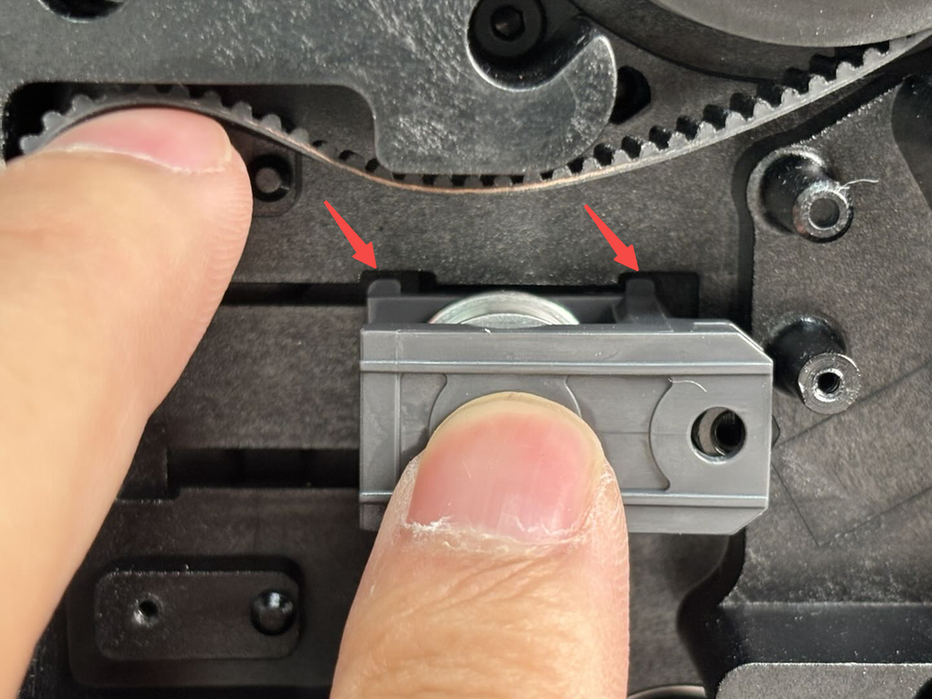

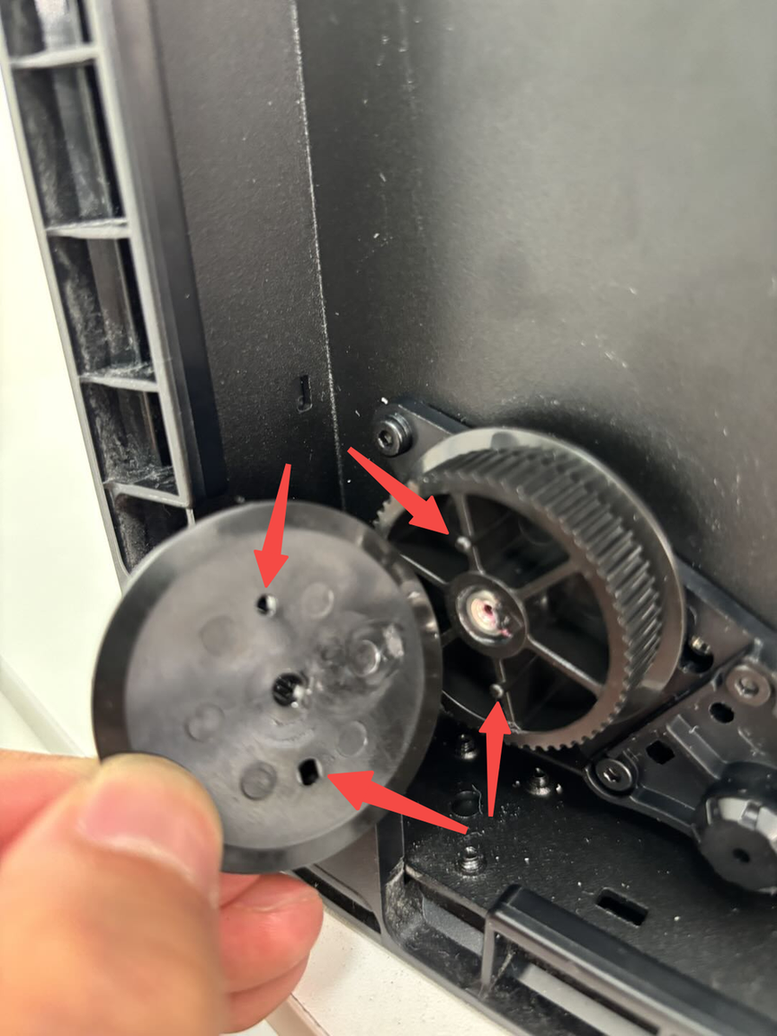

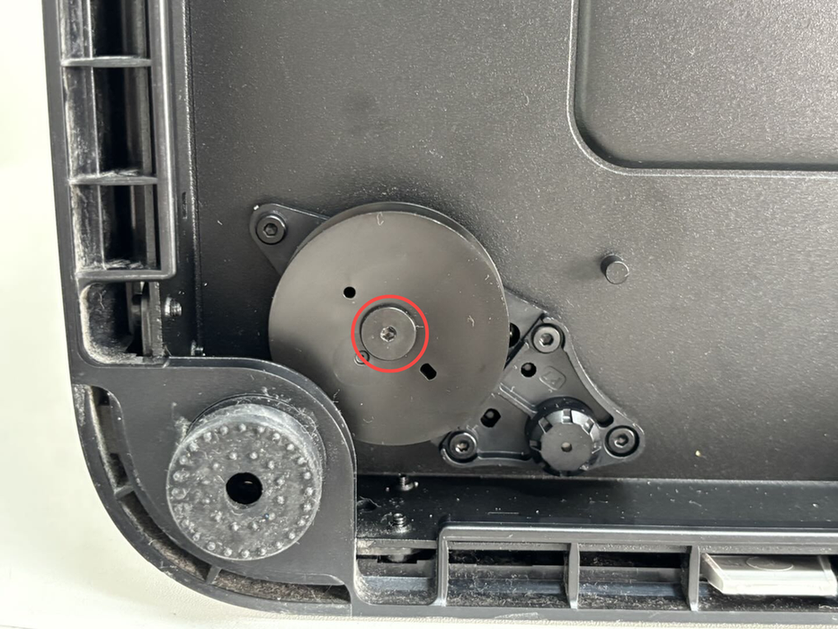

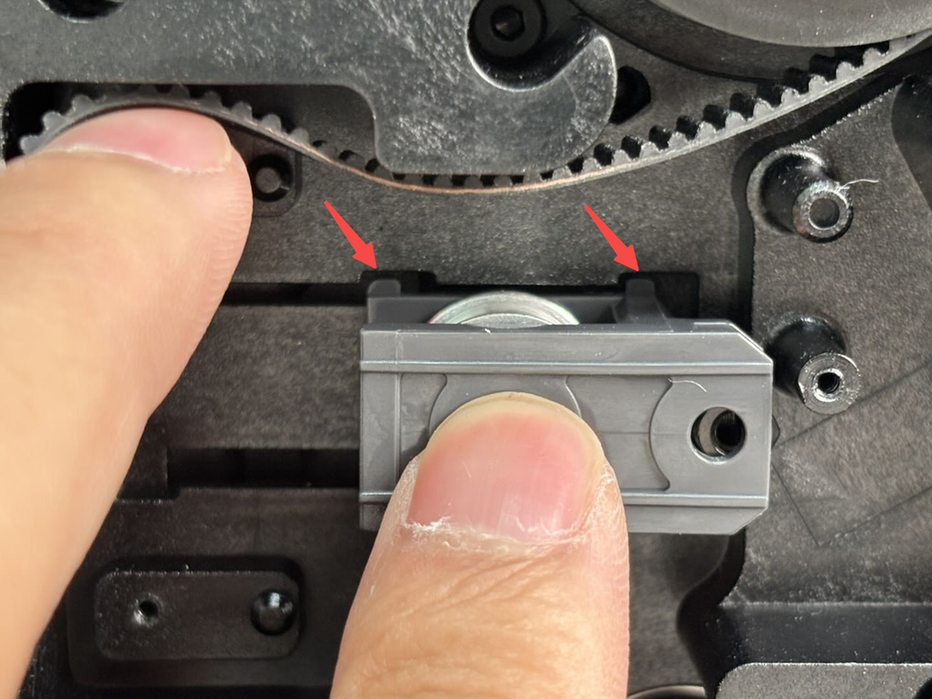

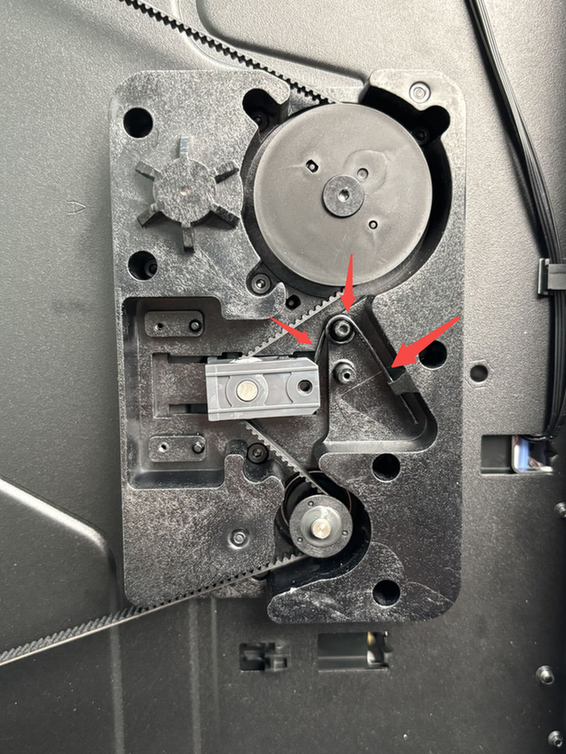

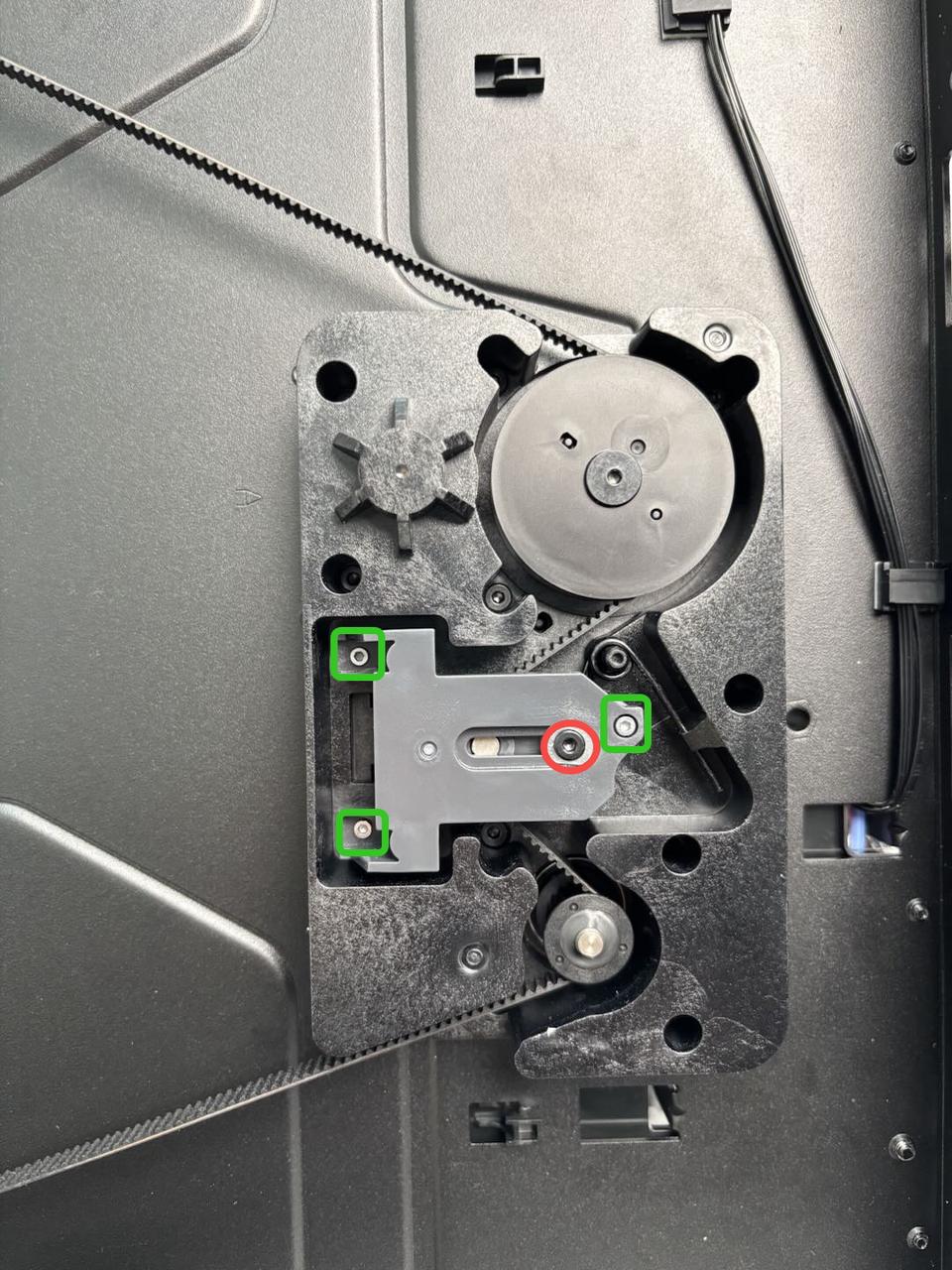

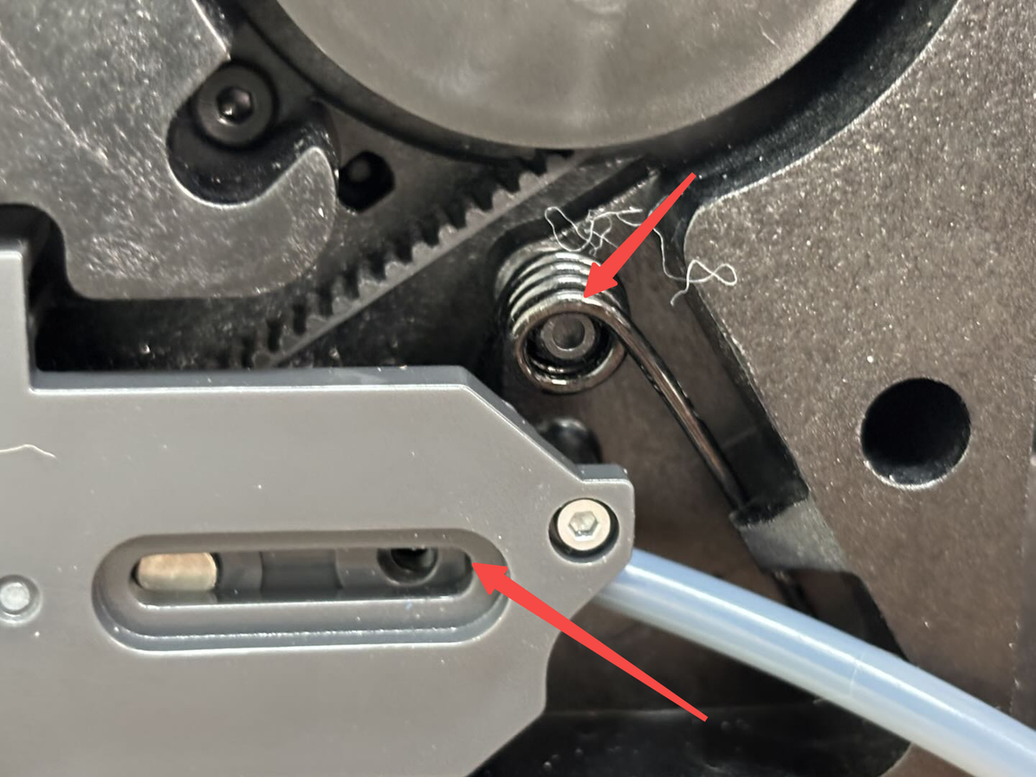

Release the Z-axis tensioner torsion spring. Use an H2.0 Allen key to remove the screw marked with a circle, and use an H1.5 Allen key to remove the 3 screws securing the Z-axis tensioner cover (marked with green boxes, BT2x5). Remove the Z-axis tensioner cover and torsion spring. Push the Z-axis tensioner slider forward until the clips on its bottom align with the notches on the printer base (two on the top row, two on the bottom row), then remove the slider.

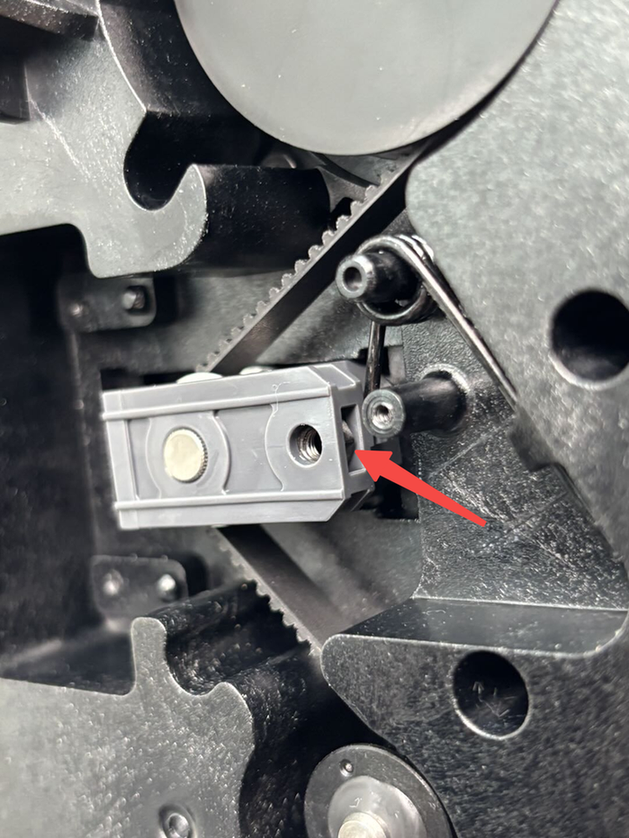

Note: There is a nut inside the Z-axis tensioner. Be careful not to lose it when removing the tensioner.

¶ Step 5: Remove the Z-belt (skip if Z belt doesn't need to be replaced)

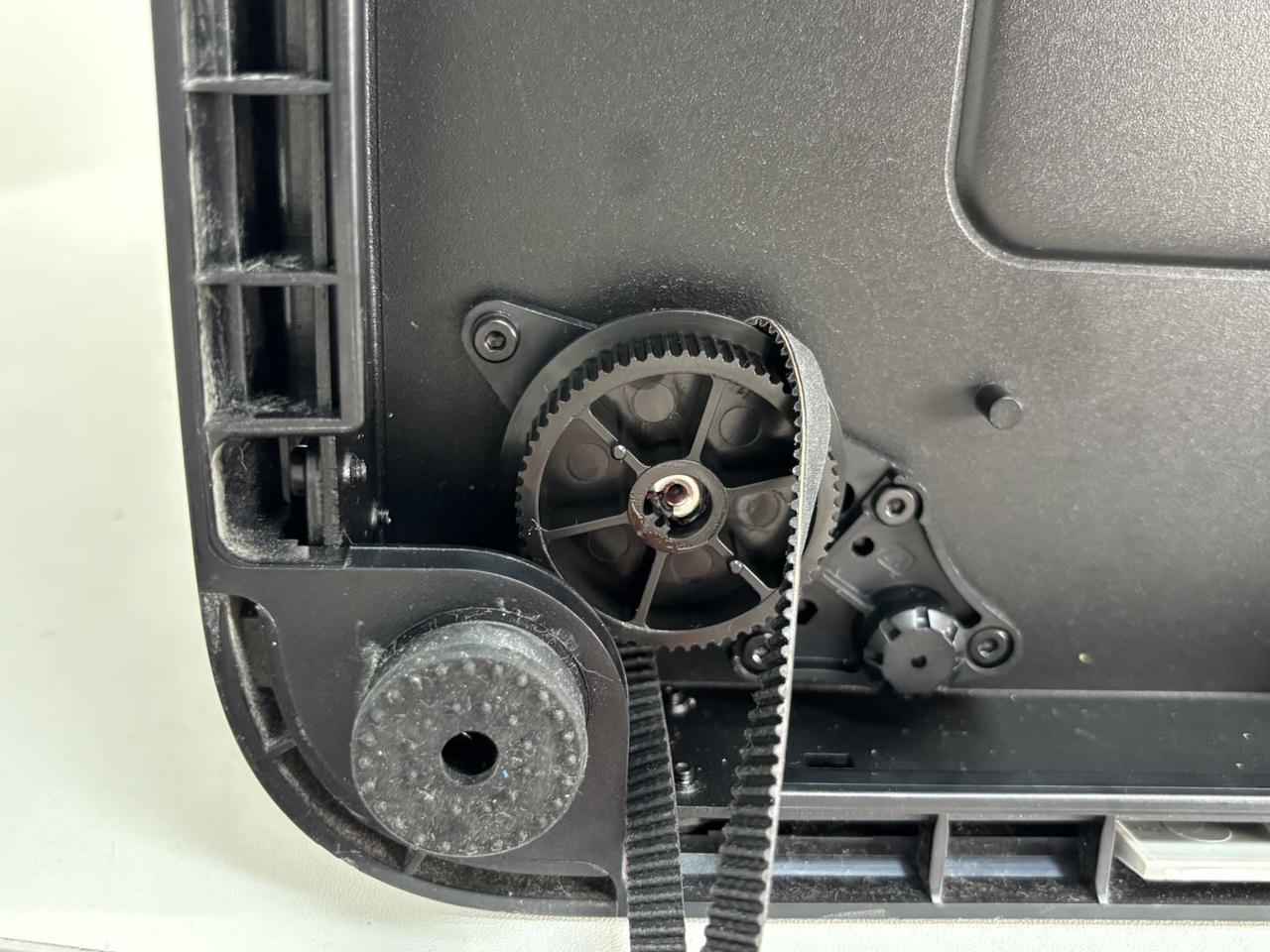

Remove the belt from the edge of the Z belt timing pulley. Since the Z-axis tensioner has been removed, you can directly take out the Z belt.

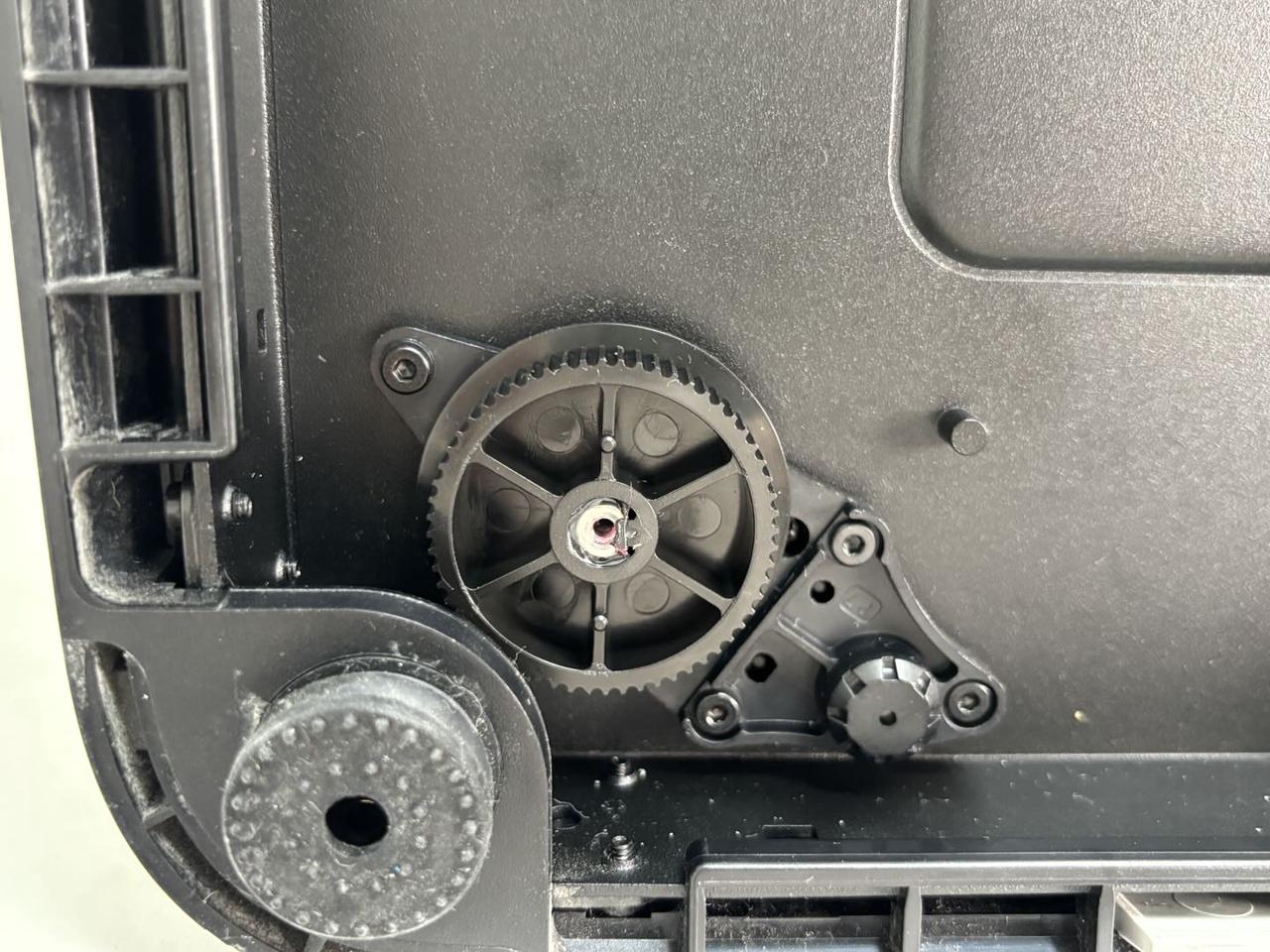

¶ Step 6: Remove the Z belt timing pulley (skip if timing pulley doesn't need to be replaced)

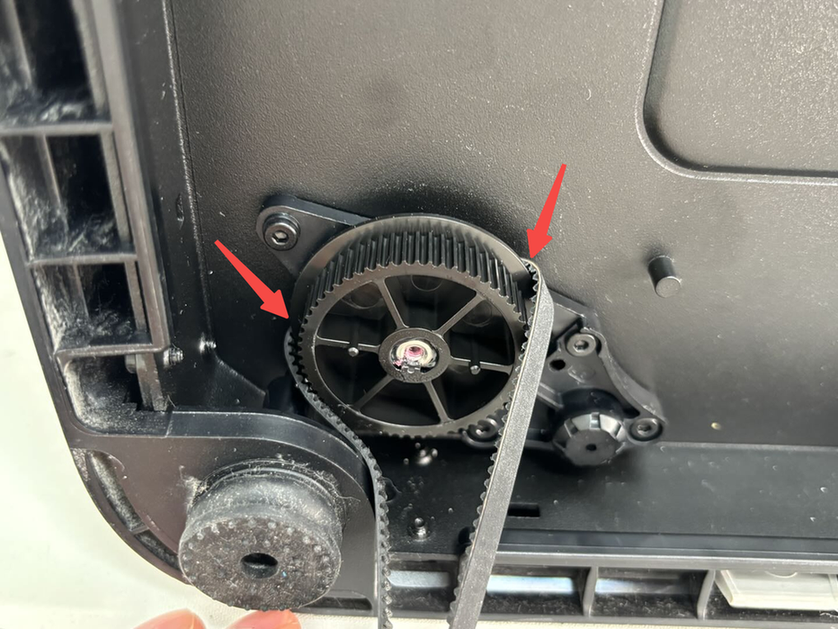

- Use an H2.0 Allen key to remove the Z belt timing pulley cover fixing screw (M3x6, 10mm diameter), then remove the cover and the screw.

- Thread the old Z belt under the Z belt timing pulley, hold both ends of the belt, and pull to remove the timing pulley.

Keep the belt close to the center of the pulley to avoid slipping while pulling.

¶ Install the Z belt/Z belt timing pulley/Z-axis tensioner

¶ Step 1: Install the Z belt timing pulley (skip if not removed)

- Align the flat side inside the new Z belt timing pulley with the flat side at the bottom of the lead screw, then install the timing pulley onto the lead screw.

- Align the two small holes on the Z belt timing pulley cover with the protrusions on the pulley, snap it into place, and secure it with a screw (M3x6, 10mm).

¶ Step 2: Install the Z belt (skip if not removed)

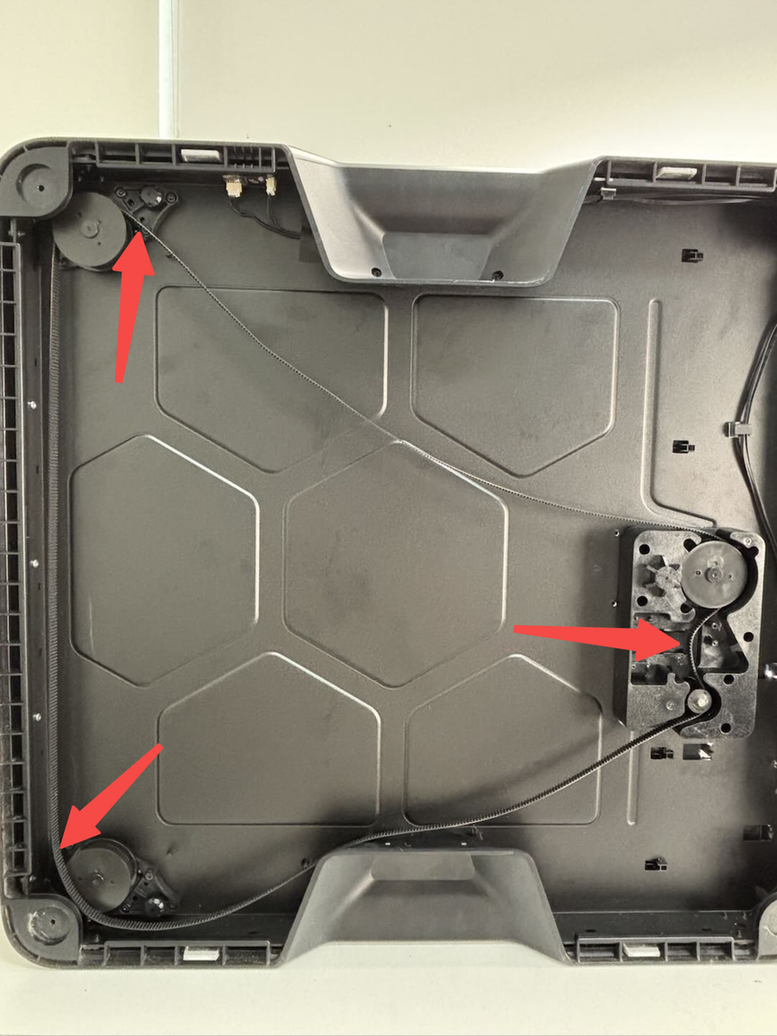

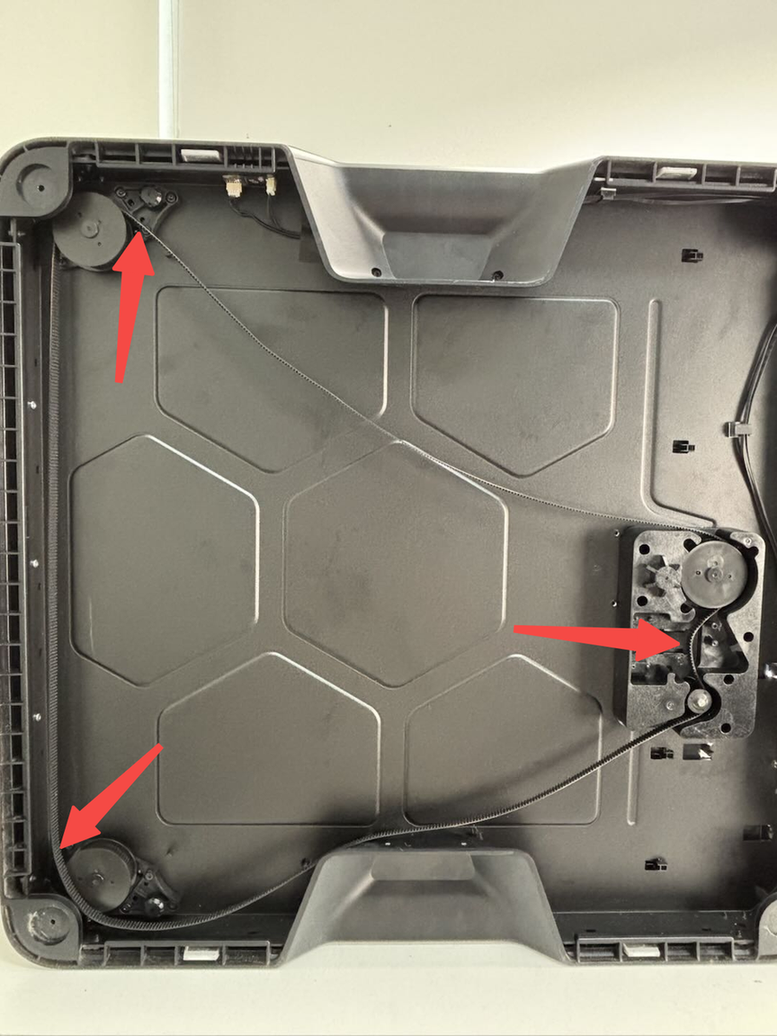

Refer to the image below and route the new Z belt around the 3 timing pulleys and the Z motor, ensuring the toothed side contacts the timing pulleys.

¶ Step 3: Install the Z-axis tensioner assembly

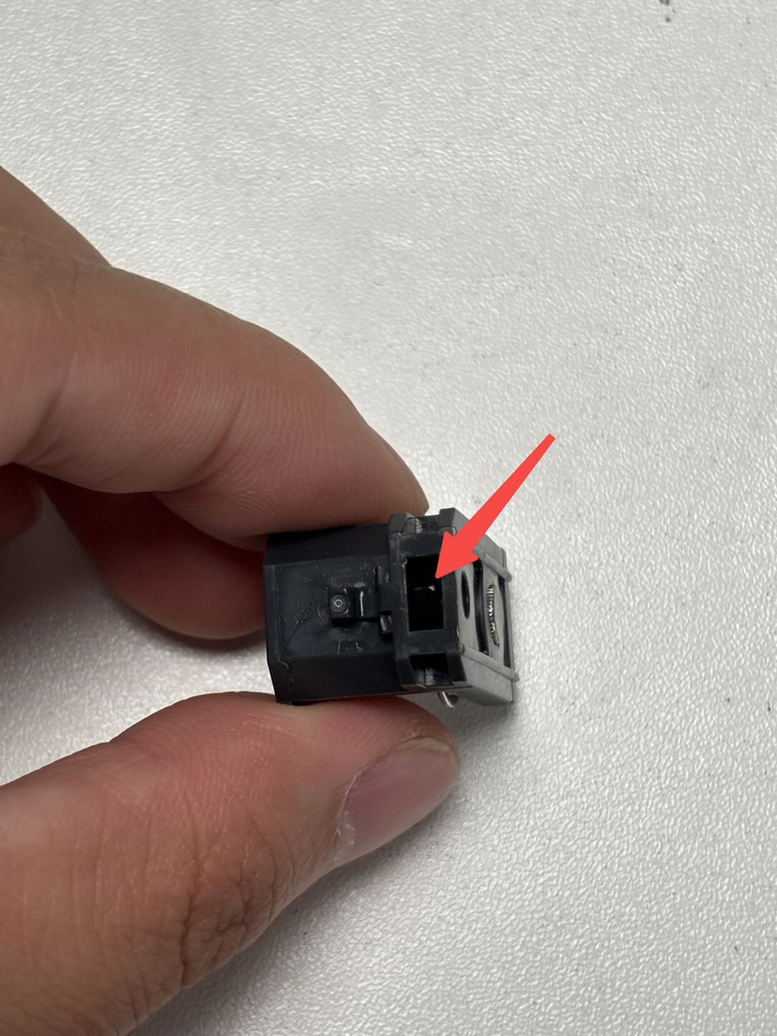

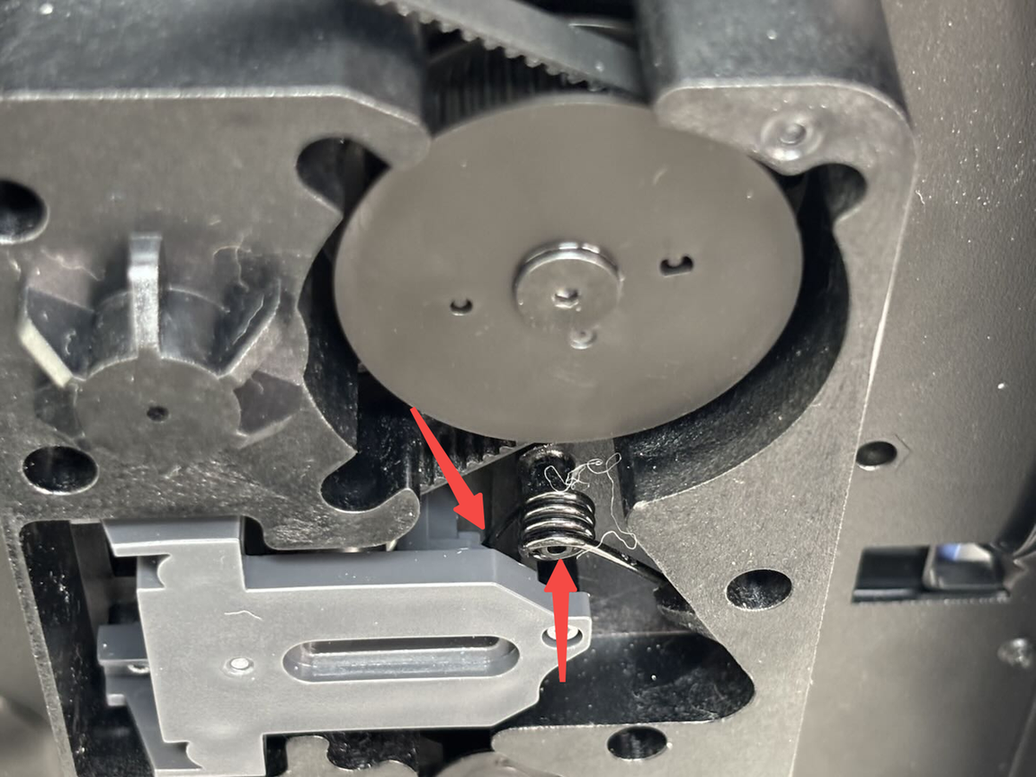

Before installation, ensure the nut is installed on the Z-axis tensioner slider. Refer to the image below and install the Z-axis tensioner in its designated position. Align the clips on the tensioner with the notches on the printer base. First, install the torsion spring onto the corresponding pillar, hook the short arm onto the slider, and hook the long arm onto the clip on the printer base.

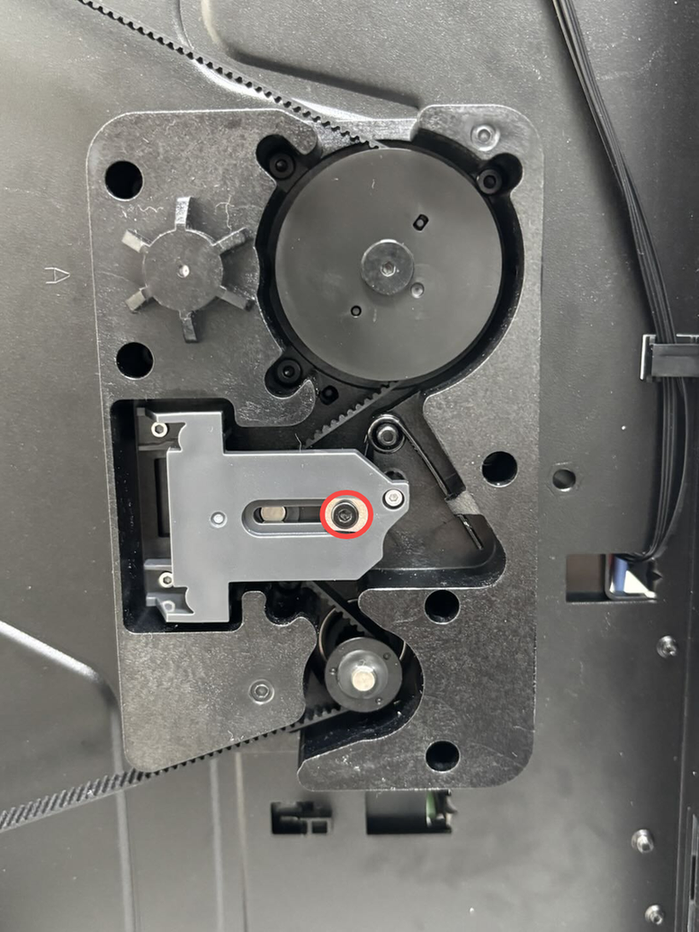

Reinstall the Z-axis tensioner cover. Use an H1.5 Allen key to tighten the 3 screws securing the cover (marked with green boxes, BT2x5). Use an H2.0 Allen key to secure the Z-axis tensioner slider fixing screw (marked with a red circle, M3x6; do not fully tighten yet—this will be done after tensioning the belt in Step 5).

Notes:

-

When reinstalling the torsion spring, ensure the short arm is hooked onto the front of the Z-axis tensioner slider.

-

Check if the torsion spring is fully seated on the shaft. If not, push it back. Vibrations during this step may cause the nut inside the Z-axis tensioner slider to fall out. Use a small piece of PTFE tube (or another item) to block the nut and prevent it from falling.

¶ Step 4: Place the printer upright and unlock the heatbed

Place the printer upright on a stable surface/floor, and use an H2.0 Allen key to remove the 4 screws (M3x35x8) securing the heatbed.

Given the printer's weight, it is recommended that two people work together to avoid potential damage.

¶ Step 5: Tension the Belt, tighten the screws, and place the printer upright

Slightly tilt the printer, manually pull the Z belt back and forth a few times to ensure smooth operation, and then use an H2.0 Allen key to fully tighten the Z-axis tensioner slider fixing screw (M3x6).

After tightening, place the printer upright on a stable surface/floor and reinstall the glass cover plate.

Given the printer's weight, it is recommended that two people work together to avoid potential damage.

¶ Verify the Functionality

-

Connect the power and start the printer.

-

Run the device self-test as shown below. If no errors are reported, the belt replacement is successful.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!