¶ Issue Description

The left hotend is secured to the hotend heater with a locking clip and moves up and down with the hotend lifting module. When the left extruder is operational, the hotend lifting module descends, approaching the rear left extrusion force eddy current sensor, maintaining a specific gap. This gap changes correspondingly with variations in extrusion force, enabling extrusion force measurement. If the sensor detects an extrusion force signal with excessively low frequency, the system will trigger an alarm, causing the heatbed to slightly descend, terminate the task, and display an error message.

Possible causes of the issue include:

-

The gap between the left extrusion force sensor eddy current coil and the lifting slider is abnormal.

-

The left extrusion force sensor eddy current coil is loose.

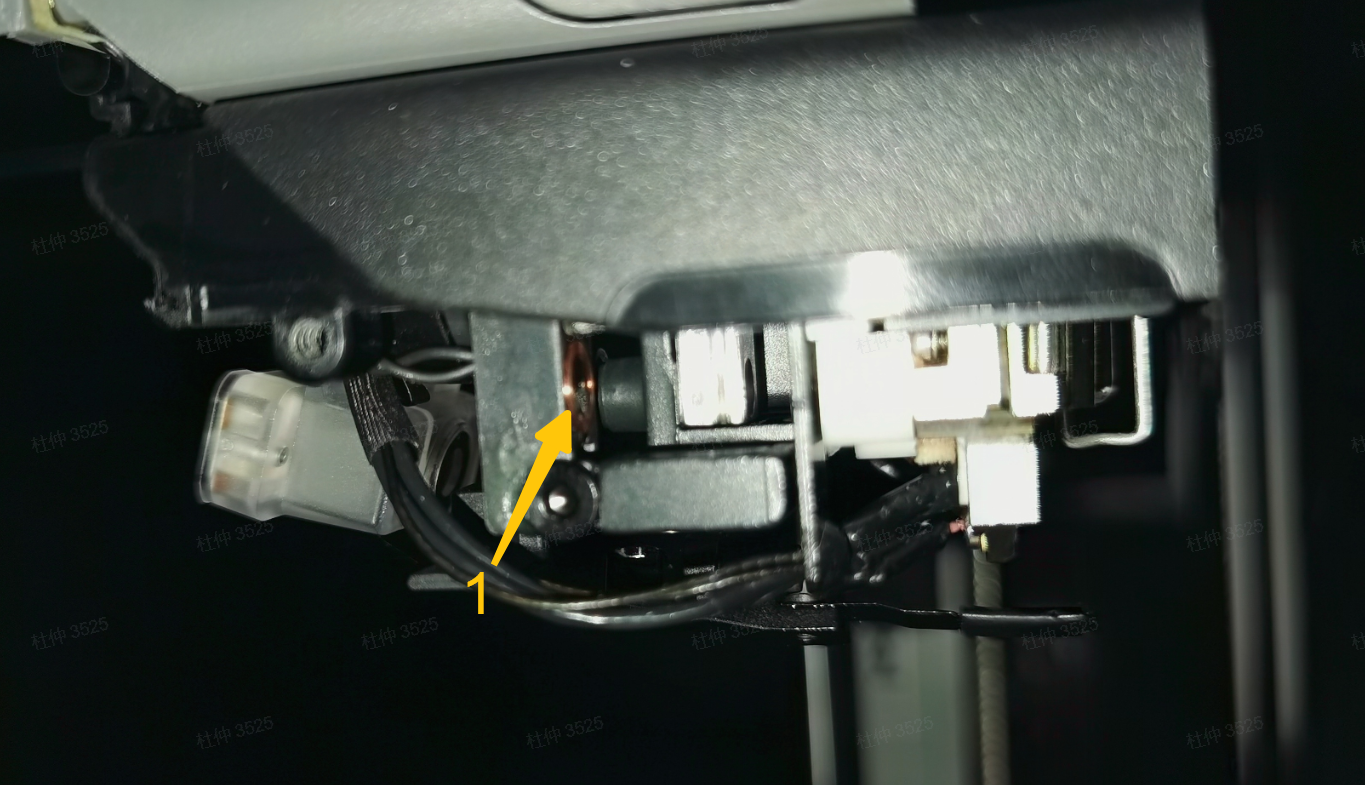

1- Left extrusion force sensor eddy current coil |

2- Hotend lifting module, 3- Gap between eddy current coil and lifting slider |

¶ Troubleshooting

¶ Tools, Equipment and Materials

-

H2.0 Allen key

-

Standard A4 printing paper

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Check if the extrusion force sensor eddy current coil is detached

-

Refer to the Wiki Replace H2D Part Cooling Fan to remove the part cooling fan duct.

-

Manually move the flow blocker to lift the left slider, exposing the left eddy current coil.

-

If the coil is loose, refer to the Wiki Replace H2D Nozzle Eddy Sensor to replace the left nozzle eddy sensor.

-

If the coil is not loose, proceed to Step 2.

¶ Step 2. Inspect the Gap Between the Eddy Current Coil and the Lifting Slider

- Check the gap between the left extrusion force sensor eddy current coil and the left hotend lifting slider. The normal gap range:

-

With the left extruder in the working position.

-

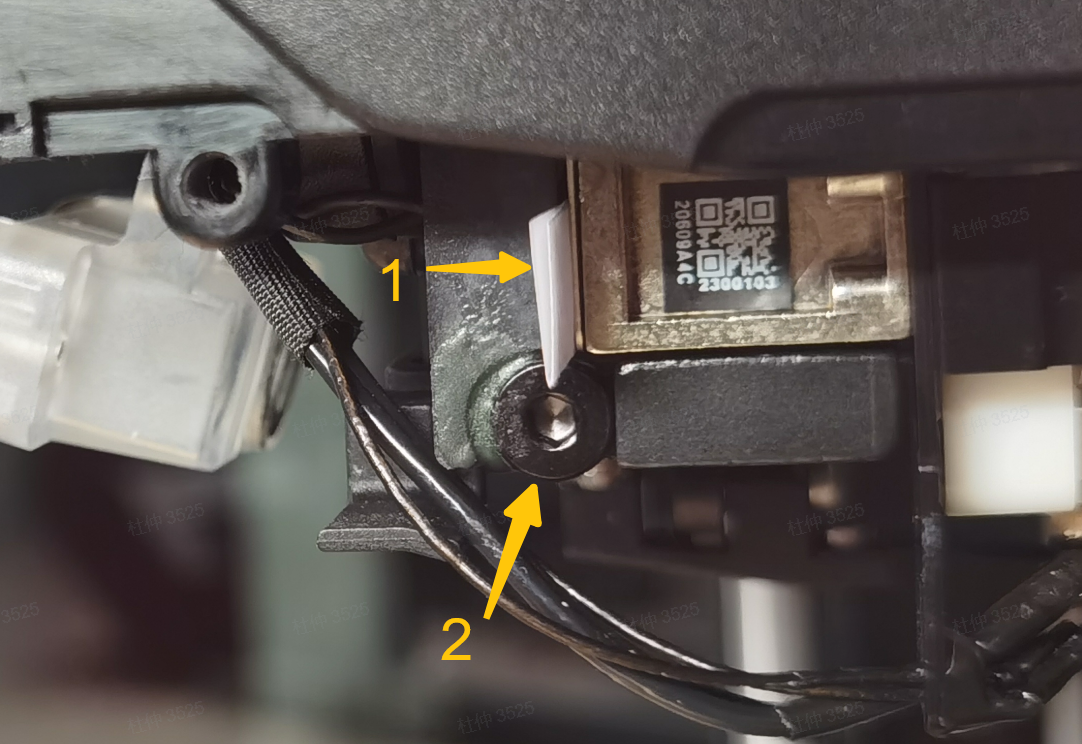

Two layers of standard printing paper (total thickness: 0.2mm) (Arrow 1 in the figure below) can slide smoothly.

-

Three layers of printing paper (total thickness: 0.3mm) cannot be inserted or experience noticeable friction when inserted.

- Gently attempt to tighten the screw (Arrow 2 in the figure below) with an H2 Allen key to check if it is loose.

The following figure shows the normal gap state: 2~3 layers of printing paper can be inserted just right:

1 - Two layers of standard A4 paper 2 - Rear locking screw of the coil bracket |

- If the gap is abnormal or the screw is loose, adjust as follows:

-

Loosen the screw and place three layers of standard printing paper (total thickness: 0.25-0.3mm) between the eddy current coil and the lifting slider.

-

Push the coil bracket toward the lifting slider and tighten the screw.

-

After tightening, remove the paper and confirm the gap is appropriate using two and three layers of paper (refer to the gap check above).

-

Finally, secure the screw with structural adhesive to prevent loosening.

- Proceed to Step 3.

¶ Step 3. Toolhead Installation and Testing

-

Install the hotend (the part cooling fan and its duct can be installed after testing).

-

On the screen, switch to the left extruder.

-

Manually trigger homing.

-

If no alarm occurs, the test is successful.

-

Refer to the Wiki Replace H2D Part Cooling Fan to install the part cooling fan and its duct.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!