¶ Issue Description

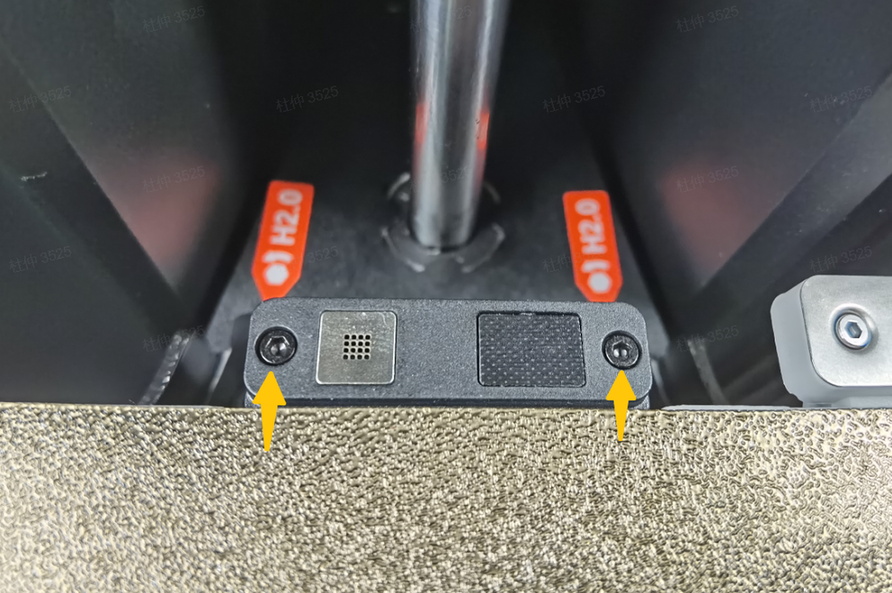

The Nozzle Offset Calibration Sensor is used to calibrate the XY offset values between the left and right nozzles to achieve better printing results in dual-nozzle collaborative printing. As shown in the image below, the small black block is the XY Offset Calibration Sensor.

Possible causes for this HMS error include:

-

Damage to the sensor body

-

Loose or detached connection between the sensor and its signal cable

-

Loose or detached connection between the sensor signal cable and the AC board

¶ Troubleshooting

¶ Tools, Equipment and Materials

H1.5 Allen key

¶ Fault Isolation Process

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Check the Offset Calibration Sensor for Physical Damage

During XY offset calibration, the nozzle may abnormally contact and damage the sensor due to incorrect height (e.g., nozzle sticking filament during Z offset calibration). If physical damage is observed on the sensor, proceed to Step 2 to replace the sensor.

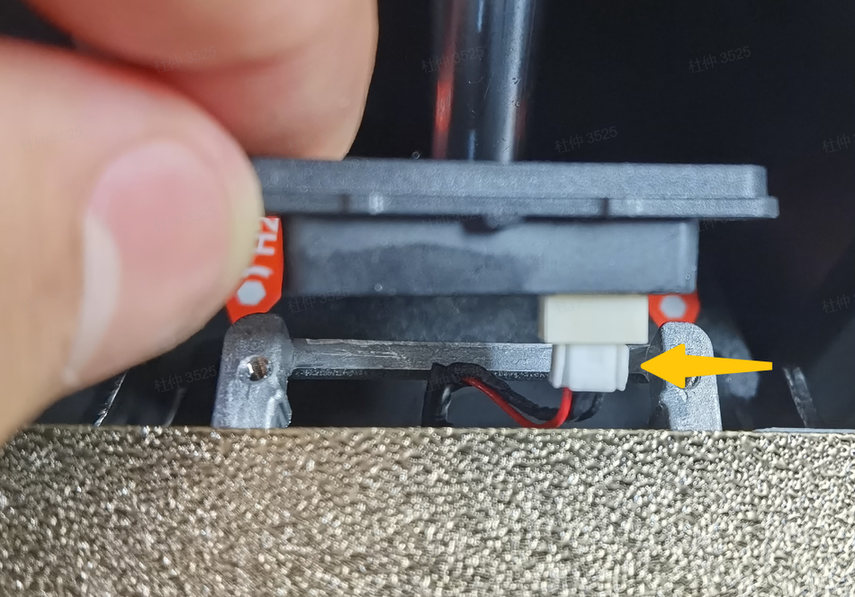

¶ Step 2. Check the Connection Between the Sensor and Its Signal Cable

-

Remove the screws.

-

Inspect the sensor connector for looseness or detachment. If found, re-plug the sensor connector.

-

Reinstall the sensor.

For detailed disassembly and assembly steps, please refer to:Replace H2D Nozzle Offset Calibration Sensor

- On the screen, run the "Nozzle Offset Calibration" to verify if the issue is resolved. If unresolved, proceed to Step 3.

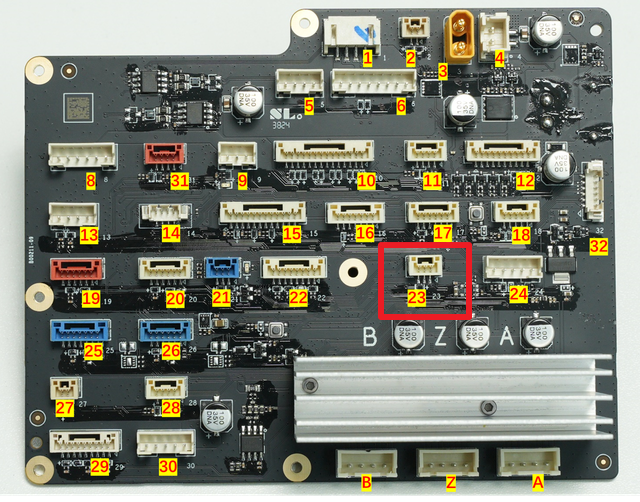

¶ Step 3. Check the Connection Between the Signal Cable and the AC Board

Ensure the printer is powered off before inspecting the connection between the signal cable and the power board!

-

Inspect the connection between the signal cable and the AC board. If loose, re-plug the connector.

¶ Step 4. Verify the Nozzle Offset Calibration Sensor

After completing the above troubleshooting steps, navigate to the calibration page on the screen and perform the nozzle offset calibration again. If the error persists, refer to Step 2 to replace the sensor.

If the above solutions do not resolve the issue, submit a ticket and upload the printer’s log files.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!