¶ Issue Description

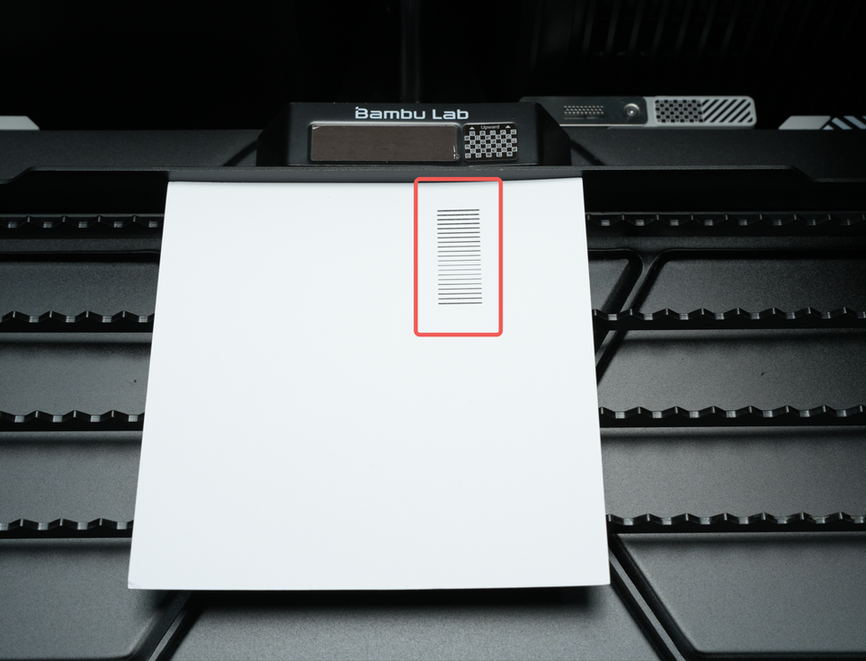

The Z-axis focus calibration of the laser module is performed by detecting lines engraved on cardstock to determine the deviation between the laser and the hotend nozzle in the Z-axis direction, thereby completing the focus.

Causes of focus failure include:

-

The test material used does not meet the requirements.

-

The test material is uneven or warped.

-

The laser engraving area already has marks, making the engraved lines difficult to identify.

¶ Troubleshooting

¶ Tools, Equipment and Materials

- Clean 350g cardstock

¶ Solutions

Users may adjust the order of these solutions as needed.

Refer to Laser Focus Calibration Introduction to check whether the material settings for focus calibration are appropriate.

-

Use the recommended 350g cardstock or other suitable alternative materials.

-

Ensure the material is placed flat on the laser platform blade strip, without warping or deformation.

-

Place the cardstock near the homing platform on the laser platform.

-

Use clean cardstock (ensure the engraving area and its surroundings are free of marks).

After completing the above checks and adjustments, retry the corresponding calibration procedure.

¶ Equivalent Codes

The following HMS codes represent the same type of issue.

| HMS Code | Description |

|---|---|

| 0C00-0300-0002-0017 | Laser engraving Z-axis focus calibration failed. Please check if the Laser Test Material (350g paperboard) is properly placed and its surface is clean and intact. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!