¶ 01.02.00.00 (20250813)

¶ New Features

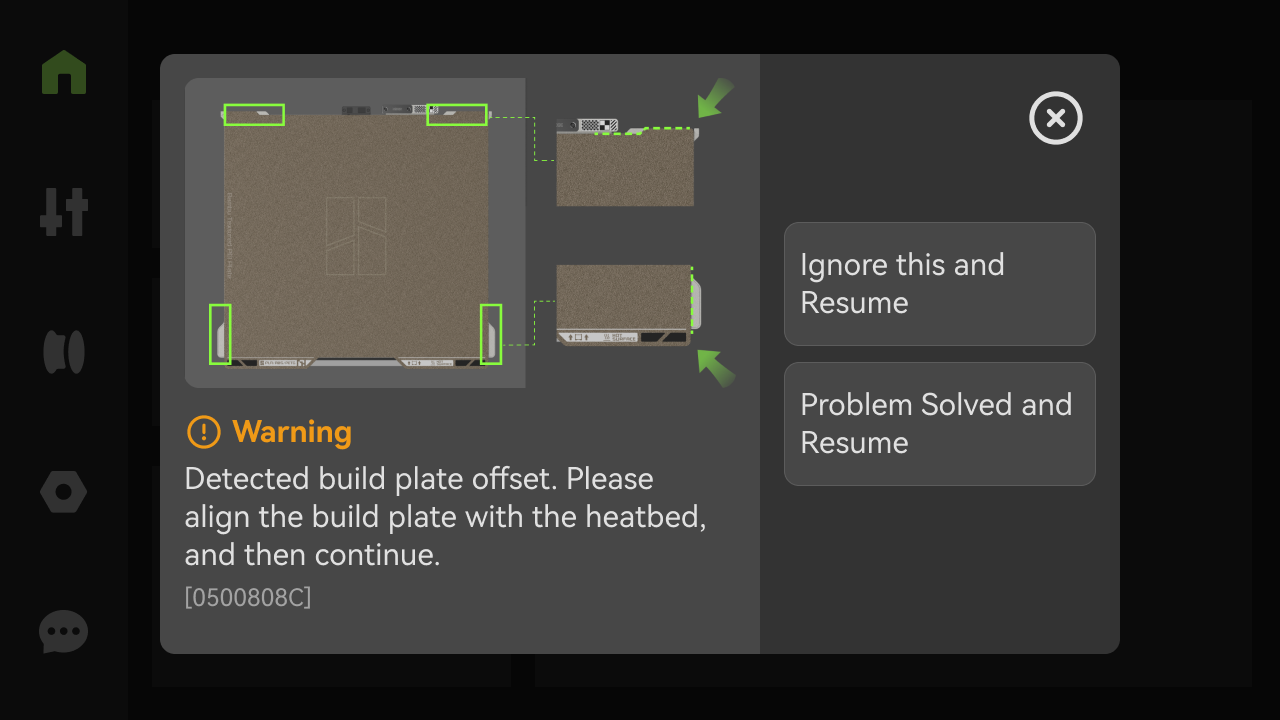

- Added build plate position detection function

This feature detects whether the build plate is correctly aligned during print preparation stage by identifying features like heatbed limit blocks using the live view camera and toolhead camera. It prevents issues such as build plate interference, bed leveling failure, and printing beyond the edge of the build plate.

The feature requires Bambu Studio version V2.2.0.85 or newer.

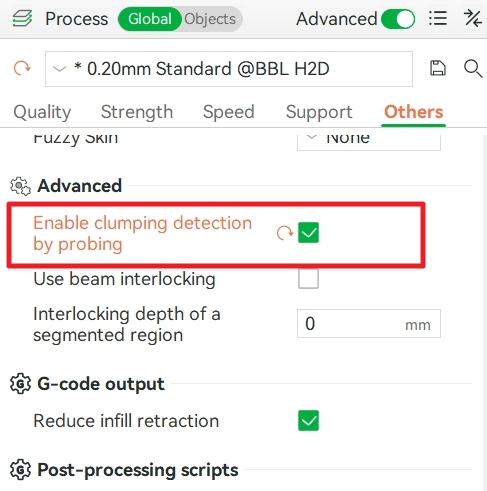

2. Added nozzle clumping detection (by probing)

This feature work in conjunction with nozzle clumping detection by nozzle camera, covers a wider range of printing scenarios.

During the 4th, 11th, and 20th layers of printing, it detects nozzle clumping using the extrusion force sensor. When performing the detection, the toolhead moves outside the heated bed and executes a probe touch; the printable area is slightly reduced, and any nozzle oozing during this process is absorbed by the prime tower to prevent print defects, for models with an existing prime tower, it will be reused; for models without a prime tower (e.g., single-color models), a small prime tower is automatically created.

This feature requires updating the Bambu Studio to version V2.2.0.85 or newer and enabling it under process presets "Other->Advanced", for more information, please refer to Introduction of H2D's Nozzle Clumping Detection by Probing

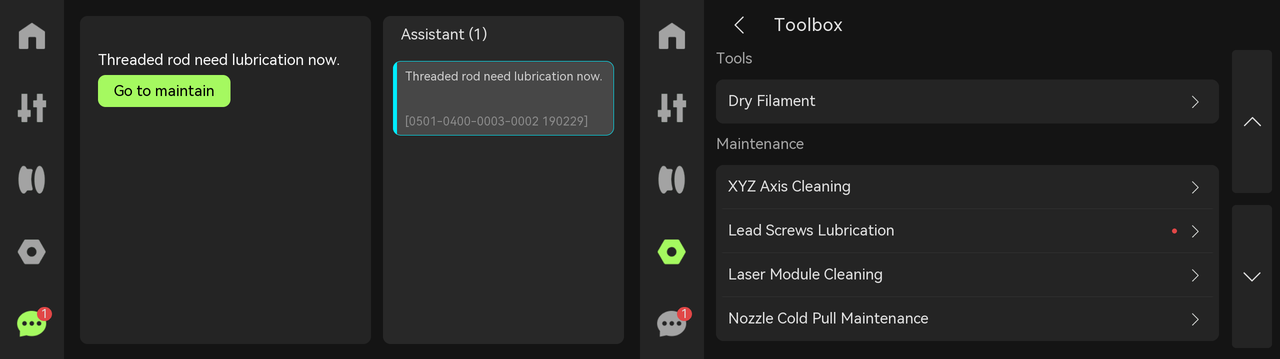

- Added maintenance reminders for XY axis cleaning and lead screw lubrication

When the XY-axis and lead screws reach their maintenance interval, an HMS notification will be triggered. Component usage duration is calculated from initial activation. After updating to this version, certain components may generate reminders – simply follow the prompts.

For detailed cleaning and maintenance guidelines, refer to H2D Regular cleaning and maintenance recommendations

- Added support for the Auto Fire Extinguishing System (sold separately.) (requires a supported version of Bambu Suite coming soon).

- Added BirdsEye camera position check. The system can detect positional shift of the BirdsEye camera due to prolonged use or vibration, then prompts users to run recalibration of the BirdsEye camera for higher accuracy.

¶ Feature Optimizations

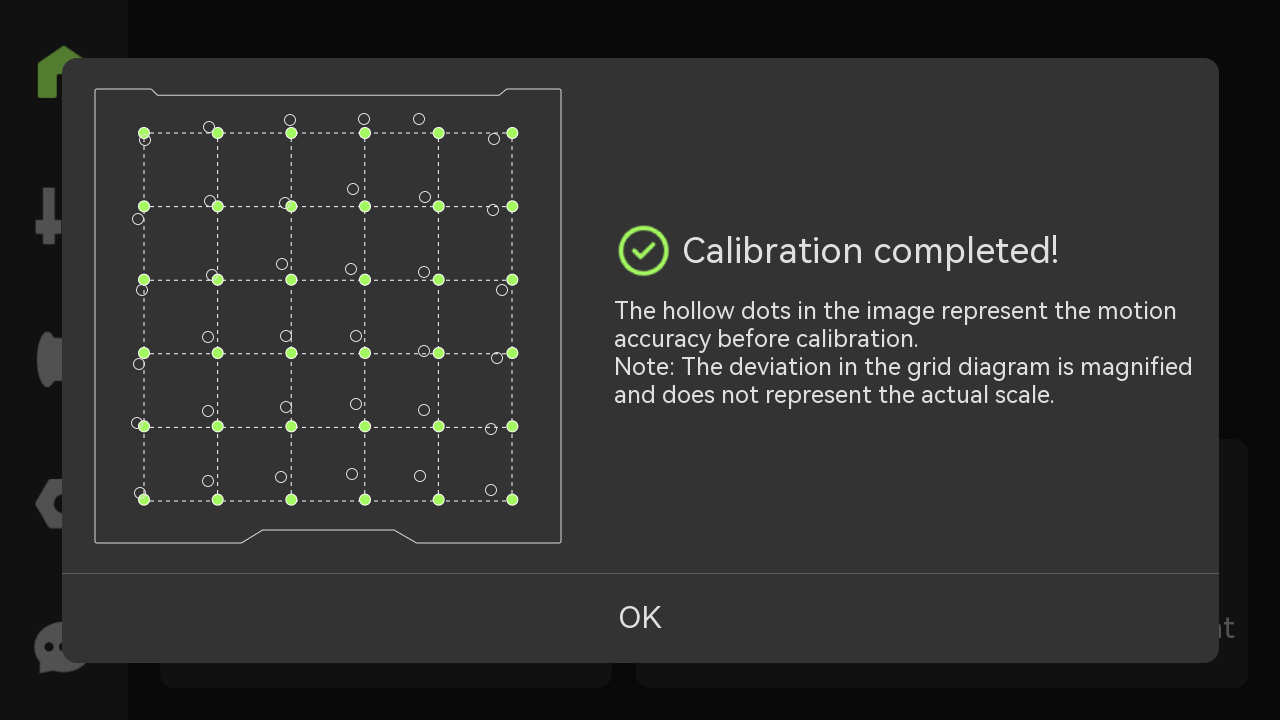

- Optimized the result display of motion accuracy calibration function.

- Optimized energy-saving mode: added control of the Status indicator and AMS indicator lights.

- Optimized the humidity display of the first gen AMS.

- Optimized extruder control, improved extrusion overload issue.

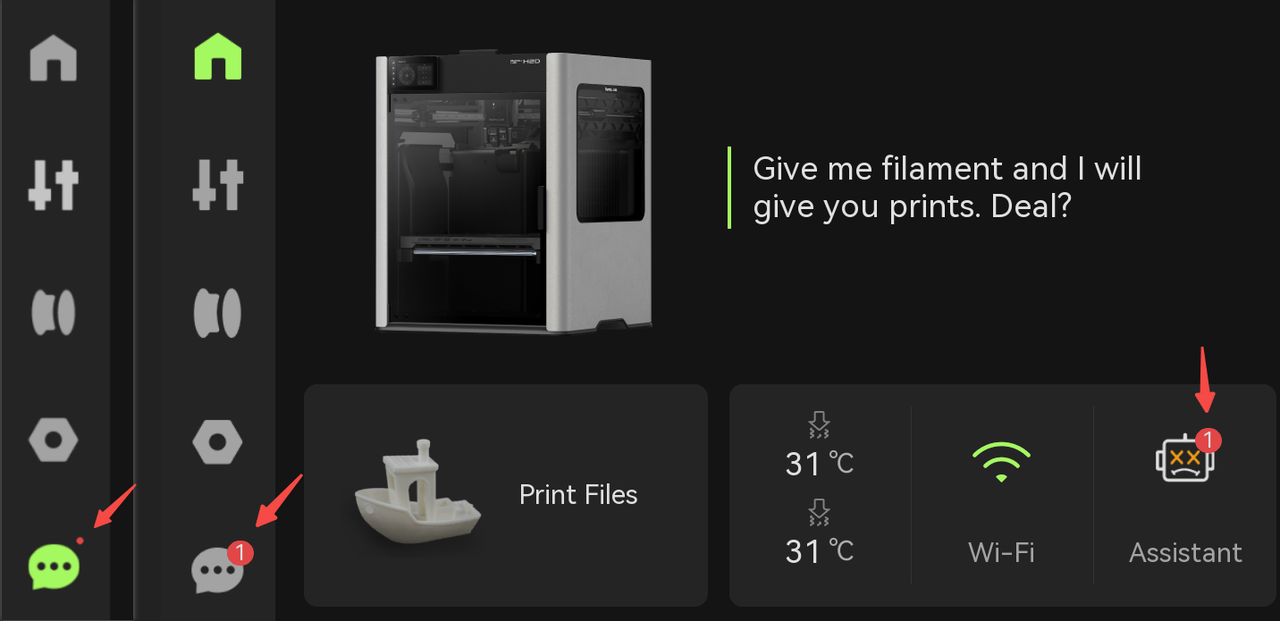

- Optimized the notification display of HMS messages.

- Optimized the position accuracy and thickness measurement accuracy of hybrid processing including laser

¶ Known Issues

- Filament PTFE tube detachment detection is temporarily disabled.

¶ 01.01.04.00 (20250630)

¶ New Features

- Added support for drying PLA material in AMS 2 Pro/AMS HT using default drying parameters without needing to unload.

- Added blade cutting offset calibration function, which can significantly improve the positional accuracy of the blade cutting module processing.

¶ Feature Optimizations

- Optimized first layer printing quality.

- Optimized the purge bin jam detection function for better detection of jam.

- Optimized the issue of large capacity USB drive formatting occasionally failing.

- Optimized print quality with the 0.2mm nozzle.

- Optimized system stability.

- Optimized sound and light: the indicator lights will now turn off after printing is completed in energy-saving mode.

- Added a sound prompt to remind users to check-in promptly when the 40W laser process check-in timer is about to expire.

- Optimized the Print-then-Cut process to be compatible with more paper sizes.

- Improved the stability of Power Loss Recovery.

- Improved the stability of Liveview Camera Streaming.

- Optimized Adaptive Air Flow system control logic.

- Improved laser module calibration success rate.

¶ Known Issues

- Filament PTFE tube detachment detection is temporarily disabled.

¶ 01.01.02.08 (20250527)

¶ New Features

- Added support for the CyberBrick™ time-lapse kit

- AI detection features for Nozzle Clumping, Spaghetti, Air Printing, and Purge Chute Pile-Up can be individually turned ON/OFF on the printer screen.

- AMS 2 Pro and AMS HT now support RFID automatic drying parameter matching

- AMS 2 Pro and AMS HT now support drying without auto-rotating the spools

- Laser & Cut processes now support tasks initialized from the USB drive file

¶ Feature Optimizations

- Optimized foreign object detection on the smooth PEI plate

- Optimized first-layer quality

- Optimized the accuracy of heatbed temperature control

- Optimized the accuracy of nozzle clumping detection

- Optimized the accuracy of nozzle camera dirty detection

- Optimized the purging strategy

- Optimized pre-printing chamber temperature check strategy

- Optimized the accuracy of laser module flame detection

- Improved the calibration success rate of liveview camera

- Resolved an issue where the pre-extrusion line could occasionally adhere to the model during layer changes (please update the Bambu Studio Presets).

- Fixed a collision issue between the nozzle flow blocker and the nozzle wiper when initiating flow dynamics calibration from Bambu Studio.

¶ Known Issues

- Filament PTFE tube detachment detection is temporarily disabled.

- The heatbed temperature cannot be controlled via Bambu Handy. This issue will be fixed in the upcoming new version of Handy (V.3.2.0).

¶ 01.01.01.00 (20250410)

¶ Feature Optimizations

Optimized AMS hardware recognition mechanism, which fixed the print job cancellation issue caused by AMS recognition errors.

¶ Known Issues

-

Foreign object detection is currently not supported on Smooth PEI Plate.

-

Filament PTFE tube detachment detection is temporarily disabled.

¶ 01.01.00.00 (20250325)

The official version of Bambu Studio supported by H2D is V2.0.0.95 and above.

The official version of Bambu Suite supported by H2D is V1.0.0.0 and above.

The official version of Bambu Handy supported by H2D is V3.0.0 and above.

¶ New Features

¶ 1. 3D Printing-Related Features:

- Nozzle Camera Contamination Detection – Contamination is now checked during both printing and preparation stages to enhance the reliability of AI algorithms.

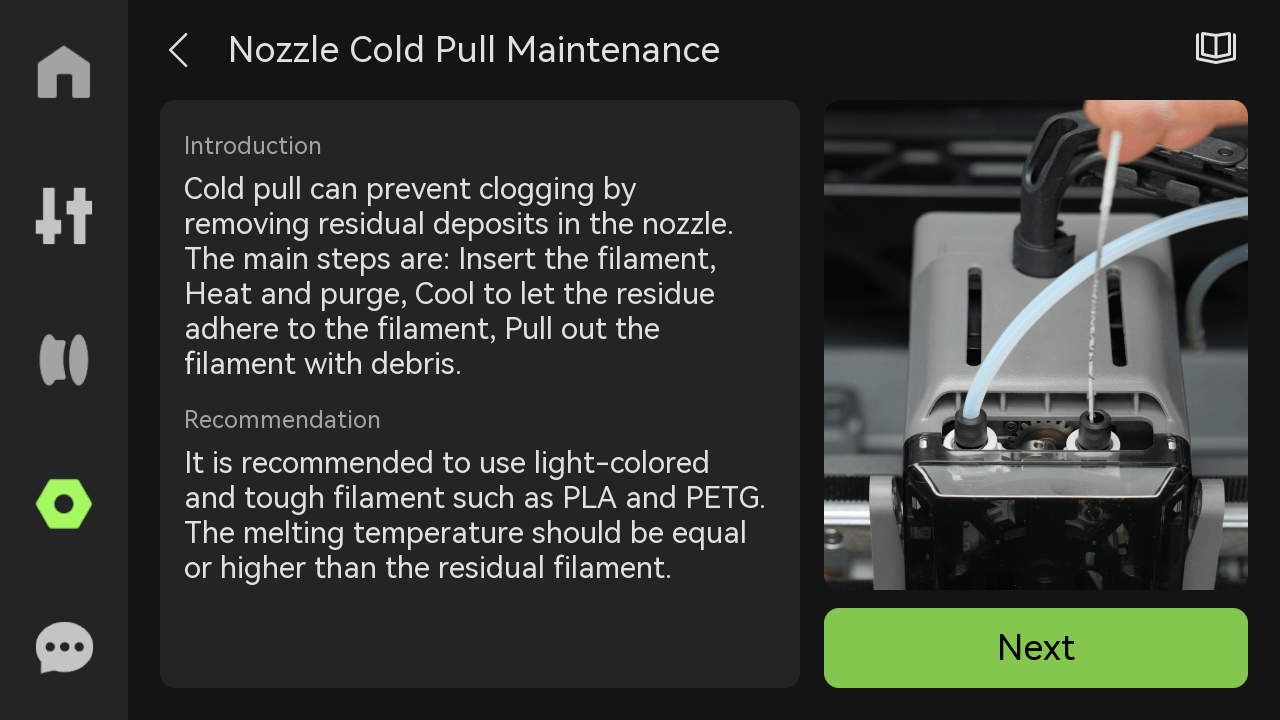

- Nozzle Cold Pull Maintenance – Added a new maintenance option for an assisted cold pull to clean the nozzle.

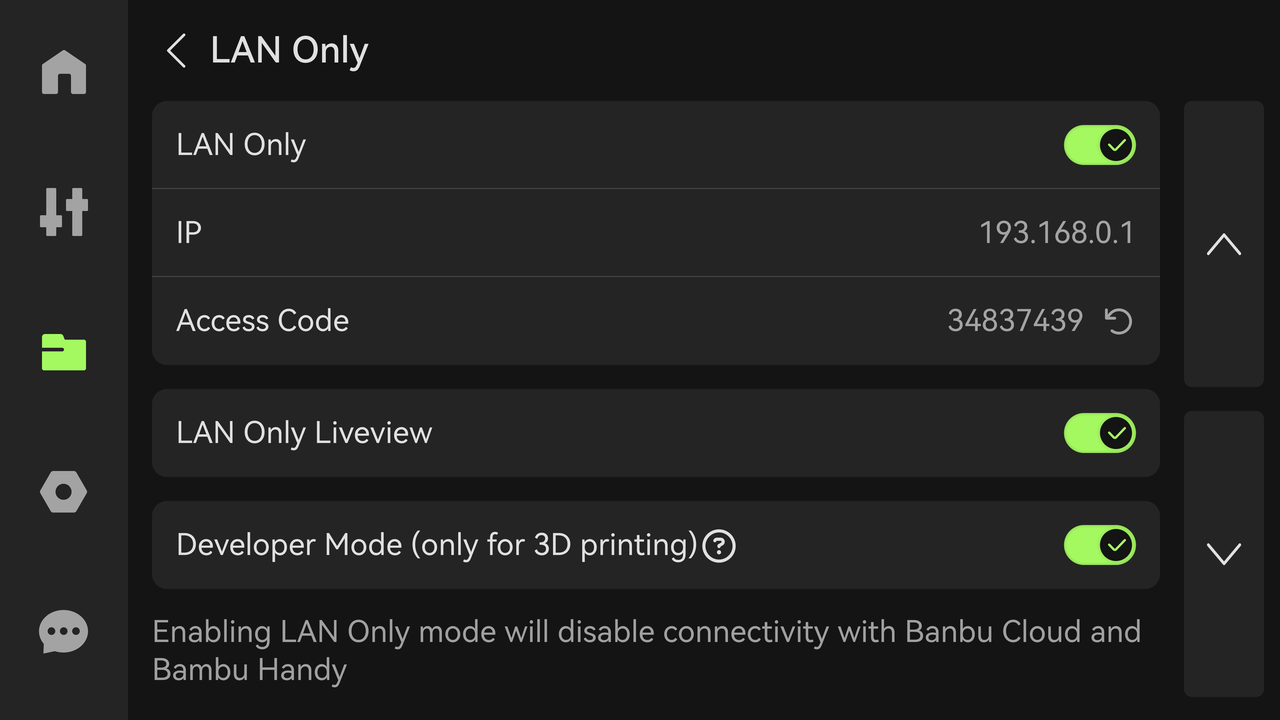

- Developer Mode (Available in "LAN Mode") – Developer mode can be enabled in case of 3D printing. When enabled, Authorization Control is disabled, allowing the printer to accept all control instructions without verification. This is intended for advanced users who require full control over printer security. A dedicated guide is available on the Bambu Lab Wiki.

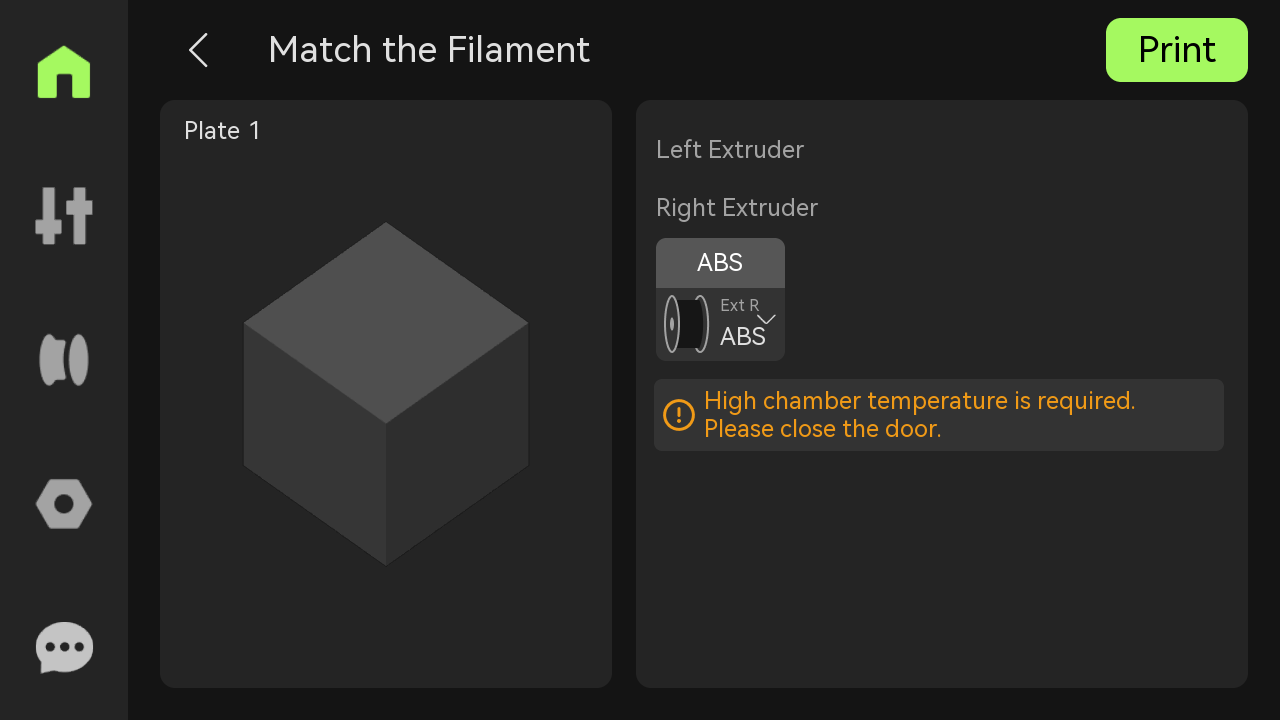

- Door-closing reminder-Added a door-closing reminder before initiating prints with high-chamber-temperature filament.

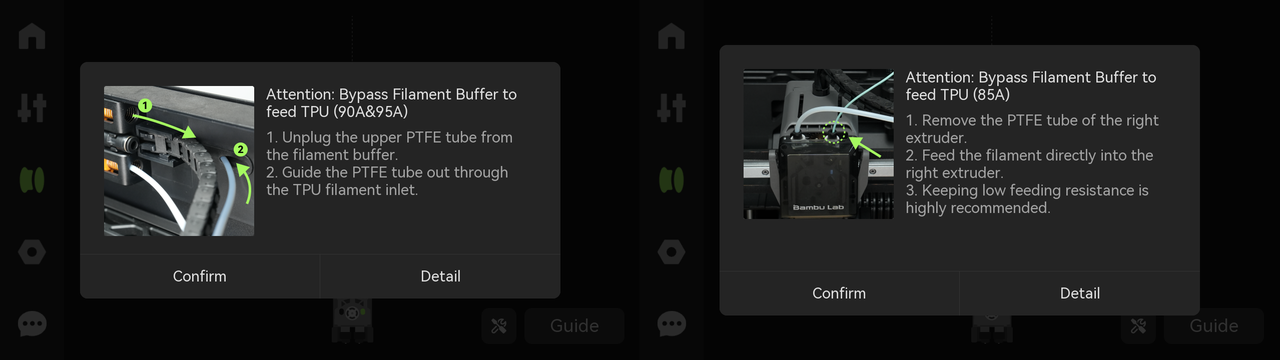

- TPU feeding modes and cold-pull operations - Optimized TPU feeding stability, added contextual reminders for TPU feeding modes and cold-pull operations.

¶ 2. Laser, Cutting Mode, Pen Mode, and Related Features:

- Pen-Filling Function – Added pen-filling function.

- Live View Camera Contamination Detection – Added dirt detection on the Liveview Camera to prevent false detection of the build plate, nozzles, and materials.

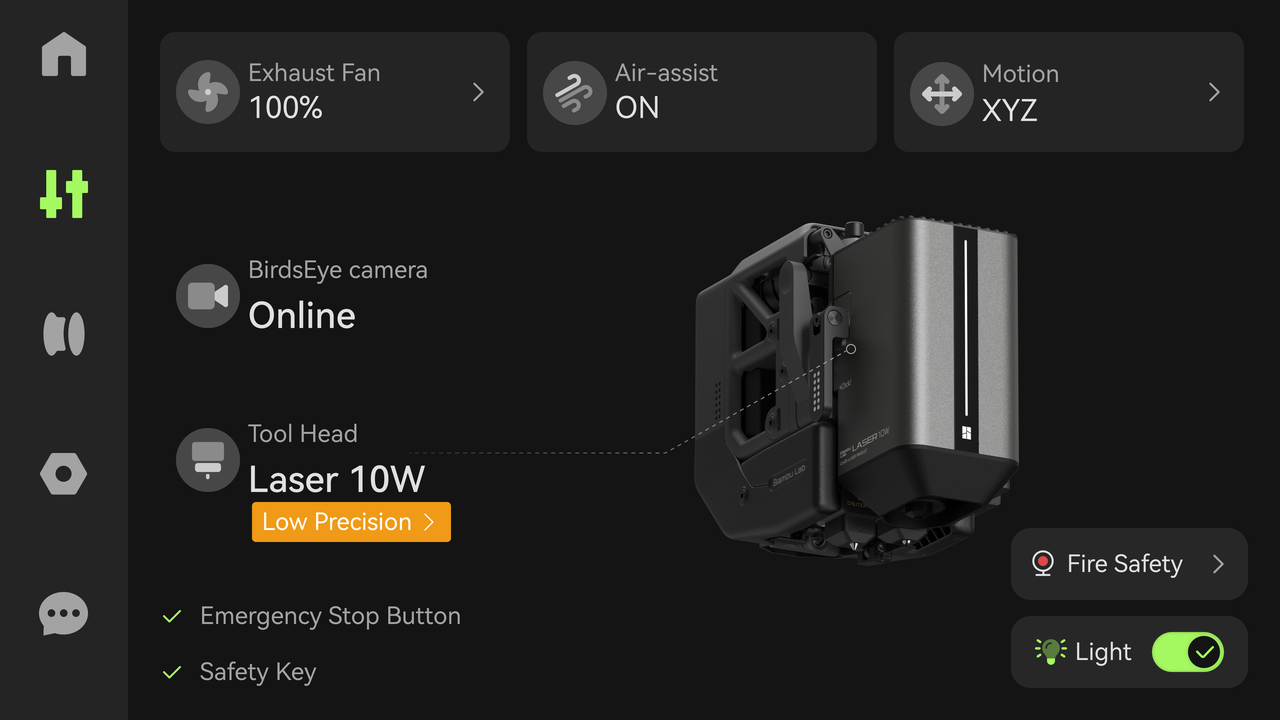

- Recalibration Reminder for External Modules – Added a reminder of low precision when switching external modules without recalibration.

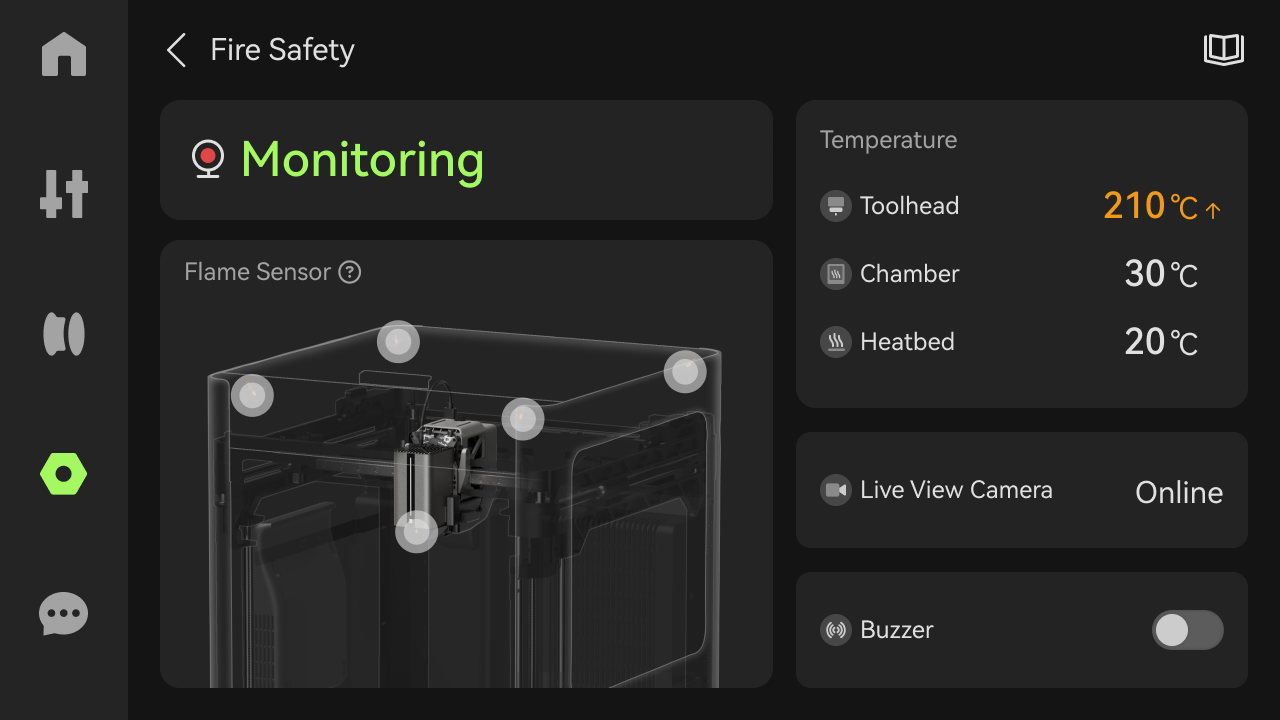

- Fire Safety Page – Added fire safety page to show the status of sensors and actuators about fire safety.

- Presence Reminders – Alerts users and perform periodic checks during high fire-risk processing to ensure someone remains near the printer for supervision.

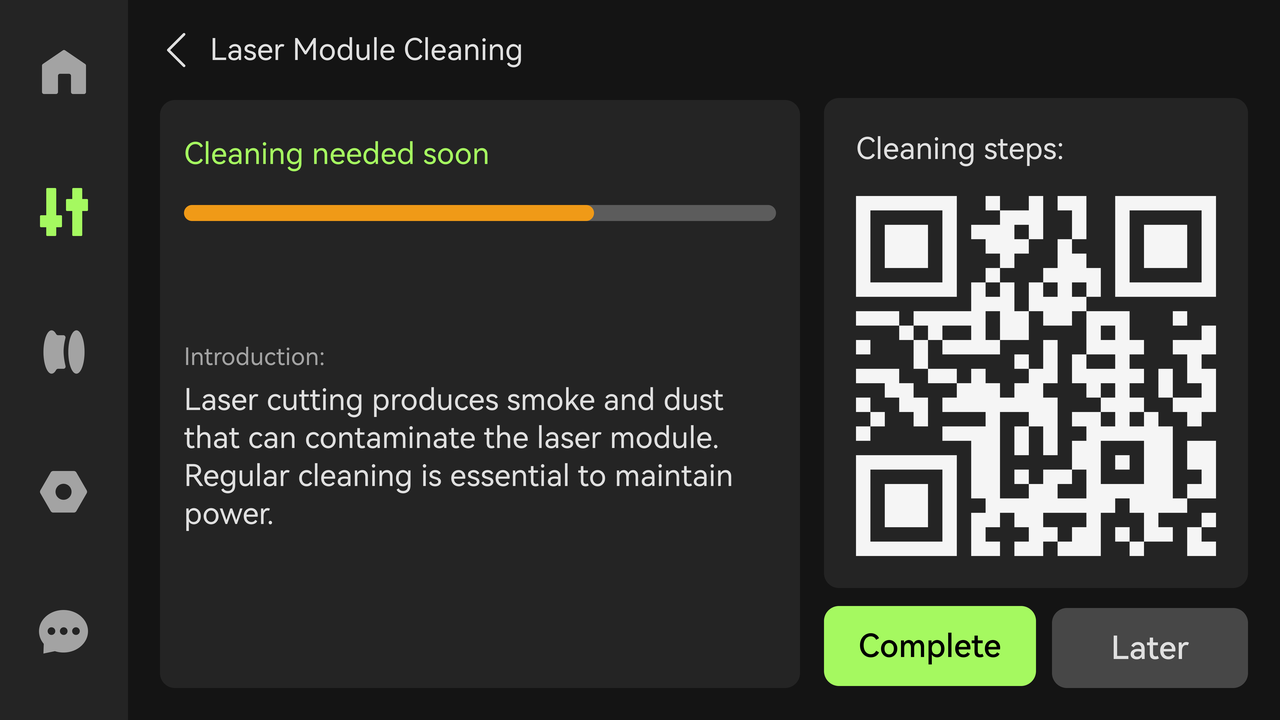

- Laser Module Cleaning Alert – Notifies users to perform deep cleaning maintenance when dust, smoke, and other contaminants reach a critical threshold.

- Physical Button Pause Function – Allows users to pause tasks by pressing the physical button in the top right section of the printer during operation.

- Support for Laser Processing of Tall Objects – Added compatibility for processing taller materials.

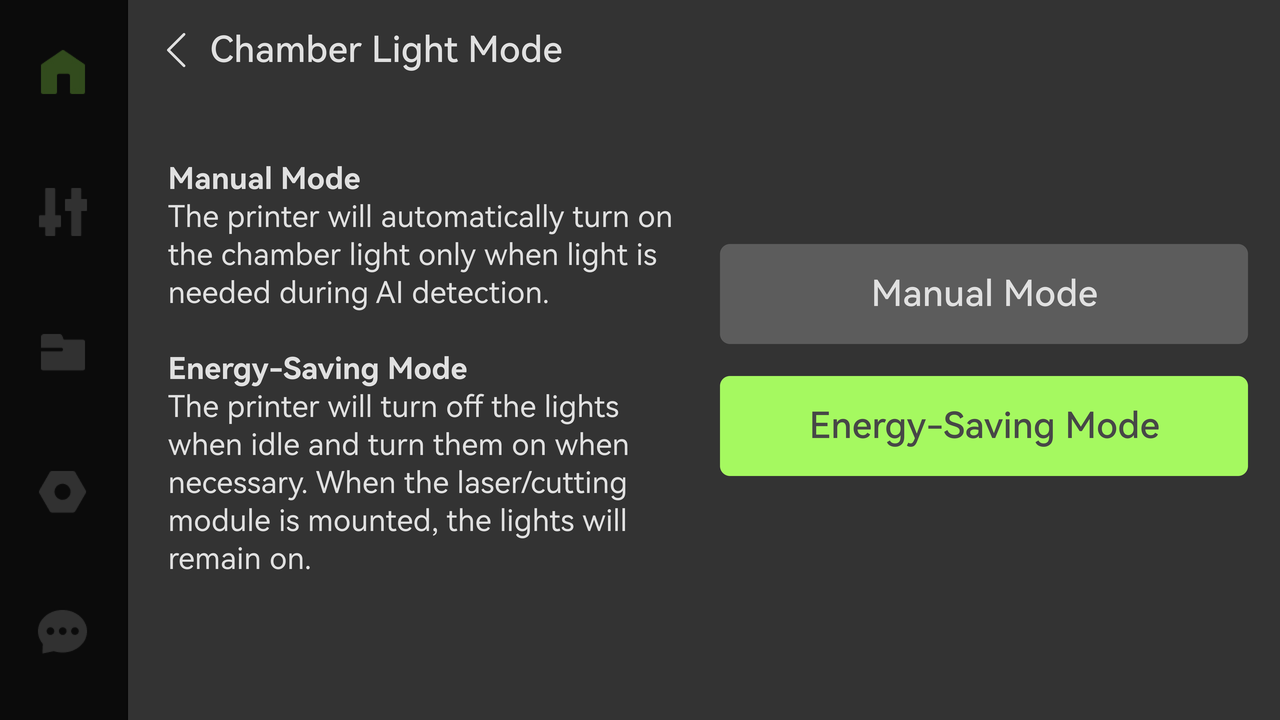

¶ 3.The chamber light supports manual mode and energy-saving mode.:

- In energy-saving mode, the printer will turn off the light when idle and turn it on when necessary.

Notes: When the laser/die-cutting is on, the light will not be turned off temporarily.

¶ Feature Optimizations

- Nozzle Offset Calibration – Improved logic for high-precision and nozzle offset calibration in print settings.

- Hotend Recognition – Added differentiation between "hotend not in position" and "hotend in position but unrecognized" scenarios to prevent workflow blockages.

- Motion Accuracy Calibration – Enhanced prompts to explicitly state the precision improvements after a successful calibration.

- AMS 2 Pro Filament Loading – Optimized performance (requires AMS 2 Pro firmware OTA v02.00.19.47 or newer).

- Heatbed and hotend control algorithms - Optimized heatbed and hotend control algorithms to improve temperature performance.

- AI vision inspection algorithms - Optimized AI vision inspection algorithms to enhance detection accuracy.

- Pre-Print Checks – Added cold pull prompts when TPU is loaded on the right toolhead, and door-closing reminders for high chamber temperature printing.

- Laser Unit Initialization – Added prompts to remove the air pump screw and install the exhaust pipe when the Laser unit is used.

- Photo Capture Speed – Increased speed for laser, cutting, and pen mode functions.

- UI & Text Refinements – Improved user interface and text descriptions for better clarity.

¶ Known Issues

- Foreign object detection is currently not supported on Smooth PEI Plate.

- Filament PTFE tube detachment detection is temporarily disabled.