¶ Background

Nozzle clumping refers to a condition during printing where extruded filament fails to adhere to the build plate and instead accumulates around the nozzle, causing clumps. This issue can cause print failure and even damage printer components, as shown in the image below.

To prevent damage from such cases, the Bambu H2D printer is equipped with Nozzle Clumping Detection. When clumping is detected, the printer automatically pauses and notifies the user to minimize potential harm.

Please note that the Nozzle Clumping Detection is not a fail proof option to detect problems.

It is meant to assist with potential problems, but it is not a guaranteed solution. There might be some detection issues, depending on the situation and the failure.

We recommend checking on the print from time to time using the Bambu Handy app Live View and to always wash the build plate before starting a print.

Initially, H2D relied on AI-based visual detection (see H2D Intelligent Detection Overview). However, when printing high-temperature materials—especially during the early layers—the nozzle camera area may exceed 85°C due to proximity to the heated bed. This leads to automatic deactivation of the visual detection, potentially affecting accuracy. To address this, nozzle clumping detection by probing was introduced, working alongside the visual system for enhanced reliability.

¶ Detection Principle and Execution

The detection runs at layers 4, 11, and 20. Before each of these layers starts, the toolhead moves to the back of the build plate and follows this detection sequence:

1. Nozzle Probing

The build plate moves up while the toolhead shifts right, performing a probing motion to touch the bed surface.

2. Collision Sensing

If the nozzle is affected by clumping filament, the tip may touch the bed surface. The eddy current sensor detects the collision, identifies it as a clumping event, and pauses the print.

If no collision is detected, the print proceeds as usual.

¶ Feature Settings

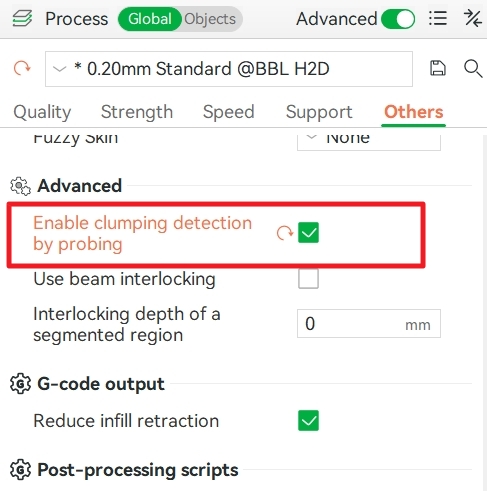

¶ Enable/Disable

You can enable or disable “Enable Touch Nozzle Clumping Detection” in Bambu Studio → Process → Global → Others → Advanced. This feature needs to be turned on manually.

¶ Software Requirements

- H2D Firmware: Version 01.01.30.00 Public Beta or newer

- Bambu Studio: Version V2.2.0.85 or newer

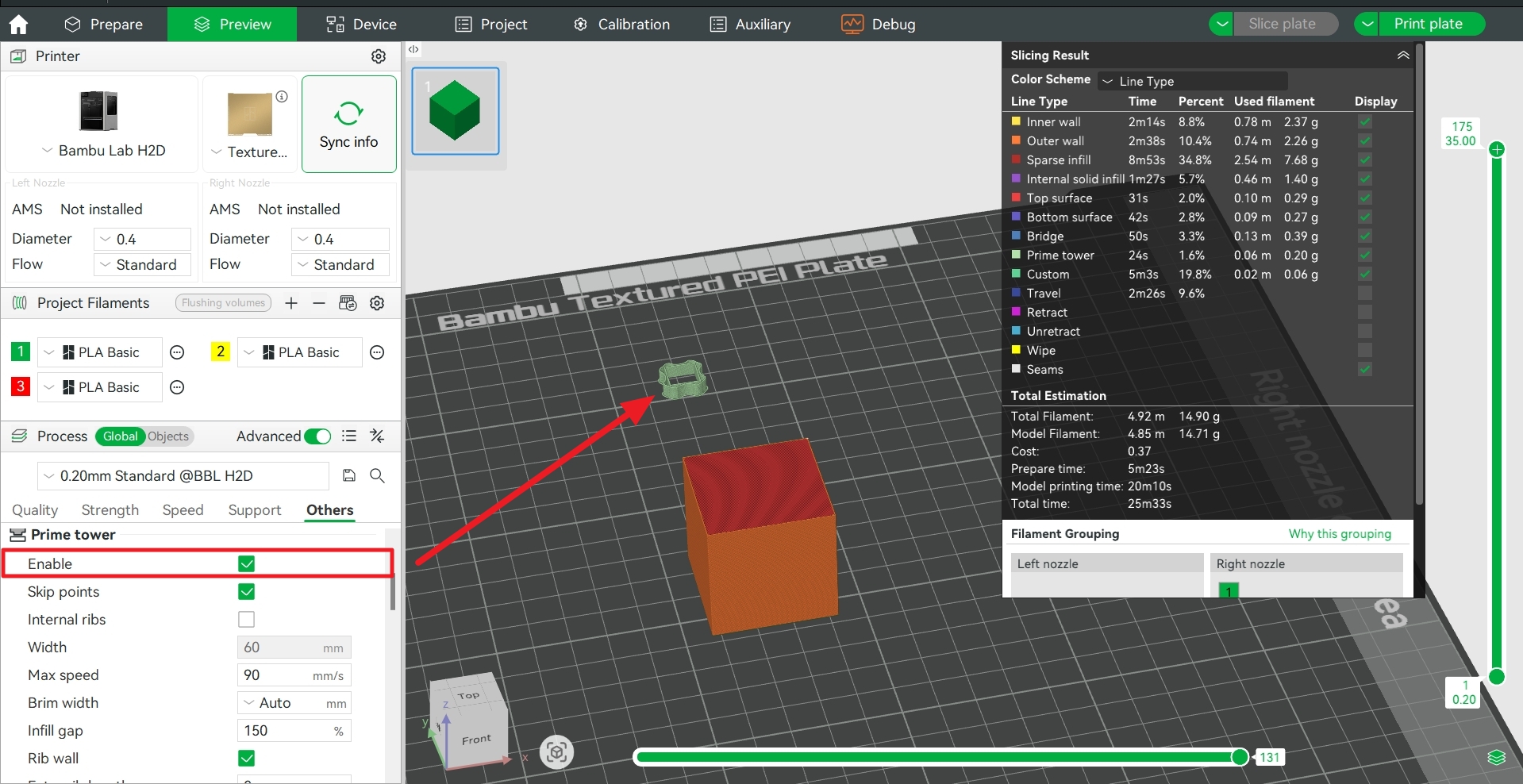

¶ Prime Tower Behavior

Because filament might ooze during detection, the system auto-generates a prime tower to absorb residue.

¶ Prime Tower Rules

-

Single-color printing:

- A 20-layer Prime tower is generated.

- If the model has fewer than 20 layers, the tower matches the model height.

-

Multi-color printing:

- If the tower already has ≥20 layers, it remains unchanged.

- If it's <20 layers but model ≥20 layers, extra layers are added.

- If the model is under 20 layers, the tower matches the model height.

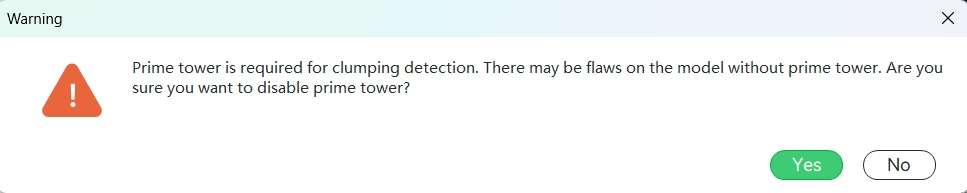

¶ Disabling the Tower

To disable the Prime tower, go to Process > Prime Tower >Enable and turn it off. Be aware this may cause slight imperfections on detection layers.

¶ Printable Area Limitation

Since the detection sequence requires the toolhead to move to the rear of the bed, the printable area is slightly reduced. See below for the affected region:

¶ Limitations

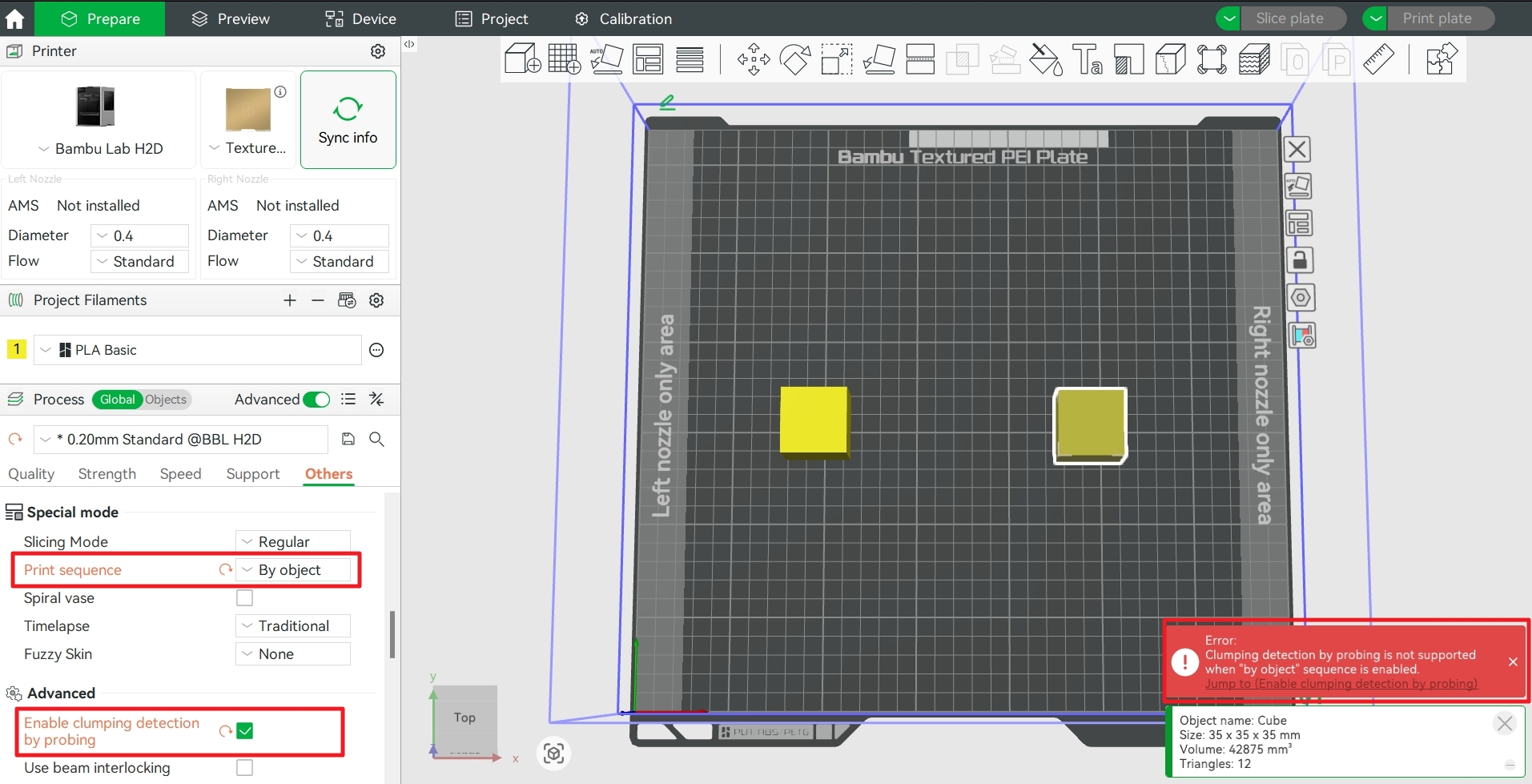

¶ Not Available in Sequential Printing for Multiple Models

When more than one model is placed on the plate and print sequence By object is enabled, the nozzle clumping detection function cannot be supported at the same time. You need to disable either the nozzle clumping detection or print sequence By object before slicing.

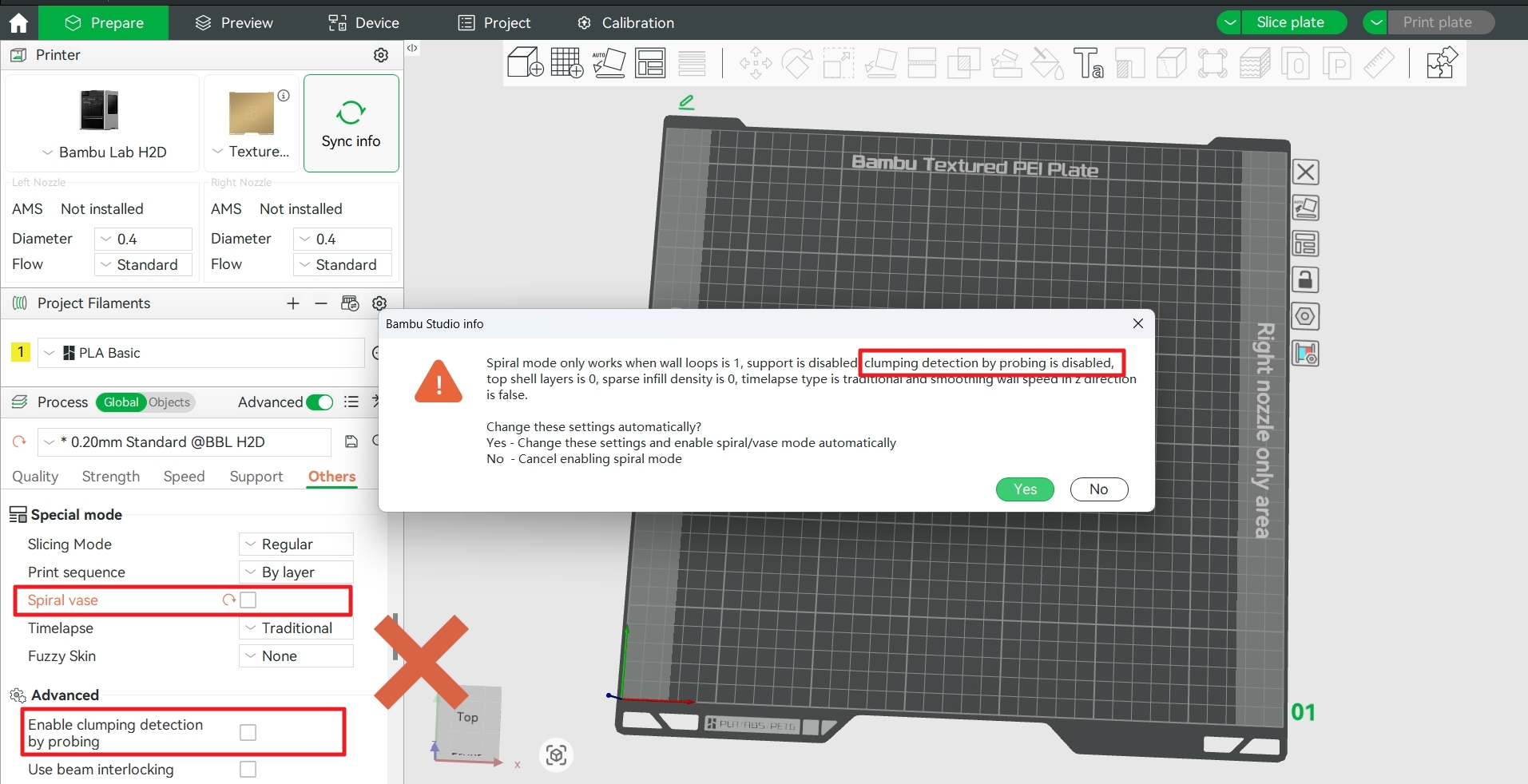

¶ Not Available When Spiral Vase is Enabled

When Spiral Vase is enabled, the nozzle clumping detection function will be disabled by default.

¶ Recommendations & Precautions

- If the hotend silicone sock is not installed, the filament may not clump properly, increasing the chance of detection failure. Make sure it's properly fitted before printing.

-

Insert a USB flash drive and enable video recording (Enable and Export Print Videos) for later analysis of clumping causes (e.g. poor first-layer adhesion).

-

Regularly clean the build plate (Textured PEI Plate Quality Expectations) to improve adhesion and reduce clumping risk.

-

If clumping occurs without detection or detection is turned off, refer to the Nozzle Clumping Cleanup Guide for H2D for proper handling.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!