¶ 01.01.00.00 (20250826)

¶ New Features

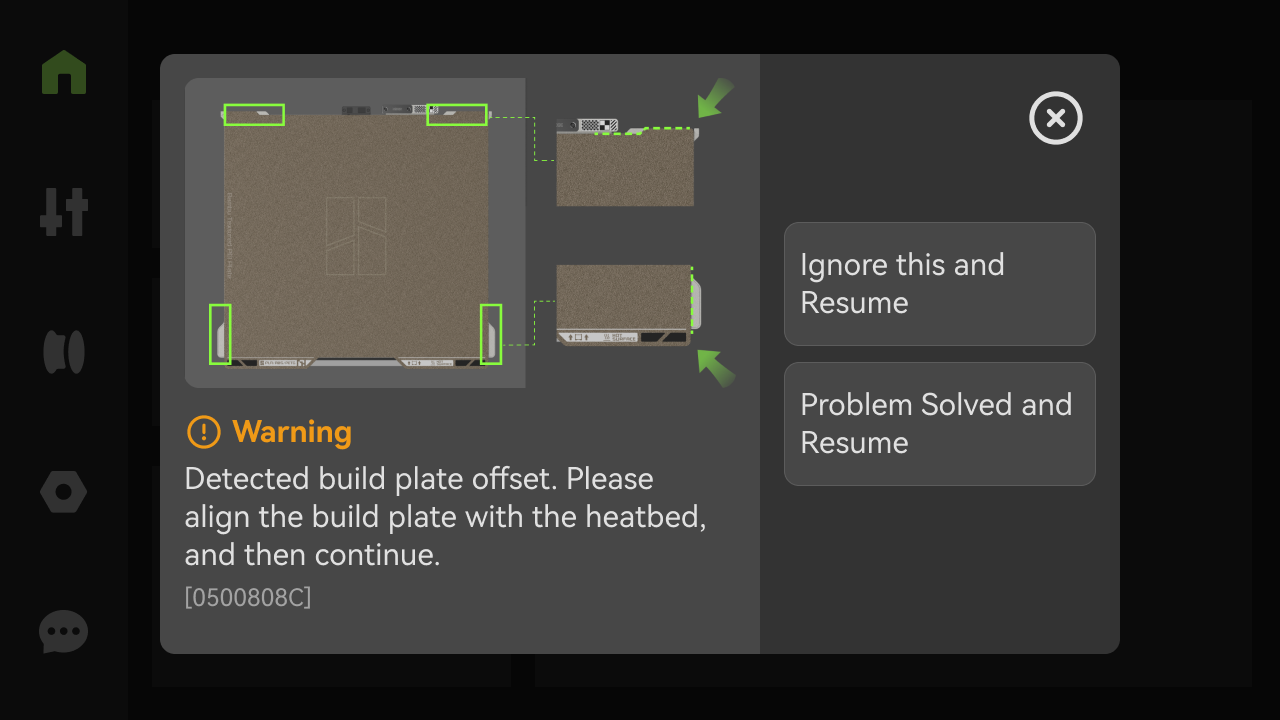

- Added build plate position detection function

This feature detects whether the build plate is correctly aligned during print preparation stage by identifying features like heatbed limit blocks using the liveview camera and toolhead camera. It prevents issues such as build plate interference, bed leveling failure, and printing beyond the edge of the build plate. The feature requires Bambu Studio version V2.2.1.58 or newer.

- Added AI nozzle clumping detection (by liveview camera)

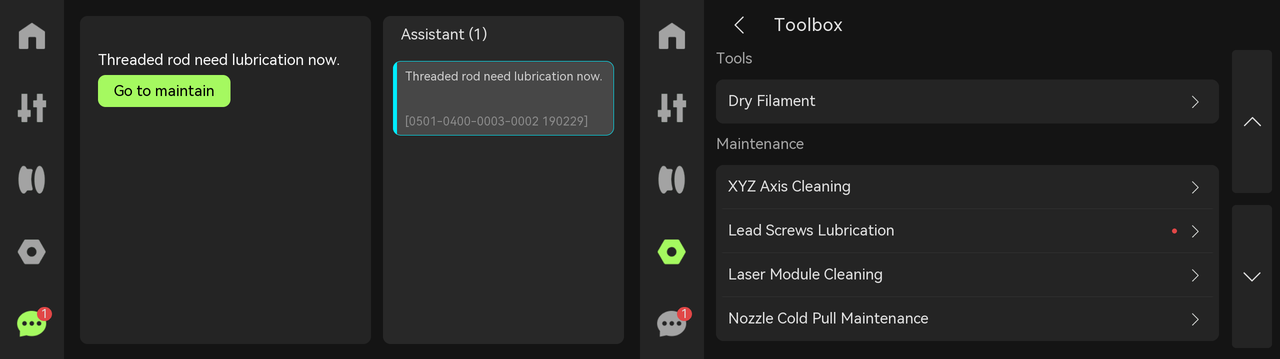

- Added maintenance reminders for XY axis cleaning and lead screw lubrication

When the XY-axis and lead screws reach their maintenance interval, an HMS notification will be triggered. Component usage duration is calculated from initial activation. After updating to this version, certain components may generate reminders – simply follow the prompts. For detailed cleaning and maintenance guidelines, refer to this wiki:https://wiki.bambulab.com/en/h2s/maintenance/period-maintenance

- Added support for the Auto Fire Extinguishing System (sold separately)

When available, it will require a supported version of Bambu Suite coming soon.

- Added BirdsEye camera position check

The system can detect positional shift of the BirdsEye camera due to prolonged use or vibration, then prompts users to run recalibration of the BirdsEye camera for higher accuracy.

¶ Feature Optimizations

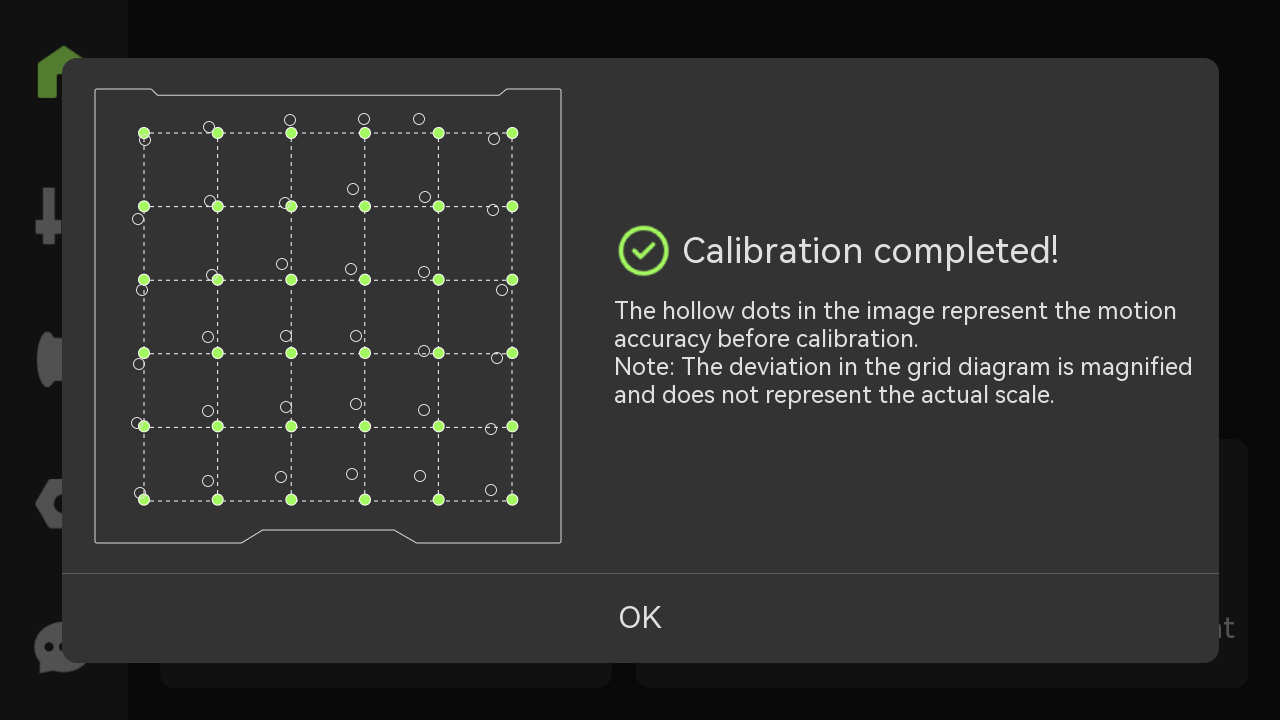

- Optimized the result display of motion accuracy calibration function.

- Optimized energy-saving mode by adding controls of the Status indicator and AMS indicator lights.

- Optimized the humidity display of the first gen AMS.

- Optimized extruder control, improved extrusion overload issue.

- Optimized the notification display of HMS messages.

- Optimized the position accuracy and thickness measurement accuracy of hybrid processing, including laser.

- Improved the reliability of the Power Loss Recovery feature.