¶ Issue Description

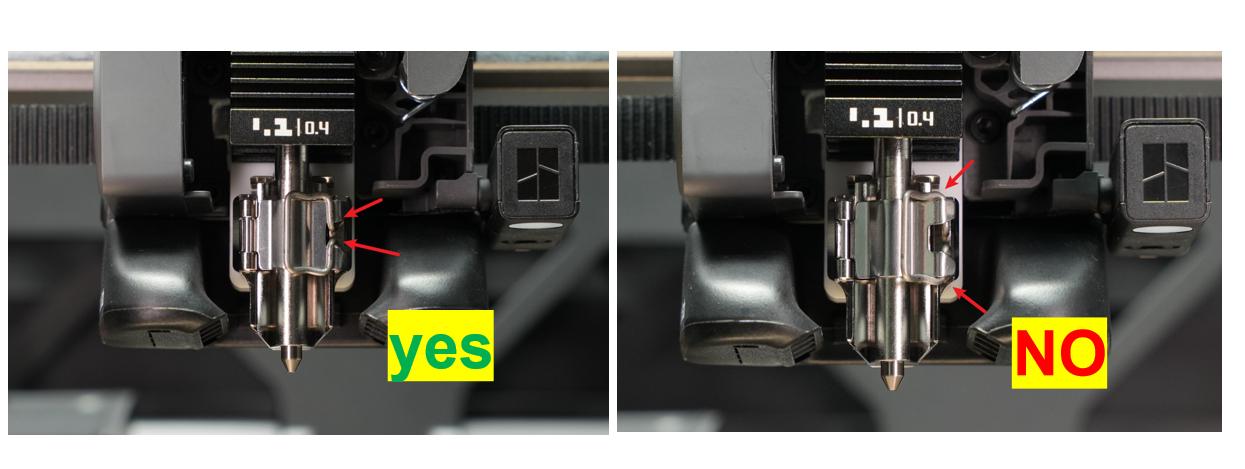

The hotend is secured to the hotend heater using a latch. As the extrusion force changes, the gap between the extrusion force eddy current sensor and the hotend heatsink also changes, enabling the system to measure extrusion force.

If the extrusion force signal frequency is too high, it indicates that the gap between the eddy current sensor and the hotend heatsink is too small. In this case, the system triggers an alert, the heatbed may slightly lower, the print job will be stopped, and an error message will be displayed.

The eddy current coil is installed on the extruder above the hotend. When correctly installed, the gap between the coil and the hotend heatsink should be ≥0.15 mm and ≤0.5 mm

Possible causes:

-

Hotend installed incorrectly

-

Eddy current coil installed too low

-

Loose or disconnected connection between the extrusion force sensor and the TH board

-

Damaged extrusion force sensor

¶ Troubleshooting

¶ Tools, Equipment, and Materials

-

H1.5 hex key

-

A4 paper

¶ Troubleshooting Measures

Users may adjust the order of troubleshooting steps based on the situation.

¶ Step 1: Check Hotend Installation

Replace H2S Silicone Sock for Hotend and Hotend

¶ Step 2: Check Gap Between Eddy Current Coil and Hotend

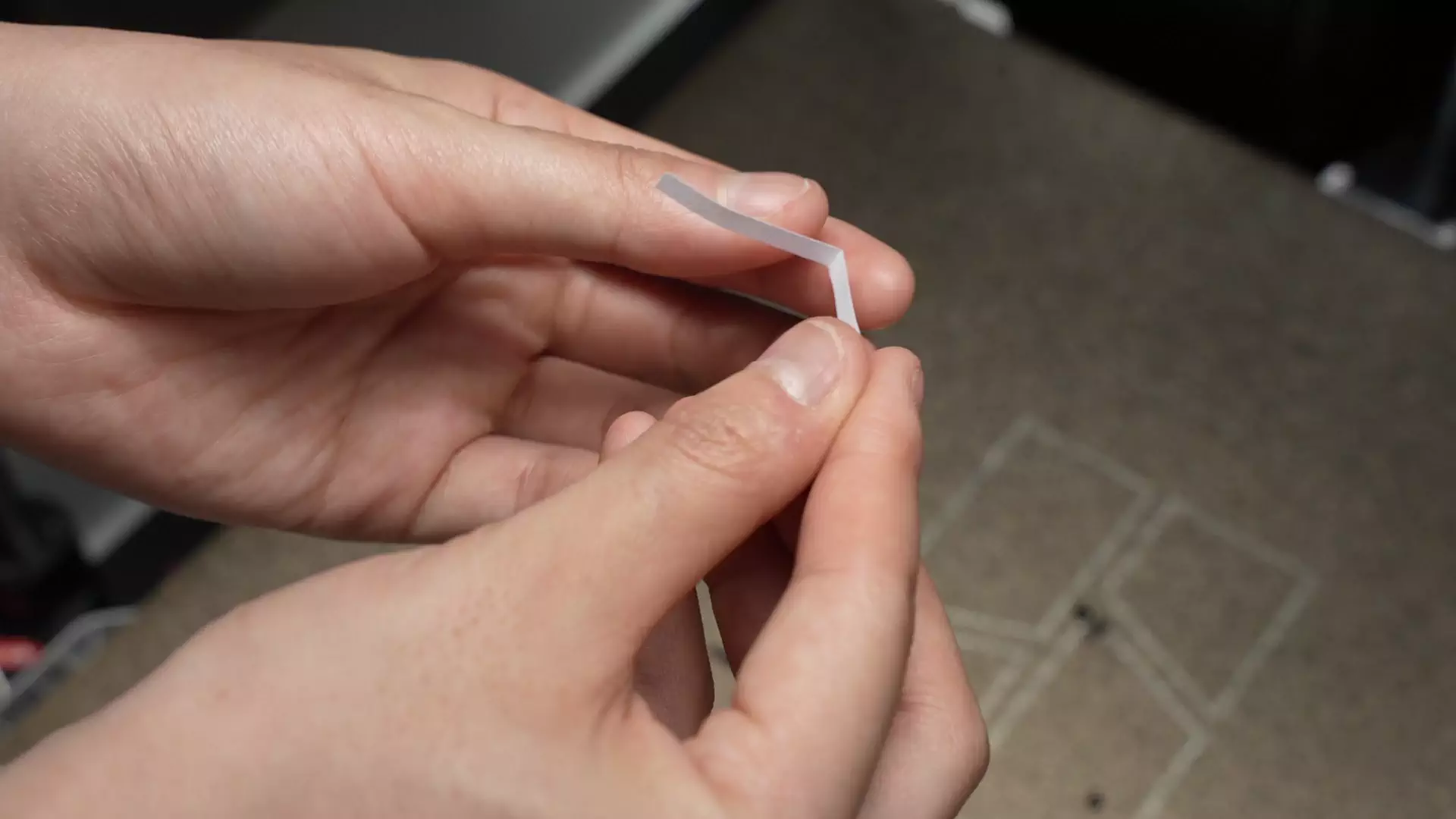

Refer to the Replace H2S Nozzle Eddy Sensor. Fold a piece of A4 paper to measure the gap. If the gap is too small, adjust according to the eddy coil replacement instructions.

Calibrate the eddy current coil position (important):After reinstalling the hotend, fold a piece of paper in half and slide it into the gap between the hot end and the eddy current coil. You should feel slight friction, but the paper should still move freely. This indicates the gap is roughly 0.2–0.3 mm, which is the correct spacing.

¶ Step 3: Check Extrusion Force Sensor Connection to TH Board

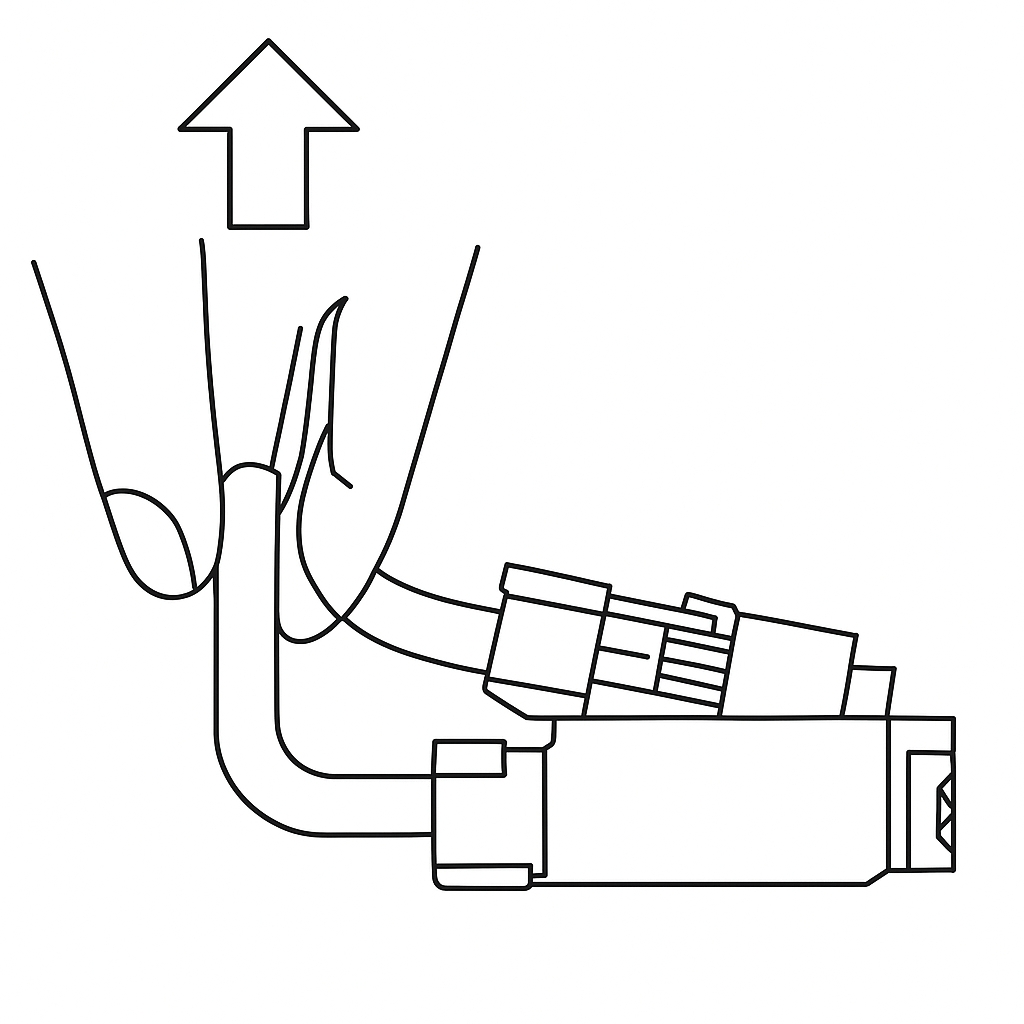

It is recommended to unplug and replug the connector once.

- To unplug: Grip the connector at its base and pull vertically away from the PCB.

- To replug: Connect the fan cable. With the socket side of the connector facing the TH board’s receptacle (the solder-pad side of the connector facing the back of the chassis), align and press the connector down. Tuck the excess cable length under the TH board, then reapply the Kapton tape.

¶ Step 4: Verify Homing or Auto Bed Leveling

Restart the printer and click “Homing” or “Auto Bed Leveling” on the screen. Observe whether the operation succeeds. Observe whether the operation succeeds.

- If homing succeeds, the issue is resolved.

- If the problem persists, continue with further troubleshooting steps.

If the above steps do not resolve your issue, please submit a ticket and upload your printer logs

¶ Conclusion

We hope this guide will provide you with useful information and help you solve problems.

To ensure that you operate safely and effectively, if you have any doubts or questions about any steps in the guide, please contact our Customer Support team before starting the operation.

We are always happy to answer your questions and provide support.

Click here to contact online technical support (service hours 9:00-21:00)