¶ Dots on the printed model walls

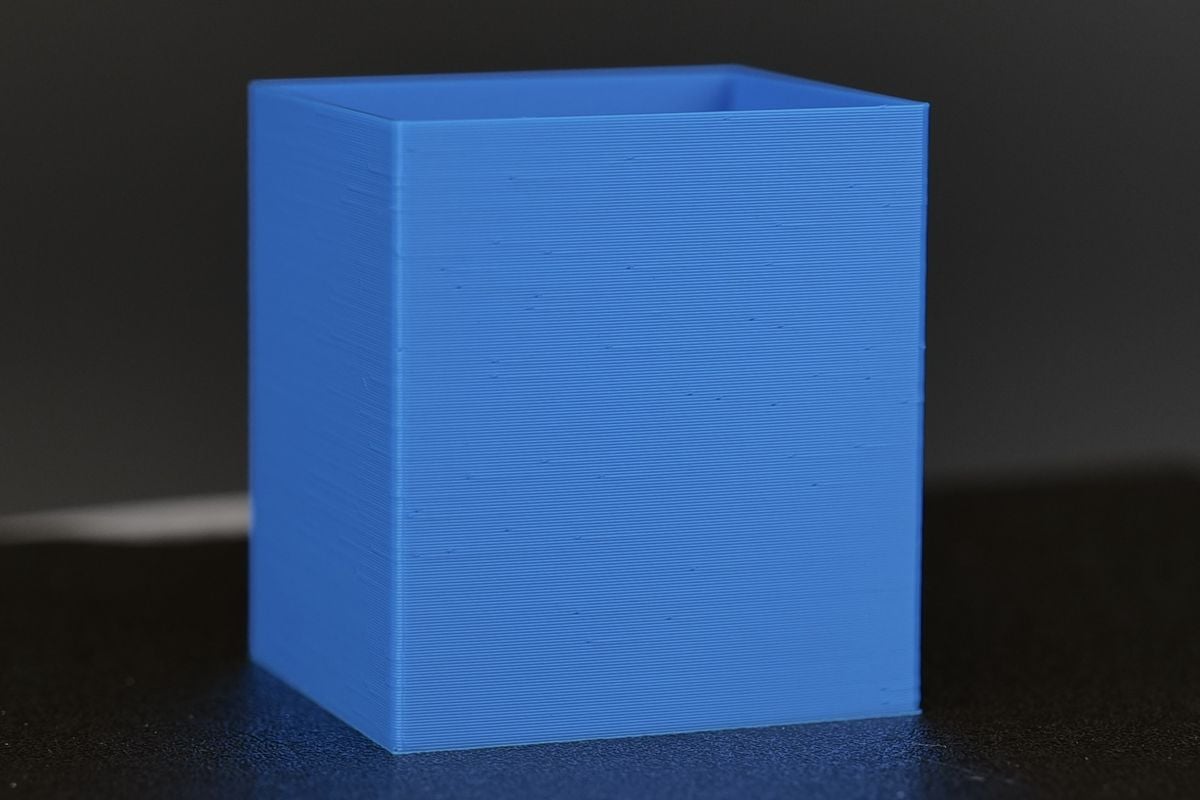

In the example below, the printed model has random dots on the surface.

¶ Potential causes and solutions

¶ 1. Seam position is set to Random

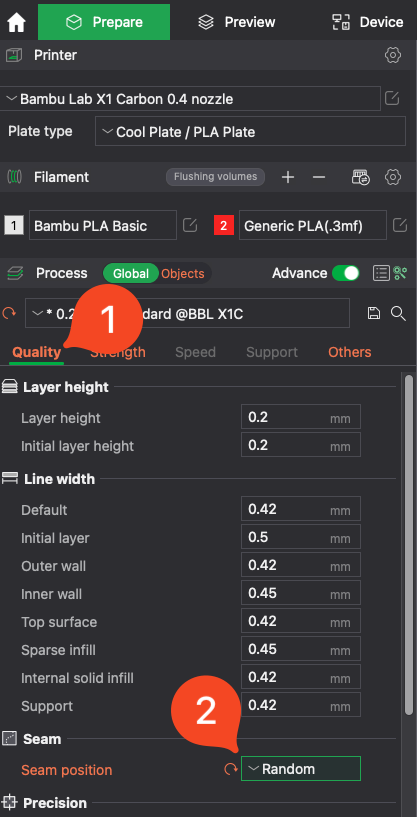

The most common reason for such a print quality defect is the Seam Position being set to Random.

You can find this option in Bambu Studio, under the Quality → Seam menu

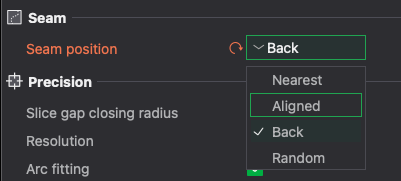

The solution is to simply change the value from Random to Aligned or Back

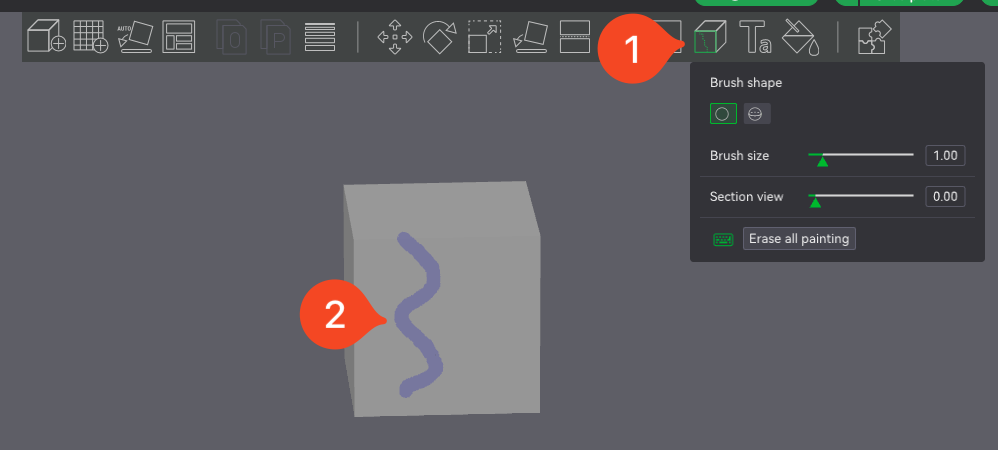

There's also the option to manually paint the seam on your model, using the paint tool in Studio

Simply select the Seam Painting tool then draw the position of the seam on your model, ideally in a place where it cannot be easily seen.

¶ 2. Filament has absorbed moisture, and needs to be dried

Another common reason for similar dots to appear on the walls of the print is moisture that gets absorbed by the filament. When this happens, the moisture will boil away when extruded from the nozzle, and cause small gaps or imperfections in the printed lines.

Filament can absorb moisture from the atmosphere, and for best results, it is recommended to dry all filaments before starting a print. This also applies to new spools of filament.

The X1C and P1S have a dedicated filament drying option in the menu, but if you have a different printer, we recommend using a filament drier.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page - We will do our best to respond promptly and provide you with the assistance you need.