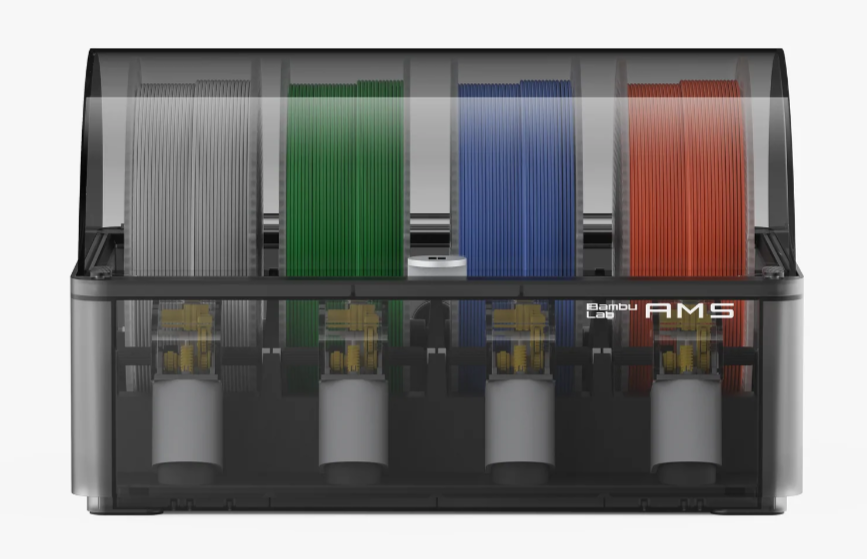

The Bambu Lab AMS is an intelligent system that ensures smooth feeding and automated mid-print filament switching by communicating with the tool head. Most AMS failures occur due to improper usage. Here are some guidelines to minimize issues and enhance the user experience.:

¶ Note:

1. The AMS supports spools with a width of 50-68 mm and a diameter of 197-202 mm. When operating the AMS, we recommend using Bambu Filament, which has been thoroughly tested to work with the AMS. If you purchase a single AMS unit, it will come with a filament buffer. If you plan to connect multiple AMS units together, you will need to purchase the AMS Hub. Here is the guide to Connect AMS Hub and multi-AMS.

2. Avoid using AMS to print flexible materials, including TPU, TPE, or absorbent PVA, as they may get stuck inside the AMS feed tube during printing.

3. Avoid using materials that are too hard (too high modulus) or too brittle (not enough toughness), including third-party fiber reinforcement materials (PA-CF/GF, PET-CF/GF, PLA-CF /GF, etc.), some Silk materials (PLA Silk) and PLA Glow-in-the-dark materials, etc. Because they may wear AMS PTFE tubes during the printing process, brittle breaks, and other problems. However, Bambu PLA-CF, PETG-CF, PAHT-CF and other official filaments are specially optimized and adjusted to ensure that the above problems will not occur in order to print compatible with AMS.

If you want to know more about Bambu Lab filaments, pleasc check this Bambu Filament Guide.

4. We highly recommend using filament with plastic spools that fit correctly inside the AMS. (Please refer to Swapping the new filament with Bambu Reusable Spool) If you prefer to use cardboard spools, we strongly advise using a Spool Adapter/Spool Adapter Ring to reduce the risk of slippage and debris getting left behind in the AMS

5. Please note that the PTFE tubes are consumables and are at risk of wear, as they may rub against the filament over time. We recommend that you check the PTFE tubes for wear during your maintenance of the machine. If the tubes are worn and not replaced in time, this may lead to feeding failures, filament accumulation inside the AMS, etc. If needed, please refer to these tutorial videos on replacing PTFE tubes.