¶ Phenomenon

The brightness of the LED light is dim or it fails to turn on.

¶ Causes & Solutions

1. The LED light is burned out or the cable is damaged, and the LED fill light needs to be replaced;

2. The AP mainboard is burned out and needs to be replaced;

3. The MC-AP connection is disrupted. Depending on the location of the problem, the MC-AP connecting cable or related boards may need to be replaced.

¶ Safety warning and Machine state before starting operation

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Tools needed

- H2.0 hex key

- Multimeter

- Tweezers

¶ Operation guide

¶ 1. Check the AP board

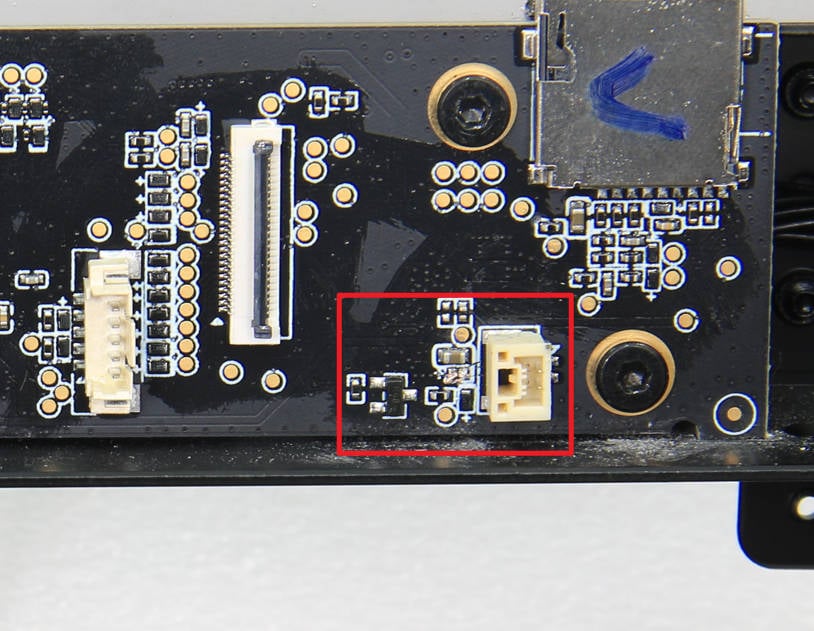

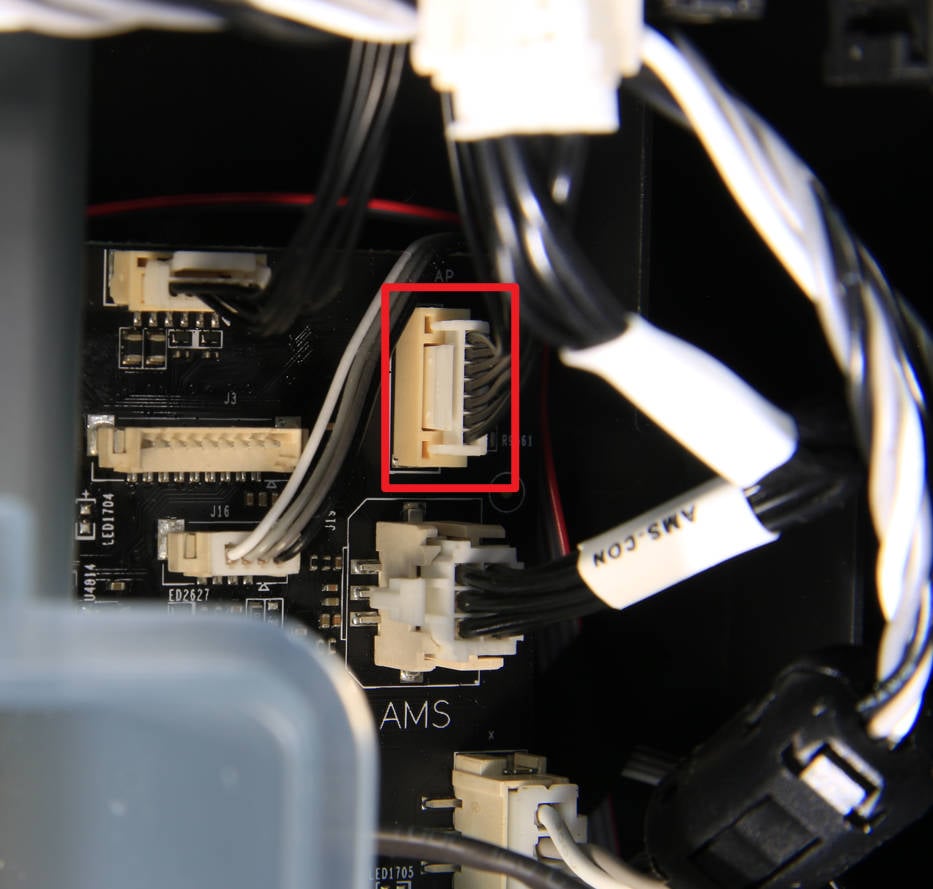

If the fault occurs after the user modifies or replaces the fill light, then the control circuit of the fill light on the AP board may be damaged. The figures below are a detailed view of the connector of the LED fill light on the AP board.

|

|

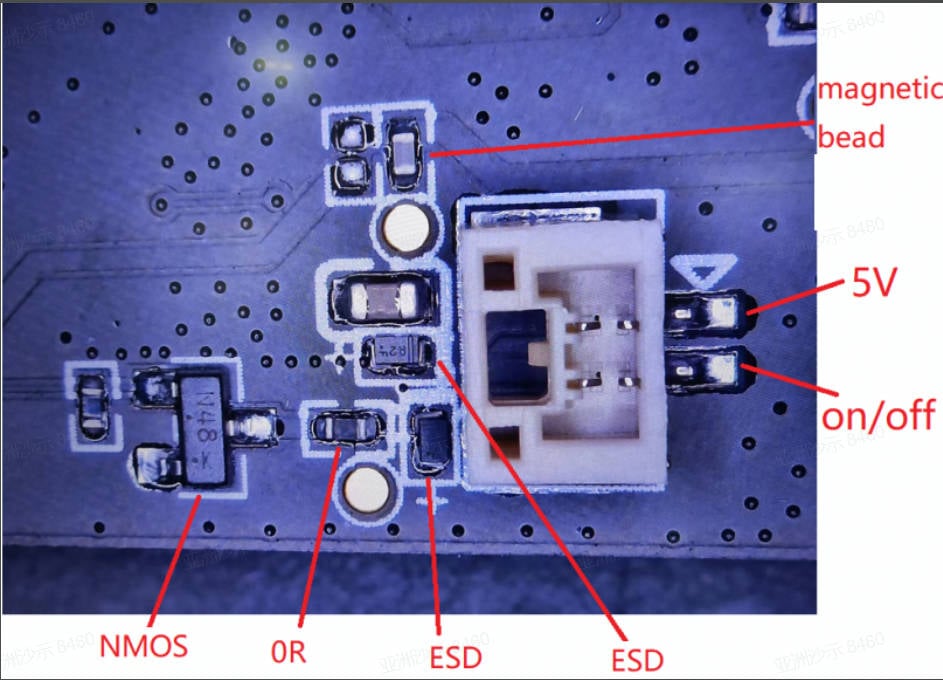

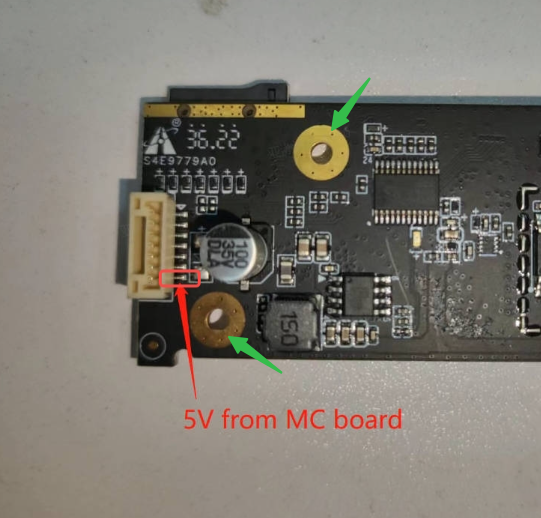

(1) If a lamp with a working voltage of 5V and a working current greater than 0.3A is installed, the 0R resistor and/or the magnetic bead may be damaged. The general fault cause is an open circuit or an increase in resistance, which causes the current path to be interrupted and the lamp cannot be switched on or off.

(2) If a voltage above 5V is injected into the connector, the ESD may have been overheated and damaged. The issue is likely a short circuit, and there will be a burnt mark on the ESD surface.

¶ 2. Check the MC-AP connection

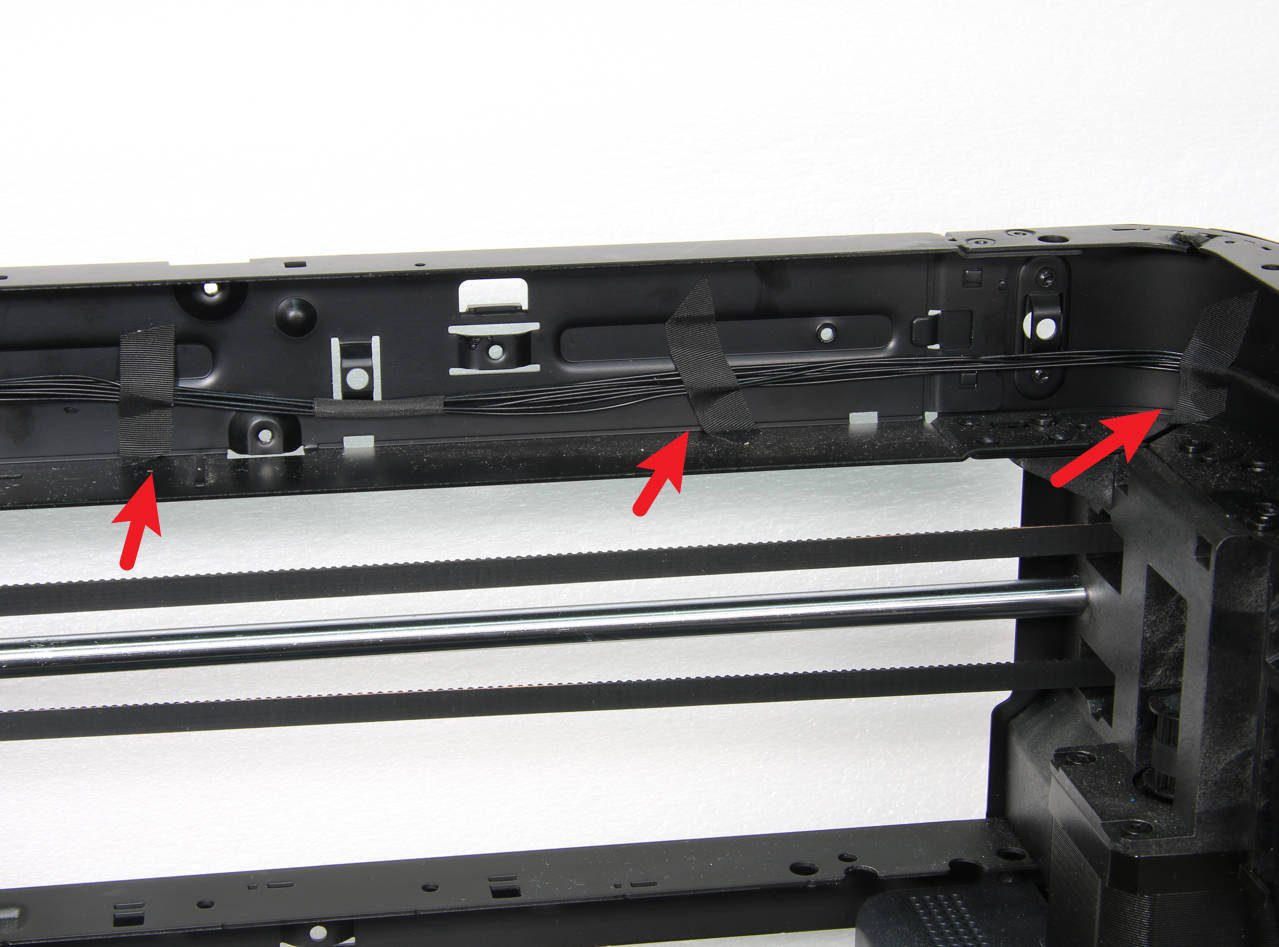

(1) Before dismantling the printer for inspection, you can do a simple pre-inspection: Power on the printer, turn on the LED light, then remove the fixing tape of the AP-MC connecting cable, shake the entire cable, and check whether the LED light will return to normal or not. If it can return to normal, it means that there is poor contact and cable contacts need to be checked.

|

|

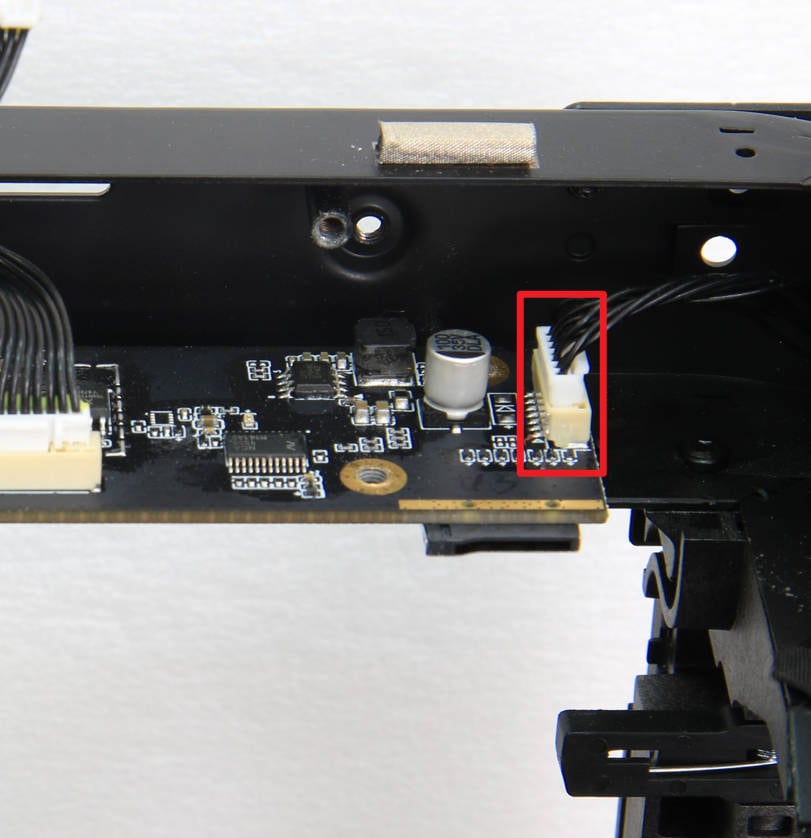

(2) Refer to the relevant steps of the MC-AP cable, find the connectors of the cable on the AP board and MC board, mainly to confirm the connector and connecting cable between MC and AP; see whether there is any disconnection, falling off, or other poor contact problems; and confirm that the plugs and seats are normal and without damage.

|

|

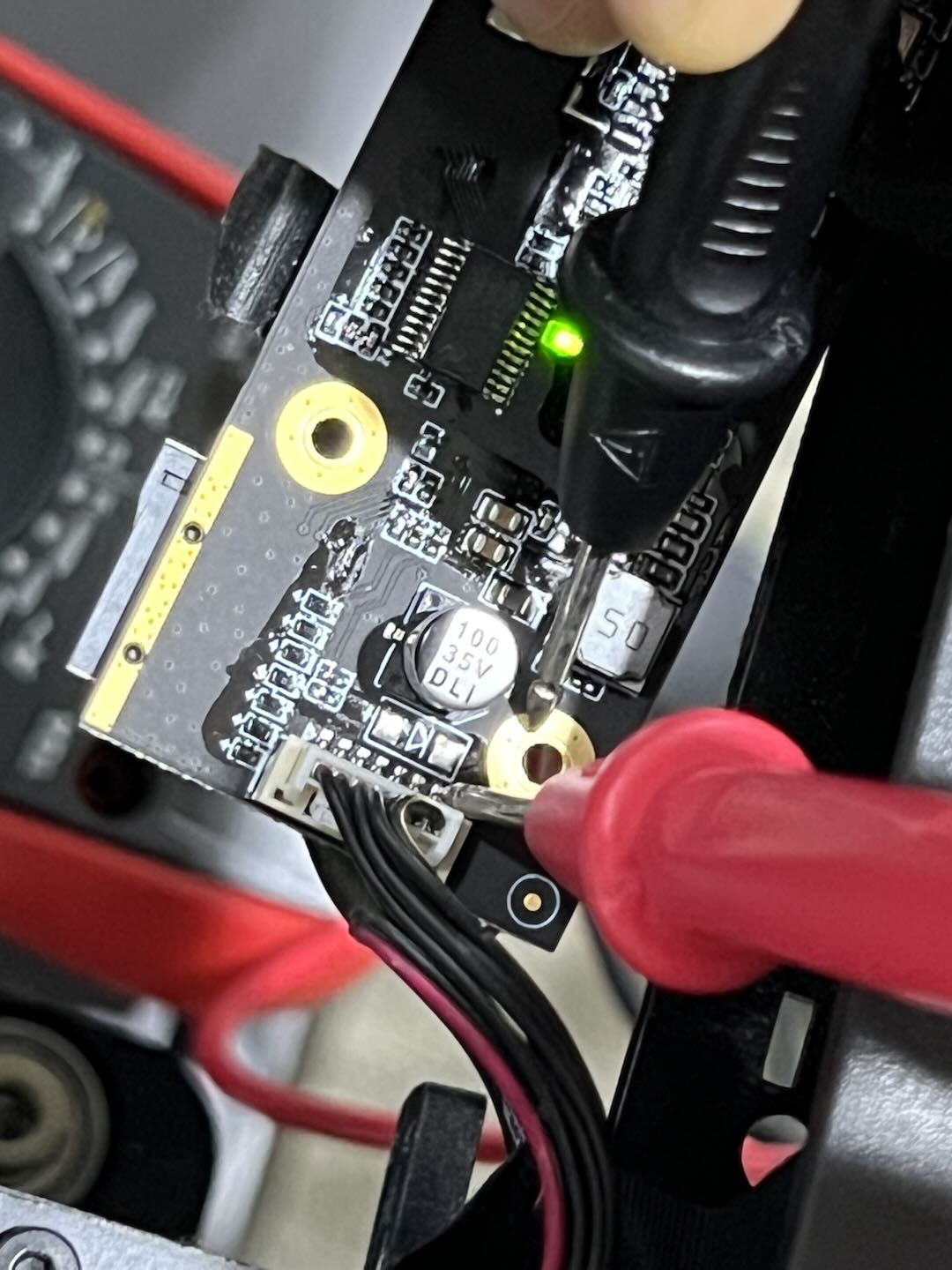

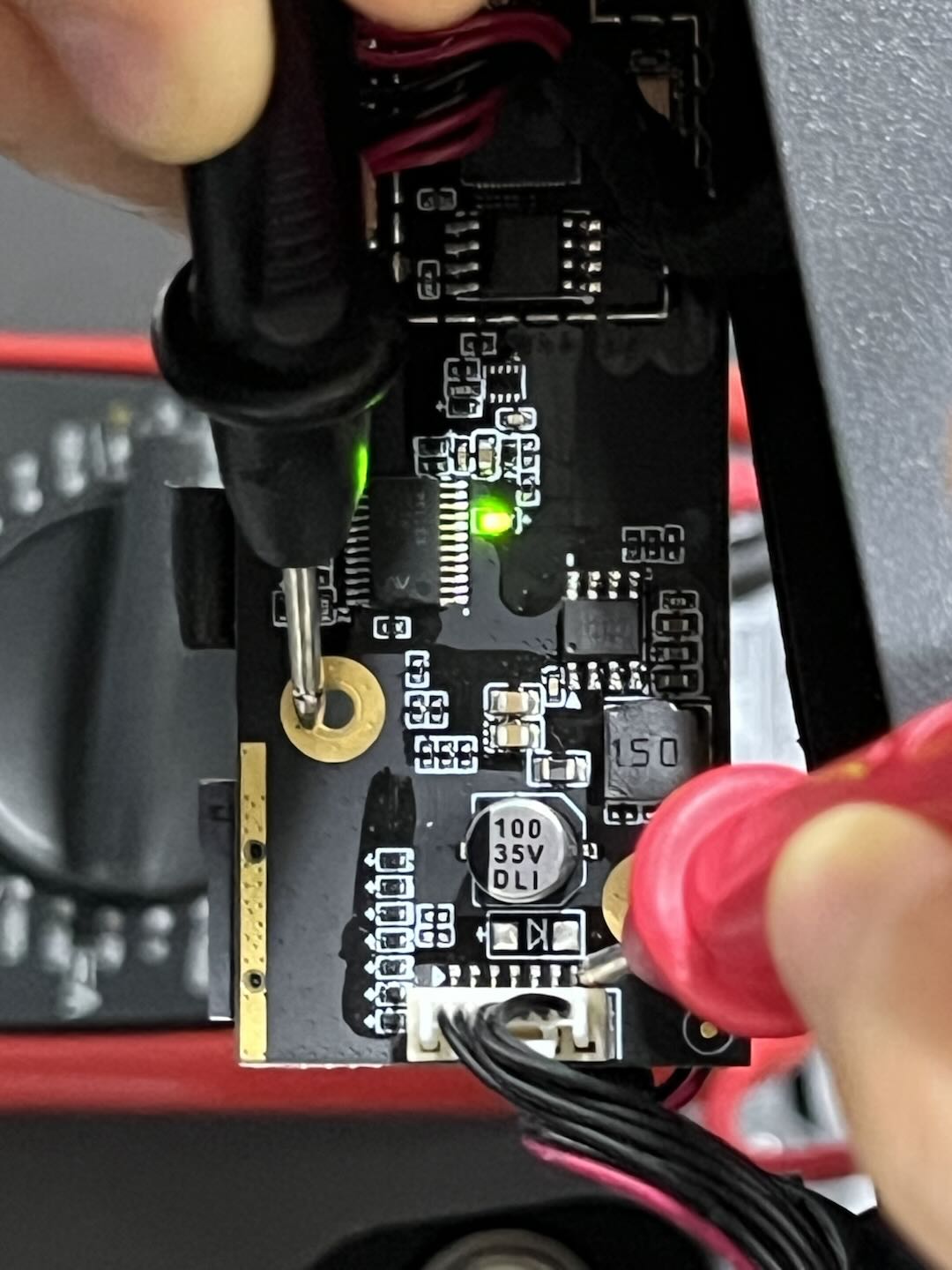

(3) Users with a multimeter can keep the MC-AP connected after loosening the AP mainboard. Then, start the printer and connect the black probe of the multimeter to the 5V pin on the AP board to test the output voltage, confirming whether it is normal.

|

|

¶ 3. Check the LED fill light

If the printer functions well except for the LED fill light turn on failure, you can try exchanging the LED fill light if there are more than one P1P printers at home.

If there are no multiple printers, directly purchase or apply for a new the LED fill light for for replacement.

¶ 4. Check other faults

If the printer is accompanied by other faults besides the abnormal LED fill light, please solve the problem in conjunction with the troubleshooting guidelines for other faults.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.