¶ Introduction to line width

¶ What is line width?

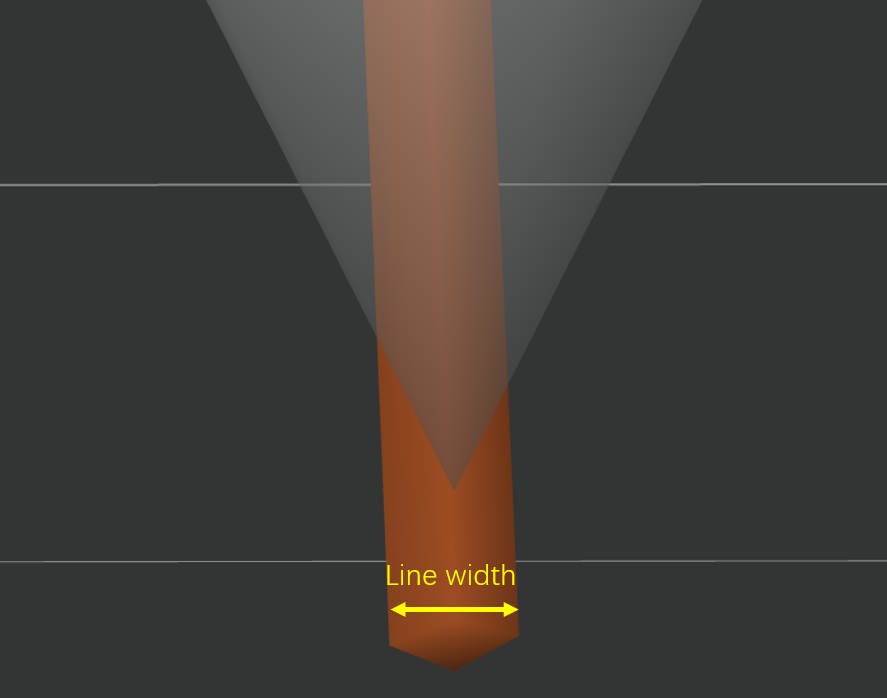

Line width means the width of a single melted filament extruded by the nozzle during the printing. Usually, the width of the extruded material is almost the same as the diameter of the nozzle.

The width of the nozzle extrusion material is determined by the nozzle diameter, that is, how wide the nozzle diameter is, and how wide the material can be extruded. If you want the line width to be wider or thinner than the nozzle diameter, you need to control the extrusion flow. Since the nozzle diameter is fixed, the set line width and the nozzle diameter are usually close, if the line width and the nozzle diameter difference is too much, it will not be able to get good print quality. For various diameter nozzles, it is usually recommended not to modify the default line width. If you want to modify it, it is recommended to set the line width range between 0.75* nozzle diameter ~ 1.5* nozzle diameter.

¶ How to control line width

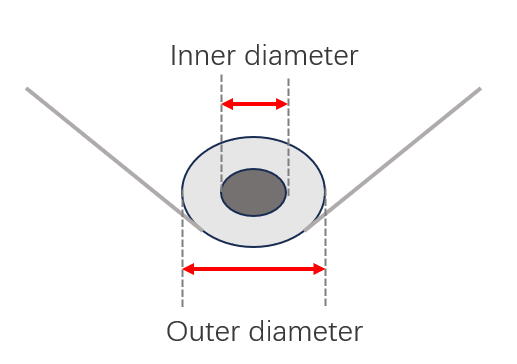

How to control the line width: During nozzle movement, the printer can increase or decrease the flow rate of the extruded filament to adjust the linewidth, that is, adjust the extrusion flow rate/tool head movement speed ratio. When the nozzle moving speed remains the same, reducing the extrusion flow rate (extrusion flow per unit time) will make the line a little thinner. With the increase in the extrusion flow rate, due to the increase in the amount of extruded filament, the extra filament will be flattened by the nozzle, forming a line wider than the inner diameter of the nozzle. It should be noted that the maximum line width that can be extruded and flattened will not exceed the outside diameter of the nozzle. The nozzle diameter we usually say refers to the "inner diameter" of the nozzle, that is, the channel through which the filament is extruded, as shown in the following figure:

¶ Examples of print effects with different line widths

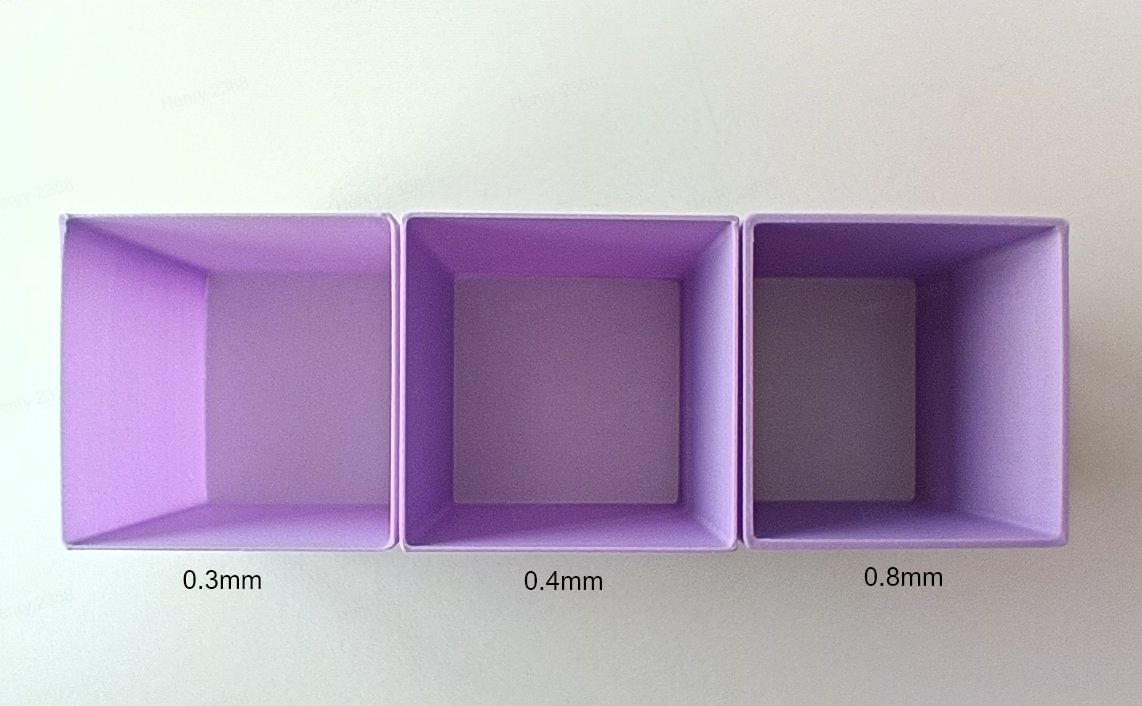

The following is the comparison of the effect of different outer wall line widths with 0.4mm nozzle:

¶ Limits on line width Settings

The nozzle can only control the line width when the filament is extruded in the previous layer or on the heat bed. If it is extruded in the free air, since the material cannot be flattened, the resulting shape will always be circular (as shown in the figure below), so the line width cannot be set for the bridge and overhang wall. You can refer to bridge settings.

¶ The cross-section of the extruded line

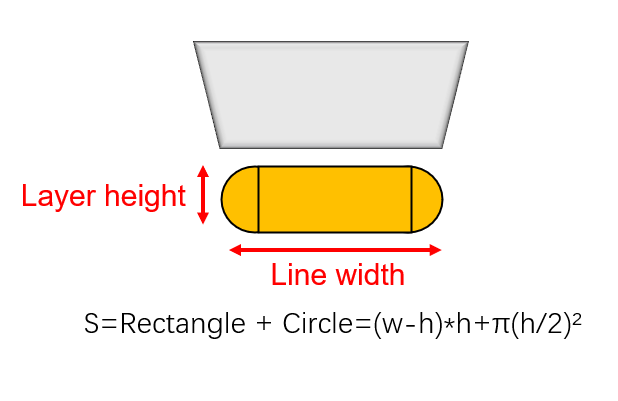

Due to the limitation of the heating capacity of the hot end, the printer has a maximum volumetric speed limit for various filaments, that is, a limit on the maximum flow rate that can be extruded per unit time. Maximum volumetric speed = Cross-sectional area of extruded line * Maximum printing speed.

For the shape and cross-sectional area calculations of the extruded lines, we assume that the cross-sectional shape of the extruded material is a rectangle with semicircular ends, as shown in the figure below (here we refer to Slic3r):

¶ Line Width Settings

In Bambu Studio, you can set the line width for each line type in Process - Quality - Line Width.

¶ Default

If the line width of other line types is set to 0, the default line width is used.

¶ First layer

Set the line width of the first layer. If it conflicts with the line width of other line types, the first layer line width is used. The default line width of the first layer is usually wider because appropriately increasing the line width/layer height ratio of the first layer can enhance adhesion and improve the printing success rate.

¶ Outer wall

Set the line width of the outer wall. The outermost shell of the model is the outer wall.

¶ Inner wall

Set the line width of all inner walls. When you set multiple wall loops, except for the outer wall, the other loops of walls are internal walls

¶ Top layer

Set the line width of the top surface of the model. The top layer refers to the top surface of the model, as shown in the figure below:

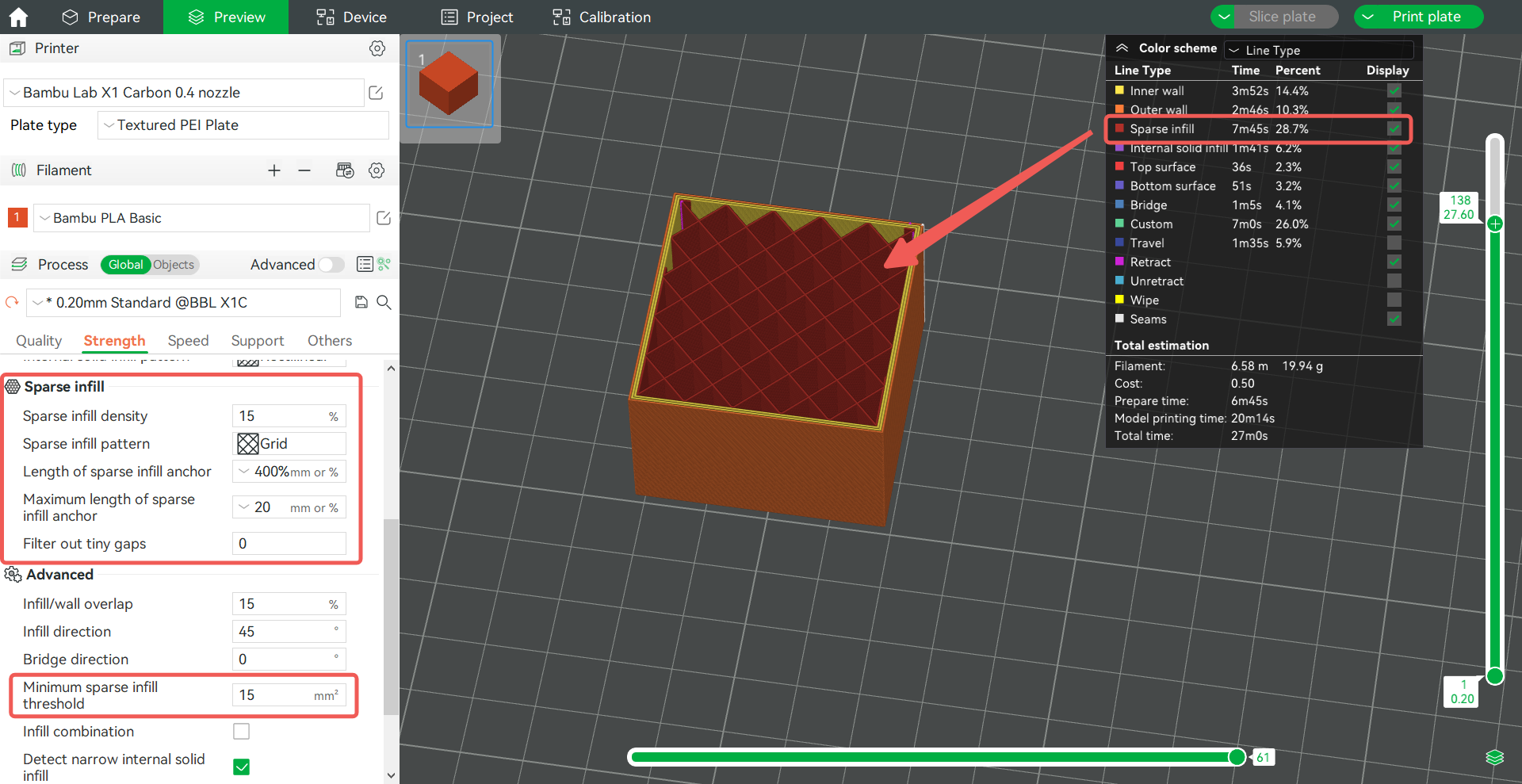

¶ Sparse infill

The line width of all sparse infill. In addition to the top shell and bottom shell, as long as there is an infilling area bigger than the "Minimum sparse infill threshold" in other layers, it belongs to sparse infill.

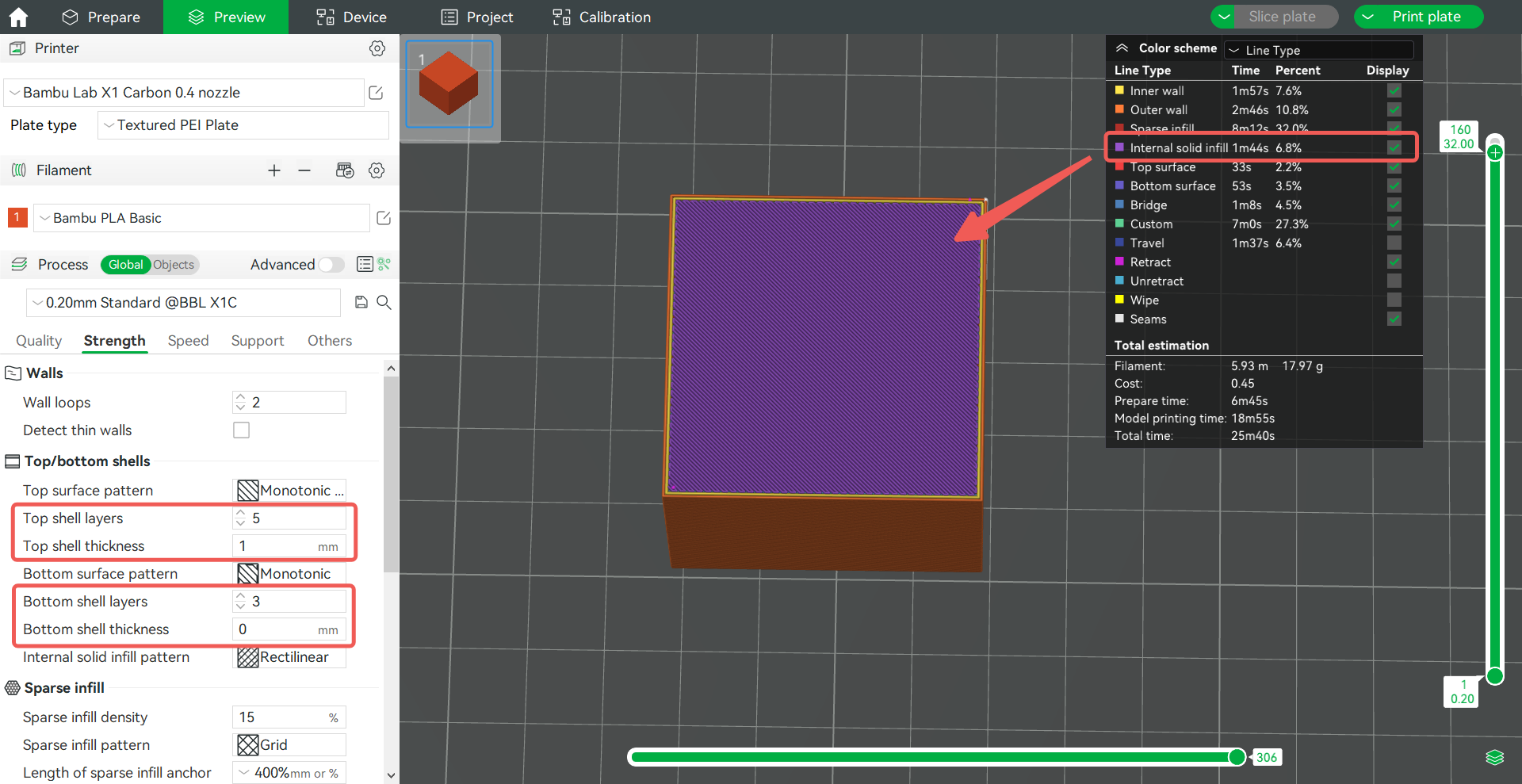

¶ Internal solid infill

Set the line width of the internal solid infill. When you set more than 1 bottom shell or top shell, except for the bottom and top layers, the other bottom/top layers belong to internal solid infill. In addition, sparse infill areas that are smaller than the “Minimum sparse infill threshold” will be replaced by internal solid infill.

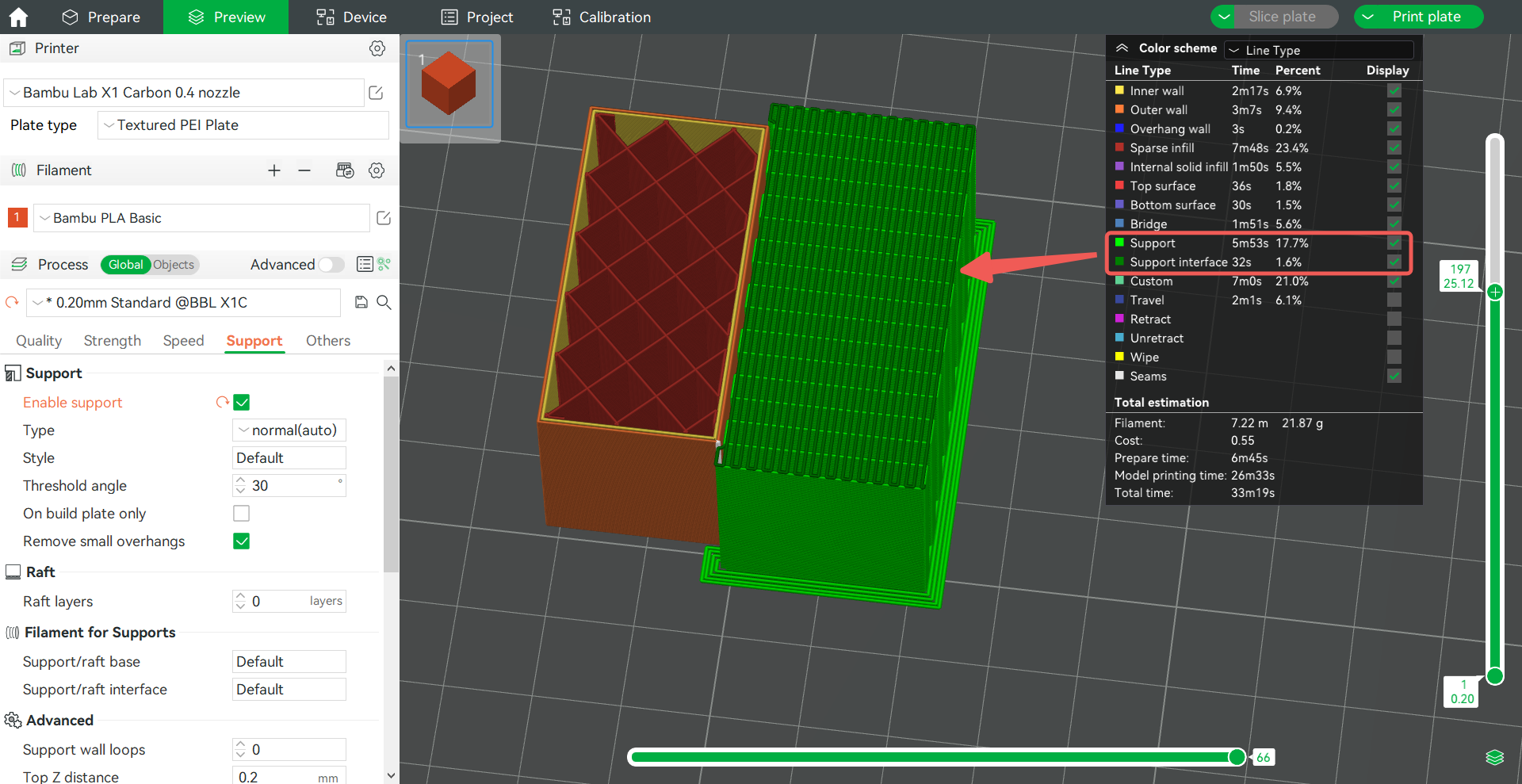

¶ Support

Set the line width of the support and support interface. You can refer to this wiki for details on support and support interface: Support | Bambu Lab Wiki