¶ X1/P1 series printers

¶ What it is

When doing the Z-axis homing, the printer will calculate the touch position when the nozzle ---- or anything else --- touches the heat bed by the 3 force sensors.

Normally, if it is the very nozzle that touches the heat bed, then the calculated position will be the same as the toolhead position. Otherwise, it is possible that it is not the nozzle that touches the heat bed, which may be:

- The build plate hasn't been placed correctly and has touched the excess chute

- The build plate hasn't been placed correctly and has touched the z-axis slider stop on the left

- The build plate hasn't been placed correctly and has touched the inner liner of the printer

- Something has been dropped on the top of those 3 z-axis sliders and had made a false signal

- There is stuff placed at the bottom of the printer chamber and has stuck the heat bed when doing z-axis homing

- The problem might be that the X and Y axis homing process is disrupted by some foreign matters, which makes the position of the tool head not at the center of the build plate.

¶ Troubleshooting guide

¶ step 1

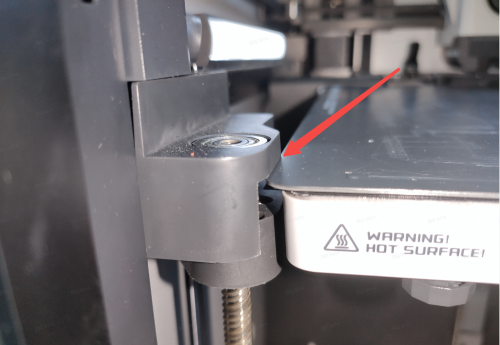

Lift the heat bed until its height is near the same as the excess chute, and check if the build plate has touched the surface of the excess chute:

¶ step 2

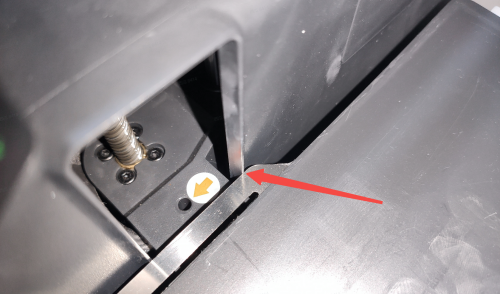

Lift the heat bed until it is near the Z slicer stopper on the left, and check if the edge of the build plate will touch the stopper:

¶ step 3

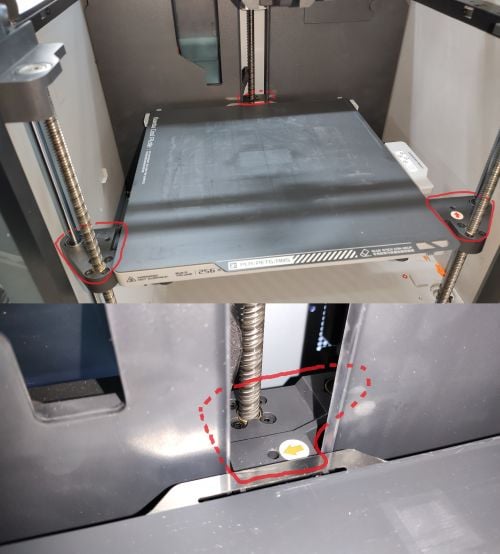

Check the rear edge of the build plate, to see if it is too close to the inner liner of the printer:

¶ step 4

Lower the heat bed, and check if there is anything on the top surface of the 3 Z slider:

In addition to checking the surface of the slider for foreign objects, you will also need to check whether the Z-axis bearing is raised in this step.

If you find the bearing is raised, please refer to the operation video below to reset the bearing. It is important to note that before following the video, please remove the hotend assembly of the tool head (click here for a guide to disassembling the hotend assembly) and then perform the operation in the video.

If you encounter any difficulties during this process, please contact after-sales service for assistance.

|

|

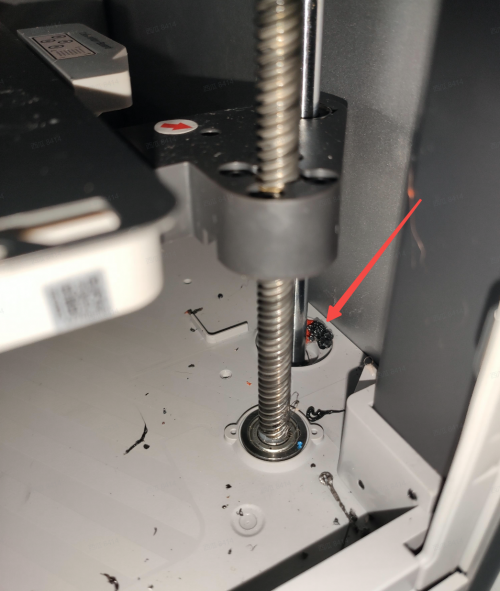

The purpose of this operation is to press the raised bearing back into place using the retaining block:

https://public-cdn.bblmw.com/wiki/X1/fix_bearing_up.mp4

Raised bearings are usually caused by the presence of foreign material, such as scrap, in the three holes at the bottom of the linear rods, which causes the bearing to be squeezed and raised out of place. If there is any foreign material in these holes, make sure they are thoroughly cleaned out or the failure may recur.

¶ step 5

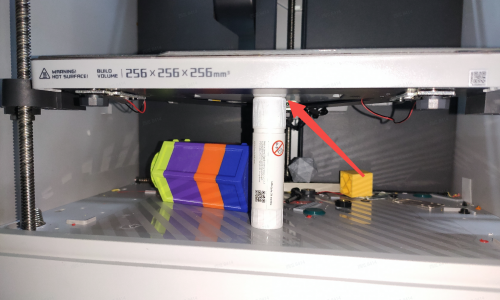

Clean the bottom of the printer. If the heat bed is near the bottom of the printer and has contact with stuff in the bottom initially, the homing process may get disrupted:

¶ step 6

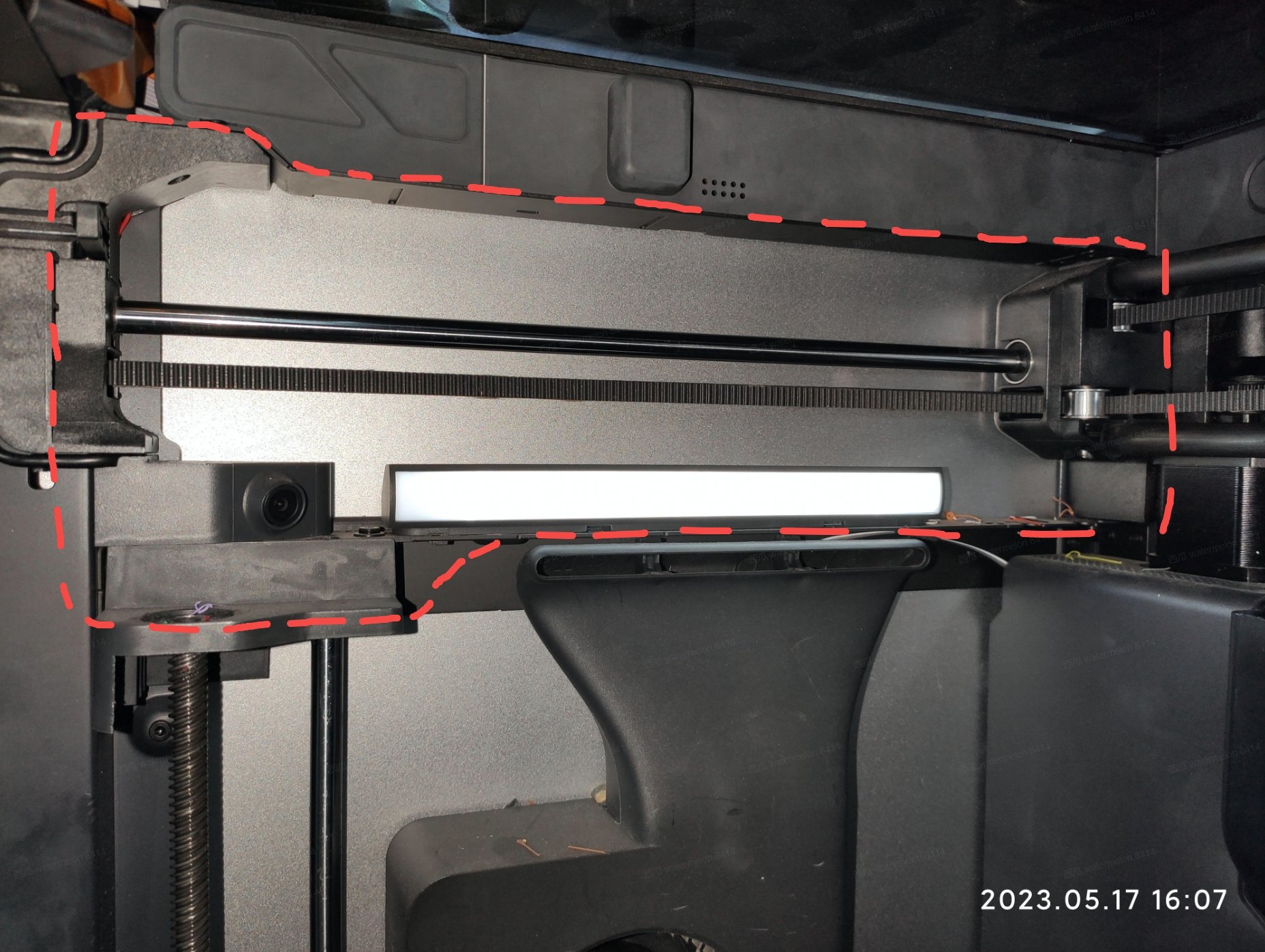

As the inner space of the XY gantry is very compact, ensure the full movement region of the X and Y sliders is clean, with no 3rd party parts or anything else being installed or placed near the slider movement region.

|

|

¶ A1 series printers

A1 series printers are equipped with a printing board detection function, you can refer to this wiki for details: Build plate detection | Bambu Lab Wiki

So, before printing, it is necessary to properly place the printing board on the heat bed. If this error occurs, there may be the following reasons:

1. The build plate was not placed or was placed crooked, resulting in the nozzle not touching the build plate correctly during detection;

2. Using a third-party build plate with different structures results in the nozzle not being able to touch the plate at the detection position;

The build plate detection process is shown in the following GIFs:

¶ Error message:

HMS_0300-0D00-0001-0003: The build plate is not placed properly.

"The build plate is not placed properly."

The error code below shares the same issue as this one:

0300-0D00-0001-0004

0300-0D00-0001-0005

0300-0D00-0001-0006

0300-0D00-0001-0007

0300-0D00-0001-0008

0300-0D00-0001-0009

0300-0D00-0001-000A

0300-0D00-0002-0003

0300-0D00-0002-0004

0300-0D00-0002-0005

0300-0D00-0002-0006

0300-0D00-0002-0007

0300-0D00-0002-0008

0300-0D00-0002-0009

0300-0D00-0002-000A

0300-0D00-0001-0003

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a Technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.