¶ What the error is

As time goes by, the pretension force of the timing belt will drop gradually, and the stiffness will get low. High print acceleration will influence the print quality if the stiffness is too low. So when the printer starts the resonance calibration, it will calculate the pretension status of the belt; if it is loose, this error will be present.

This wiki article equally applies to the HMS_0300_1100_0002_0001: The resonance frequency of the Y axis is low. The timing belt may be loose.

¶ Tools and materials needed

- IPA-Isopropyl alcohol (Or ethanol)

- Clean cloth

¶ Safety warning

Due to the need to manually move the toolhead and spray the cleaning agent, it is necessary to disconnect the power supply in advance.

¶ Troubleshooting guide for X1 and P1 series printers:

Follow the instructions in this video to re-tension the belt and clean the carbon rods:

These wiki guides can also help: Belt tensioning procedure | Bambu Lab Wiki; How to clean the carbon rods for Bambu Lab Printers | Bambu Lab Wiki

¶ Troubleshooting guide for A1 series printer:

The possible problems are ranked by probability: 1. Software bug. 2. The timing belt may be loose.

¶ 1. Solution for software bug:

We expect to release a new version of Bambu Studio in mid-November 2023. Until then, you can ignore this error message.

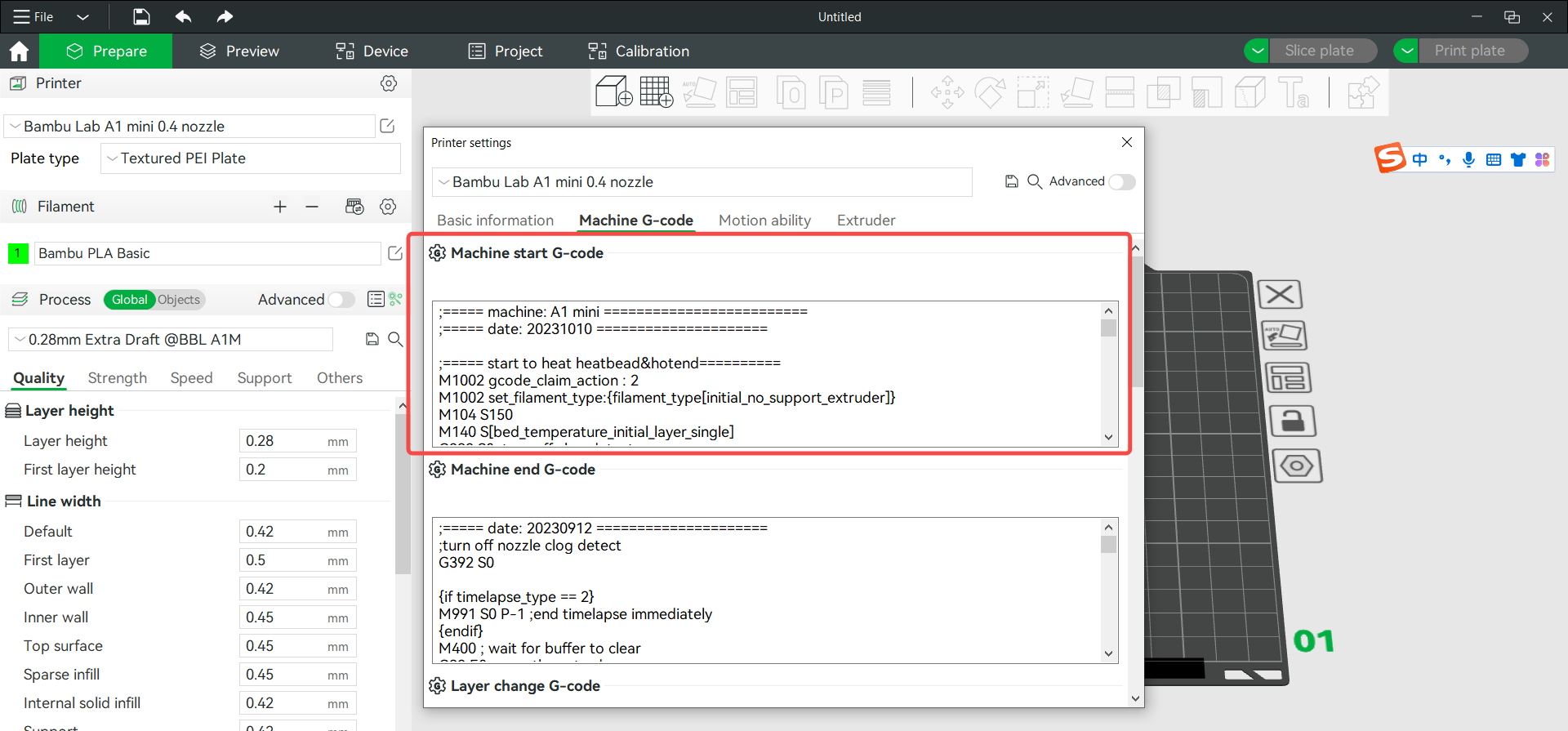

Alternatively, you can replace the "start gcode" in the current latest version of Bambu Studio (click here to download).

Click here to download the start gcode

If you encounter this error message with the built-in model for printing, you can click here to download the latest version of the built-in slice file. Then, copy it to the micro SD card to replace the factory-installed built-in model.

¶ 2. Tighten the belt as the guide below:

Use an H2 Hex key to loosen the screw on the back of the toolhead (as shown below), and tighten it again. Then perform the printer calibration again, and the error should disappear.

|

|

Do not operate the screw on the side of the toolhead, as shown below:

Get more information on A1 series timing belt tensions:

¶ Error message

HMS_0300-1000-0002-0001: The 1st order mechanical resonance mode of X axis is low.

"The 1st order mechanical resonance mode of X axis is low."

The error code below shows the same problem of different axes:

0300-1000-0002-0001

0300-1100-0002-0001

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.