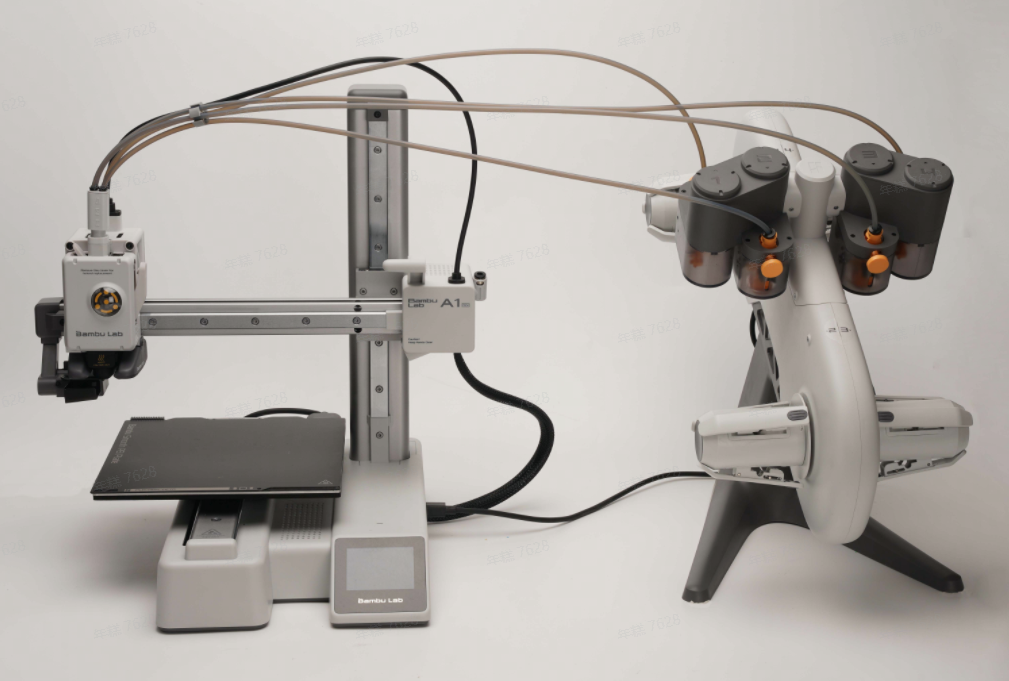

This article details the troubleshooting and solutions for filament loading and unloading failures in the AMS Lite. If you encounter loading or unloading failures while using the printer, you can refer to the error messages displayed and the specific fault symptoms to diagnose and resolve the issue following the guidelines provided in this article.

Given the detailed content, you may directly navigate to relevant sections according to the specific error messages:

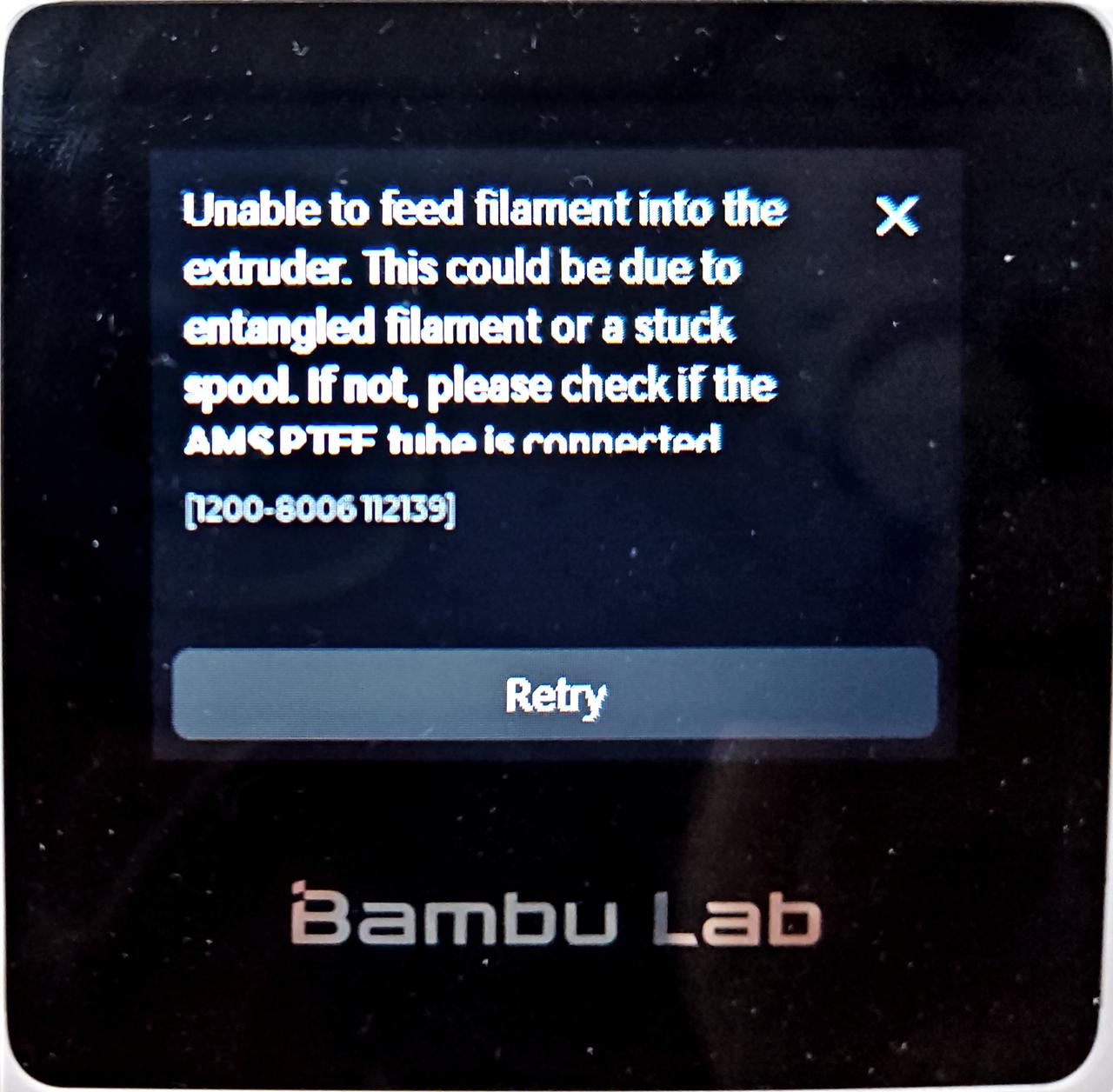

¶ Unable to feed filament into the extruder

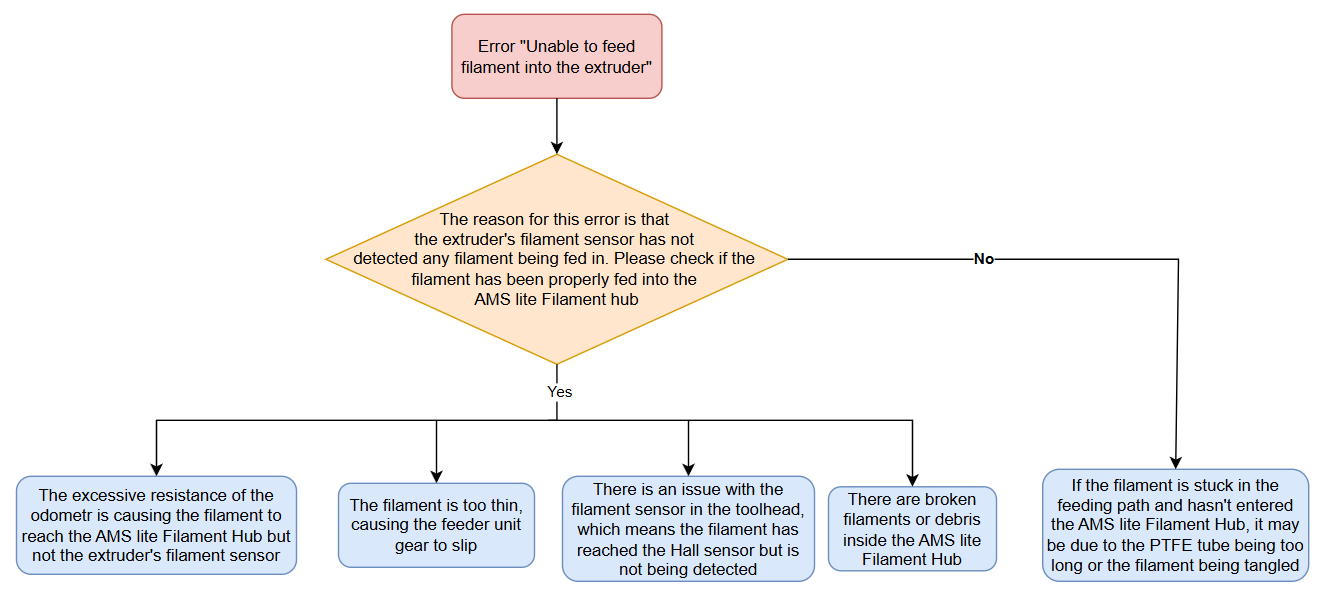

This error indicates the extruder's filament sensor continuously fails to detect filament during feeding.

Troubleshooting steps:

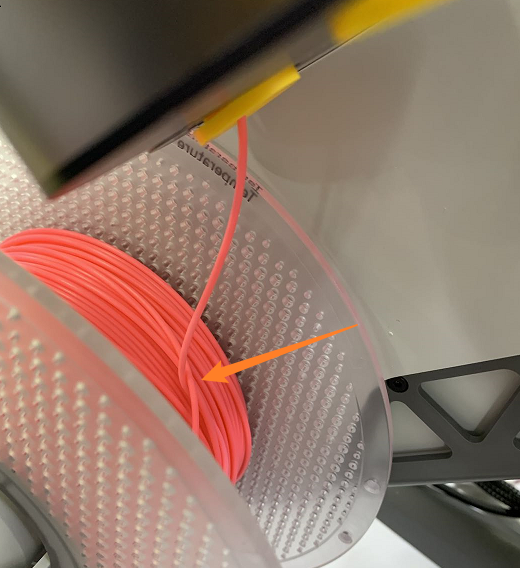

¶ 1. Filament tangled

Tangled filament may cause feeding failure. Check if the spool has knots or snags.

knots |  snags |

¶ 2. Exceeding Maximum Feeding Distance

AMS Lite's maximum effective feeding distance is 1.2 meters. If the filament sensor still doesn't detect filament after this distance, the error occurs.

¶ 3. The odometer wheel of the AMS Filament Funnel Unit is stuck

If a specific slot has significantly higher resistance compared to the others:

-

Check the corresponding slot's feeder gears for any debris and clean them promptly.

-

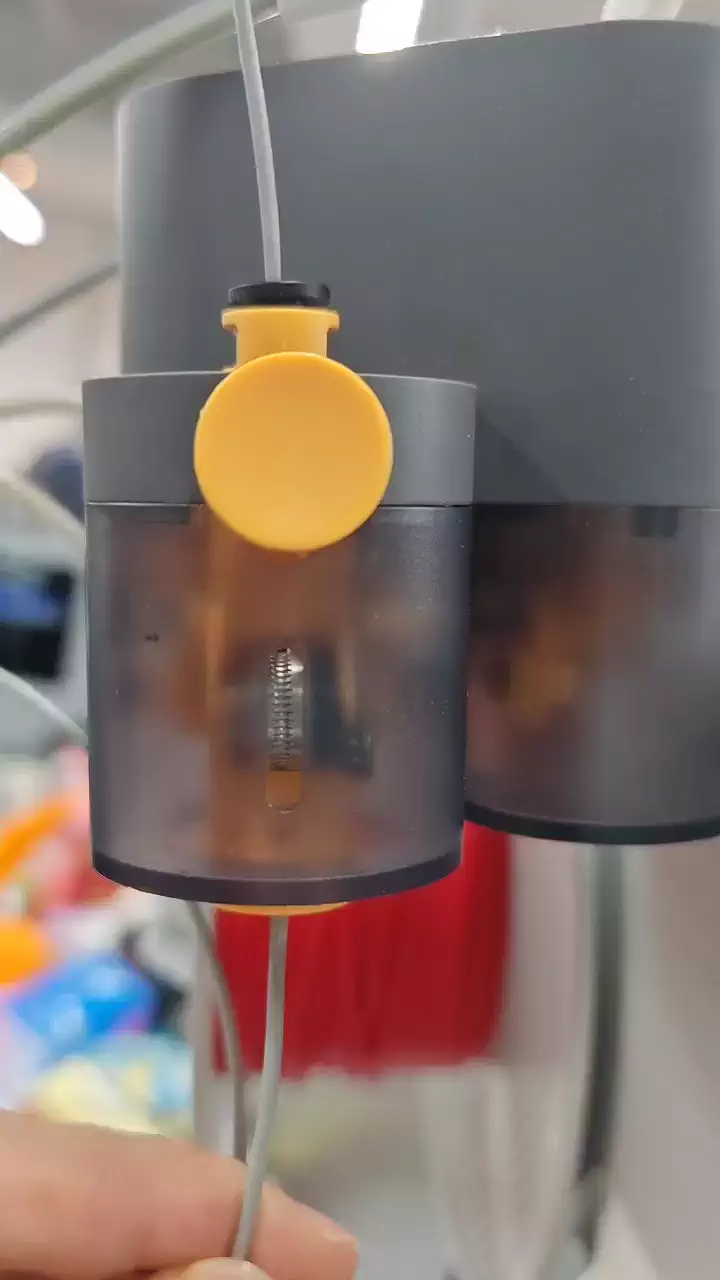

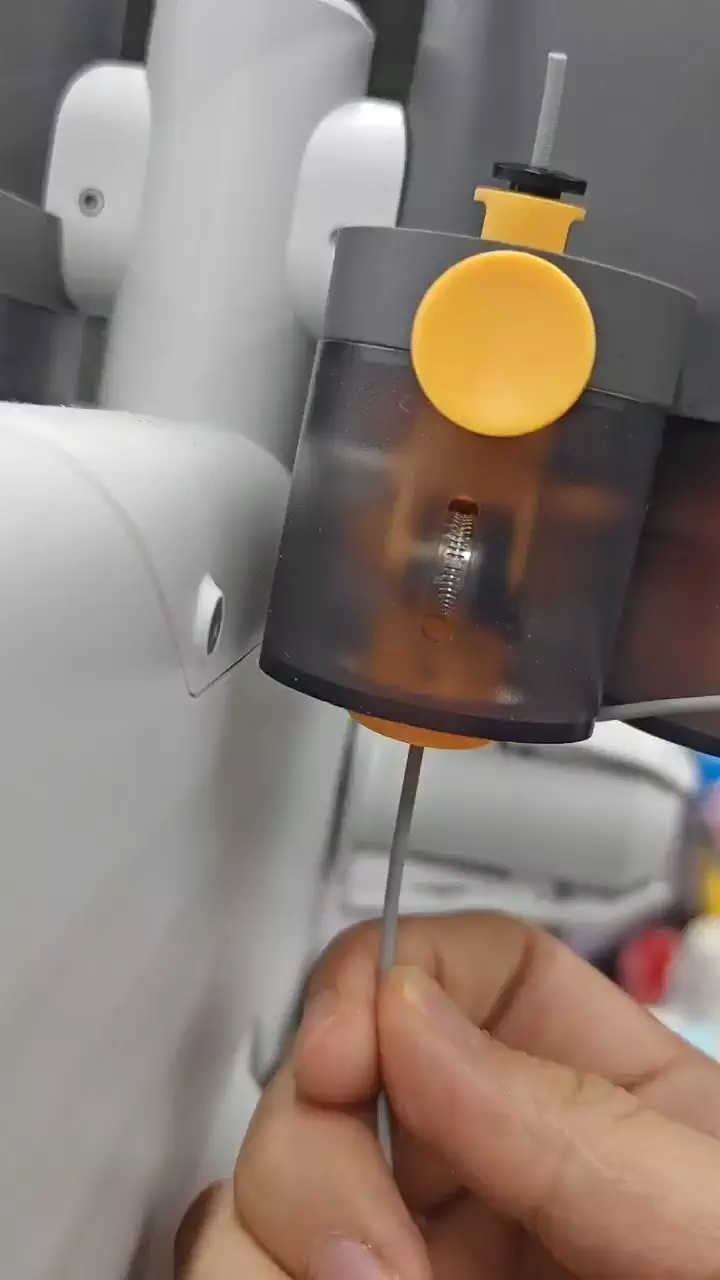

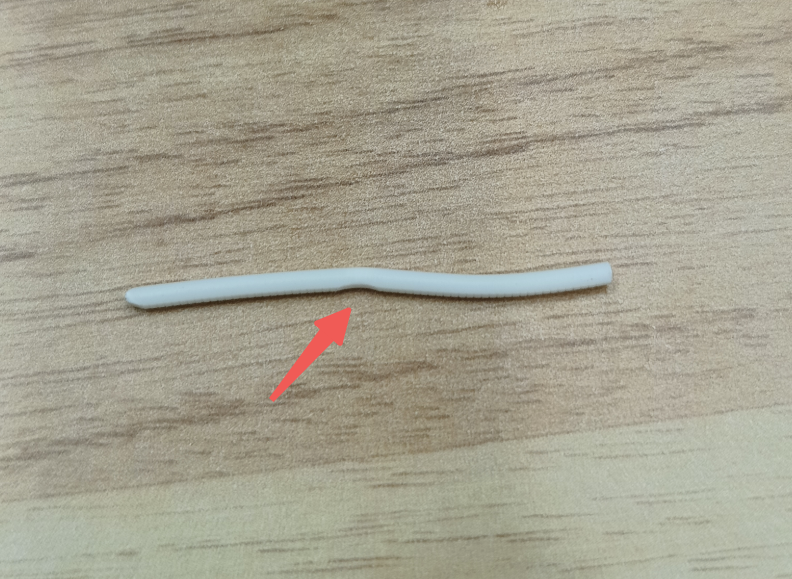

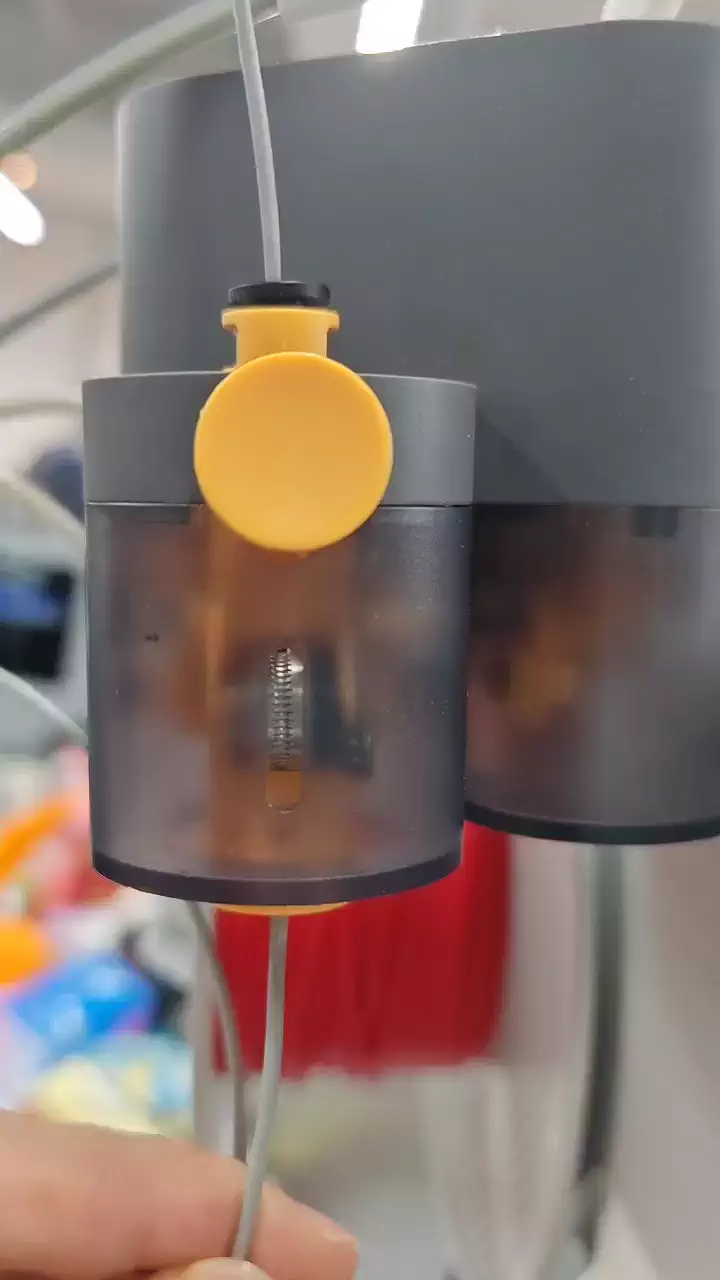

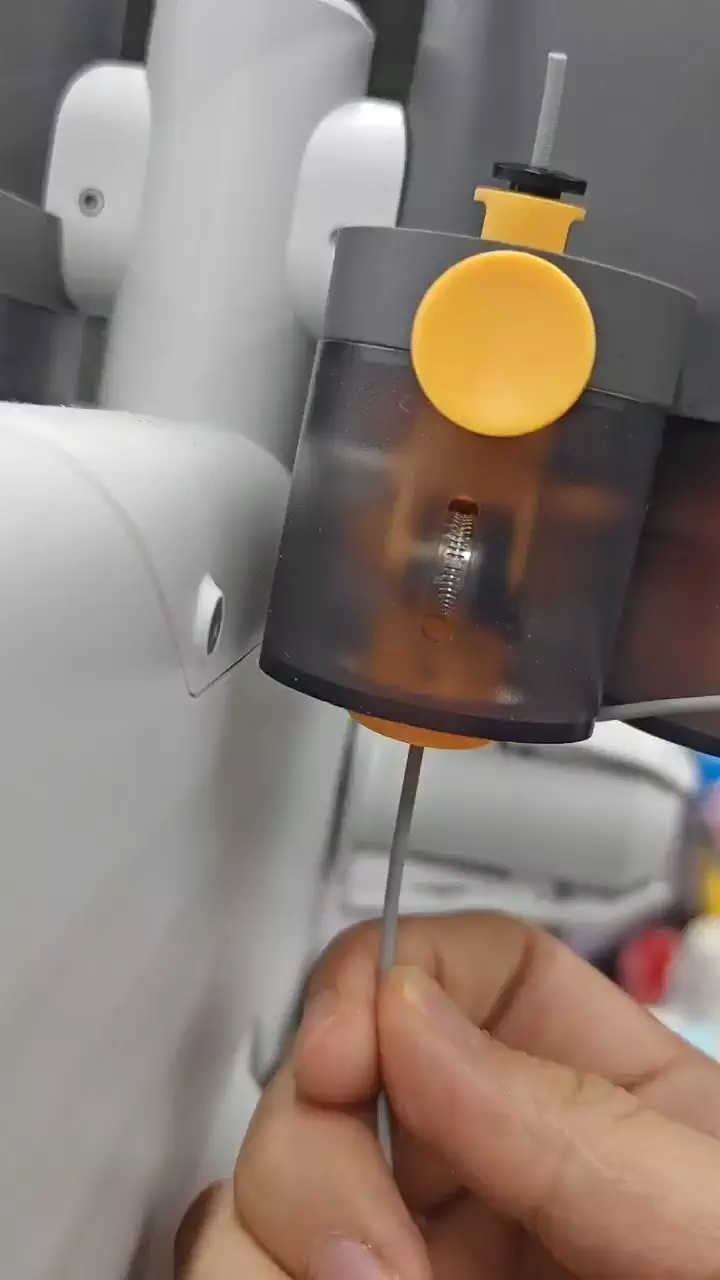

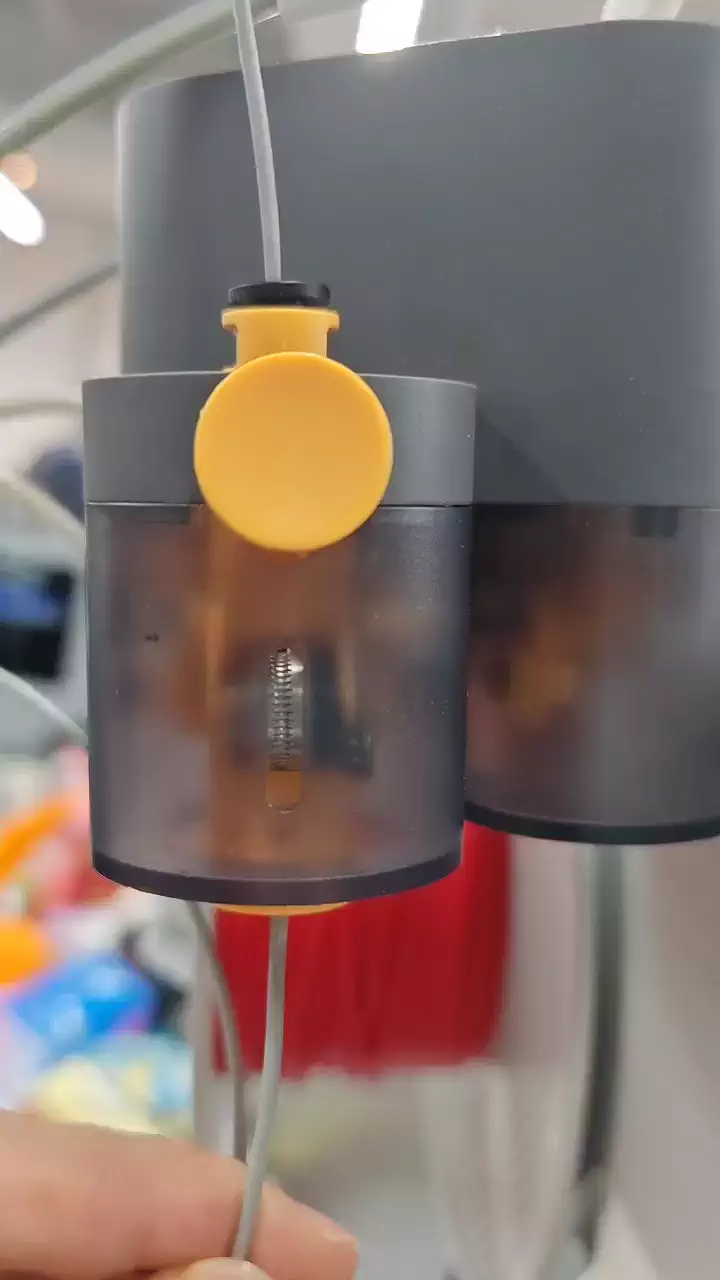

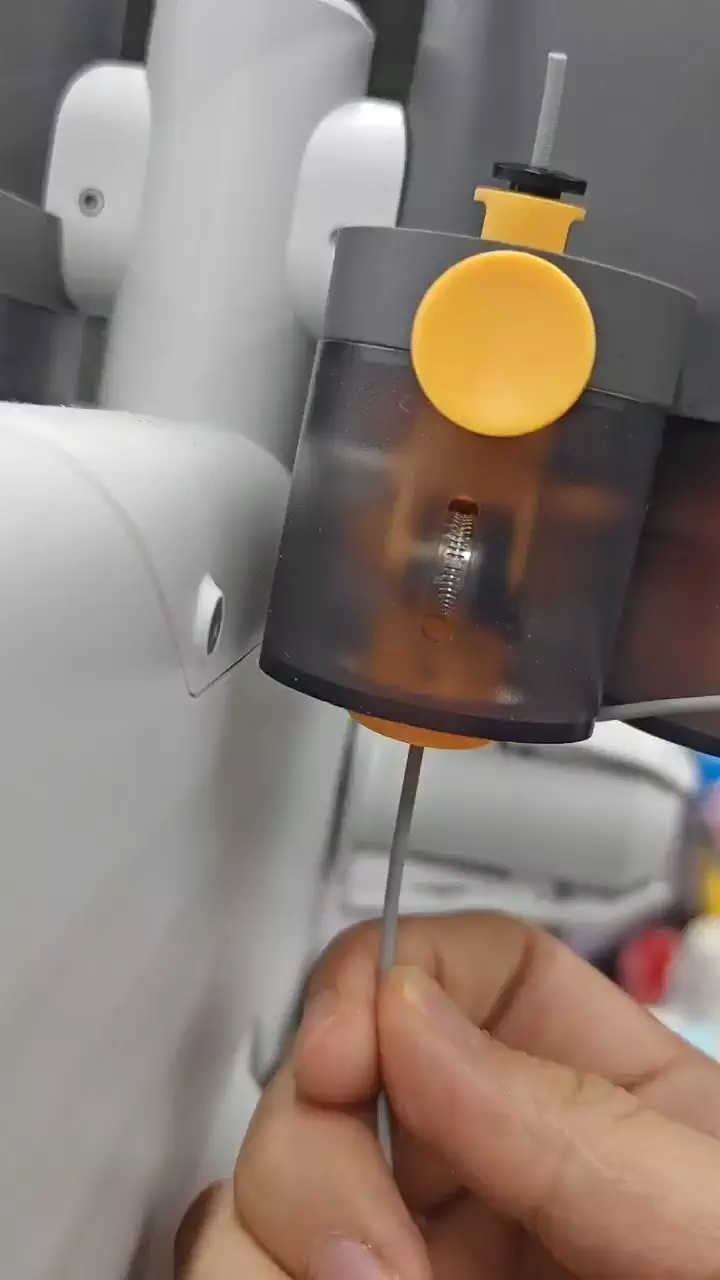

Test the movement of the odometer : insert the filament and pull it back and forth to see if it rotates smoothly. It is recommended that you replace the Filament Funnel Unit.

bad odometer |  normal odometer |

¶ 4. Filament Too Thin, Causing Gear Slippage

Each AMS lite slot has a feeder assembly with gears that grip filament. If filament is too thin or gears are damaged, slippage may occur, leading to feeding failure.

¶ 5. Extruder Filament Sensor malfunction

If all slots are displaying errors, please check the Extruder Filament Sensor and the AMS lite Filament Hub first. After manually inserting the filament, if the green dot is still not appearing on the screen.

|  |

When the filament cannot be detected, in addition to potential issues with the Extruder Filament Sensor itself, there may also be a problem with the base arm. Insert a piece of filament and check if the arm operates normally. After removing the filament, if it returns to its original position automatically.

Refer to the Wiki: Disassembly and cleaning the AMS lite Filament Hub

¶ 6. Broken Filament inside the AMS lite Filament Hub

If the filament break occurs at the outlet of the AMS lite Filament Hub, it can cause a clog when feeding from another slot, preventing two filaments from exiting the AMS lite Filament Hub. This will result in the toolhead's filament sensor not detecting the filament. You can refer to the following Wiki for instructions on cleaning the AMS lite Filament Hub:

Disassembly and cleaning the AMS lite Filament Hub

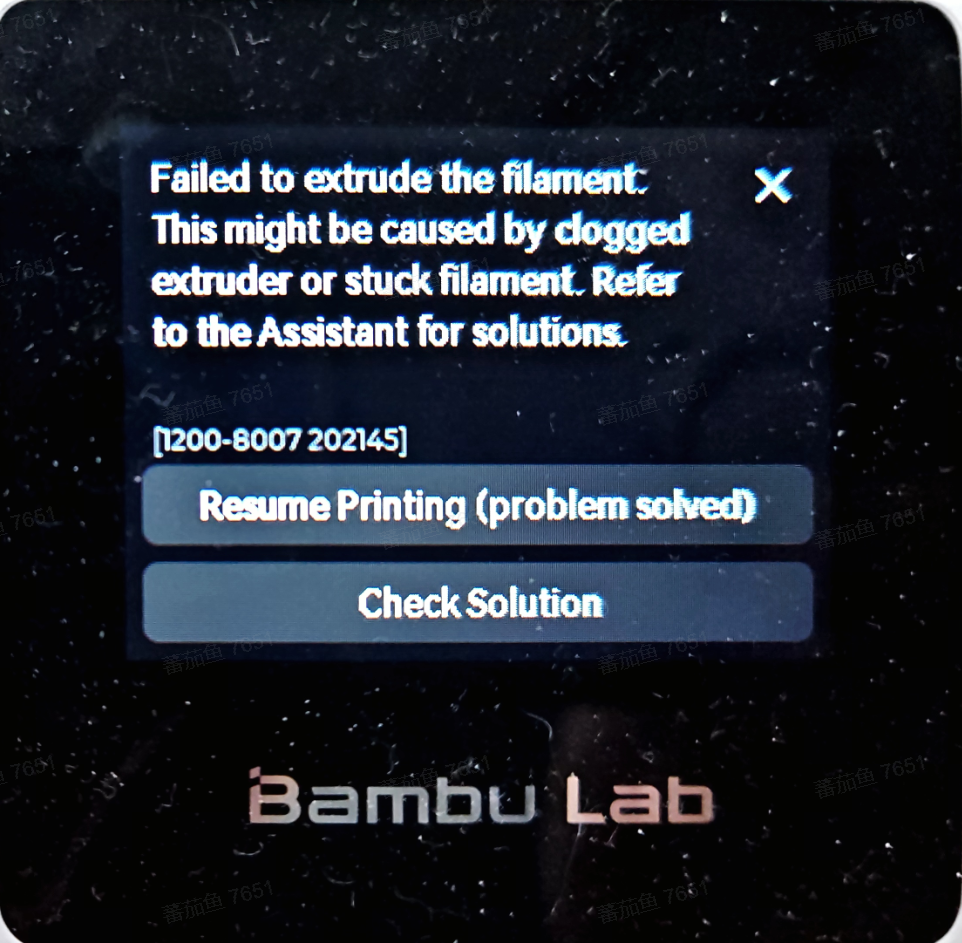

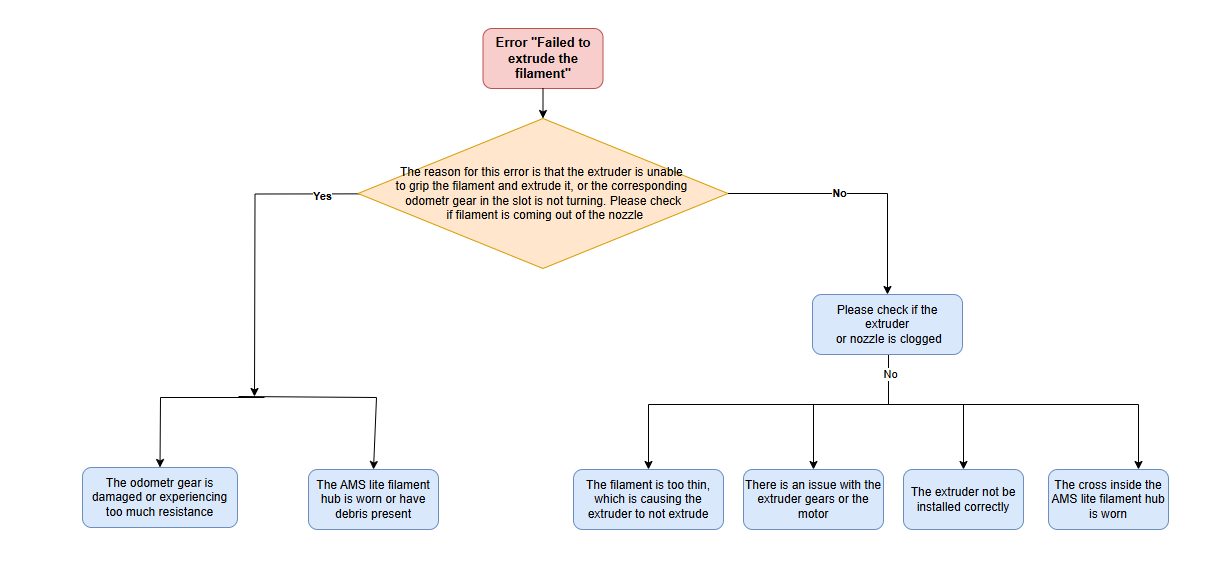

¶ Failed to Extrude the Filament

If this error occurs, it indicates that during the feeding process, the extruder's filament sensor has detected the filament, but the extruder is unable to engage with the filament and extrude it, or the corresponding slot's odometer has not rotated.

Troubleshooting step:

¶ 1. Nozzle or extruder clog

If you move the toolhead to the Purge Wiper position and test the extrusion separately, but still cannot extrude the filament smoothly, you may notice that the extruder gear moves unevenly and produces a "clicking" sound. This could indicate a clog in the nozzle.

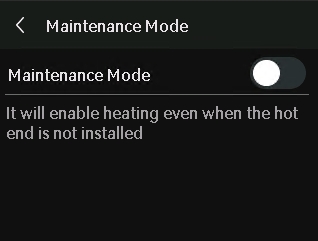

On the printer's "Settings - Maintenance" page, enable maintenance mode. Set the nozzle temperature to 170°C (the minimum extrusion temperature) and manually test the extrusion. If the extruder can successfully push the filament without the nozzle, it confirms that there is a clog in the nozzle. Please refer to the following Wiki for cleaning instructions:

If the extruder can feed the filament smoothly without the nozzle, it means the nozzle is clogged. Refer to the following Wiki for cleaning::

A1 series Nozzle Unclogging Guide

If the extruder still cannot feed the filament without the nozzle, it means the extruder is clogged. Refer to the following Wiki for cleaning:

A1 series extruder cleaning tutorial

¶ 2. Extruder gear or motor abnormal

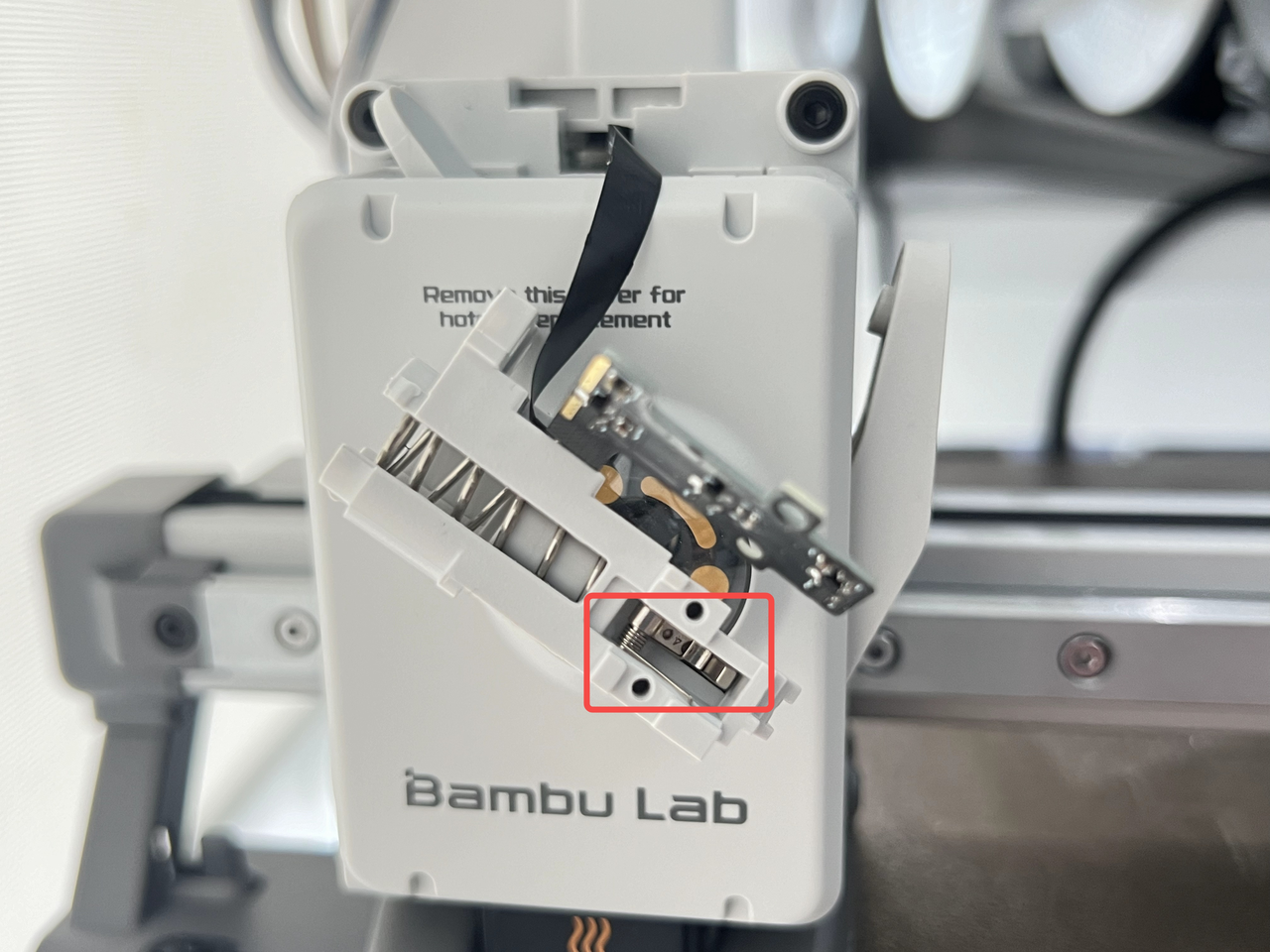

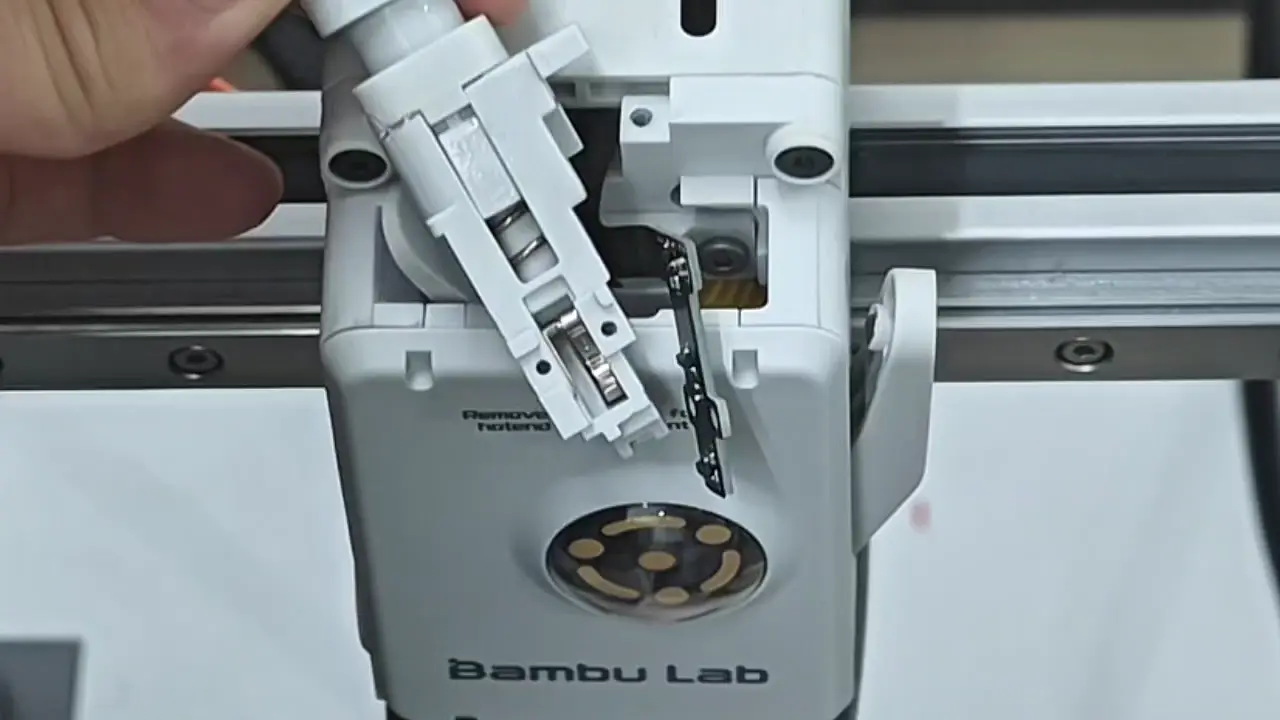

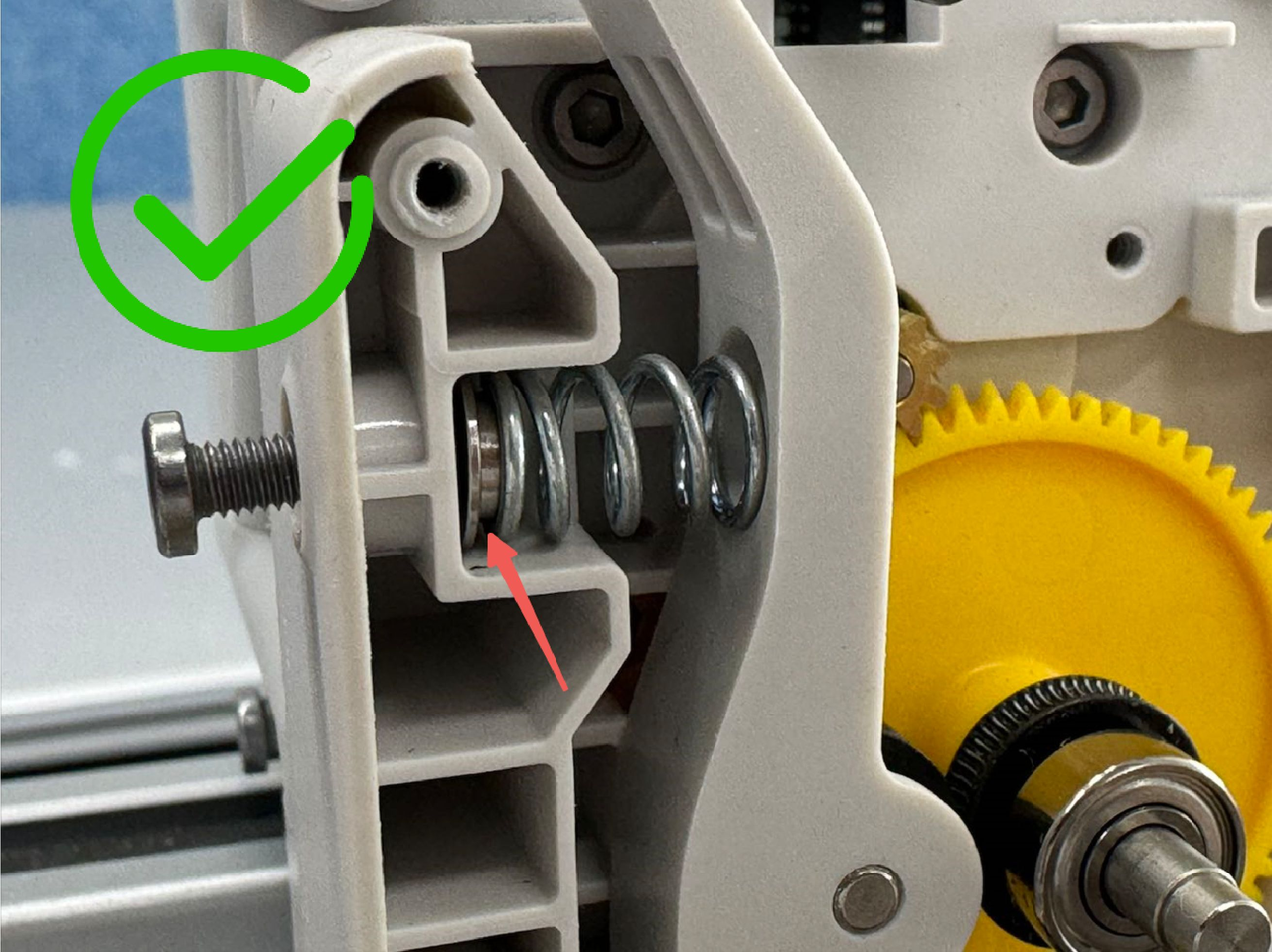

If neither the nozzle nor the extruder is blocked, but the extruder gear is rotating abnormally or has stopped, preventing the smooth extrusion of filament during printing. You can disassemble the extruder unit to check if the extruder unit is functioning properly and whether the yellow gear shows any signs of wear or missing teeth.。

¶ 3. Filament Slippage or Extruder Misalignment

If the filament cannot be extruded at all during feeding or printing, but the extruder gear rotates smoothly, it may indicate that the extruder gear is not fully engaging with the filament, or that there is slippage between the gear and the filament.

¶ Gear and Filament Slippage

The filament may be prone to wear. Please turn off the printer, remove the current filament, and check for any signs of wear. If there are any, it indicates that the filament has been worn down by the gear.

|  |

Try feeding with another spool of filament to see if extrusion occurs smoothly. If any filament only shows the gear spinning without any extrusion, refer to the troubleshooting methods for a clogged nozzle to check for clogs. If only one specific spool of filament is prone to wear, it may indicate an issue with that filament itself, and it is advisable to switch to a different filament for printing.

¶ Extruder Not Installed Correctly

If the nozzle is not clogged and the filament is not worn by the gear, but the gear continues to spin without extrusion, it may be due to improper installation of the Extruder Gear Assembly, resulting in excessive gear gap that prevents proper engagement with the filament.

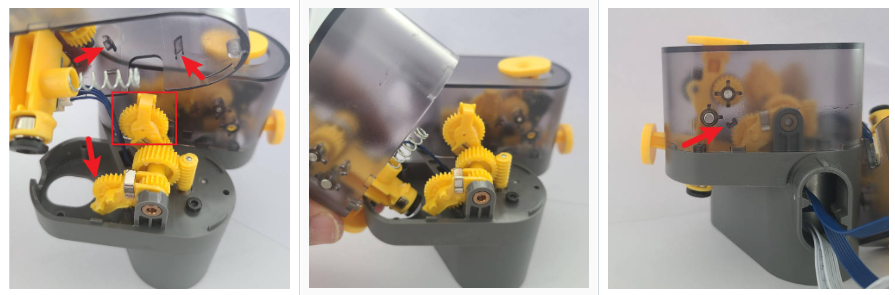

¶ 4. Excessive Resistance of the Odometer

If this error occurs in only one slot, it may be due to excessive resistance or failure of the odometer in that particular slot.

¶ Excessive Resistance of the odometer

Excessive resistance of the odometer can prevent the extruder from smoothly pulling the filament, causing the odometer to malfunction. Insert the filament into the four slots of the AMS lite, and manually pull the filament back and forth to check if the frequently error-prone slot has noticeably greater resistance than the others. If the odometer in a specific slot is jammed, it is recommended to try lubricating or replacing the odometer wheel.

bad odometer |  normal odometer |

¶ Odometer failure

If only one slot experiences extrusion failure, and there is no resistance from the odometer in that slot, the filament has already been extruded. When using the AMS lite for feeding, the success of the extrusion is determined by the odometer. If the odometer does not properly record the amount of filament fed, an error will occur. It is recommended that you replace the Filament Funnel Unit.

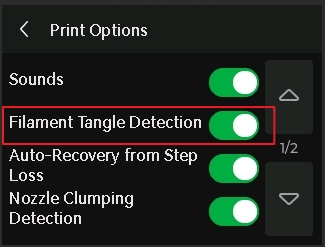

¶ 5. Abnormal filament sensor value in filament tangle detection module

Due to the current version sharing the same error message for both filament tangle detection and extrusion issues, a malfunction in the filament tangle detection module may also lead to extrusion errors. You can disable filament tangle detection to see if the errors cease. If the errors stop,recommended that you replace the filament sensor.

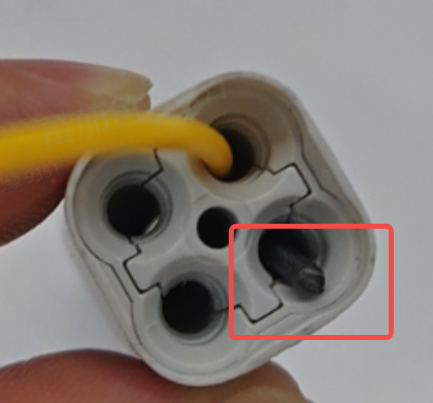

¶ 6. Worn AMS lite filament hub

If the AMS lite filament hub is worn, it may prevent the filament from being extruded or cause it to jam at the nozzle. Please refer to the following Wiki to check if the AMS lite Filament Hub is worn. If it is severely worn. It is recommended to replace the filament hub.

Disassembly and cleaning the AMS lite Filament Hub

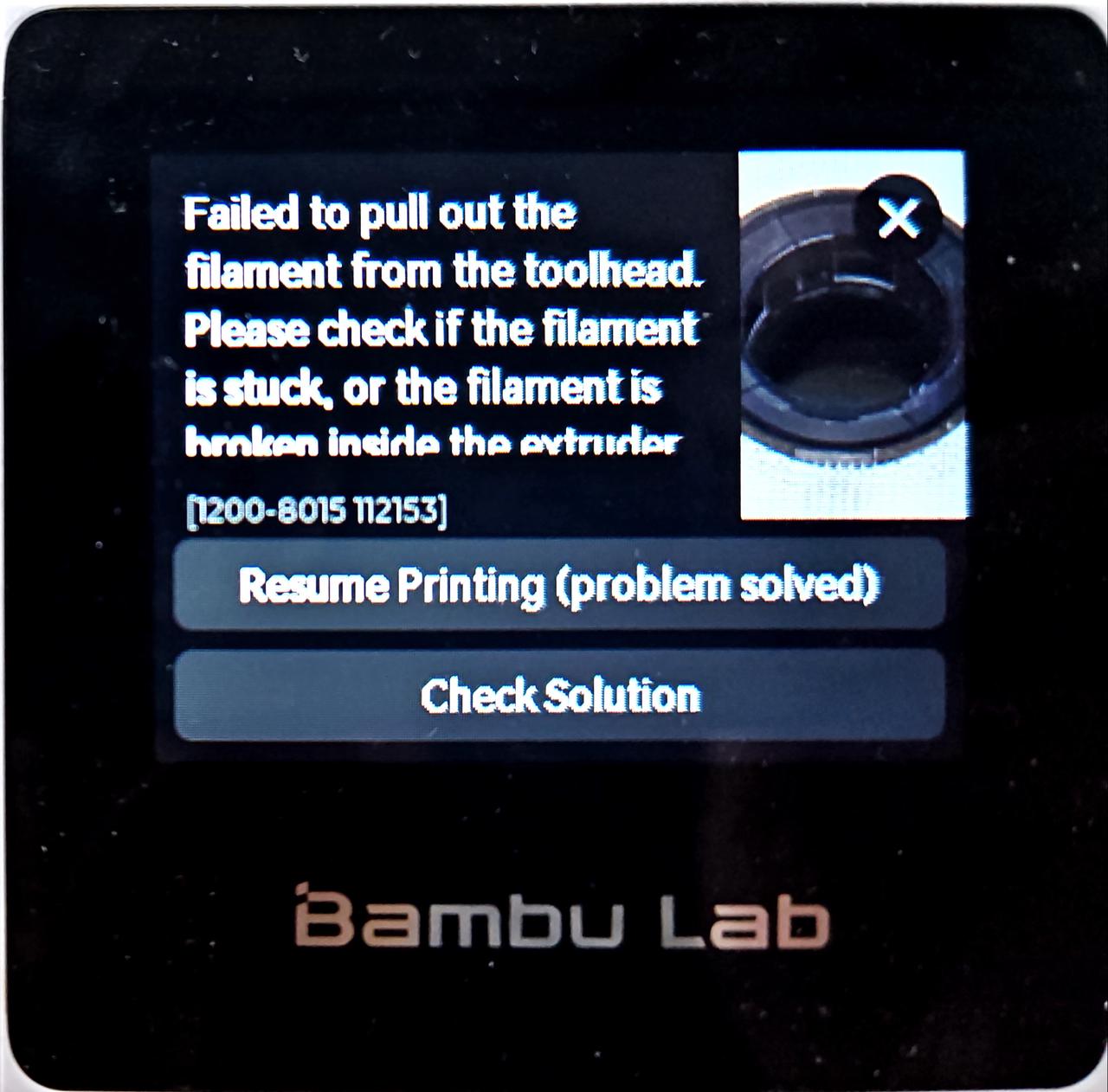

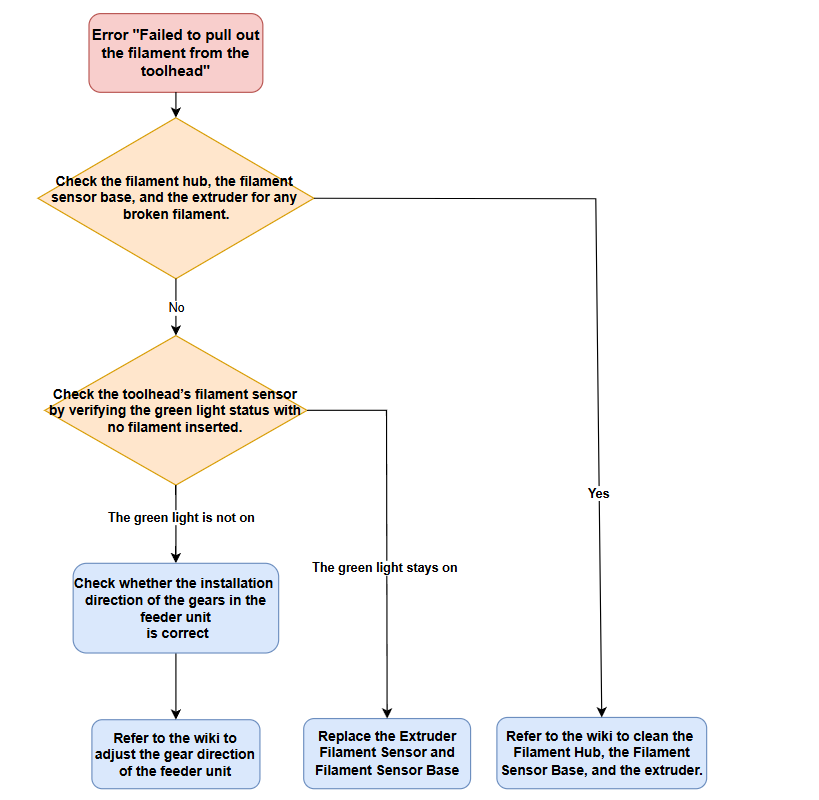

¶ Failed to pull out the filament from the toolhead

The logic for this error is as follows: when the AMS lite is unloading or changing filament, the filament should exit from the toolhead, and the filament sensor in the toolhead should detect that the filament has exited. However, the filament sensor still detects the filament.

Troubleshooting step:

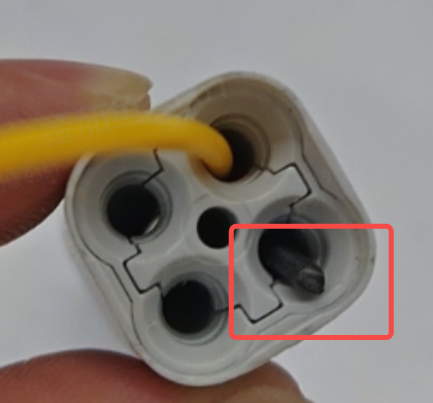

¶ 1. Check for broken filament in the filament Hub, filament sensor base, or extruder

Please refer to the following Wiki to check for any filament breaks in the AMS liteFilament Hub and filament sensor base. If there are any breaks, please remove them using tweezers:

Disassembly and cleaning the AMS lite Filament Hub

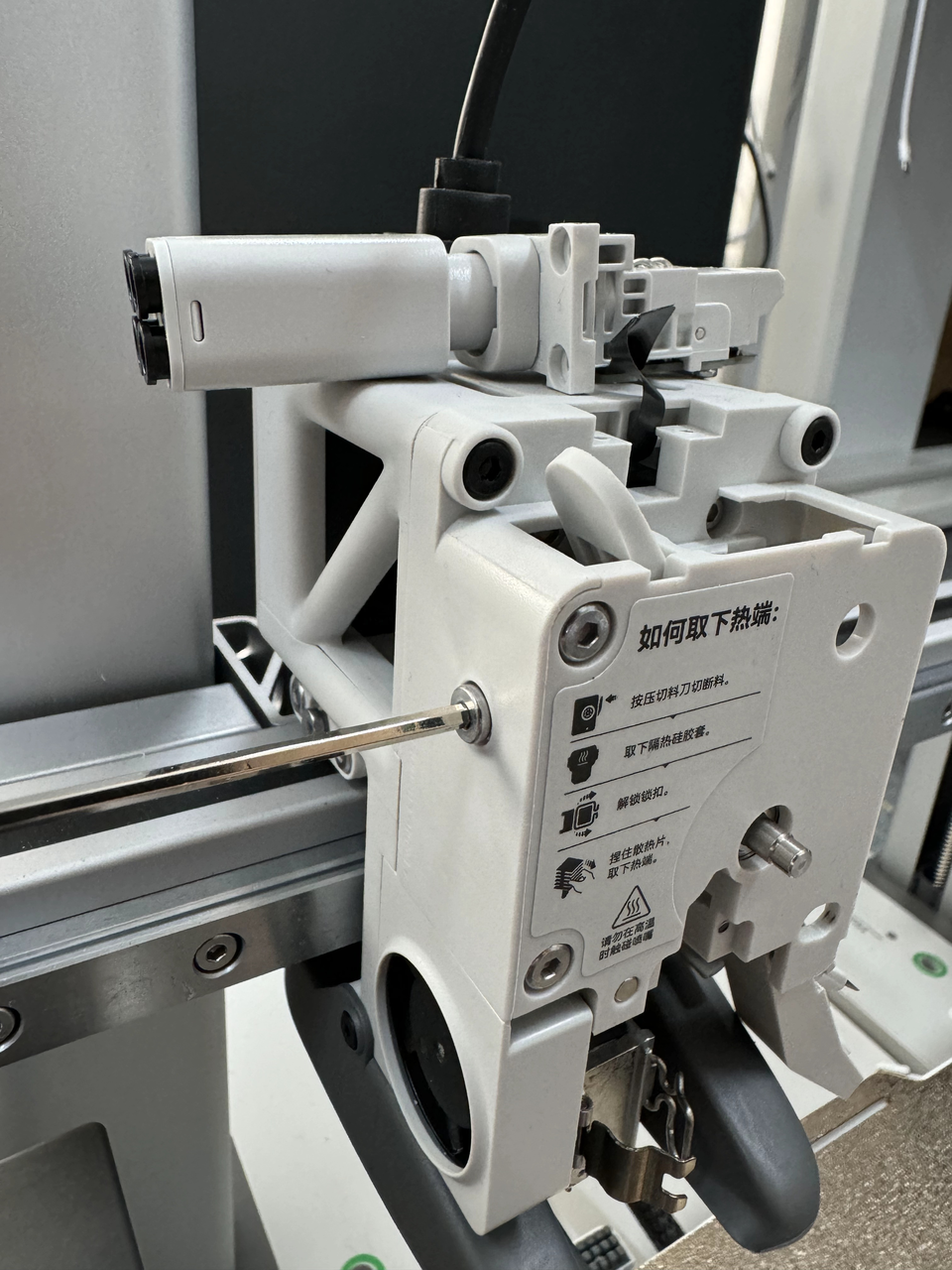

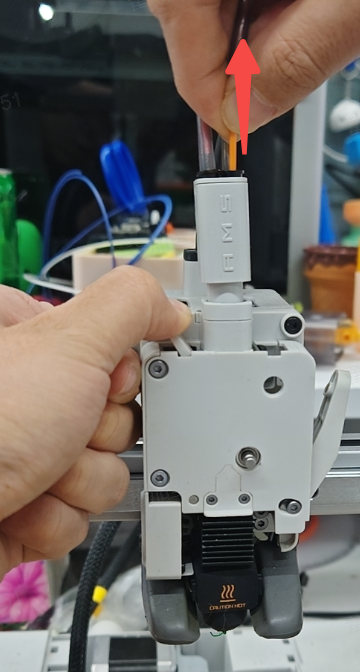

Turn off the printer. Then, press down the cutter to sever the filament. Next, hold the tension lever and remove the current filament. If the filament cannot be pulled out, it indicates an extruder clog. Please refer to the Wiki for extruder cleaning:A1 Extruder Cleaning.

|  |

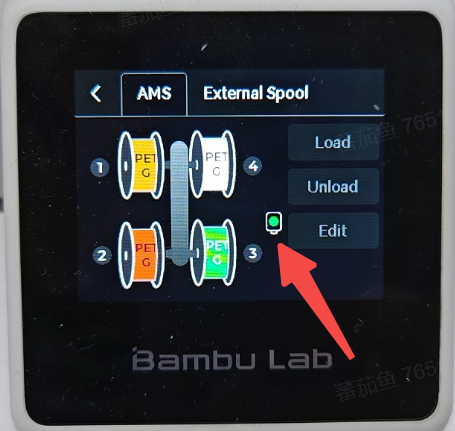

¶ 2. Extruder filament sensor Issue

Check whether the green light remains on when there is no filament in the toolhead.

If there is no filament in the toolhead and the green light remains on, you can refer to the wiki below to check whether the arm operates properly.

Disassembly and cleaning the AMS lite Filament Hub

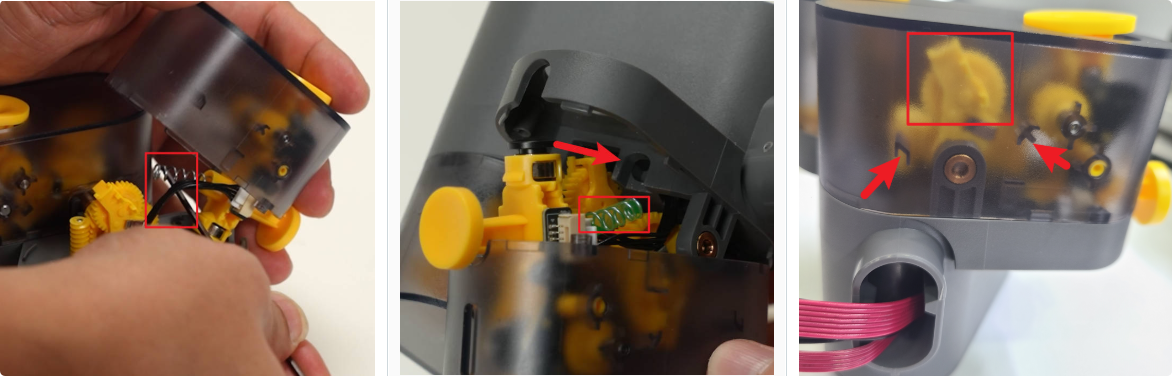

¶ 3. Verify the correct installation direction of the feeder unit gears

Please follow the Wiki instructions to disassemble the AMS Filament Funnel Unit and calibrate the gear installation orientation:

AMS lite Feeder Unit Installation Tutorial

Correct Orientation of Slot 1 and Slot 2

Correct Orientation of Slot 3 and Slot 4

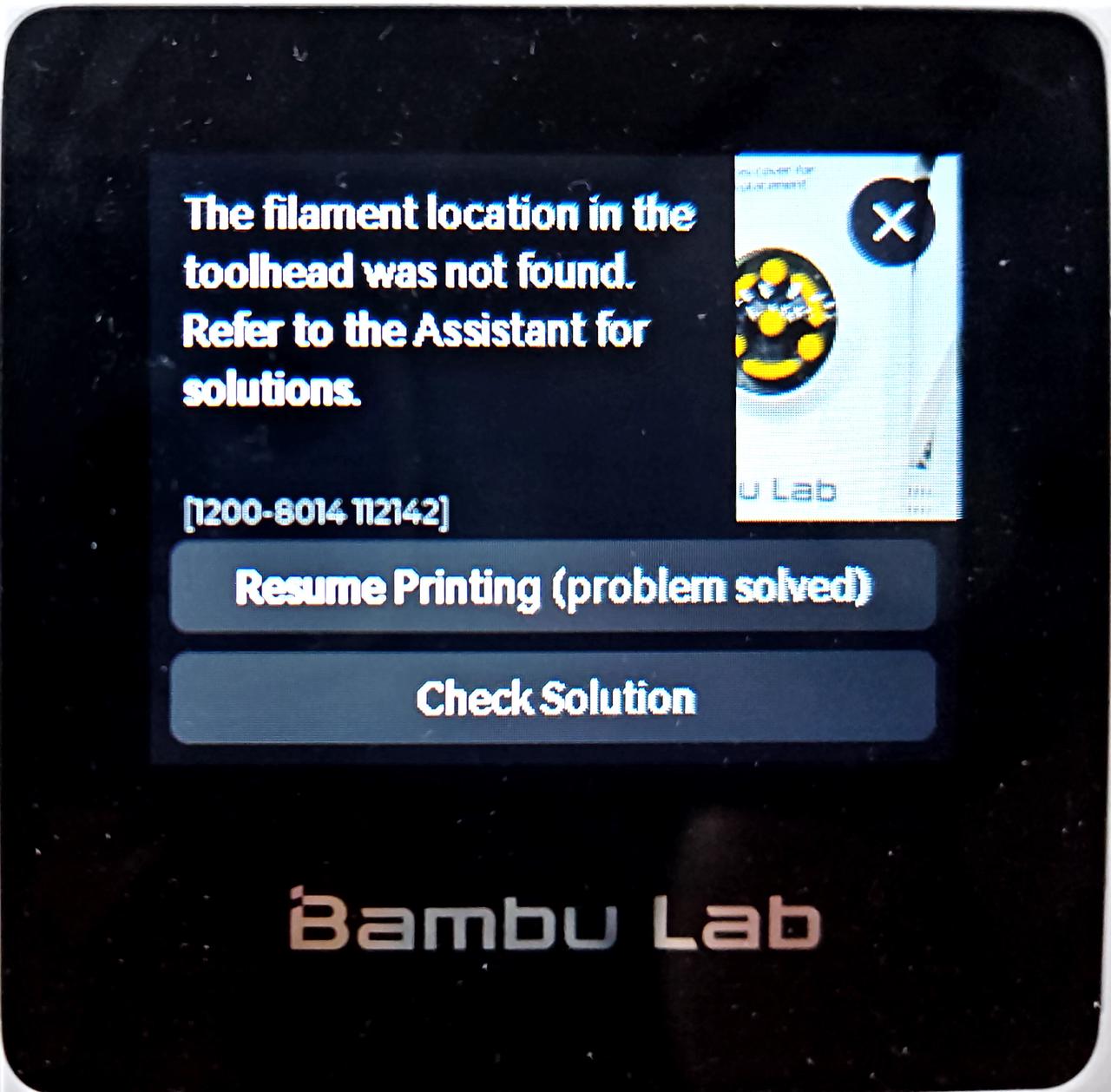

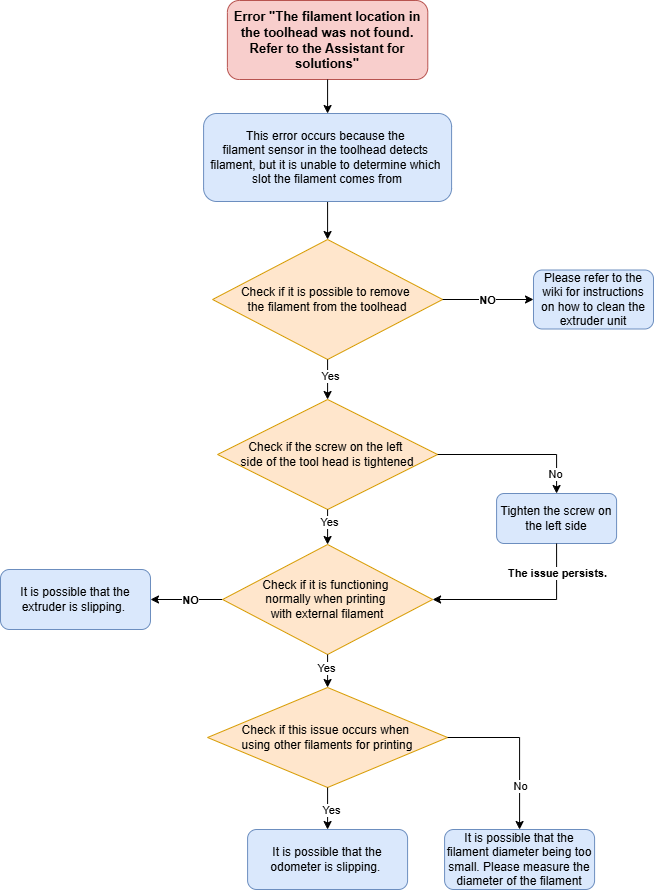

¶ The filament location in the toolhead was not found

The error message below indicates that when initiating the loading or unloading process, the extruder's filament sensor detects that there is still filament inside the toolhead but fails to determine which slot the filament is coming from. The detection process relies on data from the odometer in conjunction with the extrusion and retraction of the filament. If the detection fails, it means that the filament inside the toolhead cannot be properly extruded or retracted.

Troubleshooting step:

¶ 1. The extruder is clogged

Turn off the printer. Then, press down the cutter to sever the filament. Next, hold the tension lever and remove the current filament. If the filament cannot be pulled out, it indicates an extruder clog. Please refer to the Wiki for extruder cleaning:A1 Extruder Cleaning.

|  |

¶ 2. The filament is slipping in the toolhead

Please check if the screw on the side of the toolhead is tightened.

If it is secure, check if other filaments also have issues. If only specific filament is problematic, it might indicate that the diameter of the filament is too small.

If all the filaments are experiencing this issue and experiencing extrusion issues while printing with external filament, it may indicate a fault with the extruder. Please contact support team to request a replacement part for the extruder. Refer to Replace extruder

¶ 3. The odometer is slipping

If this error occurs only when the filament is loaded into a specific slot during the loading operation, it indicates that the internal odometer of the AMS filament funnel unit for that slot is slipping. It is recommended that you replace the Filament Funnel Unit.

bad odometer |  normal odometer |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support attention!