¶ Introduction

This article introduces how to configure the parameters when you use PLA Basic as the support for PETG HF or vice versa. Also, it provides preset files with all necessary parameters done for Bambu Studio.

PLA and PETG flaments don't adhere very well with each other, so using this filament combination can help get better support interface results and make support removal easier.

¶ Notes before operation

- This article only applies to Bambu PLA Basic and Bambu PETG HF. The following types of PLA and PETG are not supported:

- Bambu PLA Matte, Bambu PLA Silk, Bambu PLA-CF, and other types of PLA.

- PLA from other brands.

- Bambu PETG Basic,Bambu PETG Translucent,Bambu PETG-CF, and other types of PETG.

- PETG from other brands.

- Please use the parameters described in this article for printing. Otherwise, we cannot guarantee a good result and there is a high chance of failure.

- Recommended to use Support for PLA as the interface material, as PETG is generally not advised. If PETG must be used, pelase refer to the settings below—though ideal print results are not guaranteed.

¶ Filament preparation

The moisture level of a filament affects the print quality. The dryer the filament, the better the print quality。

The more moisture the filament absorbs (caused by high environmental humidity and long-time exposure to it), the higher the chances that there will be stringing, oozing, holes, coarse surface, and low strength.

To get better print quality, we strongly recommend that you dry the filament before printing, and keep it dry during the entire printing process. Please refer to this article for more information on drying and how to keep away from moisture: Filament Drying Recommendations.

¶ Drying

All filaments will absorb some moisture from the air to varying degrees. During printing, the moisture inside the filament will quickly vaporize under the high nozzle temperature. This will cause the molten filament to expand and flow more quickly, leading to stringing, oozing, holes, coarse surface, low strength, and more problems.

When using PLA Basic and PETG HF to work as support for each other, the nozzle temperature for PETG HF is too high for PLA Basic. This increases the chance of stringing and oozing. Therefore, we must dry PLA Basic and PETG HF before printing to get better print quality.

¶ Keep away from moisture

After drying, the filament will still absorb moisture from the air. So we strongly recommend keeping the filament inside the AMS or a sealed box, and make sure that the desiccant inside the AMS/sealed box is effective. This can prevent the filament from absorbing moisture. For more information on desiccant, please refer to this article: Filament Drying Recommendations.

Because the AMS lite does not offer a sealed environment for filaments, we do not recommend installing filaments on the AMS lite for a long time. Otherwise, they will become damp.

¶ Filament combination

When printing with an enclosed machine, the increased nozzle temperature and heatbed temperature at 60°C cause high chamber temperature for PLA Basic. The PLA Basic will soften and deform the extruder, leading to abnormal extrusion or nozzle clogs. If the temperature around the printer is high, the chamber temperature may be even higher. It is especially important to open the door and/or top cover of the printer to avoid clogs.

When printing with an enclosed machine with the door open, or with an open machine, the heatbed temperature at 60°C and printing with the door open can cause low chamber temperature for PETG HF. This may lead to insufficient adhesion on the support interface when printing large areas with PETG HF, increasing the risk of warping.

- Comparison sheet for using Bambu PLA Basic for the model and Bambu PETG HF as support:

| PLA Basic (Same material as the model) |

PETG HF | Support for PLA | Support for PLA/PETG | PVA | |

|---|---|---|---|---|---|

| Nozzle temperature for model material / °C | 220 | 230 | 220 | 220 | 220 |

| Heatbed temperature for model material / °C | 35 - 55 Depends on the type of build plate. |

60 Must use smooth PEI, high temperature, or textured PEI plates. |

35 - 55 Depends on the type of build plate. |

35 - 55 Depends on the type of build plate. |

35 - 55 Depends on the type of build plate. |

| Cooling when printing with enclosed machine* | Open the door | Open the door | Open the door | Open the door | Open the door |

| Pros |

|

|

|

We recommend that you read this article first before printing: PVA Printing Guide |

|

| Cons | Hard to remove support; support interface with bad quality. |

|

Price is relatively high. | Not easy to become damp; low drying and moisture-proof requirements. | |

| Notes | Enclosed printers: X1 series, P1S and enclosed P1P. |

- Comparison sheet for using Bambu PETG HF for the model and Bambu PLA Basic as support:

| PETG HF (Same material as the support) |

PLA Basic | Support for PLA/PETG | |

|---|---|---|---|

| Nozzle temperature for model material / °C | 245 | 245 | 245 |

| Heatbed temperature for model material / °C | 70 Depends on the type of build plate. |

60 Must use smooth PEI, high temperature, or textured PEI plates. |

60 Depends on the type of build plate. |

| Cooling when printing with enclosed machine* | Open the door | Open the door | Open the door |

| Pros |

|

|

|

| Cons | Hard to remove support; support interface with bad quality. |

|

Price is relatively high. |

| Notes | Enclosed printers: X1 series, P1S and enclosed P1P. |

¶ Preset profile

Download and open the following .3mf file, and then import your model in a .stl file to apply the already adjusted printing parameters on it.

When printing with other models of 3D printers, you can select the model you need, select use the modified values according to the on-screen prompt, and then the process and filament parameters from the .3mf file will be directly applied.

PLA Basic supports PETG HF.3mf

PETG HF supports PLA Basic.3mf

If you want to manually configure the parameters and understand how they work, please read the content below.

¶ Parameter configuration

In Bambu Studio, the default parameters are not appropriate for using PLA Basic and PETG HF to support each other. The following parameters must be configured to get a better print quality.

Note: When using a 0.2mm nozzle for PLA/PETG mutual support printing, it is recommended to refer to the following figure to increase the line width to increase the viscosity, otherwise it may cause spaghetti. You can also use the modifier to modify the area near the support contact surface.

¶ Use PLA Basic to support PETG HF

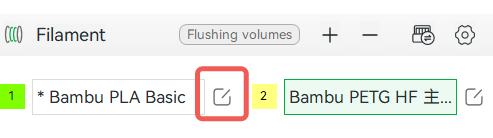

This profile use PETG HF to print the model, and PLA Basic the support.

¶ Configure the parameters

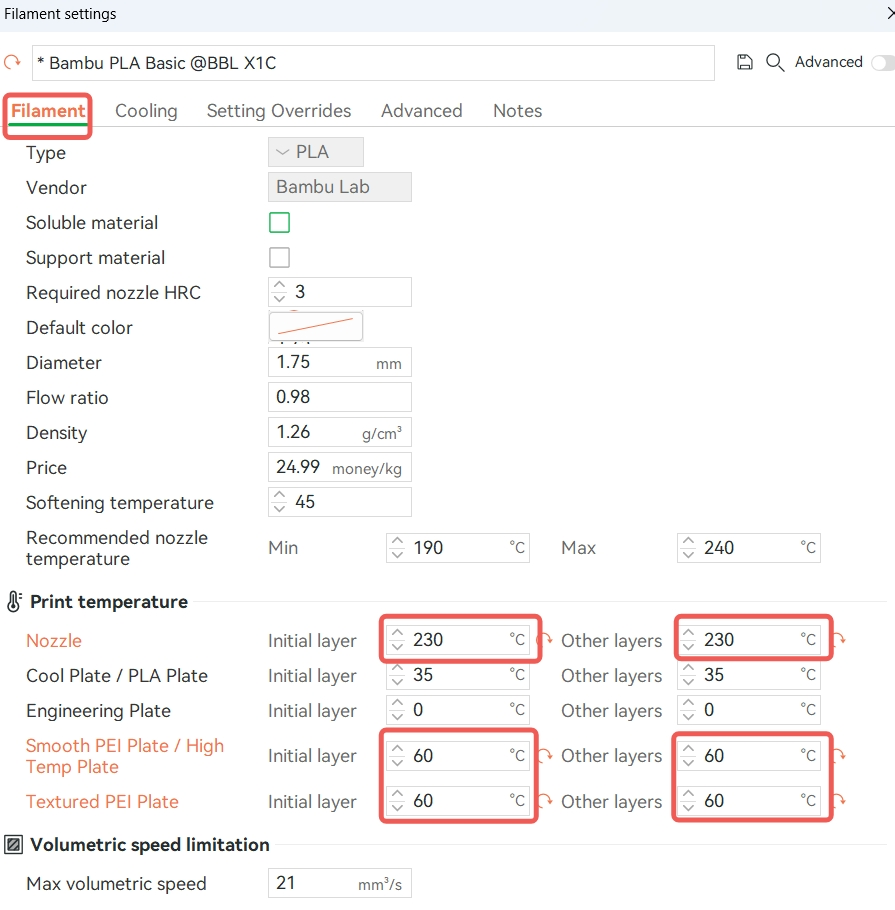

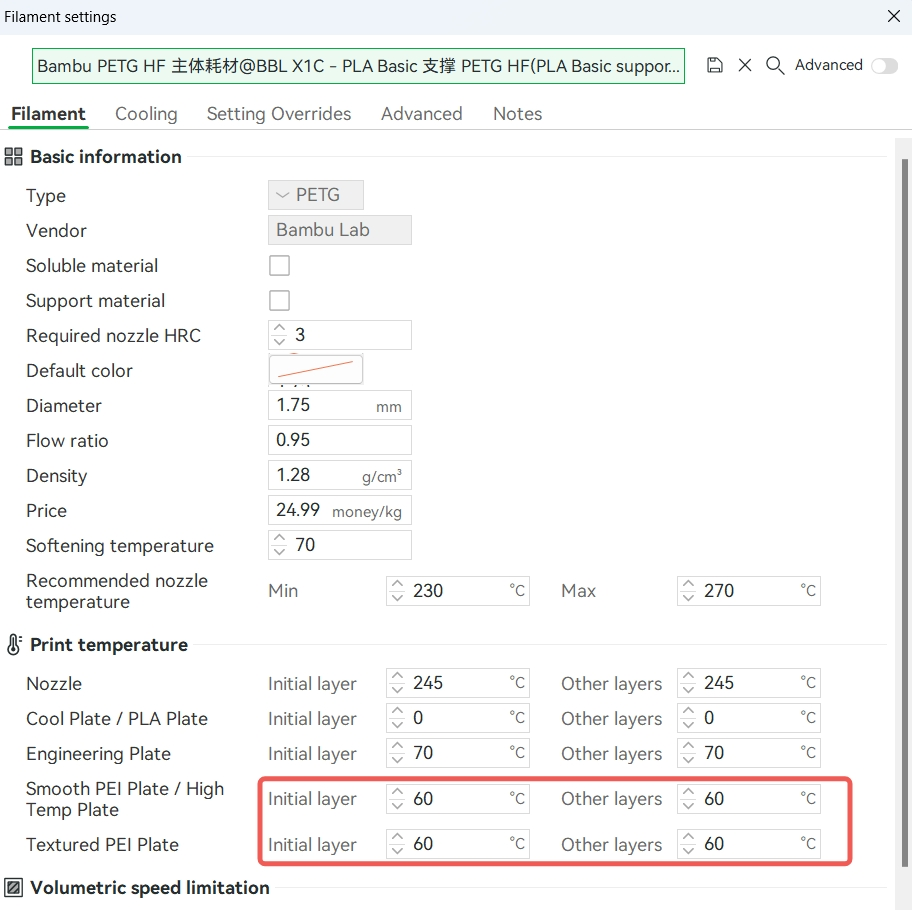

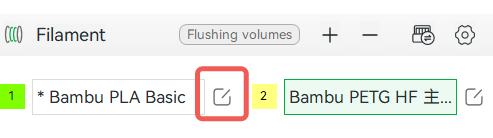

- Go to the Filament settings page.

-

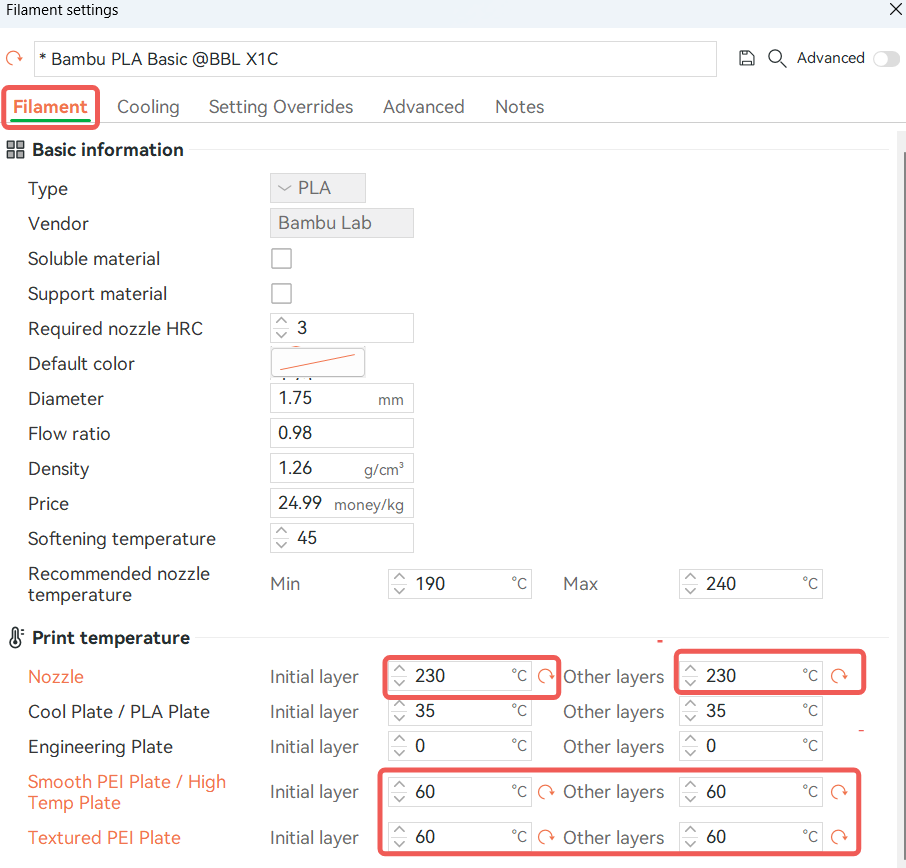

PLA Basic as the support:

- Nozzle: Set initial layer and other layers to 230 °C.

- Smooth PEI Plate/High Temp Plate: Set initial layer and other layers to 60°C.

- Textured PEI Plate: Set initial layer and other layers to 60°C.

Keep all other parameters as default.

-

PETG HF as the model material:

- Smooth PEI Plate/High Temp Plate: Set initial layer and other layers to 60°C.

- Textured PEI Plate: Set initial layer and other layers to 60°C.

Keep all other parameters as default.

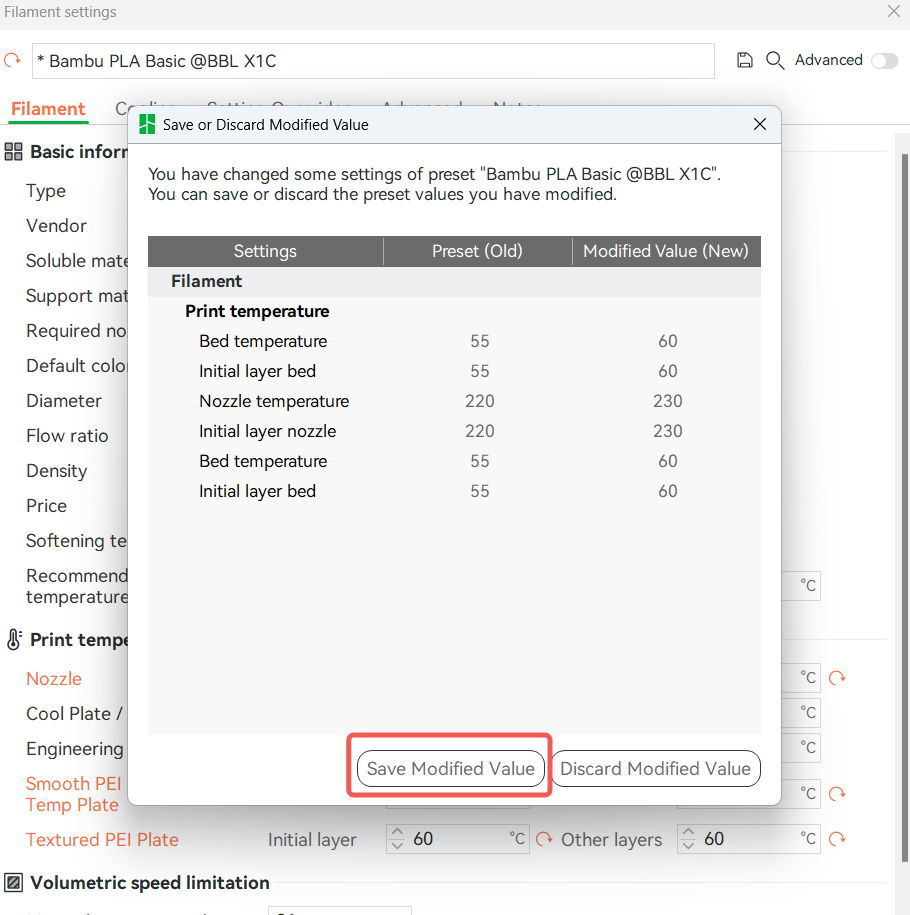

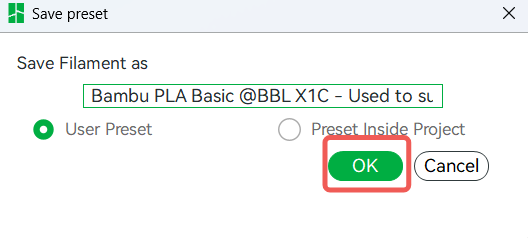

After modifying the parameters for PLA Basic, when adjusting the parameters for PETG HF, the following prompt will appear. You need to click Save Modified Value to save the parameters as a User Preset, then click OK. You don't need to configure them again and can directly use them next time.

Similarly, save the modified PETG HF parameters as a preset for quick use next time.

¶ Support parameter configuration

In Bambu Studio, there are 2 options when printing support with support filament:

-

Use the support filament as both support/raft base and interface.

This is more suitable when you need a large amount of support, but the print time will be longer. -

Use the model filament as support/raft base and support filament as support/raft interface.

This is more suitable for models that only need a small amount of easy-to-remove support.

Select an option, and see how to configure them below:

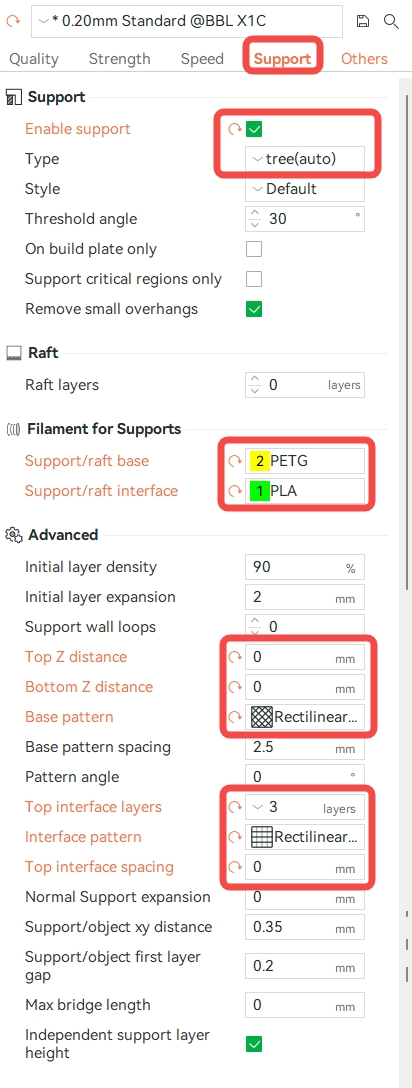

Go to the Filament settings page.

Because using PLA Basic as both the support base and interface will lead to longer print time, and the support structure is easy to fall off the model surface, we recommend only use it as the support interface. Please see the picture below for what parameters to configure.

¶ Use PETG HF to support PLA Basic

This profile use PLA Basic to print the model, and PETG HF the support.

¶ Configure the parameters

- Go to the Filament settings page.

-

PLA Basic as the model material.

- Nozzle: Set initial layer and other layers to 230 °C.

- Smooth PEI Plate/High Temp Plate: Set initial layer and other layers to 60°C.

- Textured PEI Plate: Set initial layer and other layers to 60°C.

Keep all other parameters as default.

-

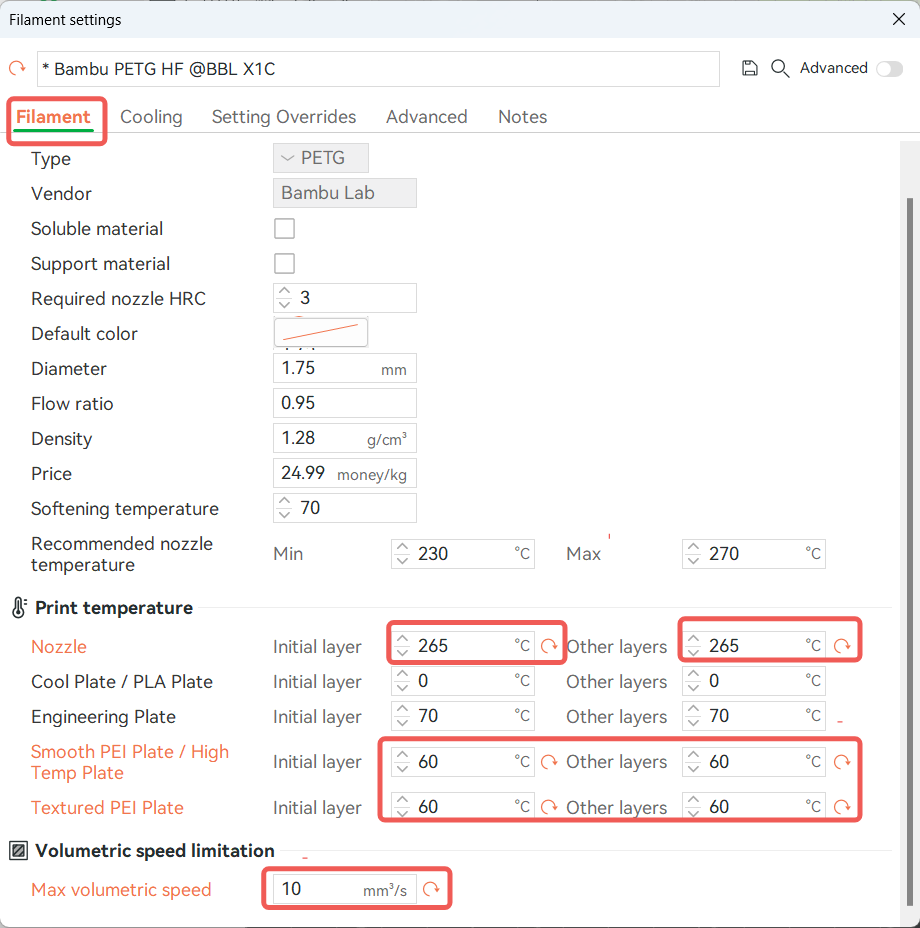

PETG HF as the support material.

- Nozzle: Set initial layer and other layers to 265 °C.

- Smooth PEI Plate/High Temp Plate: Set initial layer and other layers to 60°C.

- Textured PEI Plate: Set initial layer and other layers to 60°C.

- Max volumetric speed: Set to 10 mm3/s.

Keep all other parameters as default.

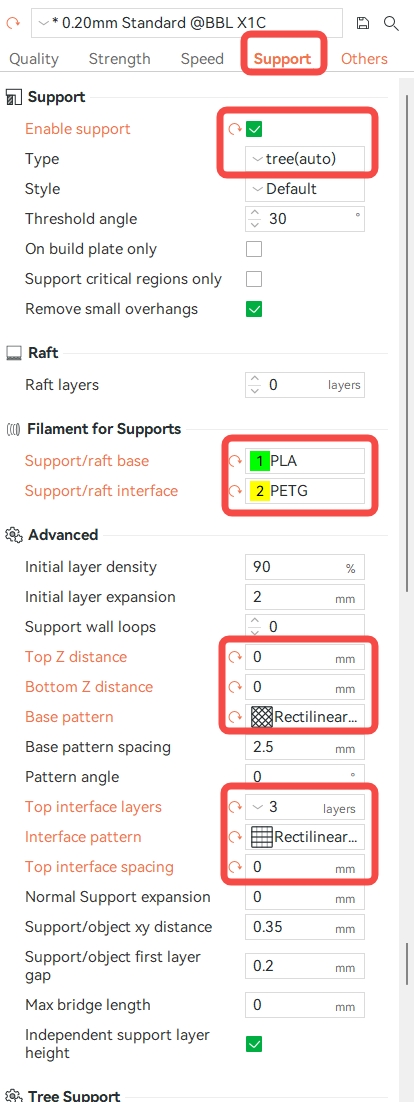

¶ Support parameter configuration

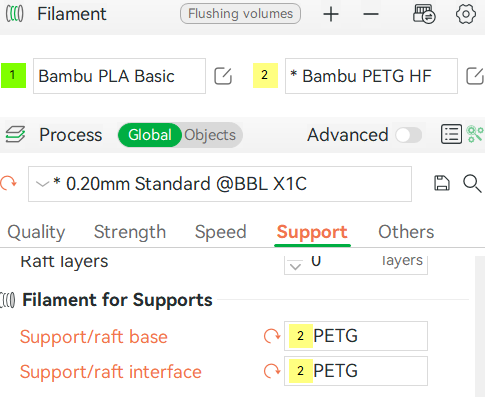

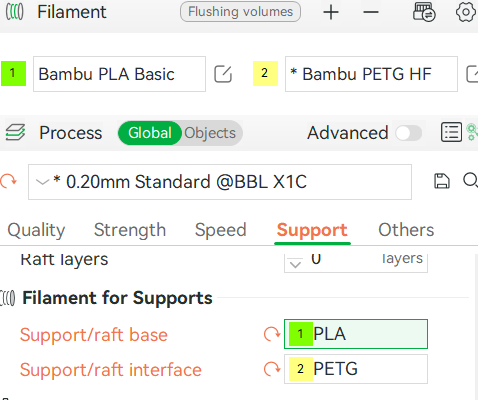

PETG HF can be both support/raft base and interface as the same time. Please see below for details:

Go to the Filament settings page.

- PETG HF as both support/raft base and interface.

Select Support/raft base and Support/raft interface to PETG HF.

- PLA Basic as support/raft base and PETG HF as support/raft interface.

Select Support/raft base to PLA Basic and Support/raft interface to PETG HF.

We recommend using PETG HF only for support/raft interface, because when it is used as the support base, the model support is easy to fall off. Please see the picture below for what parameters to configure.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a Technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.