¶ What is a clog?

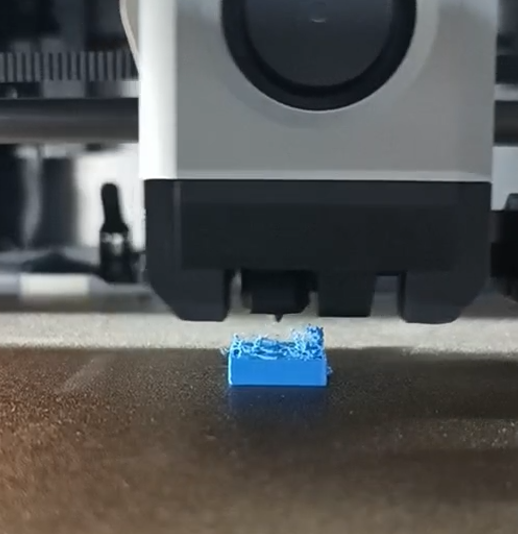

A clog is a common problem in 3D printing where the hotend or the extruder get clogged with filament and other debris.

When this clogging issue occurs, the filament stops flowing from the tip of the nozzle, or the extruder starts to generate “clicking” noises.

To better determine the source of the clog, please follow our Wiki article where we explain the process of identifying the issue: How to check which part is clogged | Bambu Lab Wiki.

We also strongly recommend double-checking the hotend and bed temperature to be set correctly for the filaments used: Filament & plate compatibility and parameter settings | Bambu Lab Wiki

¶ Extruder clog

¶ Why is this happening?

The extruder clog usually occurs because of filament deformation inside the extruder.

When this happens, the gears of the extruder cannot push the filament as expected towards the hotend, leading to a failure in extrusion.

¶ Potential causes and solutions

1. Heat Creep

Heat creep is a popular term in 3D printing that refers to the heat of the hotend transitioning to the cold side of the hotend. In the case of an extruder clog, heat creep is the most common reason caused by heat buildup inside the enclosure, which creeps inside the extruder. PLA is the most common filament that gets clogged as it has the lowest glass transition temperature, but this can also occur for PETG and TPU.

To avoid extruder clogs generated by heat creep:

- If the build plate type supports it, lower the heatbed temperature to ~35C.

- For an enclosed printer (X1 Series, P1 Series), keep the front door and/or the top cover of the printer open to avoid heat buildup inside the printer chamber.

- Use a filament with a high thermal deformation temperature (Bambu Lab Filament is less prone to heat creep clogs).

We also recommend reading the Heat creep and how to avoid extruder/hotend clogs wiki article to learn more about this issue.

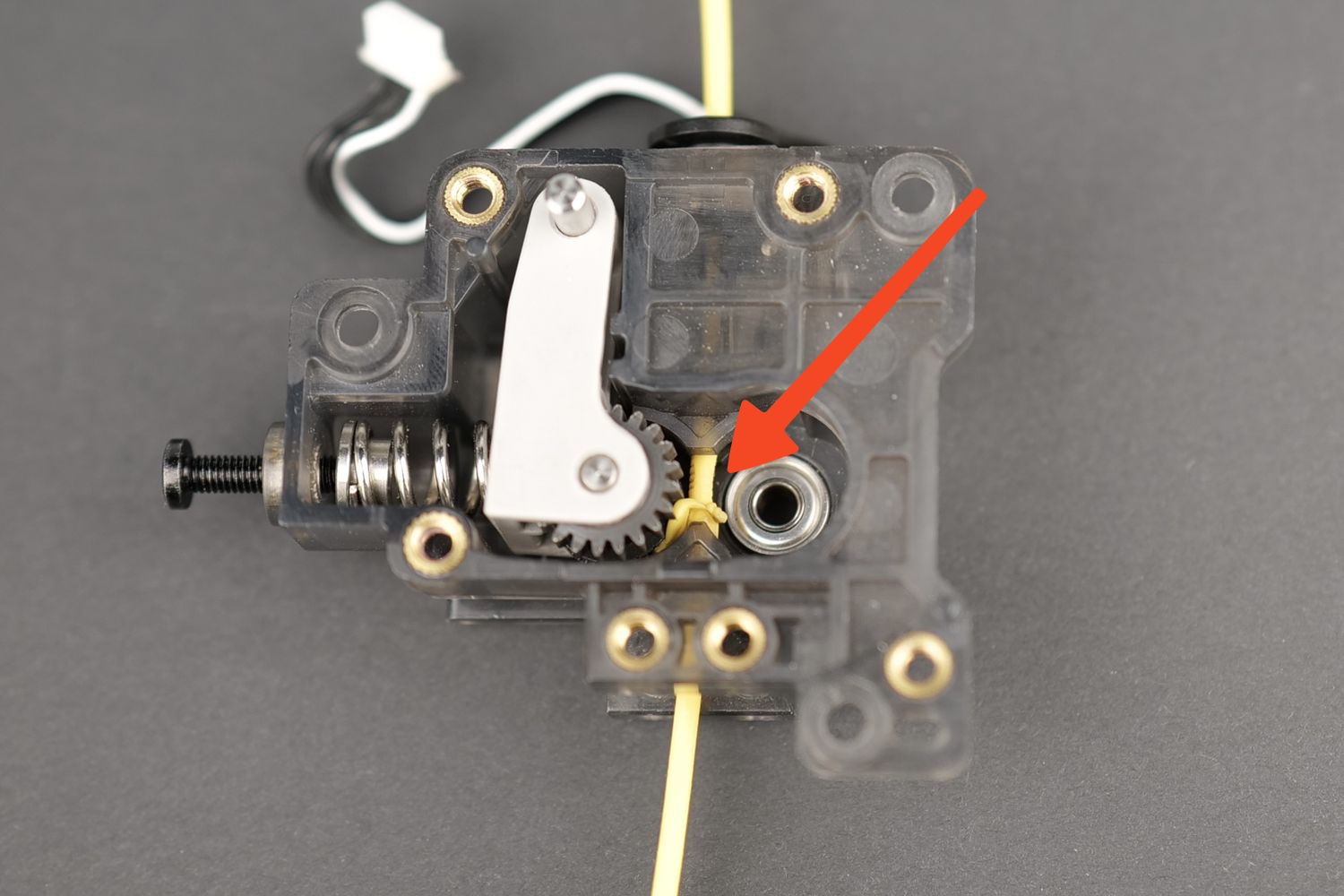

2. Extruder Gear is worn / dirty

Another common issue which can be manifested as an extruder clog is when the extruder gears are either worn out or dirty. It can happen after the printer has been used for a long time without any cleaning maintenance on the print head, or when a nozzle clog occured.

As an example, when the hotend/nozzle is clogged, the extruder will keep pushing the filament. Because the filament does not move, the extruder gears will grind the filament inside the extruder, leading to filament pieces being deposited on the gears lowering its grip.

To solve this problem, and avoid this issue in the future:

- Perform the Extruder Maintenance regularly to clean the extruder gears from any debris, and ensure proper lubrication. (Extruder Maintenance Guide: Cleaning and Lubrication - P1 series)

- If the extruder gears start to get worn out, replace them preventively to avoid an extruder clog during printing.

To test the extrusion and confirm everything works as expected, set the hotend temperature to 220C and load PLA filament into the extruder.

Next, extrude some filament using the on-screen buttons or from Bambu Studio/Handy then observe the flow of the filament.

If the filament is extruded smoothly from the hotend, in a simple vertical line, then this confirms the extruder is working as expected, and there is no anomaly in the hotend or the extruder gears.

3. Filament is too soft / gets flattened

In some situations, the filament can be either too soft for reliable extrusion (ex: TPU 85A) or the filament can be damp and will be flattened by the extruder gears (ex: damp PVA).

To solve this problem, and avoid this issue in the future:

- Avoid using very soft filament which can be compressed too much against the extruder gears

- Avoid using damp PVA filament, as this type of filament can lose its printing proprieties and will lead to clogs

- Confirm the filament compatibility of the printer, before using a new filament in it

- Properly dry filament, even if it was just taken out of the box

4. The filament diameter is incorrect

The filament diameter is another common reason for why the extruder could be clogged. Low-quality filament can have a big difference in tolerance from the ideal 1.75mm size leading to a clog.

In other cases, the filament can change its shape to become thicker due to bending or compression, or to become thinner due to the wear on the extruder gears.

To solve this problem, and avoid this issue in the future:

- Use High-Quality filament which has good tolerances and has been proven to be correct

- Always cut small pieces of filament if there has been a bend in it, to ensure it will be extruded smoothly

¶ Nozzle clog

¶ Why is this happening?

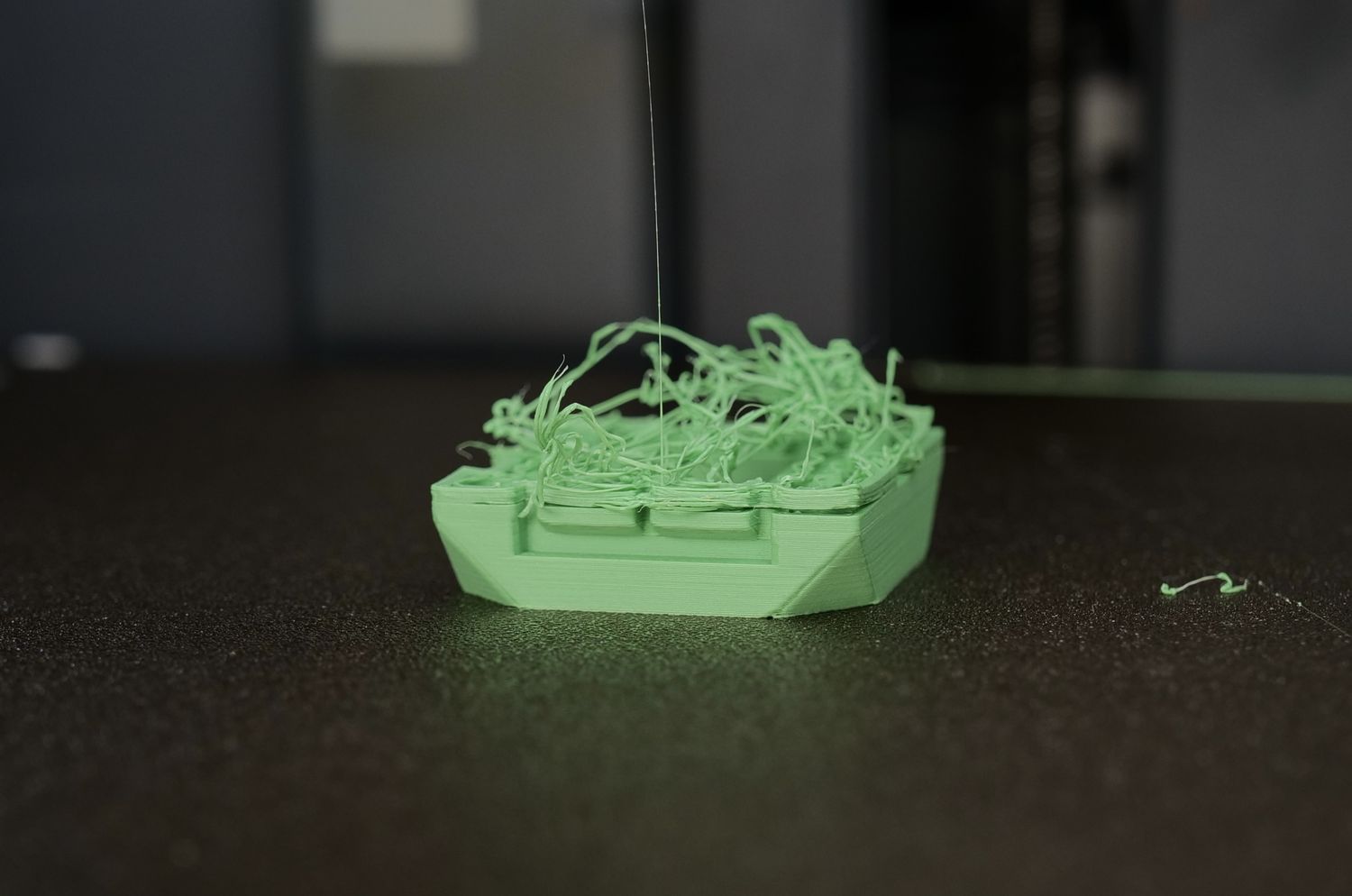

A nozzle clog is usually occurring due to small particles that reach inside the nozzle which block the orifice of the nozzle through where the filament would need to flow. These particles could be small specks of dust, or small debris from the extruder which can contaminate the filament.

In other cases, a nozzle clog occurs due to the additives included in the filament (ex: Carbon Fiber) which improve the features of the filament, but in turn, can lead to a high chance of a clog.

Another common issue for a nozzle clog is using a temperature too low for the filament used for printing. If the temperature is too low, the filament will not be extruded as expected, and it can in turn, lead to a hotend clog or an extruder clog.

¶ Potential causes and solutions

1. Nozzle melting speed is too slow leading to clogging

If the temperature of the nozzle is too low, the filament will not be extruded smoothly or will not be extruded at all.

In some situations, when using Sport Mode or Ludicrous Mode, the filament will not be melted efficiently and the extrusion will be inconsistent or a clog will occur.

To solve this problem, and avoid this issue in the future:

- Double check that the filament temperature set in the slicer, and on the printer is set according to the needs of the filament used.

- Confirm that the hotend temperature is stable, and the silicone sock is correctly installed on the hotend

- When using Sport Mode or Ludicrous Mode it's recommended to use a layer height of 0.16 mm or lower, and increase the hotend temperature by +10C for each speed change from normal.

- If the nozzle is worn out, or cannot be unclogged, replace the nozzle with a new one.

2. The channel inside the nozzle is narrowed, preventing smooth extrusion

After printing filament containing fiber and other particles (such as PAHT-CF, PA-GF, etc.), the inside of the nozzle may be partially clogged due to particle residue and accumulation, so the nozzle needs to be unclogged and cleaned frequently. We recommend following the Nozzle/Hotend Unclogging Procedure for best results and for more insight about this.

To solve this problem, and avoid this issue in the future:

- When printing filaments containing Carbon Fiber, it is recommended to use 0.6 mm or 0.8 mm nozzles to reduce the risk of nozzle clogging; do not use 0.2 mm nozzles as the risk of nozzle clogging is extremely high. For better printing of these filaments, please refer to the wiki: Printing Tips for Engineering materials like PAHT-CF | Bambu Lab Wiki

- After the nozzle is used for a long time, there will be more residue inside, which may also lead to poor extrusion. It is necessary to clean the inside of the nozzle with multiple cold pulls until the extrusion is smooth.

- After printing PAHT-CF, PET-CF, PPA-CF, PPA-GF, PPS, PPS-CF, and other high-temperature materials with high melting temperatures, when you want to print PLA, TPU, PETG, and other low-temperature materials with lower printing temperature and lower hardness, it is recommended to set the nozzle temperature to 250 - 300 °C first. Then, manually withdraw the high-temperature material, put in the low-temperature material to be printed, and then manually insert it to ensure that the residue of the high-temperature material and the new low-temperature material have been extruded. Next, set the nozzle temperature to 220 - 240 °C, and continue to extrude when the temperature is dropping. When it is stable, continue to extrude and make sure that the new material can successfully be extruded out of the nozzle. Finally, prepare for the next printing. If it is found that it fails to extrude when flushing the last material with new material, it is necessary to increase the temperature of the nozzle and use a needle to clear the nozzle.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.