¶ Introduction

TPU 90A is a thermoplastic polyurethane (TPU) filament with a Shore hardness of 90A.

- Hardness: TPU filament hardness is typically measured in Shore A, with 90A representing the hardness level of this filament.

- Elasticity and Flexibility: TPU 90A can stretch and bend over a wide range without breaking, with strong recovery. This characteristic makes TPU 90A excel in applications requiring elasticity and flexibility.

- Wear Resistance: TPU filament offers good wear resistance, maintaining stable performance over prolonged use.

In terms of applications, TPU 90A can be used in products that require elasticity and wear resistance, such as shoe soles, sports equipment parts, mobile phone cases, and smartwatch bands. Overall, TPU 90A is a high-performance thermoplastic polyurethane filament with versatile applications, and different hardness levels allow it to meet the needs of various use cases.

¶ Printing Guide

¶ Filament General Preparation

¶ Filament Storage Environment

To ensure that TPU filament does not absorb moisture and affect print quality during the 3D printing process or while stored, it is recommended to keep the filament in an environment with humidity below 20% RH. It is advisable to store the filament in a storage box with a desiccant (silica gel desiccant is recommended).

Please place silica gel desiccant in the storage box before storing the filament.

¶ Filament Drying

TPU filament has a high moisture absorption rate and easily absorbs moisture from the environment. If TPU with moisture is used directly in 3D printing, the moisture will rapidly vaporize when heated during printing, causing defects such as bubbles and holes in the printed product, which severely affects print quality and may even lead to print failure. Therefore, we recommend using the following equipment and parameters for drying.

For more details, please refer to: Filament Drying Recommendations.

| Blast (Forced Air) Drying Oven | Heatbed |

|---|---|

| 70 ℃, 8 h | 90 ℃, 16 h |

Due to the A1/A1mini being an open printer, it is not possible to dry the filament on a heatbed. If you have an X1 or P1 (sealed) printer, you can use the heatbed for drying.

If using a heatbed for drying, flip the filament every 4 hours and cover it with a PC box or filament box.

Heatbed drying reference: How to Dry Filament on the X1 and P1 Series Heatbed.

Please be aware of the following risks during the drying process:

⚠️ Spool Expansion Risk

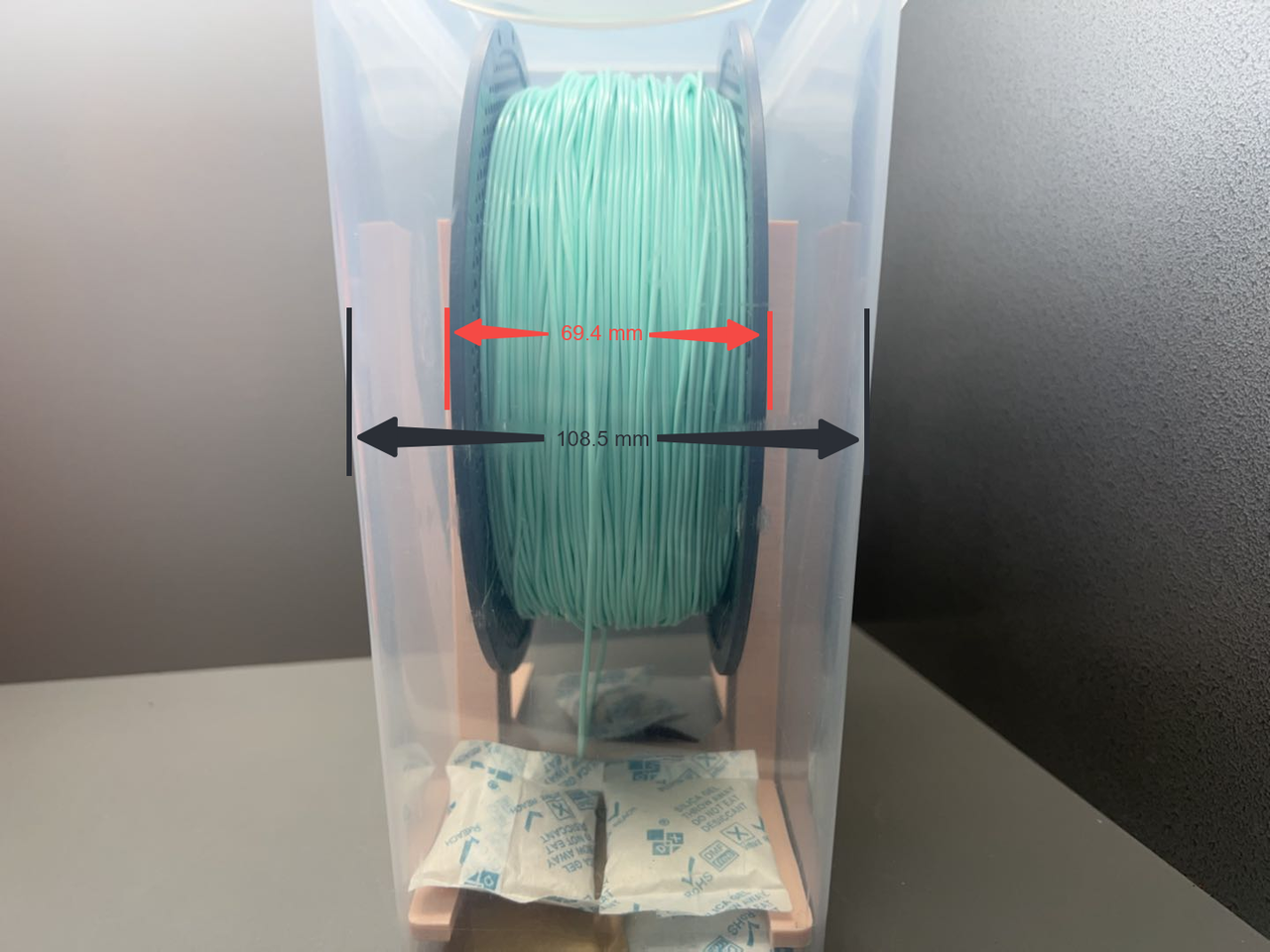

Before drying, the width of the undeformed spool edge is approximately 65.4 mm. During drying, the TPU filament expands when exposed to heat, causing the spool to deform and increase in size. After drying under the given parameters, the width of the spool edge may expand to approximately 69.4 mm.The 4L sealed box can ensure smooth spool rotation with a maximum width limit of approximately 67.5 mm. The 5.8L sealed box can ensure smooth spool rotation with a maximum width limit of approximately 108.5 mm, which is sufficient to allow the filament to rotate and load smoothly after expansion.

Therefore, we strongly recommend using a 5.8L sealed box for loading the filament after drying.

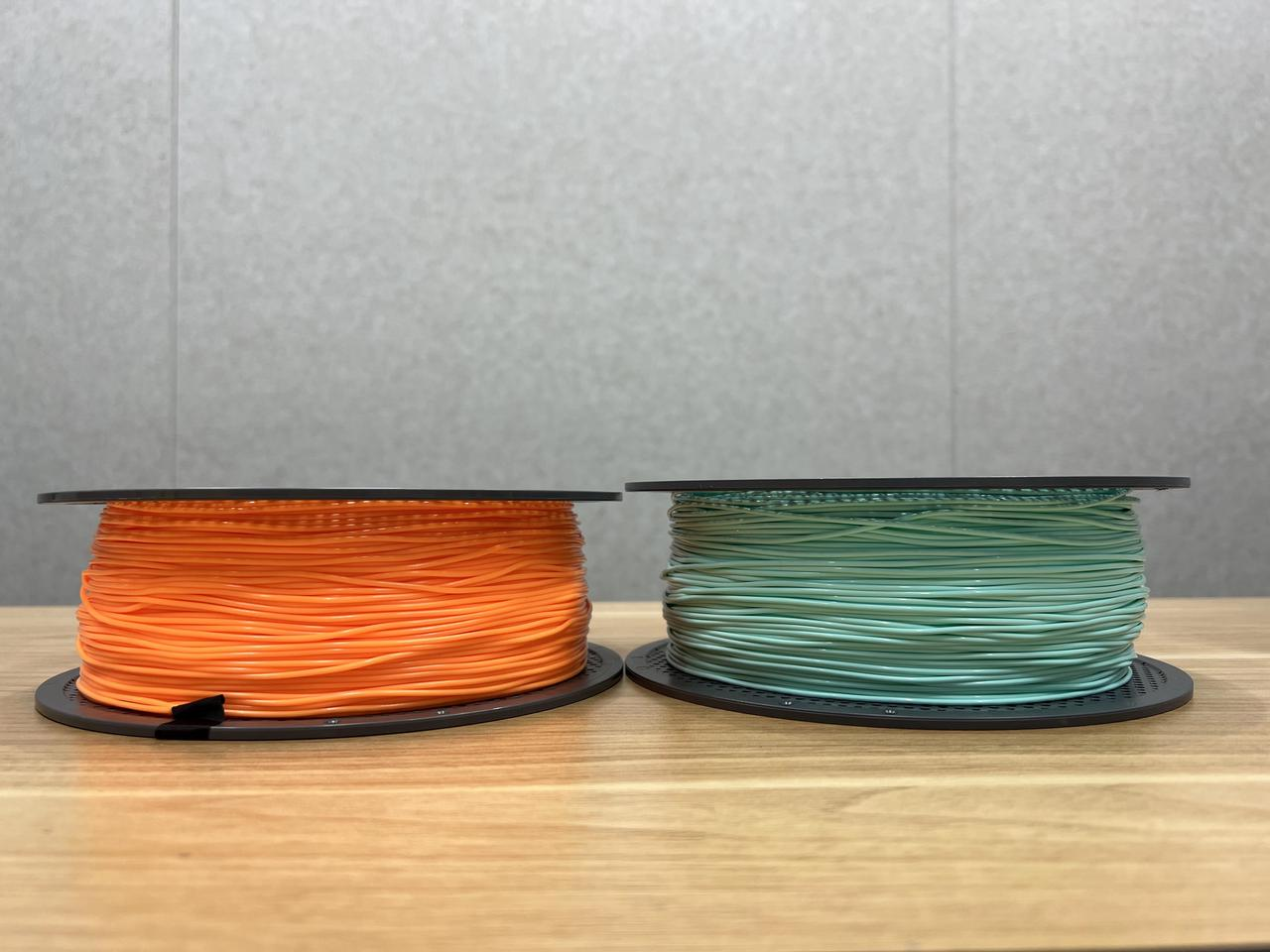

The right side filament spool is the expanded spool after drying The right side filament spool is the expanded spool after drying |

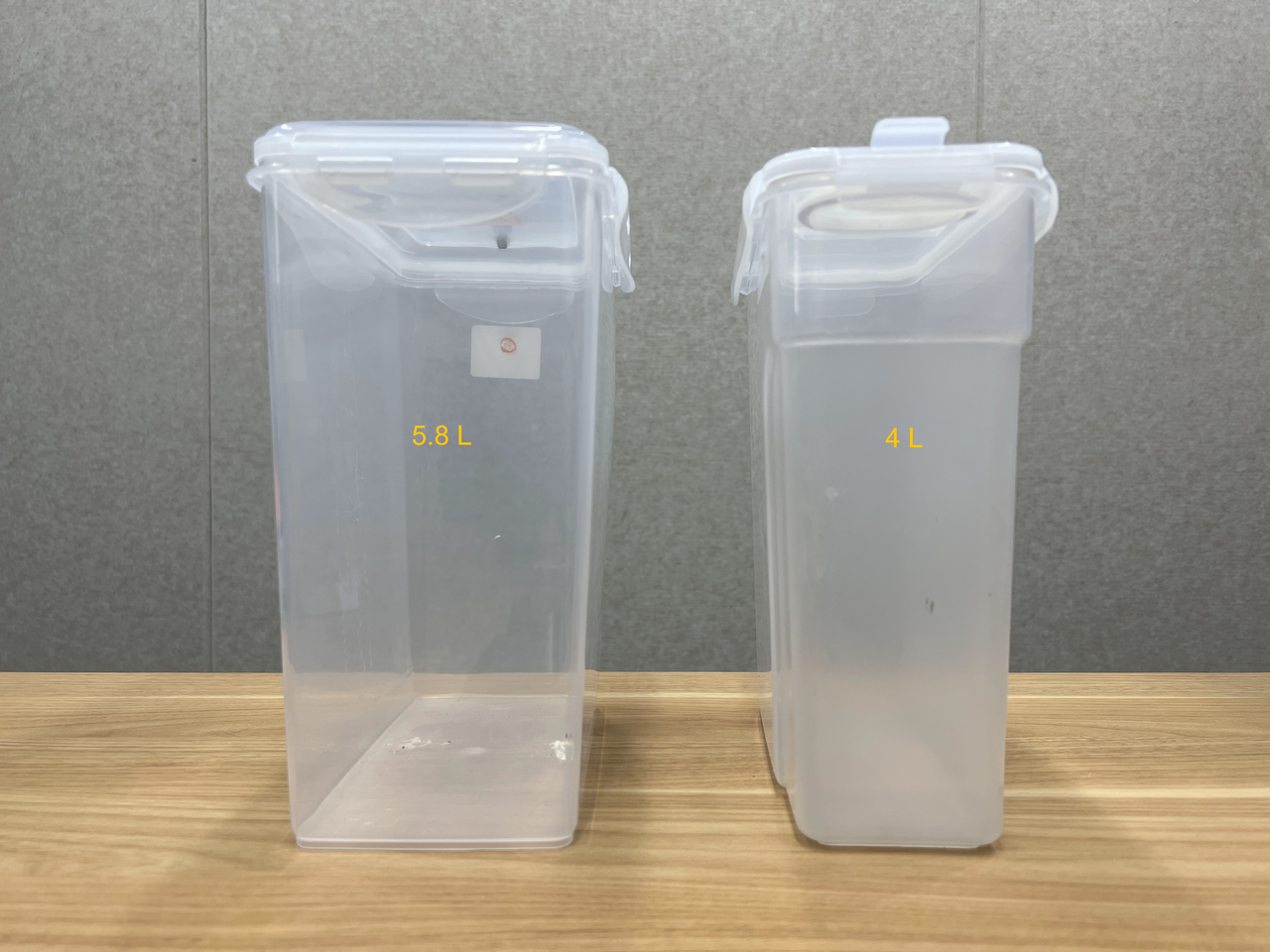

4L and 5.8L Sealed Boxes 4L and 5.8L Sealed Boxes |

The maximum width limit of the 5.8L sealed box is approximately 108.5 mm The maximum width limit of the 5.8L sealed box is approximately 108.5 mm |

The maximum width limit of the 4L sealed box is approximately 67.5 mm The maximum width limit of the 4L sealed box is approximately 67.5 mm |

Note:

-

When drying, using a heat-resistant heavy object to press down on the TPU spool can help prevent deformation. If the spool does not deform, the filament can be loaded using the 4L sealed box.

-

If using a sealed box for loading, be sure to use the spool holder to ensure smooth rotation of the filament. Additionally, to reduce loading resistance, please open the side opening of the sealed box.

Side opening of the sealed box |

Ensure smooth rotation of the filament |

4L sealed box holder link:https://makerworld.com.cn/zh/models/807064?from=search#profileId-784185

5.8L sealed box holder link:https://makerworld.com.cn/zh/models/437644?from=search#profileId-353897

¶ General Machine Preparation

¶ Hotend

To ensure the best print quality and results with TPU filament, it is strongly recommended to use a new hotend or a dedicated hotend for printing TPU.

| Filament | 0.2 mm hotend | 0.4 mm hotend | 0.6 mm hotend | 0.8 mm hotend |

|---|---|---|---|---|

| TPU 90A | Not compatible | Recommended | Recommended | Recommended |

¶ Build Plate

The textured PEI plate may become overly sticky after applying adhesive, so it is not recommended to use adhesive when printing with a textured PEI plate.

For other build plates, adhesive must be applied to prevent issues such as poor first layer quality, lack of adhesion, or even print failure.

Using a cool plate supertack to print TPU may result in overly strong adhesion, so cool plate supertack should not be used.

| Filament | Cool plate | Engineering plate | High Temperature/Smooth PEI Plate | Cool plate supertack | Whether to apply adhesive |

|---|---|---|---|---|---|

| TPU 90A | Recommended | Recommended | Recommended | Not compatible | Yes (except for the Textured PEI plate) |

Printer

Check and maintain the extruder (if there are foreign objects or filament residue, disassemble and wipe it clean). If the extruder gear is worn, it needs to be replaced (Otherwise, there may be issues with filament slipping).

If the hotend is not new, check the hotend condition (whether there is residue; if there is, raise the temperature and perform cold pulling 2-3 times using PLA / PETG filament, but do not use fiber-reinforced filaments for cold pulling).

Flushing Operation Steps (using PLA Matte as an example):

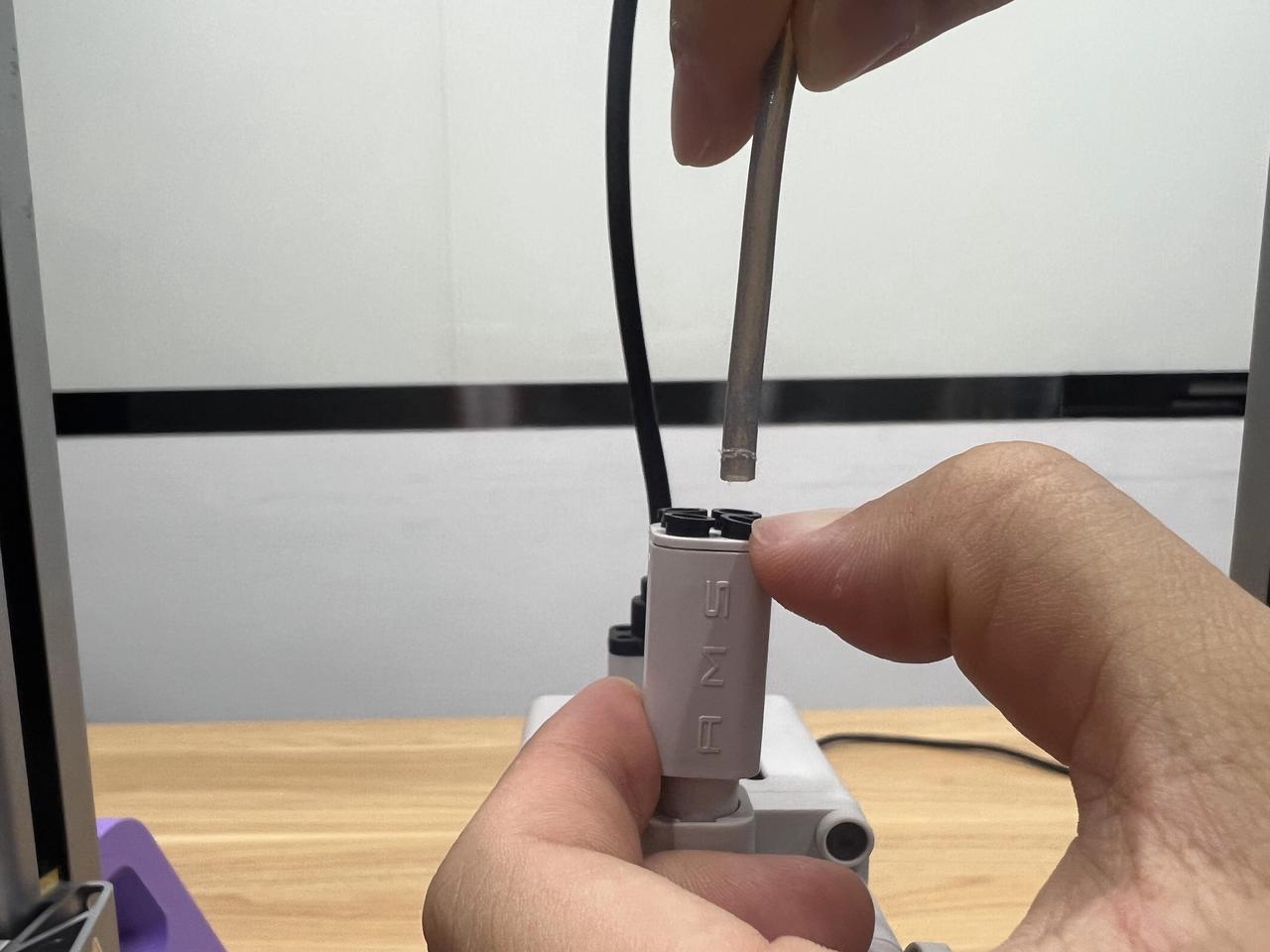

- For ease of operation, first disconnect the PTFE tube from the toolhead.

- It is recommended to raise the hotend temperature to 250°C, then insert a segment of PLA Matte filament into the toolhead.

- Press the "Extrude Down" button on the interface and observe whether the filament is extruded continuously and evenly. (This step should be repeated 3-5 times.)

Note: If you want to further clean the hotend to achieve better print quality, cold pull method is recommended. Please refer to this wiki: A1 mini Nozzle Unclogging Guide.

¶ Operating Precautions and Parameter Settings

¶ Filament Loading and Unloading Prerequisites

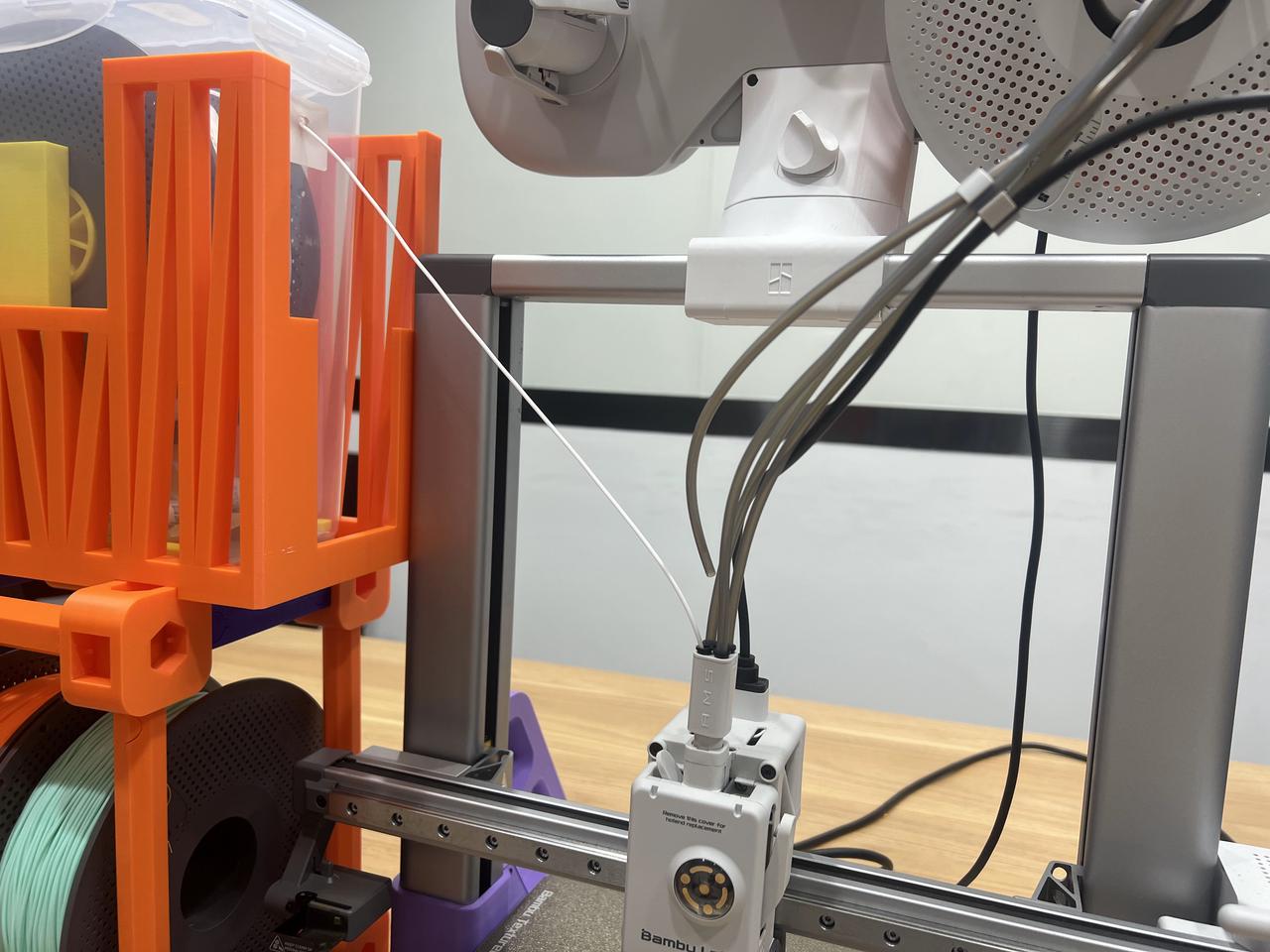

All filaments must have the spool elevated (the spool's discharge port should be higher than the toolhead's load port) to ensure smooth loading.

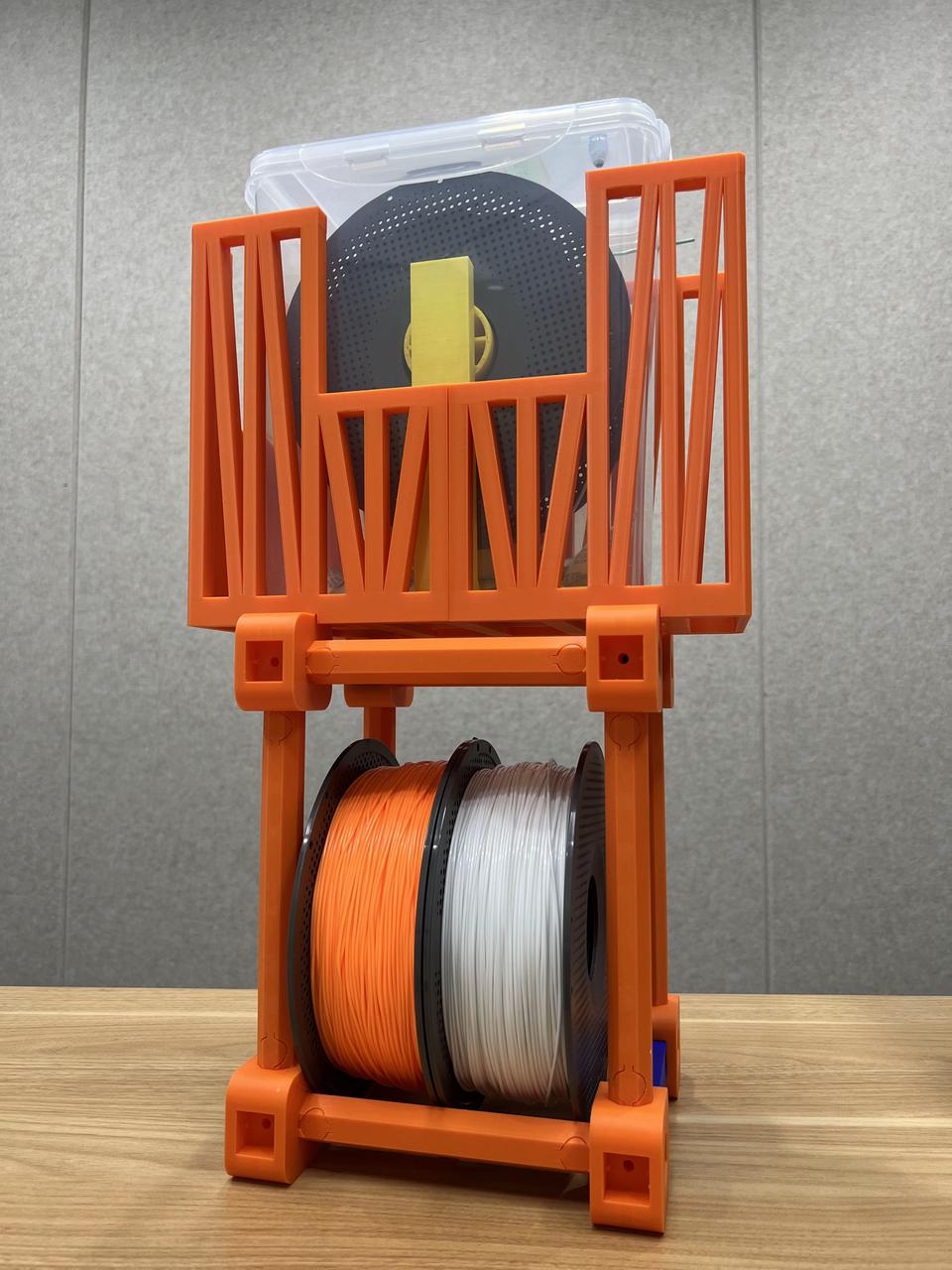

The spool holder links are as follows: TPU filament spool rack.

¶ TPU 90A Loading

Pre-loading Reminders:

- Ensure the filament is fully dried before loading.

- When using a filament spool for loading, load the filament through the side opening.

Pre-loading Preparation:

- Remove one of the PTFE tubes connected to the toolhead, and make sure there is no other filament inside the extruder.

- Place the spool holder next to the printer, ensuring the filament discharge port is positioned higher than the extruder inlet.

|

|

Loading Steps:

- It is recommended to preheat the hotend to 250℃.

- Pull the filament from the spool and directly insert it into the extruder inlet.

- Slowly and intermittently click the "Down Arrow" button to load the filament until it extrudes smoothly and continuously from the hotend.

TPU 90A Loading Precautions:

- During filament loading through the toolhead, if you notice significant resistance, please check whether the filament spool rotates smoothly inside the filament container.

- Once the extruder gear has gripped the TPU filament, slowly click the extrude button to ensure the filament extrudes smoothly from the hotend, avoiding loading failures.

¶ TPU 90A Unloading

For A-series printers, manual unloading is required after heating up the hotend. Automatic unloading using the cutter is not supported.

Unloading Steps:

- Preheat the hotend to 250℃.

- Slowly click the "Up Arrow" button to reverse the extruder gear, while gently pulling the filament out of the toolhead.

¶ Parameter Settings

In addition to the preset parameters, specific parameter settings should be adjusted according to the characteristics of the model.

- The recommended printing temperature for TPU 90A is 225℃, with a heatbed temperature of 30 - 35℃.

- Please keep the default max volumetric speed limit during printing, and avoid increasing the print speed.

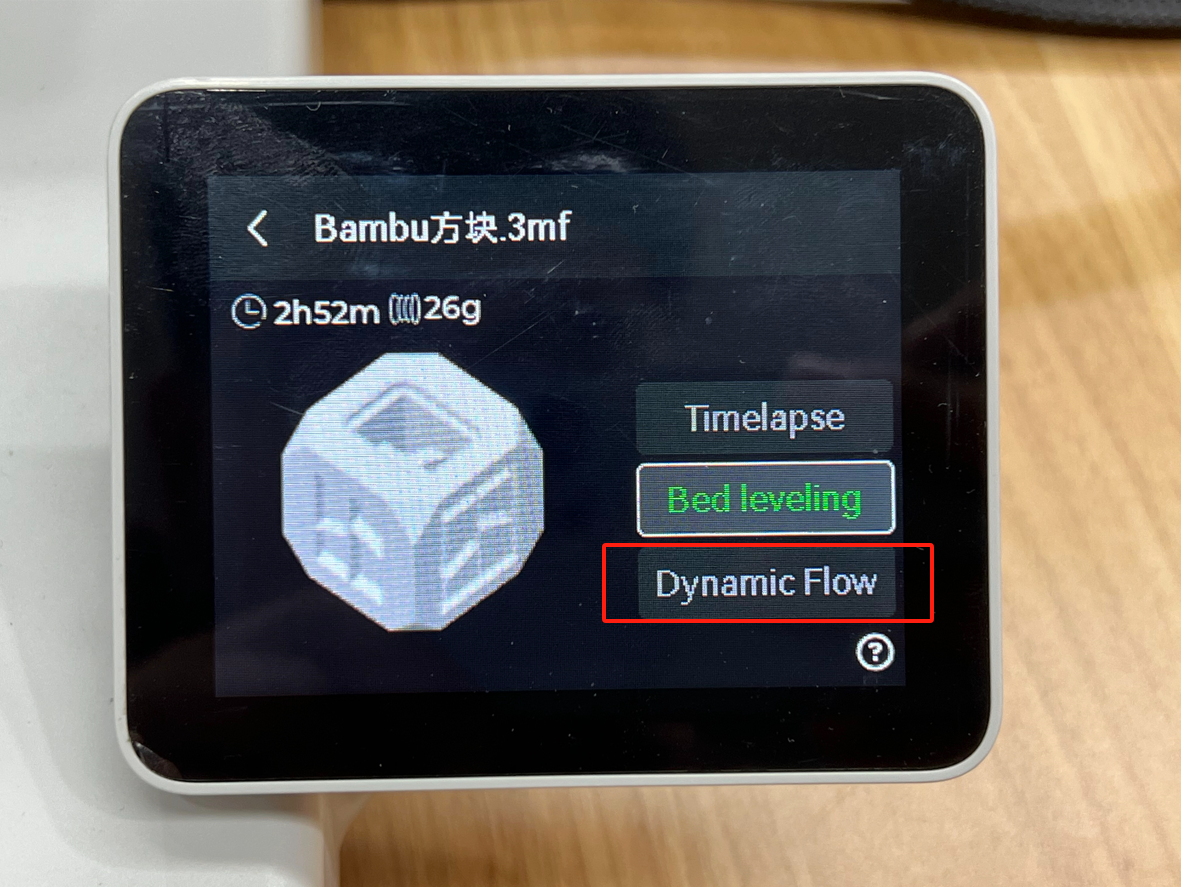

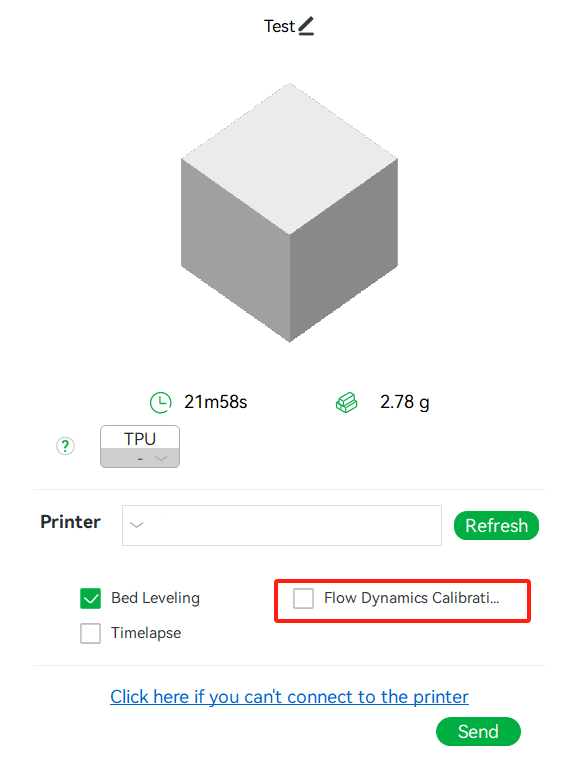

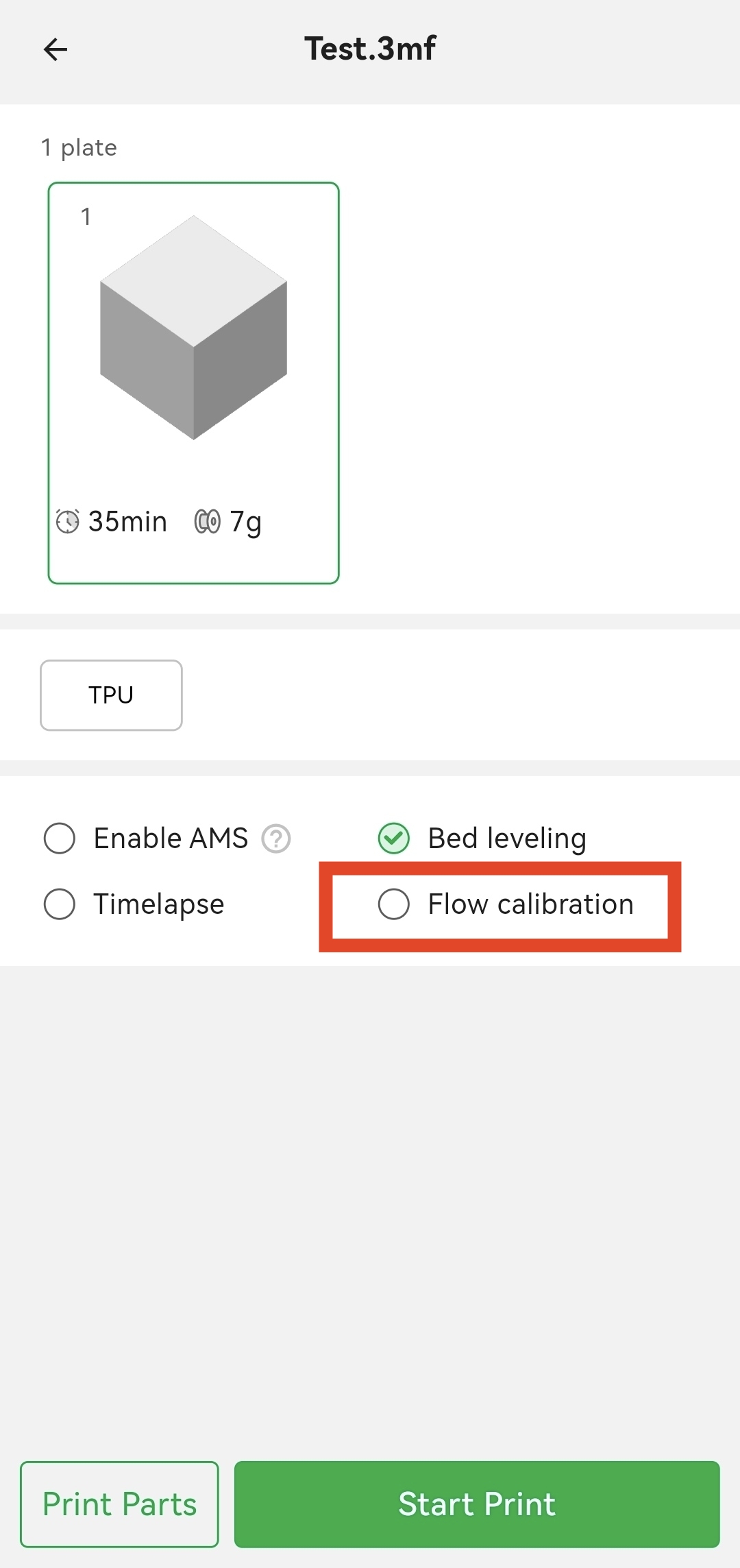

- When printing TPU 90A, please disable flow dynamic calibration.

|

|

|

- It is not recommended to print tall and thin models, as TPU filament is relatively soft. When the printed model reaches a certain height, it may wobble, leading to print failure.

¶ Common Printing Issues

TPU filament is prone to the following problems:

- Under extrusion (Nozzle clogging, loading resistance, filament slipping)

- Extruder clogging (Filament bending, causing a clog in the extruder gear; disassemble the extruder and remove the clogged filament)

- Stringing and oozing (You can use a larger diameter hotend, fine-tune the retraction settings, further dry the filament, and apply post-processing to the model)

For detailed troubleshooting and solutions, please refer to this wiki: Common print quality problems and solutions.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!