¶ 1 Introduction

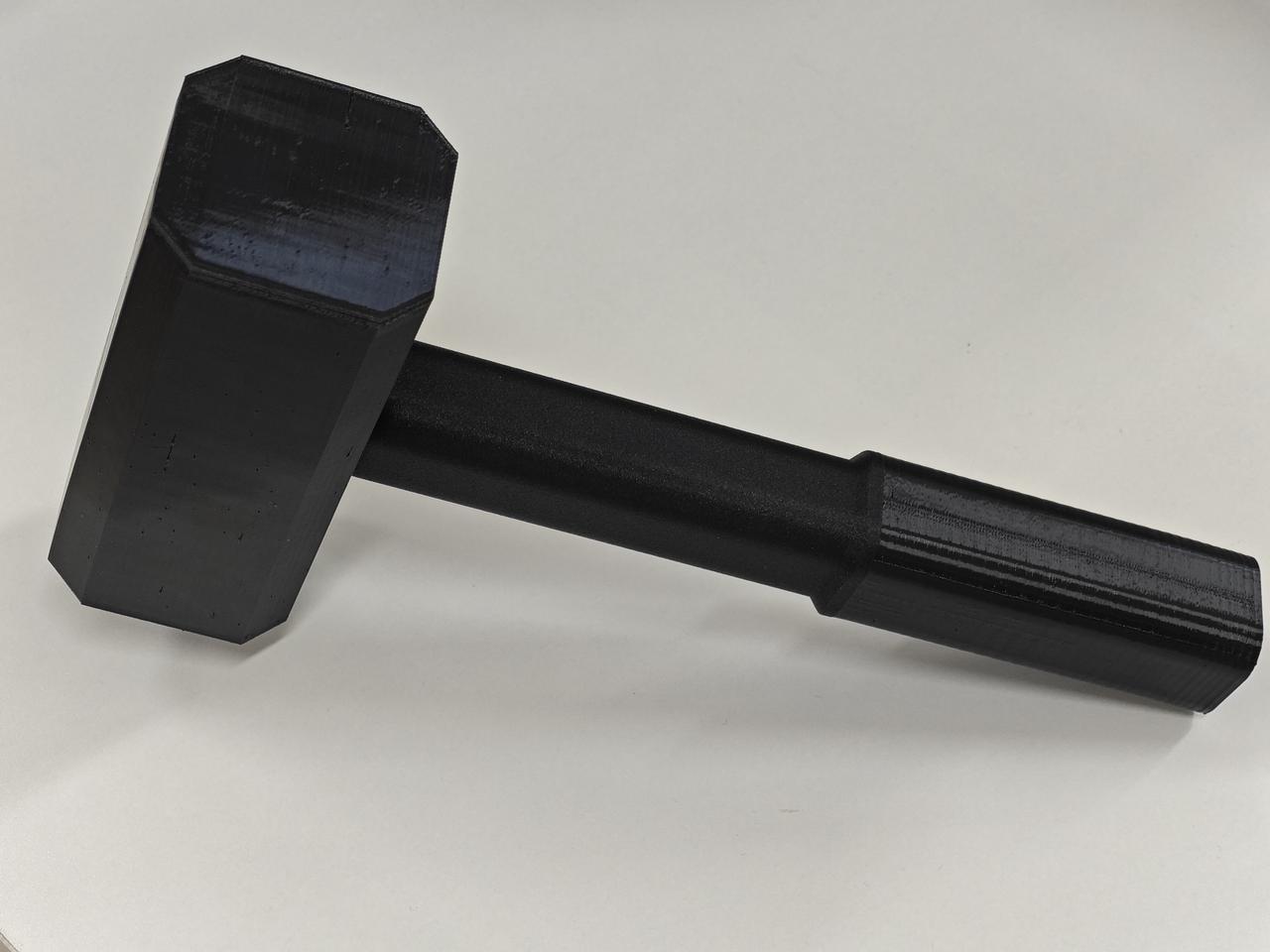

The H2D printer supports printing with rigid filaments (left hotend) and TPU filaments (right hotend), enabling soft and hard filament multi-material printing. To optimize the soft and hard filament multi-material printin experience, two new features have been introduced on the H2D to help users better combine TPU and rigid filaments in their printed parts.

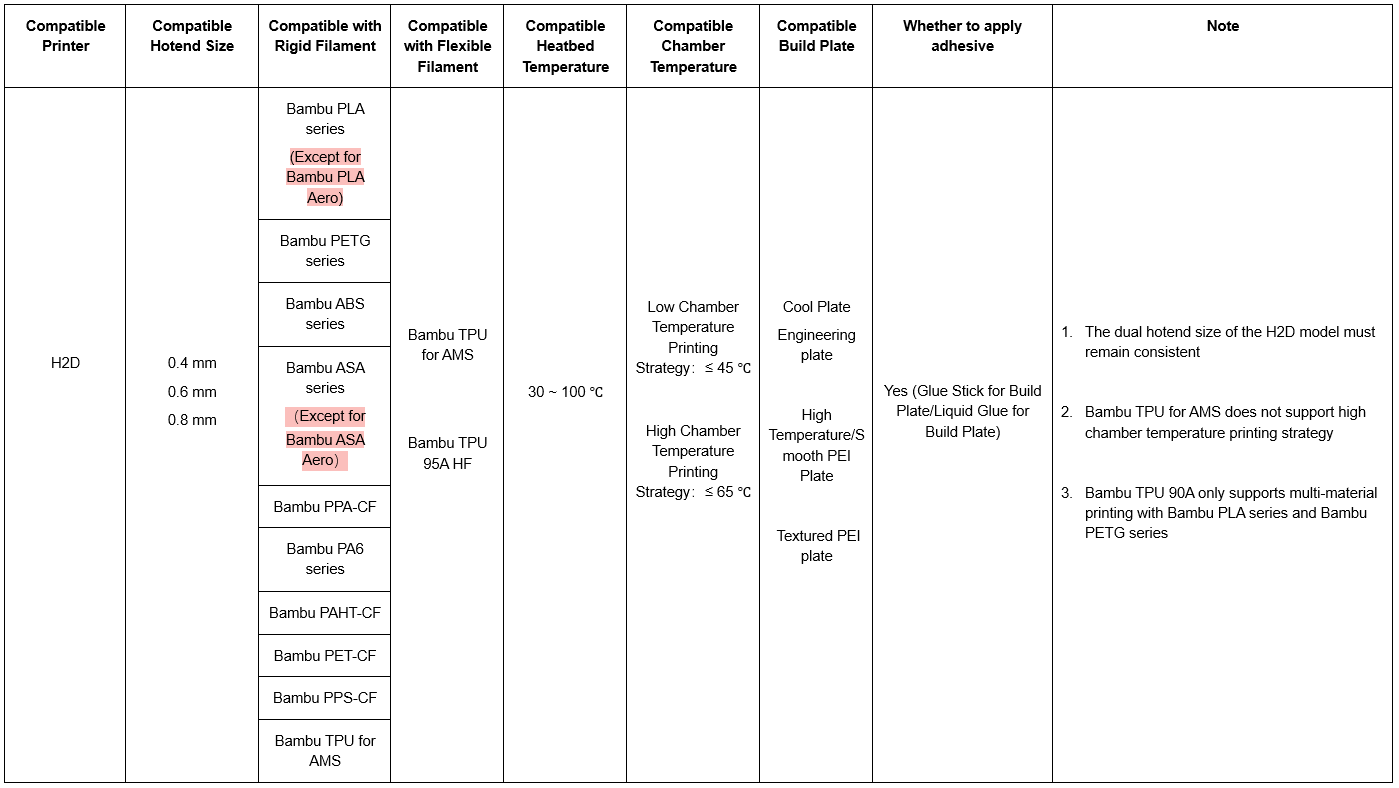

¶ 2 Applicable Models, Accessories, and Filaments

¶ 3 Studio Beam Interlocking Function

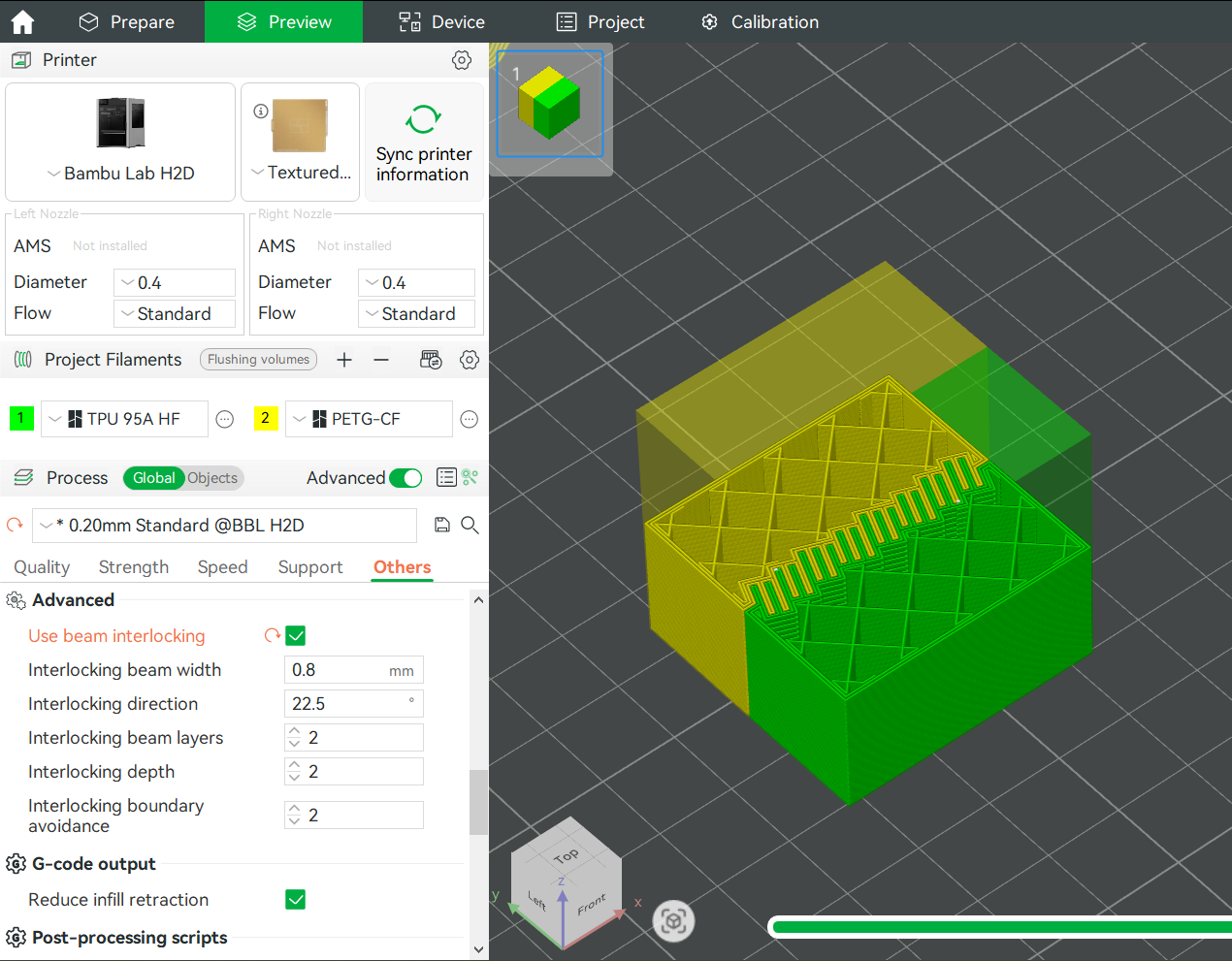

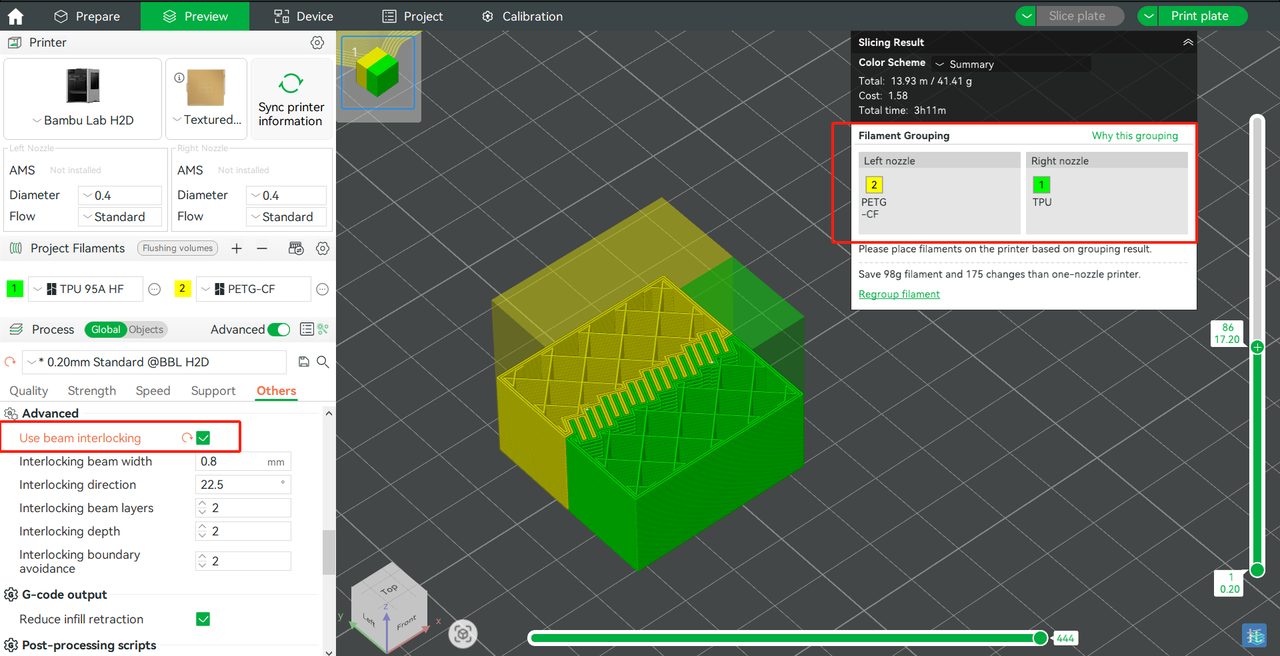

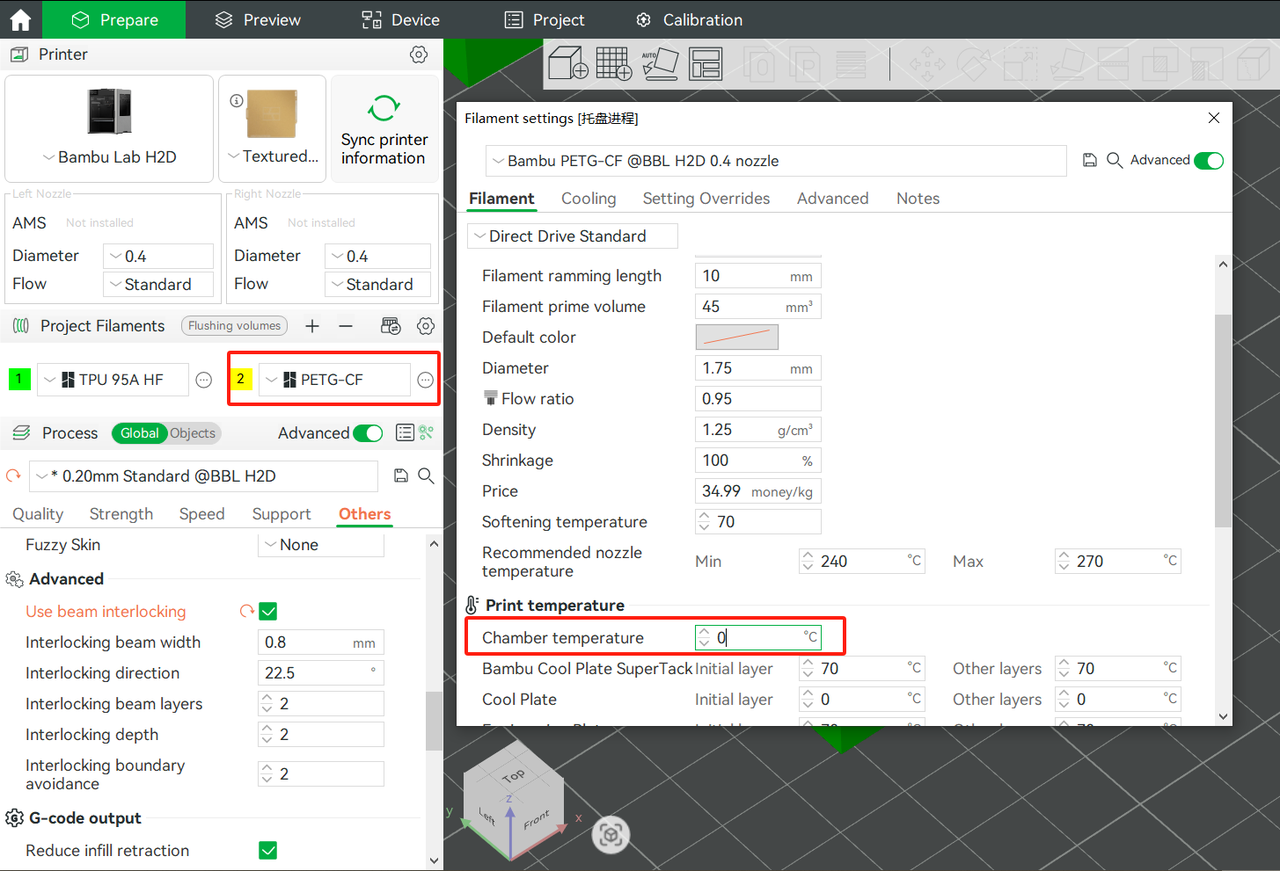

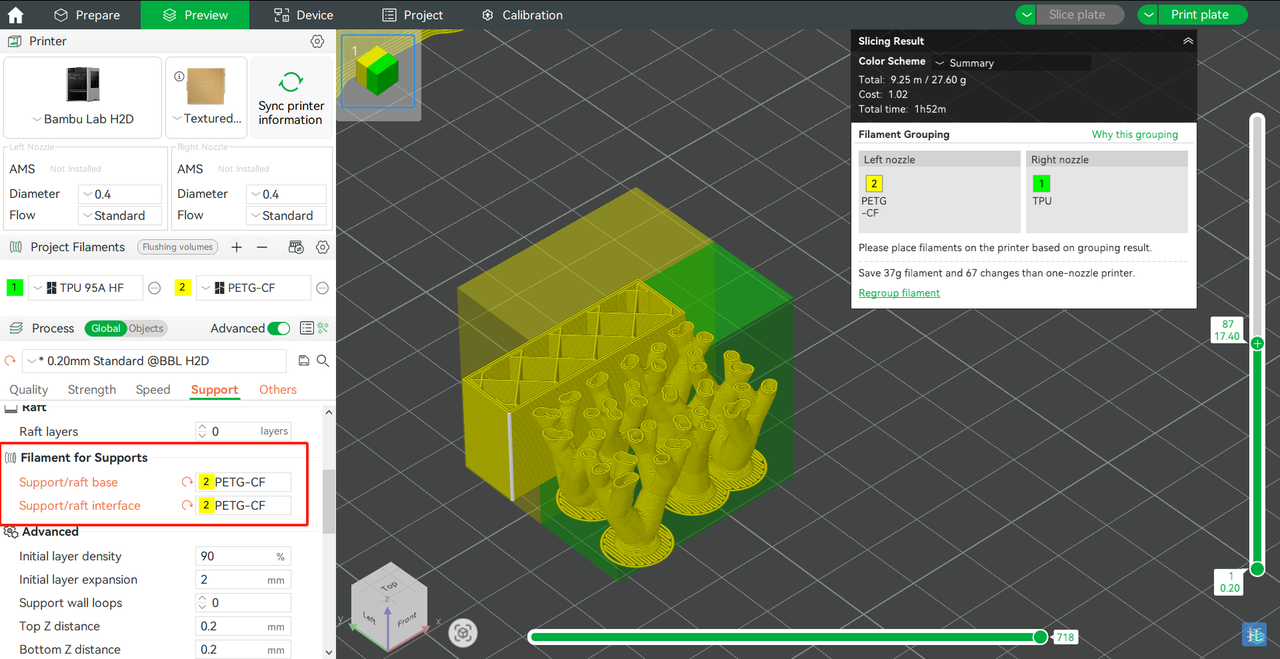

To improve the bonding strength between rigid and flexible filaments, Bambu Studio has a preset "Use Beam Interlocking" option (the slicing option and interlocking structure are shown in the image below). This feature enhances the connection at the interface between the two different filaments, which will increase the application value of hybrid models with rigid and flexible filaments.

¶ 3.1 Operation Process

Using PETG-CF and TPU 95A HF as an example, the process for printing with interlocking structures is as follows:

- Loading: PETG-CF is loaded from the left hotend, and TPU 95A HF is loaded from the right hotend.

Note: When the heatbed temperature is above 80°C, the glass cover plate must be removed.

- Slicing settings: Enable the "Use beam interlocking" option, adjust the relevant parameters according to the actual model, and ensure that the chamber temperature is turned off.

- After setting the support base filament to a rigid filament, you can start the print (if the model requires support)

¶ 4 High and Low-temperature Filament Multi-Material Printing (Experimental Feature)

Preface:

In the ongoing journey to push the performance boundaries of H2D, we developed this feature to provide creators with more powerful tools, fully unleashing the limitless possibilities hidden behind each print. With this feature, users can cleverly combine flexible TPU with reliable engineering filaments on the same printed part, achieving unprecedented product excellence. The combination of TPU and engineering materials in printing holds immense application potential across various fields. For example, in industrial design, it allows for the direct printing of soft and hard combined component models, providing more realistic references for product development.

However, it is important to note that in order for the printer to successfully transform your creativity into a product, please make sure to strictly follow the tutorial guidance we provide when using this feature. Improper operation may damage the printer and affect your normal usage and future experience.

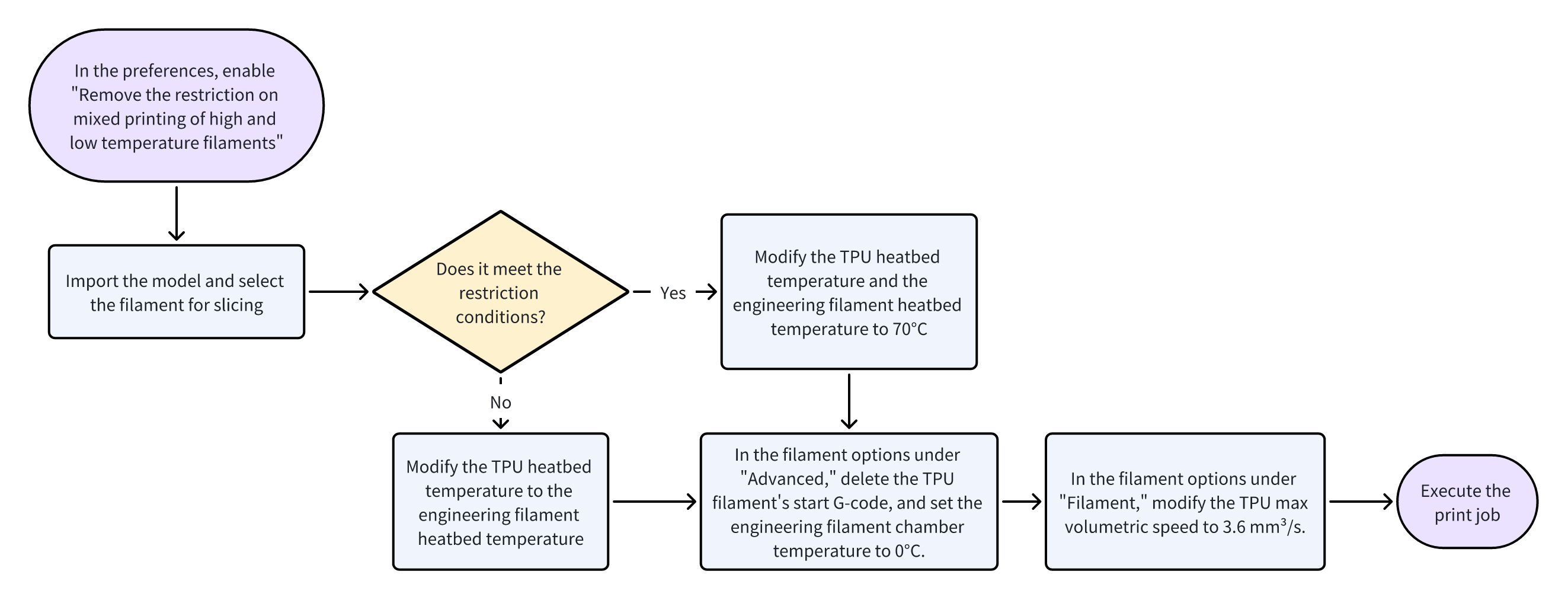

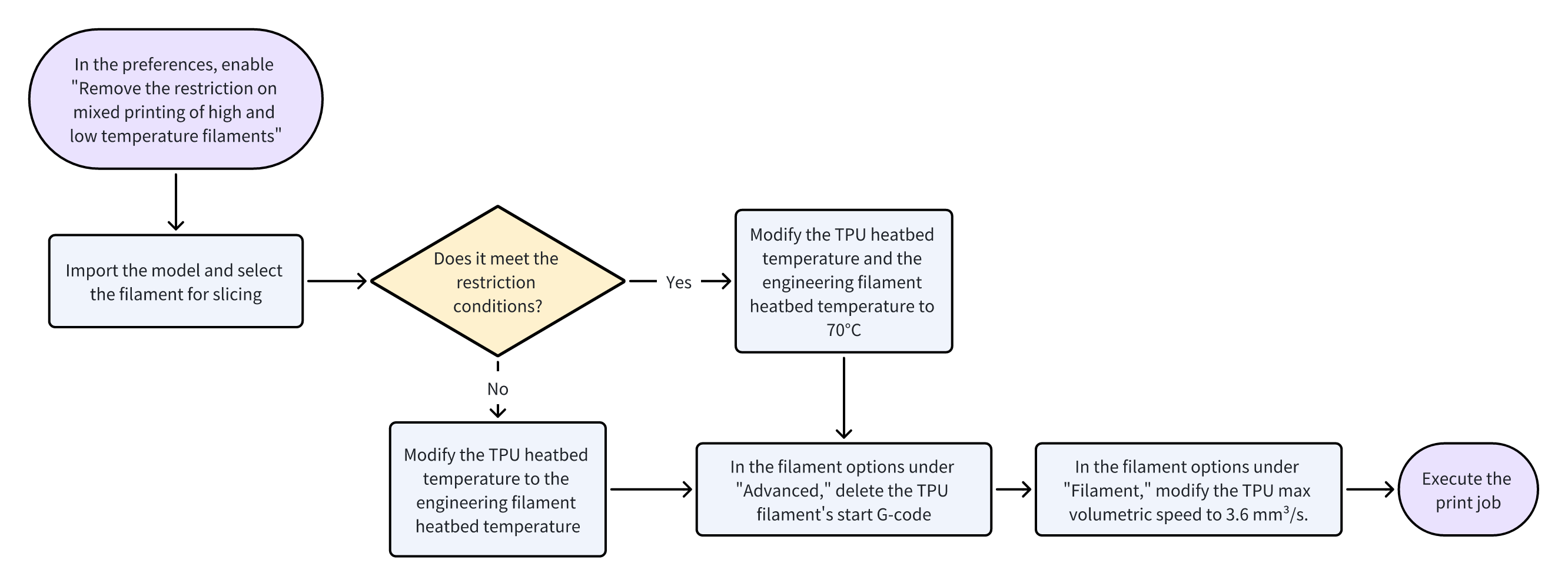

Below is the operation process:

¶ 4.1 Filament Preparation

We strongly recommend using Bambu Lab official filaments to ensure print quality and equipment safety. Due to the high temperatures during the printing process, which can cause filament to soften, this feature currently only supports TPU 95A HF filament. Additionally, printing with flexible filaments is only allowed on the right hotend.

If you plan to use third-party filaments, be sure to carefully read their manual and consult the manufacturer to confirm compatibility with this feature before use.

Additionally, the TPU filament used must be dried before printing. If not dried, there is a high risk of clogging during the printing process, which may prevent the print task from being successfully completed. We recommend using AMS HT, setting the temperature to 75°C and drying for 18 hours. If your filament has significant moisture absorption, you can adjust the drying parameters as needed to optimize the drying process and ensure the filament is in the best printing condition.

You can refer to the following Wiki for guidelines on filament drying and TPU printing:

When loading filament, it is recommended to use AMS HT or a sealed box as the storage container for the filament. If the storage method causes the extruder to apply excessive drag force during the loading process, it can result in the TPU not extruding, leading to a "dry run" and ultimately print failure. Therefore, make sure to minimize loading resistance in the loading chain, such as avoiding the use of excessively long PTFE tubes and ensuring the spool rotates smoothly without any jamming.

¶ 4.2 Model-Based Printing Mode Selection

⛔ Printing Model Restrictions:

Restriction 1:

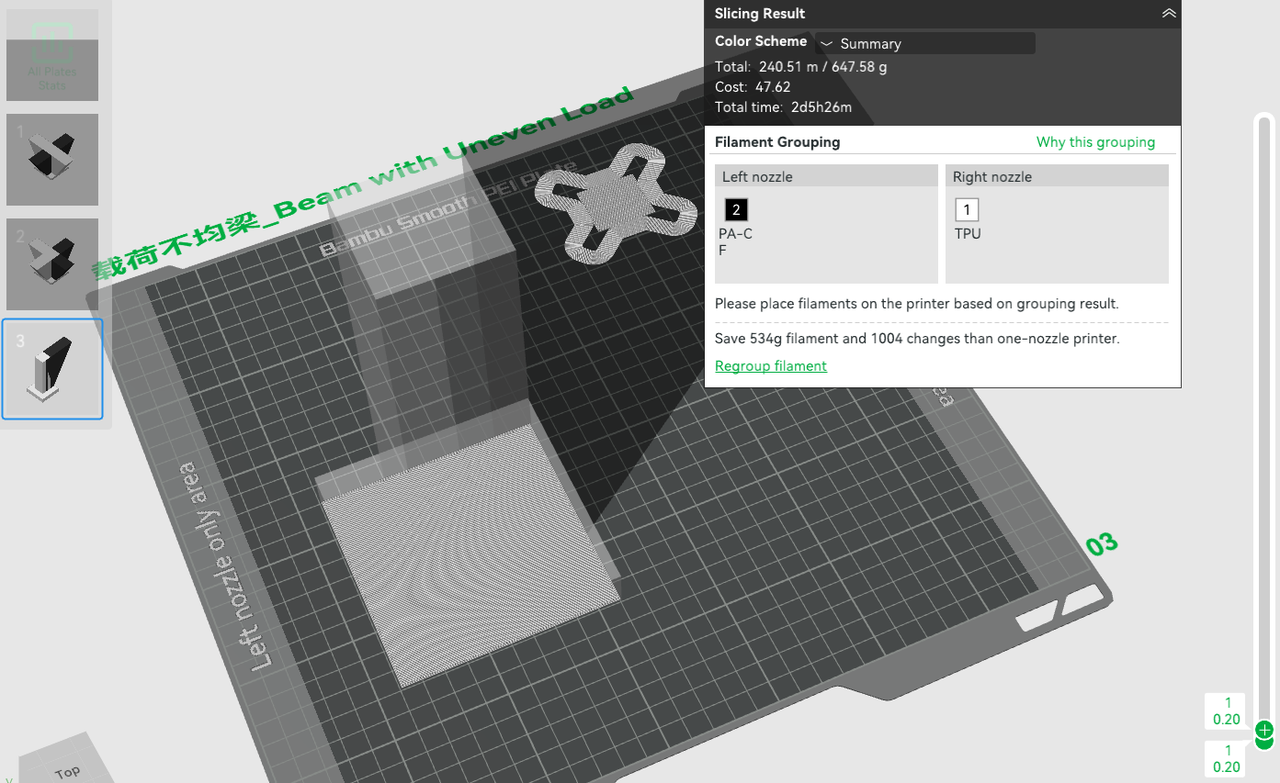

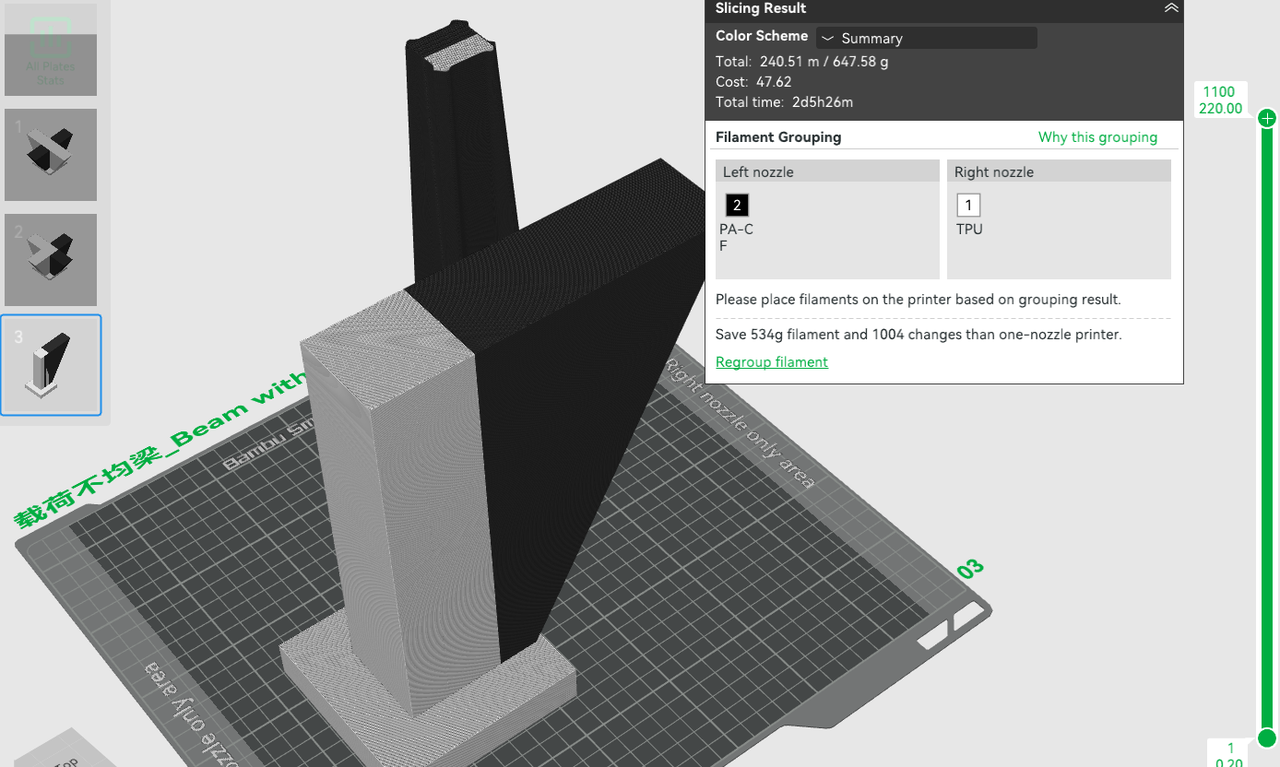

If the first layer of your model is entirely made of TPU or if TPU serves as the primary load-bearing structure of the model, please select a low chamber temperature printing slice. In the heatbed temperature settings, please take note of the following:

-

Do not modify the TPU heatbed temperature;

-

Set the heatbed temperature for the engineering filament below 70°C to prevent deformation of the model base structure due to its own weight.

Printing Mode Selection

When selecting the printing mode for your model, if the majority of your model is printed with TPU and you aim for a higher printing success rate, we recommend using low chamber temperature printing. A low chamber temperature environment better accommodates the characteristics of TPU filament, reducing potential issues during the printing process. Additionally, if the parts of your model that connect to the heatbed are entirely made of TPU, please set the heatbed temperature for the engineering filament below 70°C.

On the other hand, if you want to maximize the strength characteristics of the engineering filament and pursue high strength printed parts, you can opt for high chamber temperature printing. However, high chamber temperature printing imposes stricter requirements on both the filament and the printer. Your filament must be fully dried, and this mode is only supported when loading TPU 95A HF via an external spool. Furthermore, to ensure print quality and device safety, you must use either a new hotend or a dedicated hotend specifically for TPU printing.

¶ 4.3 Low Chamber Temperature Printing Slice and Printer Preparation

¶ 4.3.1 Printer Preparation

Before starting low chamber temperature printing, the printer needs to be properly prepared.

First, remove the glass cover plate to prevent the heatbed from increasing the chamber temperature. For detailed removal steps, please refer to the image below:

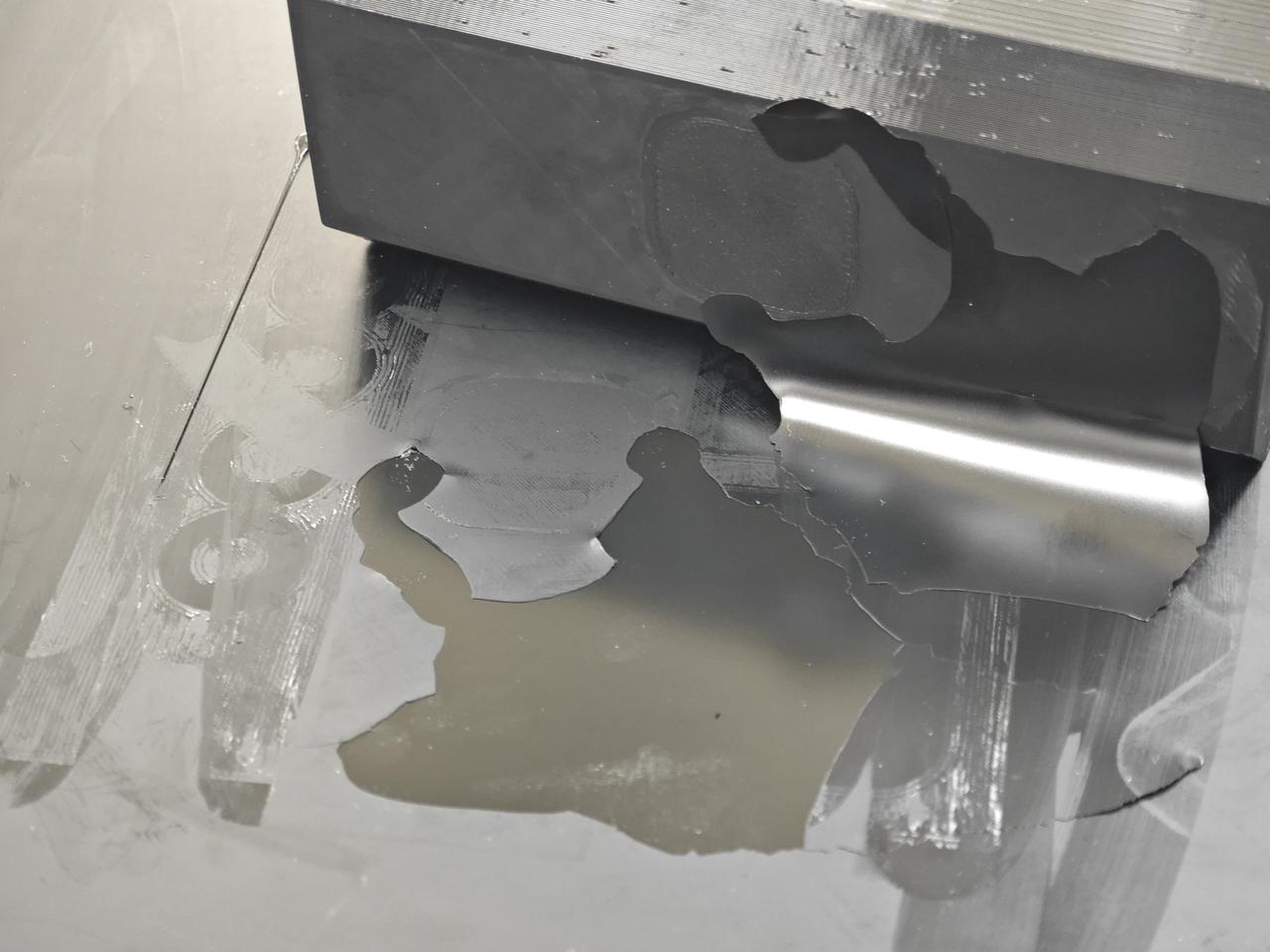

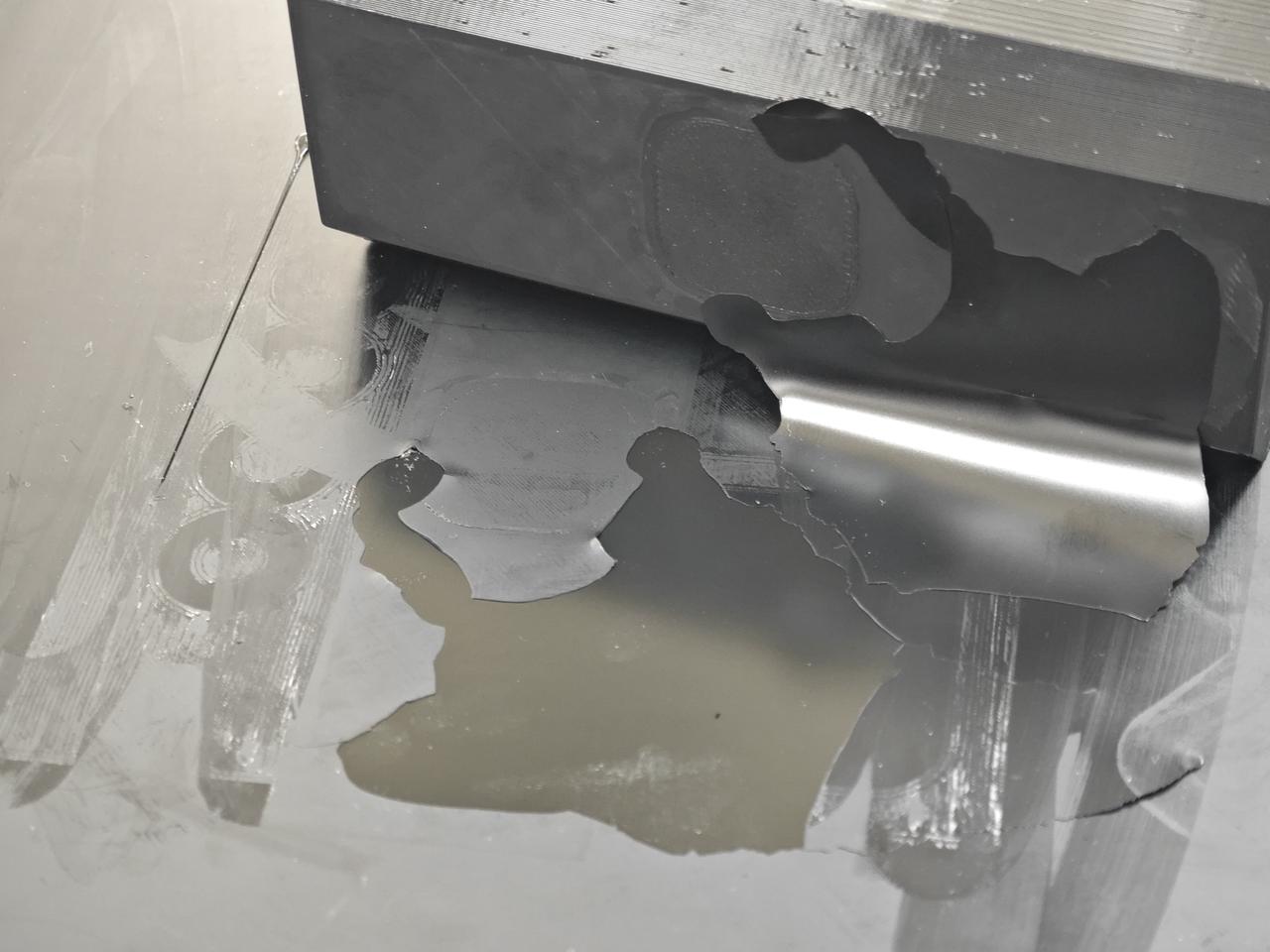

The high temperature build plate can create a very strong bond with TPU. Before printing, be sure to apply glue to the build plate to protect it. If the glue is not applied, damage like the one shown in the image below may occur.

You can refer to this Wiki for detailed steps on applying glue: https://wiki.bambulab.com/en/general/how-to-use-bbl-liquid-glue

Please make sure that the build plate is coated with glue before printing. If you unfortunately forget to apply the glue, use alcohol to soak the area where the model is attached to the print bed, and gently remove it.

¶ 4.3.2 Slicing Settings Example and Steps

Setup Process:

The 3MF file that has been set up:

Low chamber temperature TPU 95A HF PAHT-CF.3mf

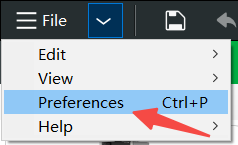

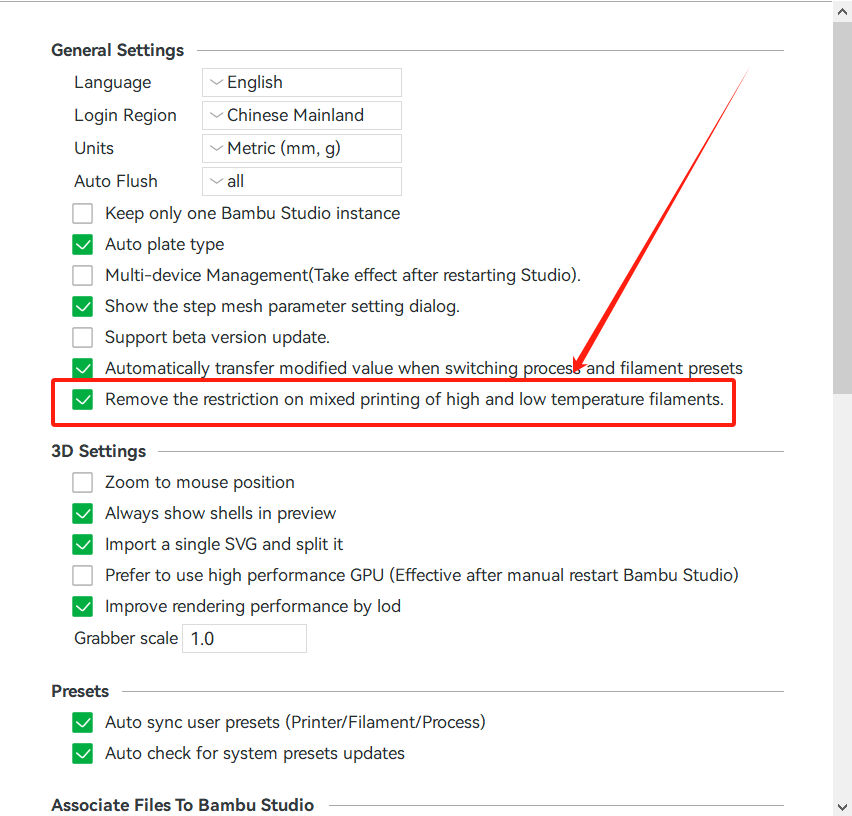

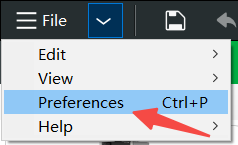

- In Bambu Studio, go to the preferences in the top-left corner

- In the preferences, check the option shown in the image.

Note! Before checking this option, please make sure you are aware of the risks of high and low-temperature filament multi-material printing and have carefully read this document.

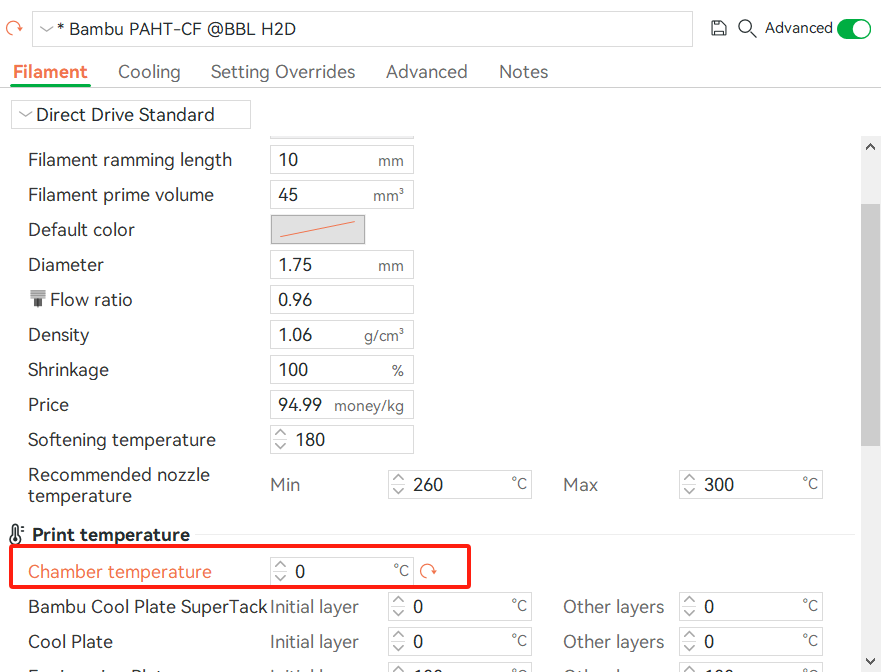

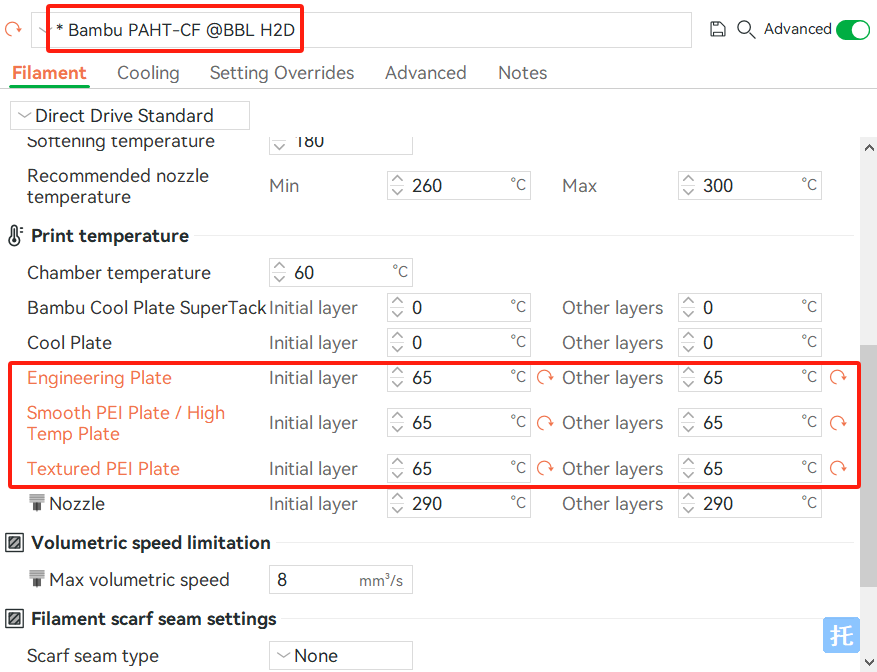

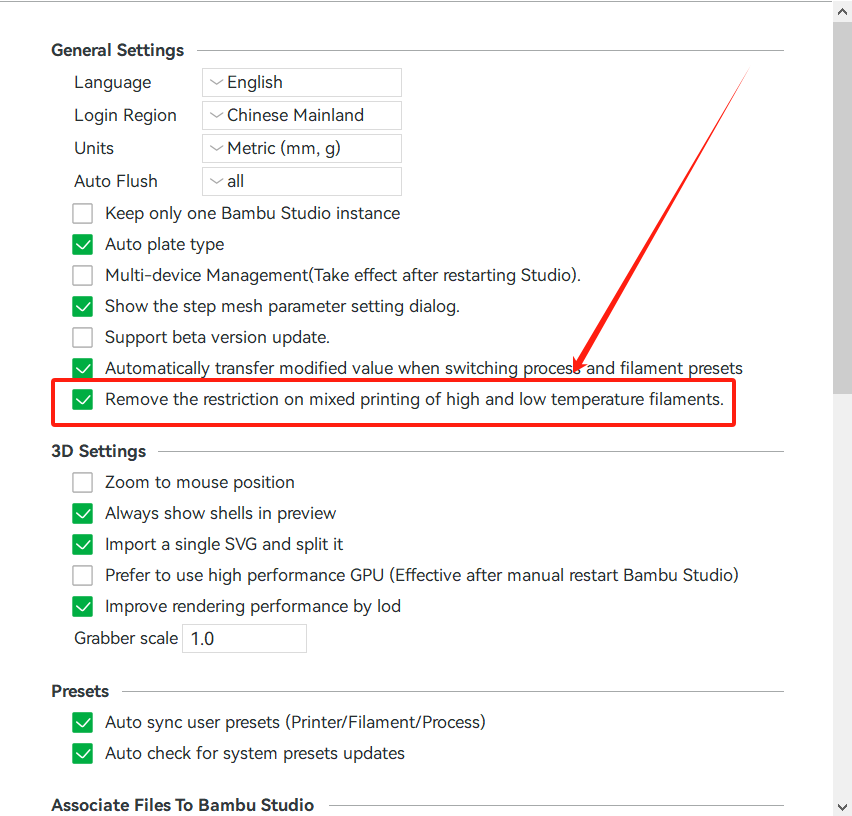

- Adjust the settings for the engineering filament. For example, with PAHT-CF, first set the chamber temperature to 0°C.

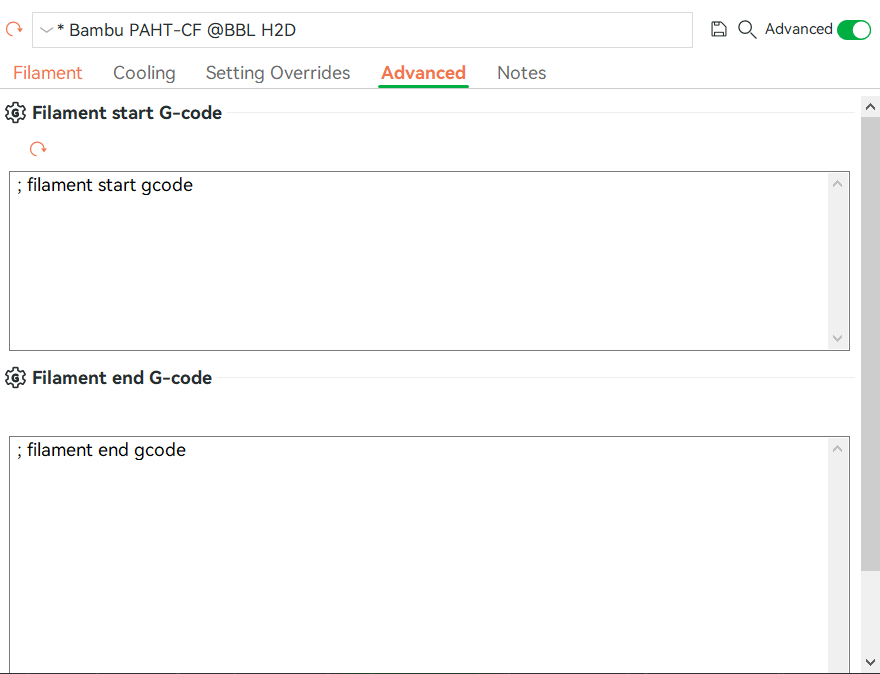

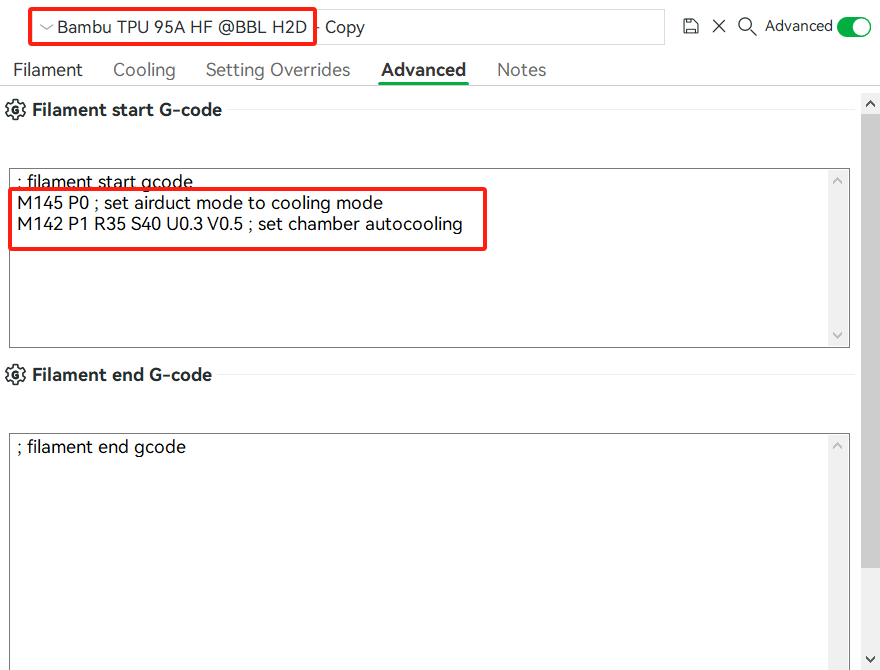

- Modify the filament Start Gcode in the advanced settings and delete "M145 P1; set airduct mode to heating mode". The image below shows the state after deletion:

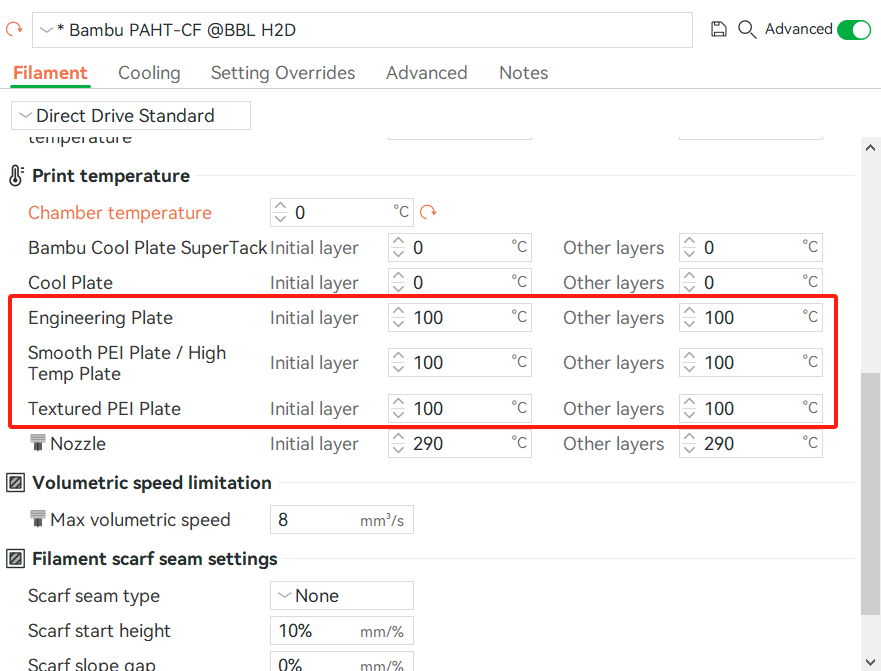

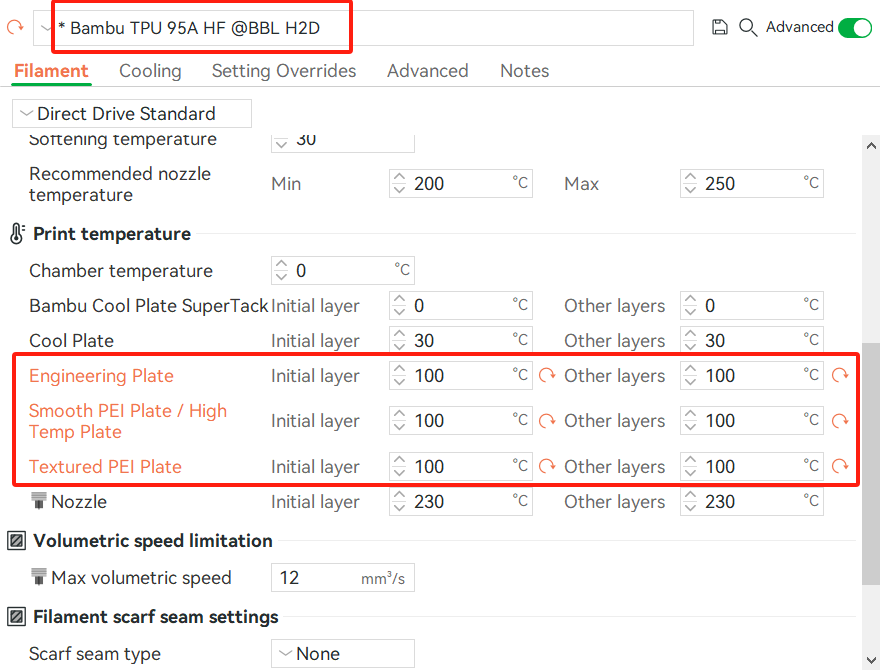

- Record the build plate temperature used for the engineering filament, such as 100°C for PAHT-CF.

- In the TPU filament settings, modify the build plate temperature to the temperature required for the engineering filament

Note: If your model meets Restriction (i.e., the first layer is entirely made of TPU or TPU serves as the primary load-bearing structure of the model), do not modify the TPU heatbed temperature. Instead, set the engineering filament heatbed temperature to no more than 70°C.

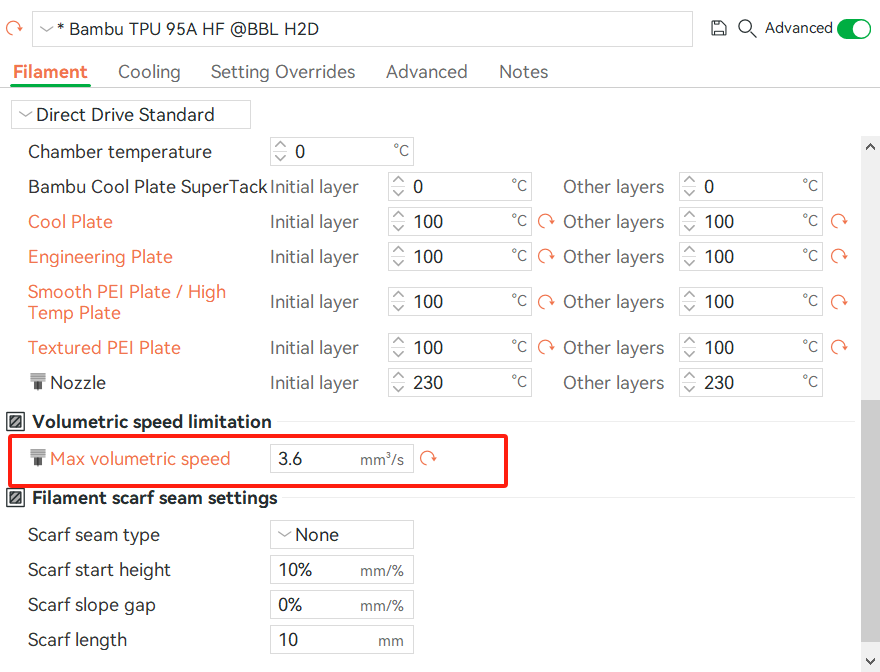

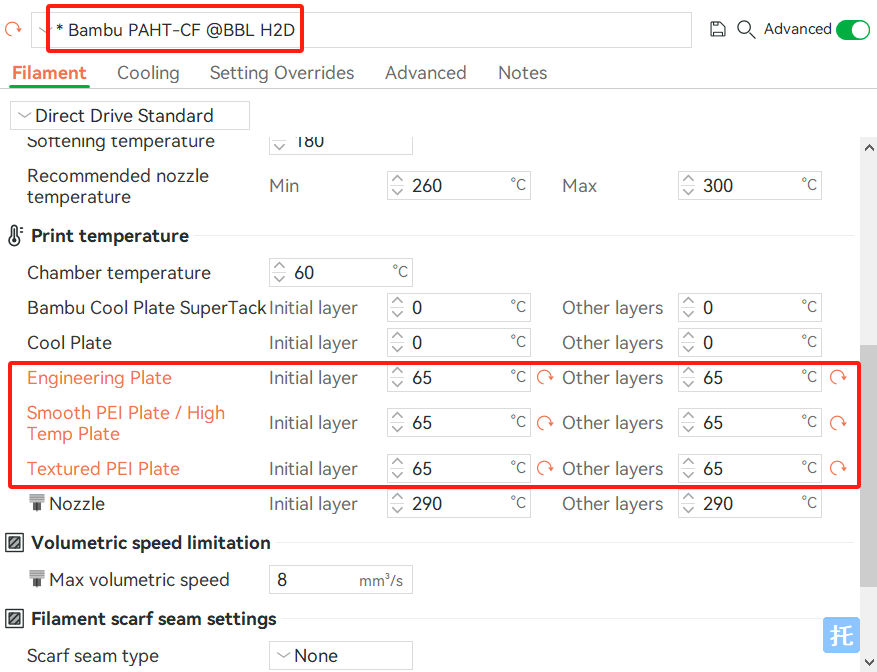

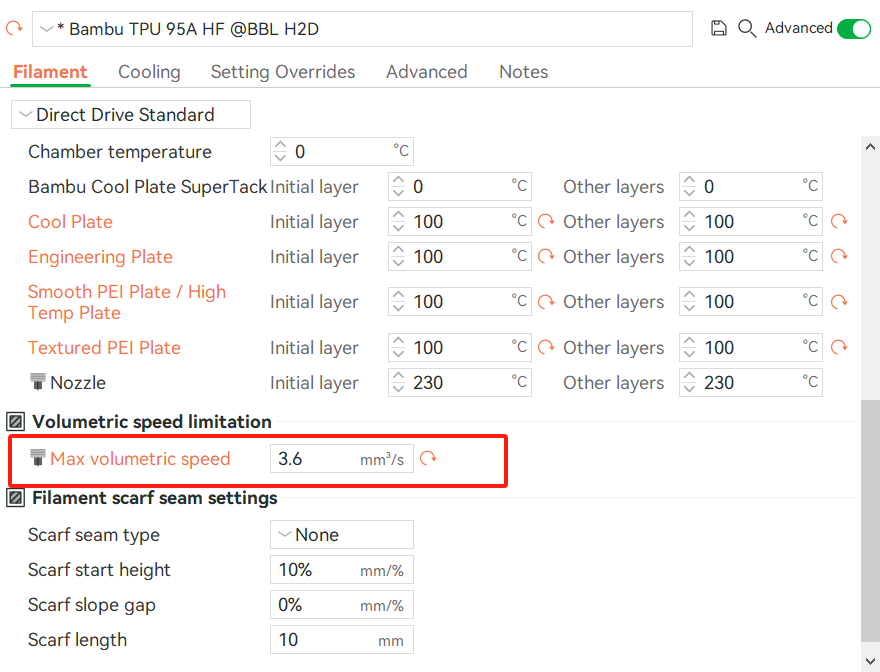

- Set the max volumetric speed of TPU 95A HF to 3.6 mm³/s.

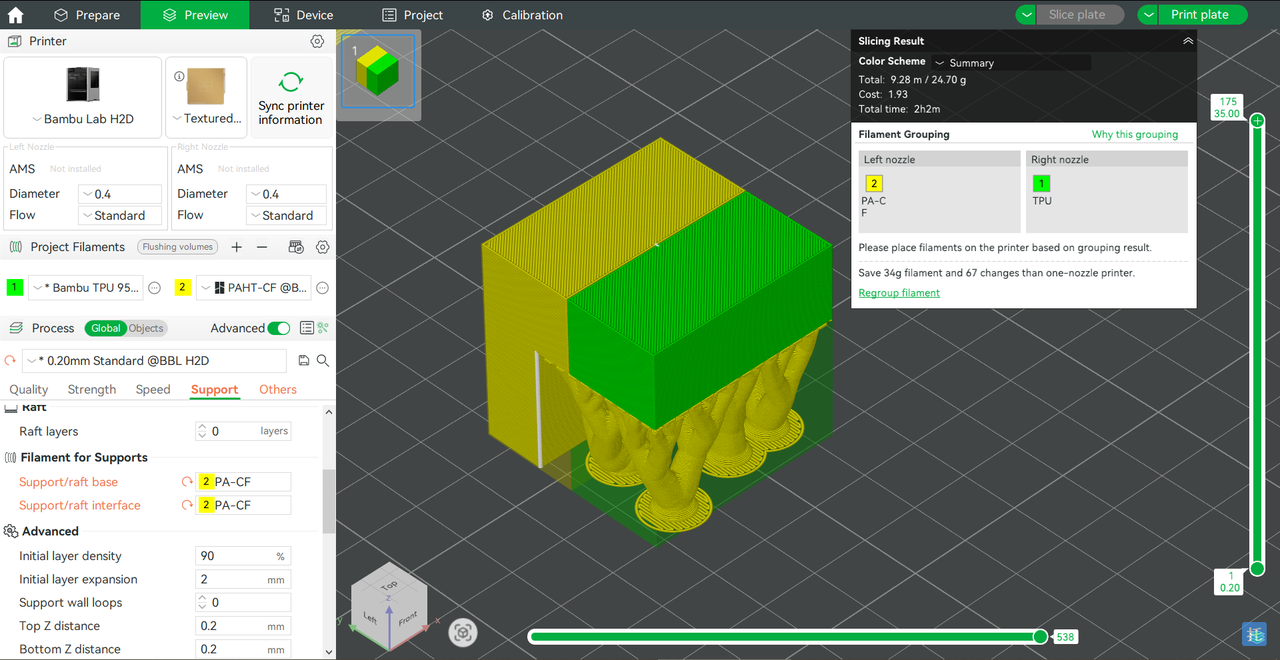

- Finally, slice the model and start the print

¶ 4.4 High Chamber Temperature Printing Slice and Printer Preparation

¶ 4.4.1 Printer Preparation

The high temperature build plate can create a very strong bond with TPU. Before printing, be sure to apply glue to the build plate to protect it. If the glue is not applied, damage like the one shown in the image below may occur.

You can refer to this Wiki for detailed steps on applying glue: https://wiki.bambulab.com/en/general/how-to-use-bbl-liquid-glue

Please make sure that the build plate is coated with glue before printing. If you unfortunately forget to apply the glue, use alcohol to soak the area where the model is attached to the print bed, and gently remove it.

¶ 4.4.2 Slicing Settings Example and Steps

The 3MF file that has been set up:

High chamber temperature TPU 95A HF PAHT-CF.3mf

- In Bambu Studio, go to the preferences in the top-left corner

- In the preferences, check the option shown in the image.

Note! Before checking this option, please make sure you are aware of the risks of high and low-temperature filament multi-material printing and have carefully read this document.

- In the TPU 95A HF filament settings, modify the build plate temperature to the temperature required for the engineering filament

Note: If your model meets Restriction (i.e., the first layer is entirely made of TPU or TPU serves as the primary load-bearing structure of the model), do not modify the TPU heatbed temperature. Instead, set the engineering filament heatbed temperature to no more than 70°C.

- Delete the following information:

TPU filament information -> Advanced -> In the filament Start G-code, delete the following two lines.

- Set the max volumetric speed of TPU 95A HF to 3.6 mm³/s.

- Finally, slice the model and start the print

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!