¶ Issue Description

When using an external spool for printing, the system continuously monitors the extrusion force of the extruder motor. If abnormal extrusion force is detected, the print task will automatically pause and can only continue after the issue is resolved.

This alert is designed to identify "air printing" phenomena.

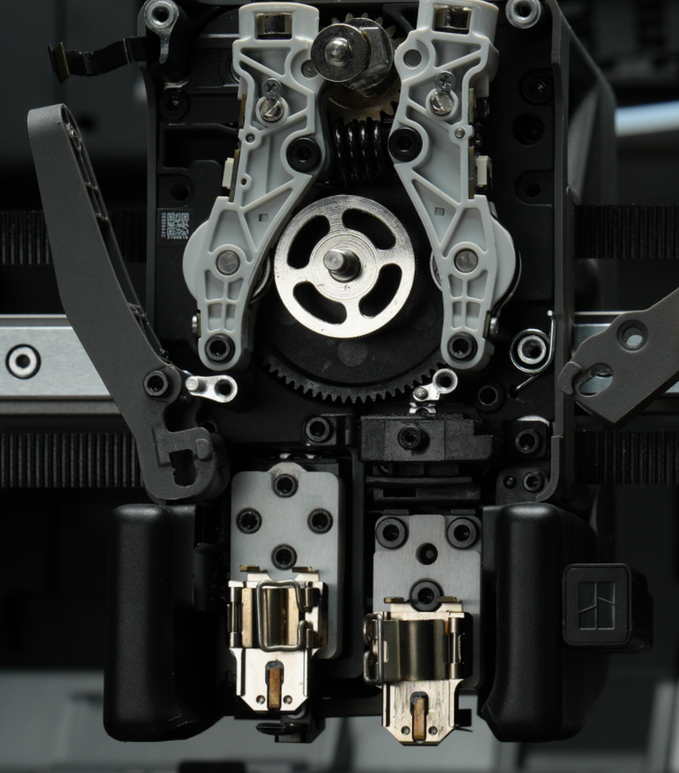

Extrusion related components |

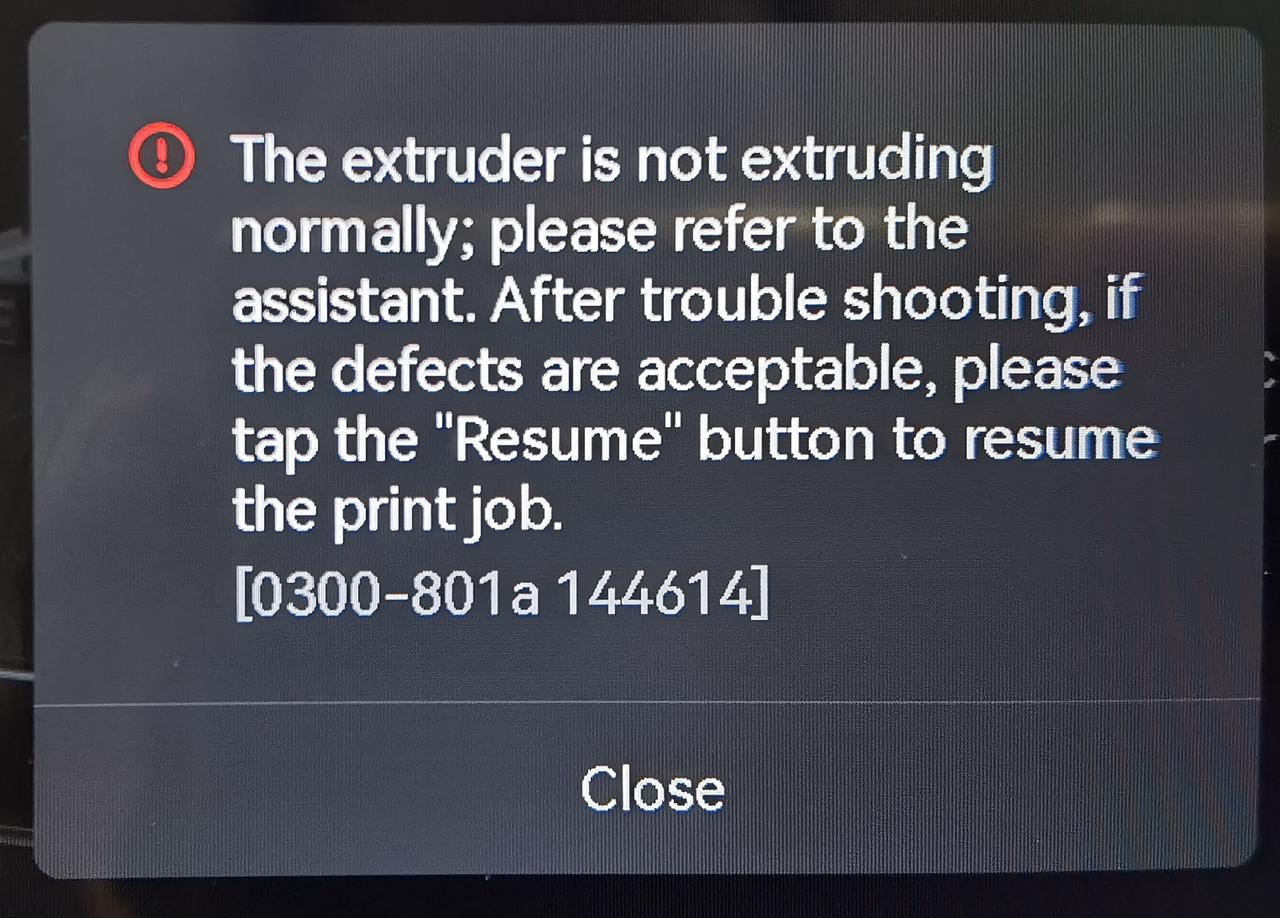

Air printing alert |

Possible causes of this issue include:

-

Filament diameter too thin or worn, causing the extruder gears to slip while driving the filament.

-

Hotend clogging, preventing the filament from extruding through the nozzle.

-

Mismatch between the filament set in the slicer and the actual filament used.

Notes: The conditions for detecting air printing through the extruder motor are as follows:

-

Currently only supports when the filaments of the external spool are PLA, PETG, PLA-CF, PETG-CF, PA-CF, PET-CF.

-

Extrusion flow rate must be greater than 9.6 mm³/s.

-

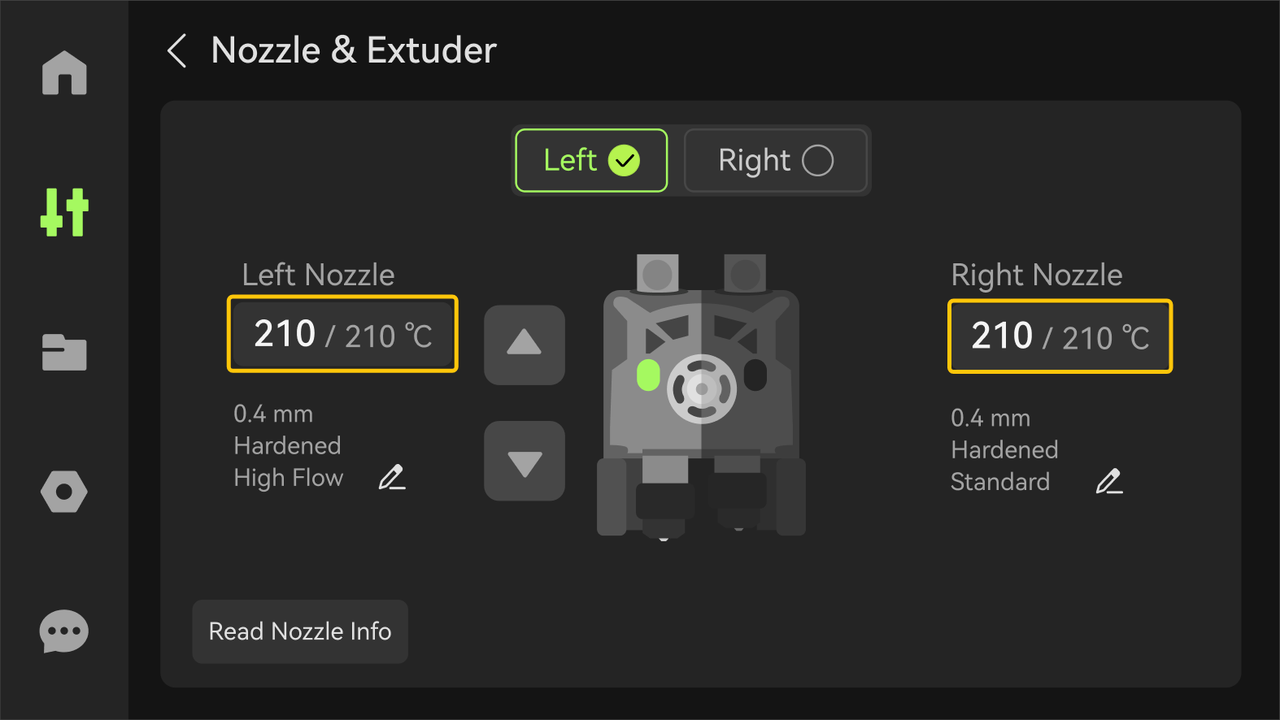

Only supports 0.4mm hotends for now.

The detection timeliness varies with the type of printing filament and printing speed, and there may be a delay. After troubleshooting, decide whether to continue printing based on the actual print condition.

¶ Troubleshooting

¶ Tools, Equipment and filaments

-

H2.0 Allen key

-

H1.5 Allen key

-

Diagonal cutting pliers/scissors

-

Needle-nose pliers

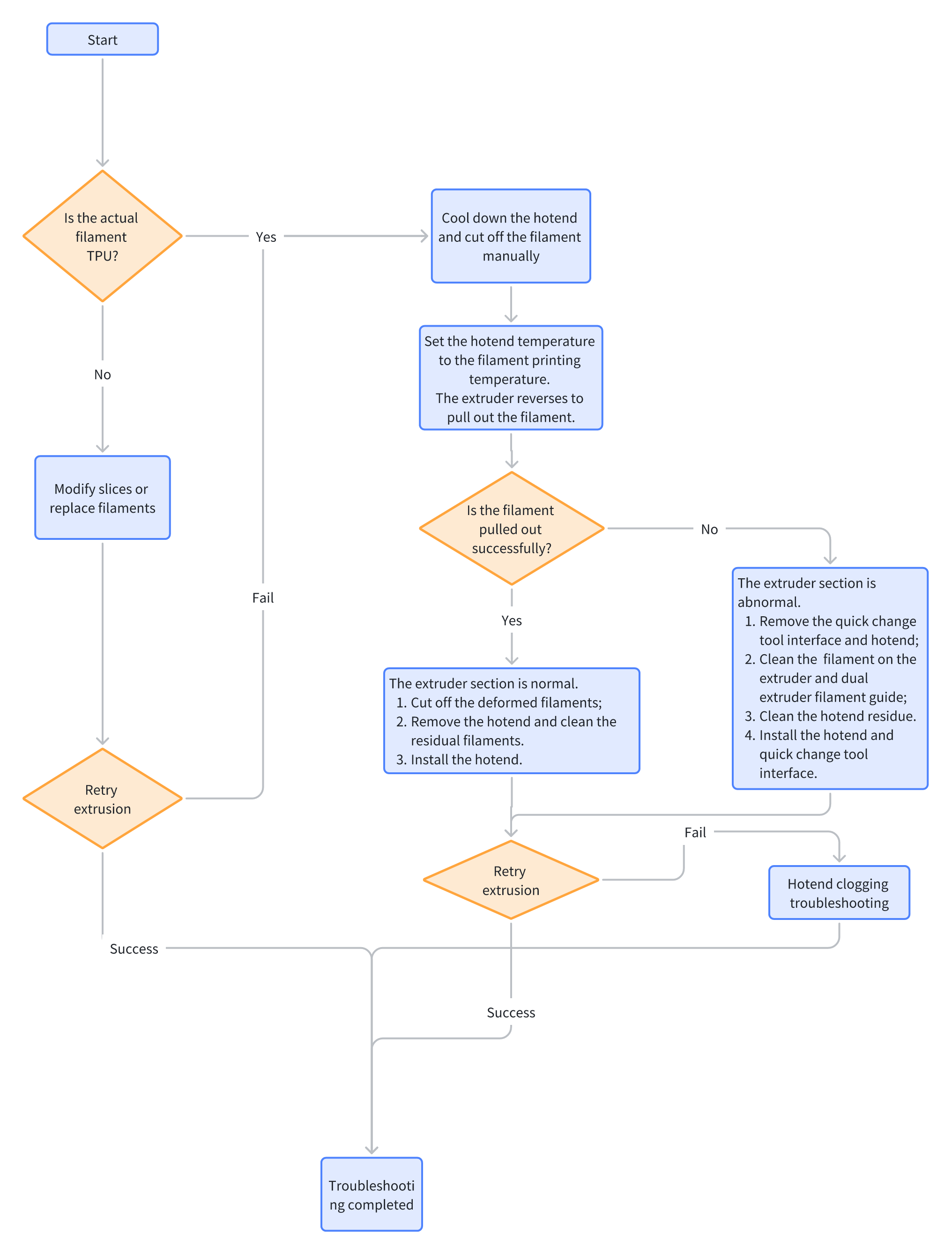

¶ Fault Isolation Process

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Check Slicer Filament Parameter Settings

-

If the filament type set in the slicer does not match the actual filament used, it may cause air printing. Adjust the slicer parameters or replace the filament to ensure they match.

-

Retry the extrusion. If the air printing alert persists, proceed to Step 2.

¶ Step 2. Cool down the hotend and manually cut the filament

- Set the hotend temperature to 0°C and wait for it to cool down to room temperature.

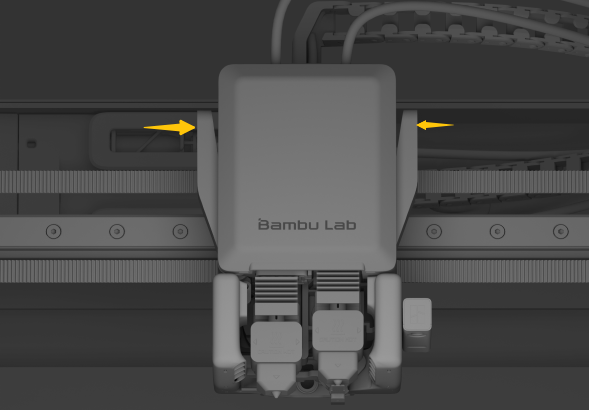

- Press the cutter on the side with the extrusion issue to cut the filament.

¶ Step 3. Heat up the hotend and attempt to pull out the filament in reverse

-

Set the hotend temperature to the filament’s printing temperature and wait for it to heat up.

-

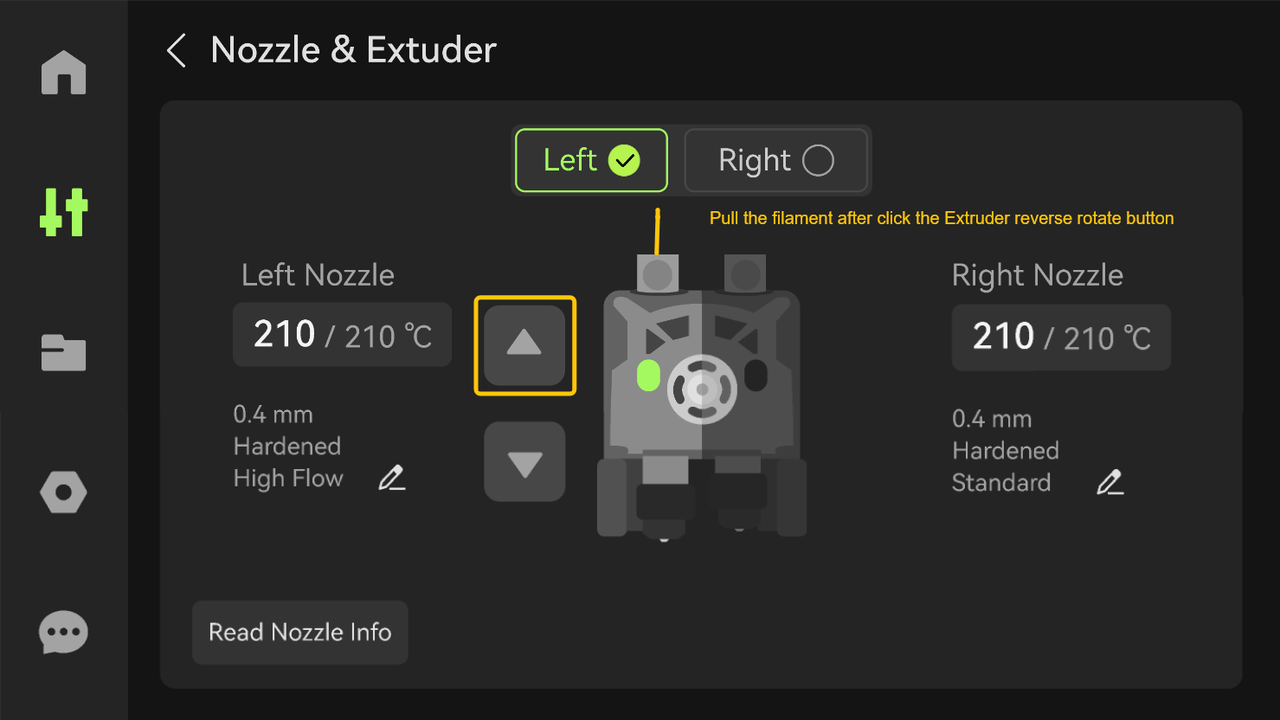

Disconnect the PTFE tube at the top of the extruder.

-

Operate the extruder to rotate in reverse while manually pulling the filament.

¶ Step 4-1. If the filament is successfully pulled out in Step 2, the extruder is functioning normally

-

Trim the bent or expanded front end of the filament.

-

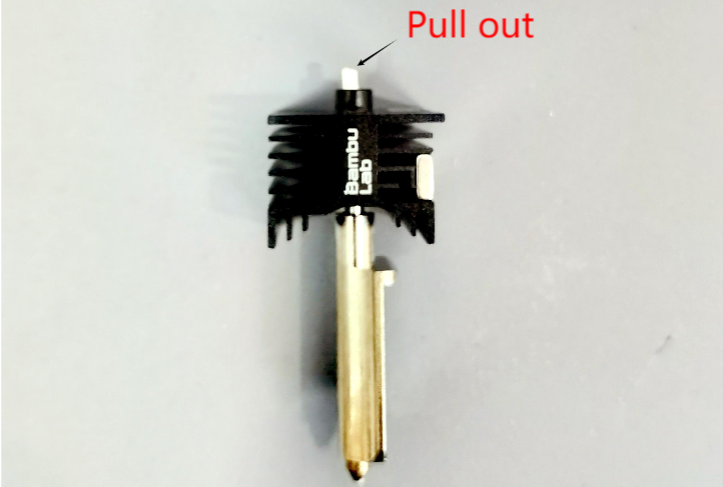

Set the hotend temperature to 100°C, remove the hotend, and use needle-nose pliers to remove residual filament from the hotend entrance while it is still warm (be cautious of high temperatures; wear gloves if necessary).

¶ Step 4-2. If the filament cannot be pulled out in Step 2, the extruder may be malfunctioning

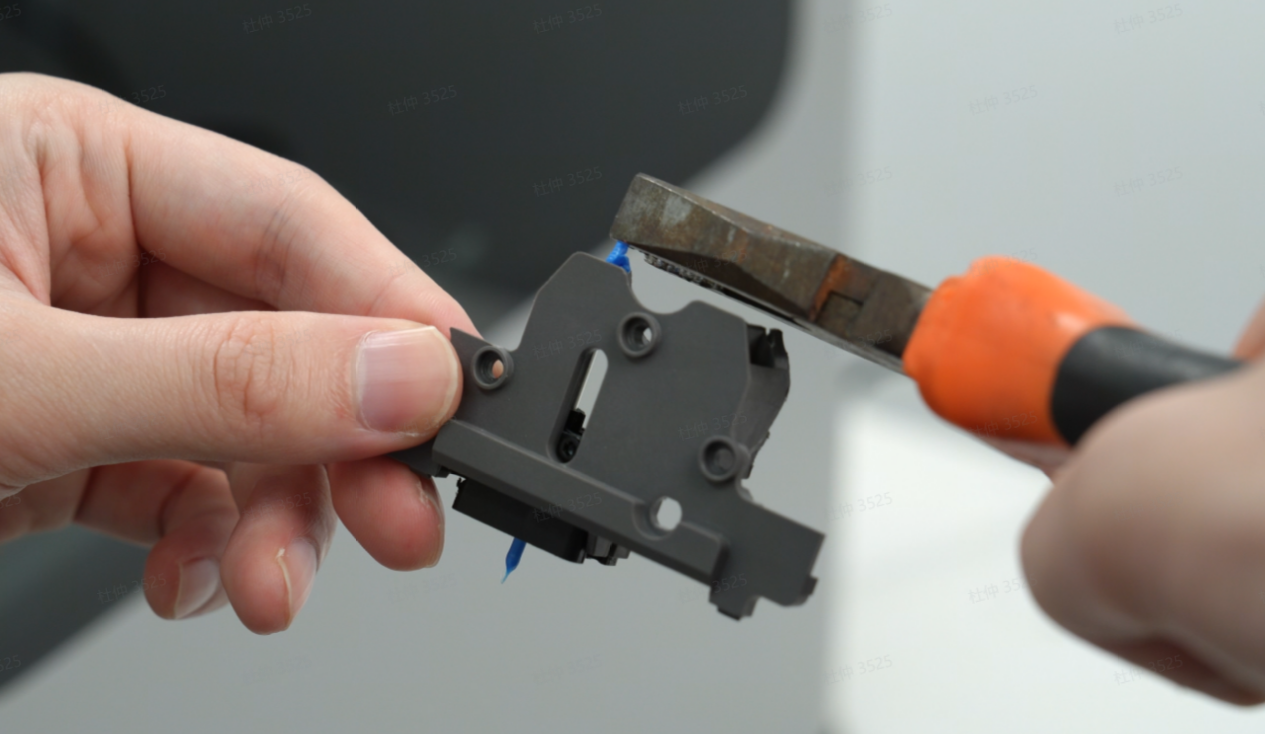

- Disassemble the extruder front cover and hotend.

Refer to Steps 1–5 in the Wiki How to Disassemble and Assemble H2D Toolheadto remove the quick change tool interface and hotend.

![img_20250113_154035[1]_cn.jpg](/h2/troubleshooting/hmscode/0300_0900_0002_0003/img_20250113_154035%5B1%5D_cn.jpg)

-

Use needle-nose pliers to remove residual filament from the hotend while it is still warm (be cautious of high temperatures; wear gloves if necessary).

-

Use scissors to trim any deformed filament inside the toolhead, disconnect the PTFE tube above the toolhead, and manually pull out the filament from the toolhead.

-

Check if the filament is stuck at the front cover guide entrance or inside it. If so, clean it (refer to How to check which part is clogged in H2D)

¶ Step 5. Install the hotend and quick change tool interface, then attempt extrusion

-

Install the hotend and quick change tool interface (refer to How to Disassemble and Assemble H2D Toolhead)

-

Heat the hotend to the filament’s printing temperature.

-

Insert the filament, and press the forward extrusion button on the screen to attempt extrusion.

¶ Step 6. If the extrusion test fails, troubleshoot a hotend clog (refer to Nozzle/Hotend Unclogging Procedure for X1/P1)

If the above solutions do not resolve the issue, submit a ticket and upload the printer’s log files.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!