¶ Issue Description

During the extruder switching process, the lifting motor drives the lifting mechanism to move the left hotend up and down, while coordinating with the flow blocker’s swing to complete the switch. If the left hotend fails to move up or down properly, the printer will pause and report an error.

Possible causes for this issue include:

-

Deformation of the flow blocker, causing interference with the hotend and preventing smooth swinging.

-

Jamming of the lifting mechanism.

-

Filament clogging in the extruder, preventing the left hotend from moving up or down.

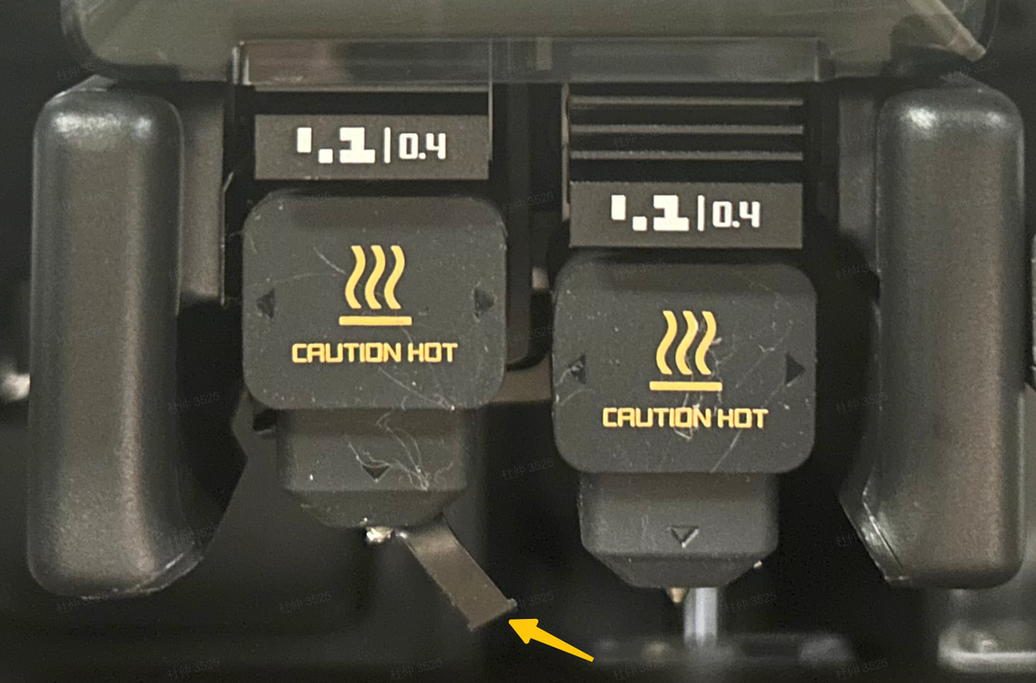

If no foreign objects or jamming are found during troubleshooting, but this error still occurs, observe whether the flow blocker encounters resistance when moving from left to right, particularly when reaching the far-right limit position (as shown in the image below). If the situation matches the one shown, there are three possible causes. Refer to Step 5 below for troubleshooting:

.gif)

You can eliminate the impact of foreign objects getting stuck by removing the hotend and extruder filament guide.

Replace H2D Dual Extruder Filament Guide

- Structural friction or insufficient lubrication between the flow blocker and its bracket may prevent the flow blocker from reaching its proper position.

- The magnet on the far-right side of the flow blocker bracket may have weakened, resulting in insufficient magnetic force to attract the flow blocker bracket into place.

- The flow blocker magnet may be positioned too high—this could be due to excessive high-temperature tape layers, or the screw on the right side of the flow blocker magnet bracket not being properly tightened.

¶ Troubleshooting

¶ Tools, Equipment, and Materials

-

H2.0 screwdriver

-

H1.5 screwdriver

-

Diagonal cutters/scissors

-

Needle-nose pliers

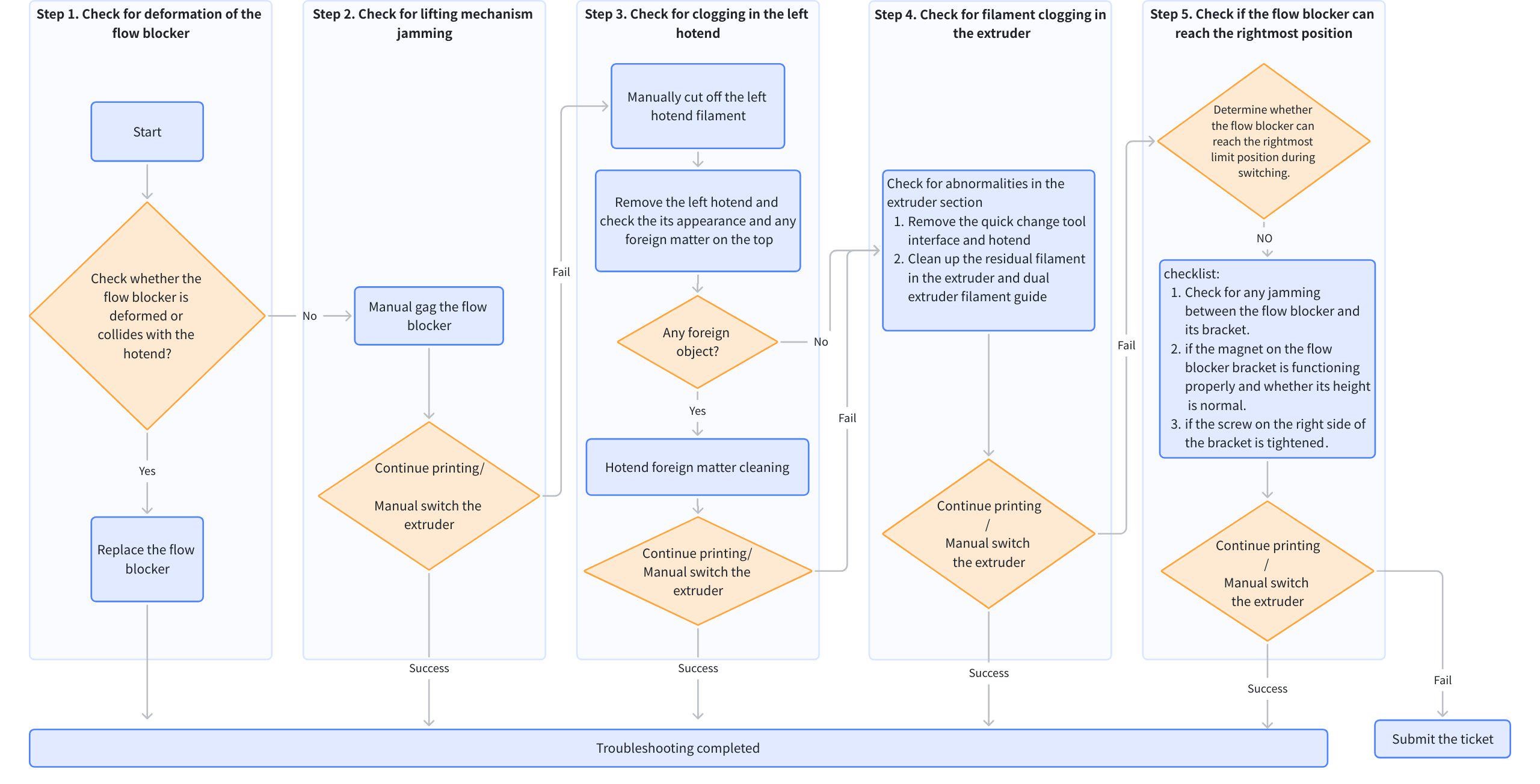

¶ Fault Isolation Process

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Visual inspection for deformed flow blocker and collision with hotend

When the flow blocker is deformed, it cannot properly switch to directly below the left or right hotend.

If the flow blocker is deformed, refer to this Wiki Replace flow blocker assembly to replace the H2D nozzle blocking component. If the printer is in a paused printing state, resume printing.

If the flow blocker is normal, proceed to Step 2.

¶ Step 2. Check for lifting mechanism jamming

If the printer is in a paused printing state, retry printing.

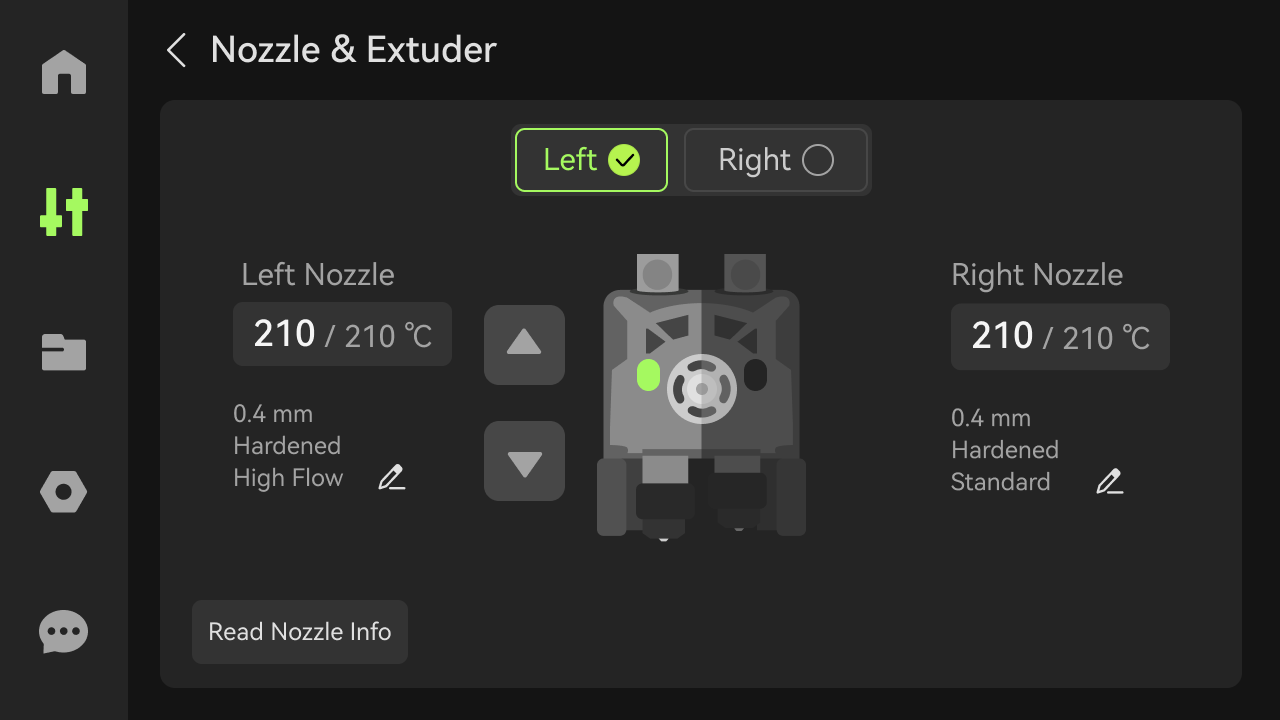

If the printer is idle, navigate to the Nozzle and Extruder page and manually switch between the left and right extruders.

You can also manually swing the flow blocker back and forth to check for unusual resistance and determine whether the left hotend can move up and down properly.

If the issue persists, proceed to Step 3.

¶ Step 3. Check for clogging in the left hotend

-

Press the left cutter to cut the filament.

-

Disassemble the hotend and inspect it, removing any foreign objects.

If there is severe material overflow on the outside of the hotend or foreign objects at the top of the hotend, it may obstruct the left lifting motion. Clean any foreign objects from the hotend before reinstalling it.

-

If the printer is in a paused printing state, click to resume printing. If the issue persists, proceed to Step 4.

-

If the printer is idle, manually switch between the left and right extruders. If switching fails, proceed to Step 4.

¶ Step 4. Check for filament clogging in the extruder

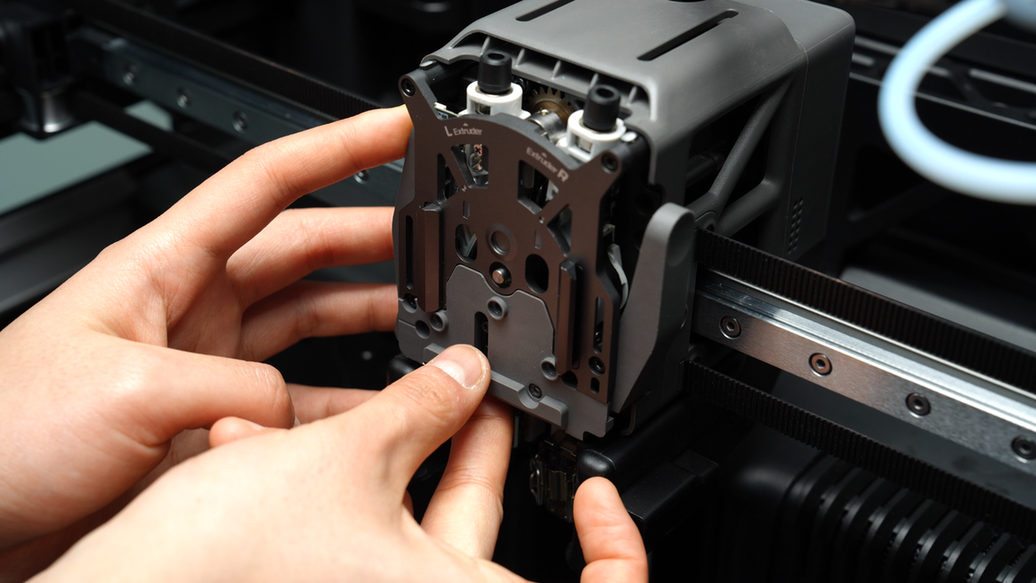

Refer to the Wiki, disassemble the quick change tool interface.

Use scissors to cut away any deformed filament, disconnect the PTFE tube, and manually pull out the filament from the toolhead.

Simultaneously, check if the filament is stuck in the dual extruder filament guide entrance or internally. If so, clean it.

Reinstall the hotend and extruder front cover, then resume printing:

-

Refer to the Wiki How to Disassemble and Assemble H2D Extruder to reinstall the hotend and quick change tool interface.

-

If the printer is in a paused printing state, click to resume printing. If no alert appears, the issue is resolved.

-

If the printer is idle, manually switch between the left and right extruders. If switching occurs without alerts, the issue is resolved.

¶ Step 5. Observe whether the flow blocker encounters difficulty reaching the far-right limit position during movement from left to right.

-

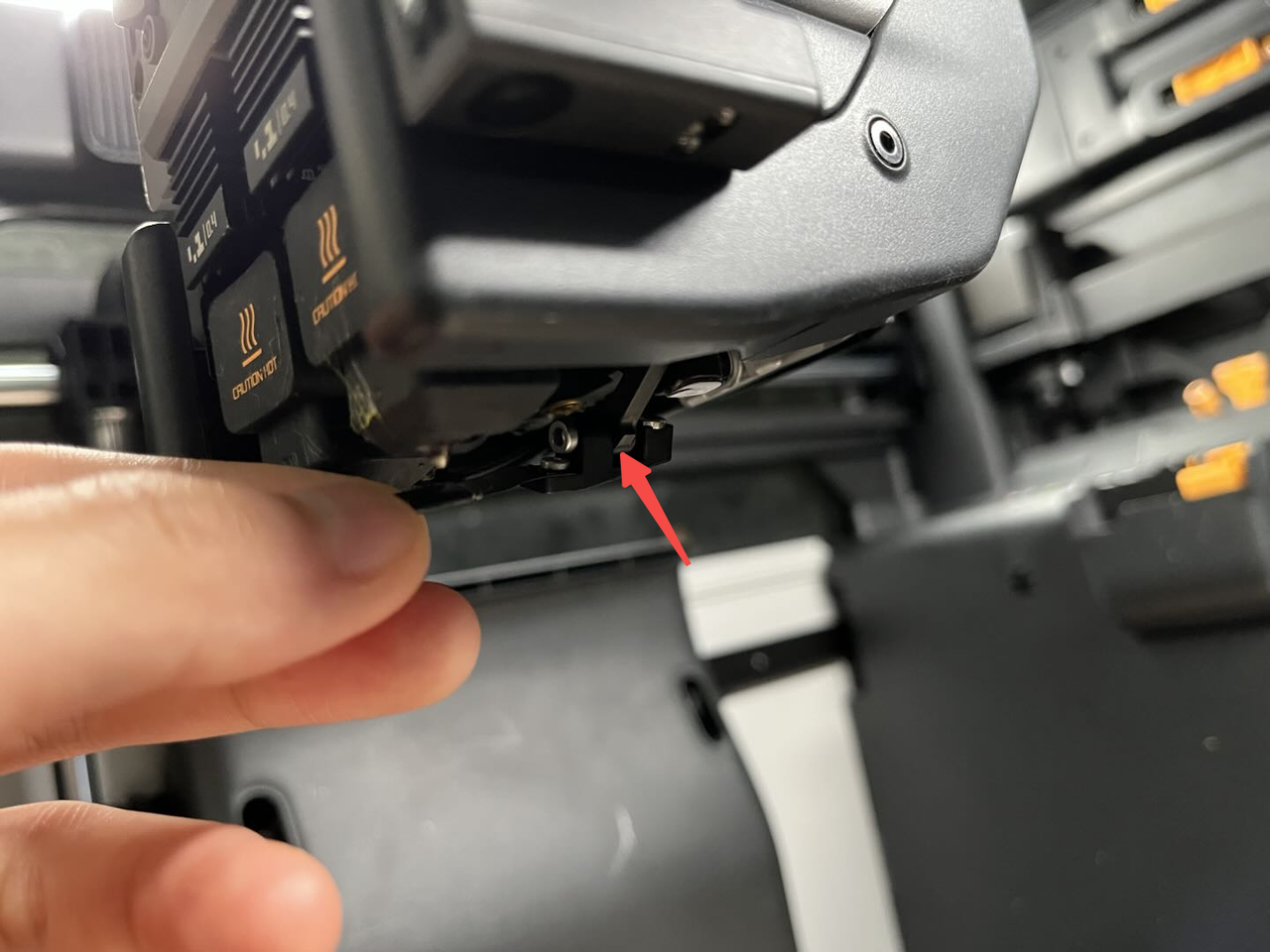

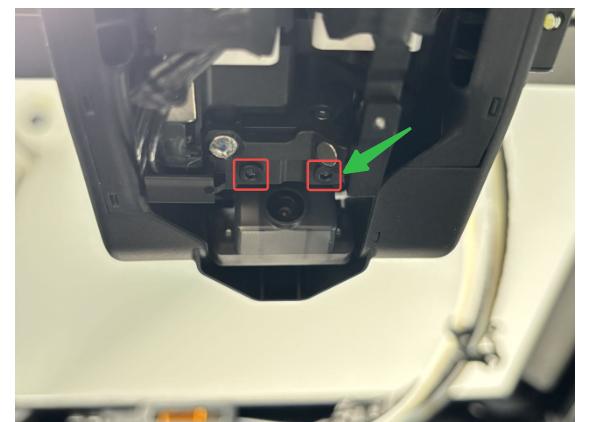

First, confirm whether the flow blocker assembly can move freely. Eliminate the possibility of malfunction caused by overtightened screws (circled in the image below).

.gif)

-

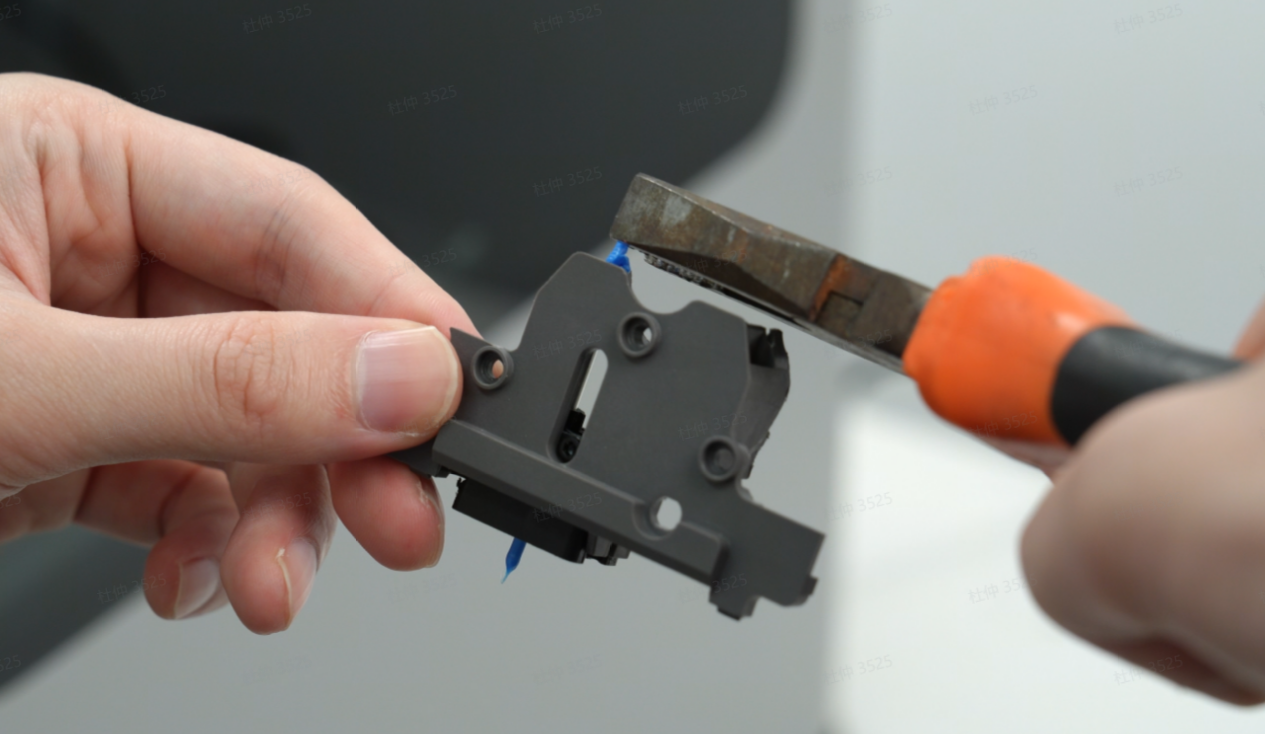

If the overtightened screw have been ruled out, refer to this Wiki to disassemble the flow blocker assembly. Use the lubricant provided in the accessory box to lubricate the moving parts indicated by the arrows below.

-

If the issue persists after lubrication, the screw shown in the arrow below on the flow blocker magnet bracket may be at an incorrect height. Tighten the screw as needed.

-

It might be caused by the Magnet degradation: Remove the high-temperature tape from the flow blocker magnet bracket and try again. You may also test the magnet using a piece of iron, such as the non-tip portion of a screwdriver (as some screwdriver tips are magnetized). If the magnet has no magnetic force, it needs to be replaced.

If the above solutions do not resolve the issue, submit a ticket and upload the printer’s log files.

¶ Equivalent Codes

The following HMS codes represent the same type of issue.

| HMS Code | Description |

|---|---|

| 07FE-8000-0002-0001 | The lifting action is abnormal during the extruder switch. Please check whether the flow blocker is stuck or there is filament stuck in the toolhead. |

| 07FF-8000-0002-0001 | The lifting action is abnormal during the extruder switch. Please check whether the flow blocker is stuck or there is filament stuck in the toolhead. |

| 18FE-8000-0002-0001 | The lifting action is abnormal during the extruder switch. Please check whether the flow blocker is stuck or there is filament stuck in the toolhead. |

| 18FF-8000-0002-0001 | The lifting action is abnormal during the extruder switch. Please check whether the flow blocker is stuck or there is filament stuck in the toolhead. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!