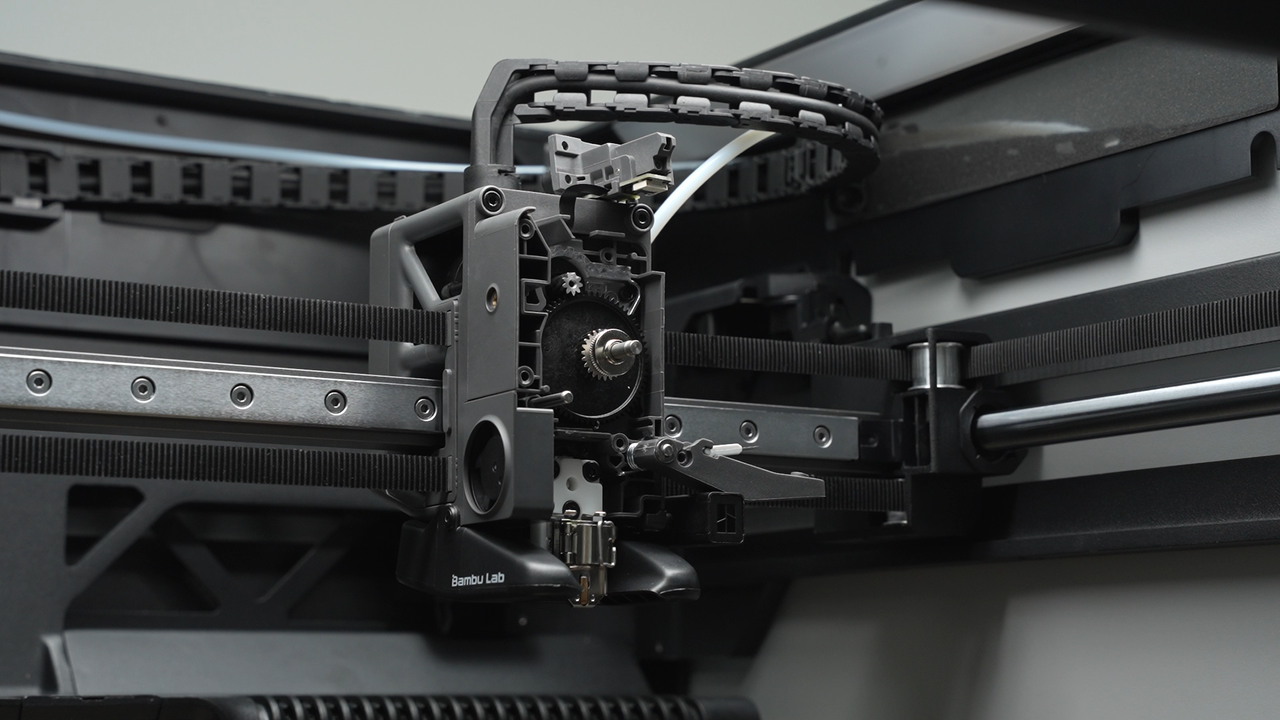

¶ Issue Description

When printing with an external spool, the system continuously monitors the extrusion motor’s resistance.

If abnormal extrusion resistance is detected, the printer will pause and require troubleshooting before printing can resume.

Possible causes:

- Filament is jammed inside the toolhead

- Clogged hotend

- Mismatch between the filament type used in slicing settings and the actual filament

¶ Troubleshooting

Safety Notice: Before disassembling the toolhead, always power off the printer to avoid electric shock.

¶ Tools, Equipment, and Materials

- H2.0 hex screwdriver

- H1.5 hex screwdriver

- Flush cutter / scissors

- Flush cutter / scissors

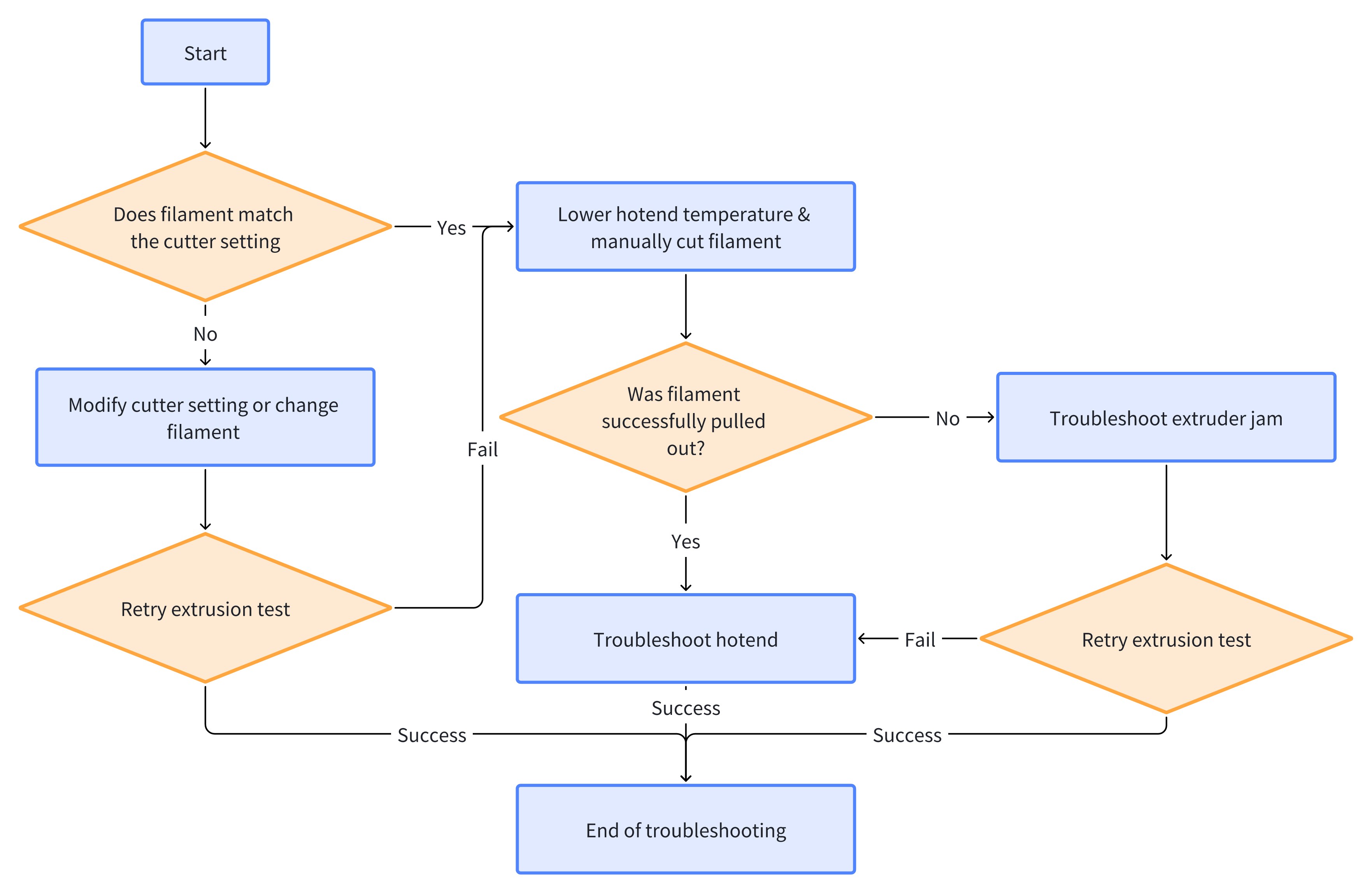

¶ Troubleshooting Workflow

See the detailed steps below:

¶ Troubleshooting Steps

Users may adjust the order of steps depending on their situation.

¶ Step 1. Verify Filament Consistency

Check that the filament selected in the slicer matches the actual filament loaded. If there is a mismatch between the two, take one of the following actions:

- Update slicing parameters to match the current filament

- Replace the filament to match slicer settings

Try extruding again. If extrusion still fails, continue with Step 2.

¶ Step 2. Cool Down the Hotend and Cut the Filament

- Set the hotend temperature to 0 °C and wait until it cools down to room temperature.

- Press the cutter lever to cut the filament.

¶ Step 3. Heat the Hotend and Attempt to Pull Out the Filament

- Set the hotend temperature to the printing temperature of the filament and wait until it heats up.

- Remove the PTFE tube on top of the extruder.

- Rotate the extruder motor in reverse while gently pulling the filament upward.

¶ Step 4. If Filament Cannot Be Pulled Out → Clean the Extruder

The extruder may be clogged. Please refer to How to Check Which Part is Clogged in H2S for cleaning instructions.

After cleaning, try extruding again. If the blockage persists, proceed to Step 5 to troubleshoot the hotend.

¶ Step 5. If Filament Can Be Pulled Out → Check for Hotend Blockage

If the filament was successfully pulled out in Step 3, the extruder is likely not clogged. The hotend may still be clogged.

Please refer to Nozzle/Hotend Unclogging Procedure for H2S

- If extrusion works normally after cleaning, the problem is resolved.

- If extrusion still fails, the hotend may be worn out or permanently damaged. In this case, replace the hotend.

If the above steps do not resolve your issue, please submit a ticket and upload your printer logs

¶ Conclusion

We hope this guide will provide you with useful information and help you solve problems.

To ensure that you operate safely and effectively, if you have any doubts or questions about any steps in the guide, please contact our Customer Support team before starting the operation.

We are always happy to answer your questions and provide support.

Click here to contact online technical support (service hours 9:00-21:00)