¶ Printed model warping

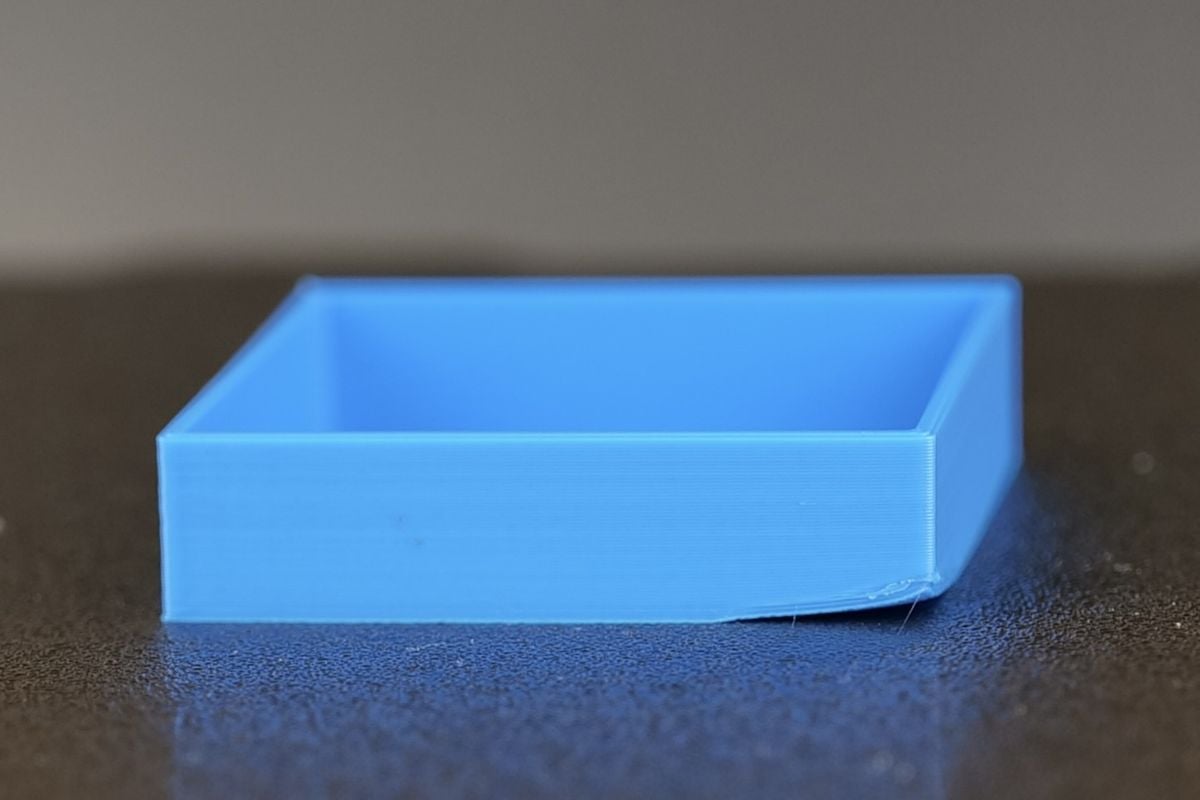

In the example below, the corner of the model has warped

Related wiki links:

¶ Potential causes and solutions

¶ 1. Heatbed temperature set too low / Incorrect Plate Type

One of the most common mistakes that lead to models warping or getting loose from the heatbed is having an incorrect heatbed temperature for your filament, or an incorrectly selected plate type.

For example, if you slice a model for the Cool Plate and print it on the Textured PEI Plate, there is a high chance the model will warp, and get loose from the heatbed.

This is caused by the different plate proprieties and requirements. The Cool Plate requires around 35℃ for PLA while the Textured PEI Plate requires around 55℃ - 65℃ for PLA.

Selecting the correct plate type according to the filament used, while also ensuring the plate is clean before starting a print will give you the best chances of success when printing.

¶ 2. Part cooling fans set too high

Most of the time, PLA can benefit from as much cooling as possible when printing fast. But there can be situations where too much cooling is applied to a model leading to warping.

The Bambu Studio filament profiles are fine-tuned for best results for each type of filament, and should work as expected.

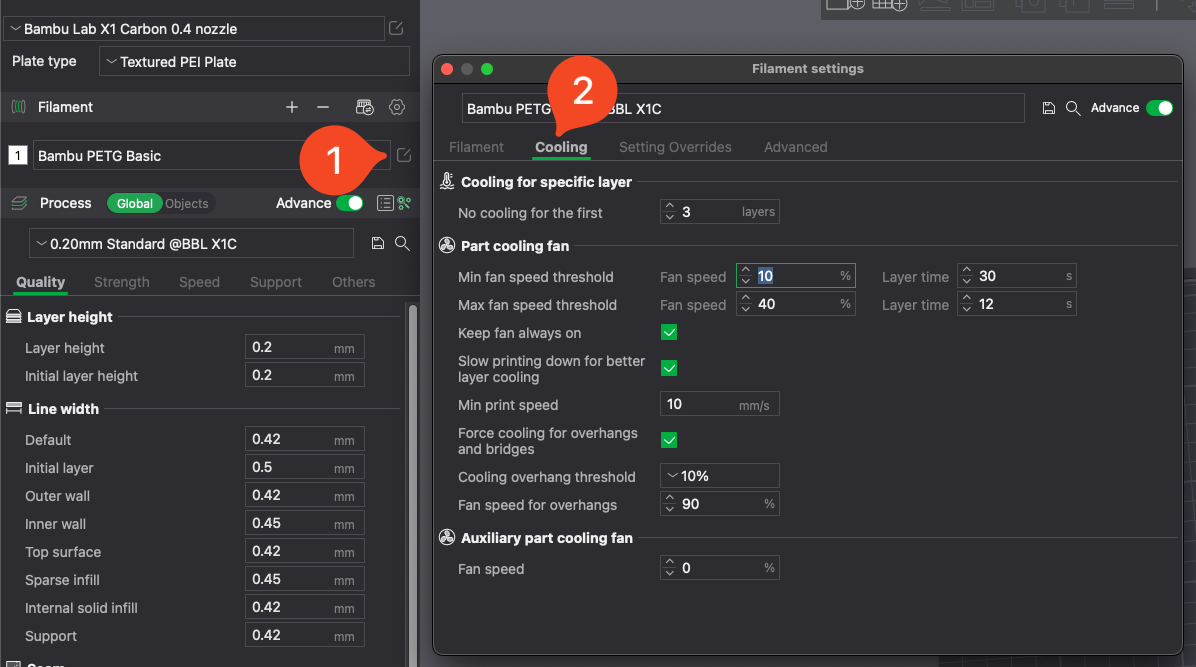

If you encounter warping, we recommend double checking the Cooling tab, under the Filament Settings:

One of the most important setting to change when it comes to warping is the No cooling for the first X layers option. Ideally, you should have no cooling for the first 3 layers on most common filaments (PLA, PETG, TPU, etc)

This will ensure the best adhesion and slow cooling of the printed layers to avoid warping and a print failure.

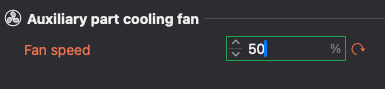

We also recommend adjusting the Auxiliary part cooling fan if needed, by lowering it to about 40-50%.

The filament which benefits the most from a higher Auxiliary part cooling fan speed is PLA, but this mostly applies on small objects or models that have high overhangs.

If you encounter warping of the printed models, lowering the fan speed of this Auxiliary cooling fan could help.

¶ 3. Environmental temperature is too low

Common filaments that exhibit warping easier than PLA are PETG, ABS, ASA, PA, PC.

Most of the time, the warping appears due to the fast cooling of the printed layers which generates stress forces between the layers.

These higher temperature materials are usually printed with less to no part cooling in an enclosed 3D printer, for the environmental tempearture around the part to be higher and allow slow cooling of the model.

If you print some of these filaments on a printer which is not enclosed, like the A1, warping can be common because the temperature around the model will be the same as your room temperature.

If the room where the printer is used is under 20C, warping issues occur even with PLA and PETG filaments which are more forgiving.

In situations like this, it's best to ensure a higher heatbed temperature (+10C) to give the model a better chance of success by slowing down the cooling between the printed layers and ensure there are no drafts of air around the printer.

Air drafts can cool the model faster, increasing layer bonding tension and leading to filament warping.

¶ 4. Large model size and high infill density

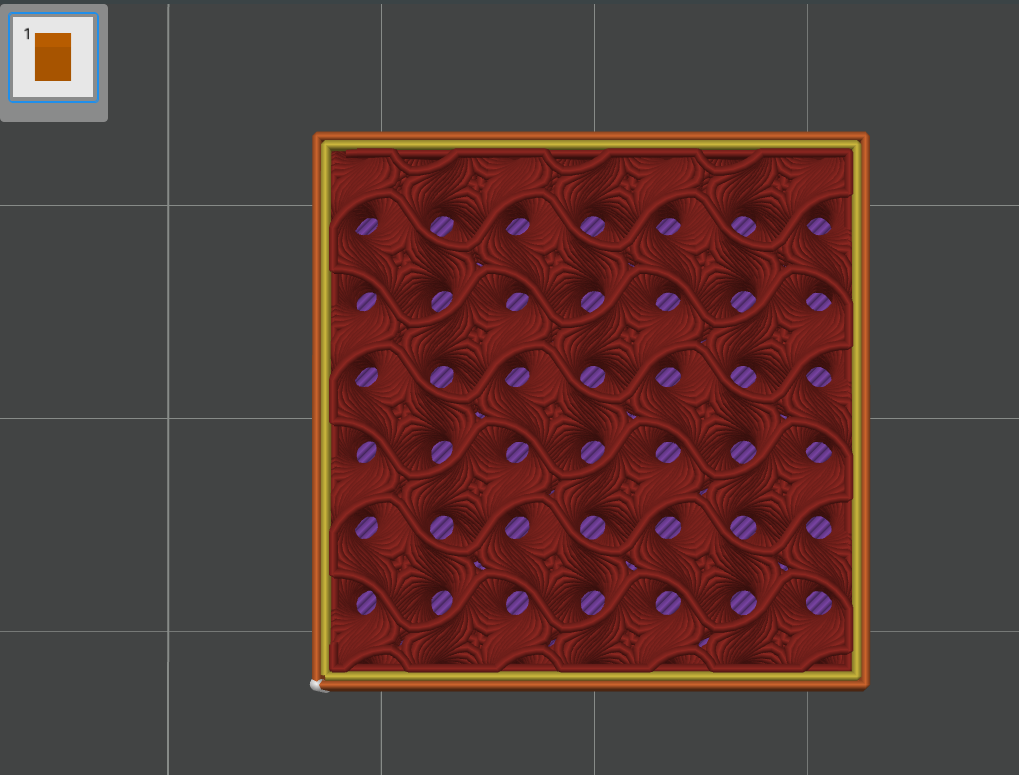

Large model size and high infill density - If the prints size is large and the infill density is set high, e.g. 60% (default is 15%), and warping occurs, please adjust it appropriately. In addition, the infill pattern with more straight lines is more likely to shrink, you can change the infill pattern to Gyroid to reduce the risk of shrinkage. For some of the structural parts with high requirements for strength, you can set 5 layers of walls and about 25% fill density, and try to avoid using more than 50% fill density to reduce the tendency of shrinkage; for most of the non-structural parts with low requirements for strength, you can directly choose the default 2 layers of walls and 15% fill density.

Gyroid infill:

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!