¶ P1 series Version 01.09.00.00 (20250825)

¶ Feature Optimization

- Optimized RFID reading reliability for the AMS;

- Optimized Bambu Farm Management, enhanced network stability when managing large amounts of printers;

- Added Russian language support;

- Fixed UI glitch problems.

¶ Known Issues

- The stop button doesn't respond when performing filament loading with AMS on Handy;

- While the printer now supports E3D hotends in the accessory setting menu, the current Bambu Handy version doesn't support 1-click printing with E3D hotend options. The current Bambu Studio doesn't have slicer setting for the E3D by default. The following update of Handy and studio will fix this issue.

¶ P1 series Version 01.08.02.00 (20250603)

¶ New Features

- Authorization Control for Enhanced Security

-

The printer now verifies whether control commands originate from official or authorized software. If not, the commands will be rejected.

-

You can still:

Use third-party slicers with Bambu Connect.

Operate the printer completely offline.

Send files directly to the printer in LAN mode, without cloud connectivity requirements.

Downgrade firmware to a previous version if needed.

- Developer Mode (Available in "LAN Mode")

-

When enabled, Authorization Control will be disabled, allowing the printer to accept all control instructions without verification.

-

This mode is intended for advanced users who want full control over their printer’s security.

¶ P1 series Version 01.08.01.00 (20250520)

¶ Bug Fixed

Fixed the print quality issue that occurred on some devicess after upgrading from an earlier version.

¶ P1 series Version 01.08.00.00 (20250429)

¶ Things to know before updating

Things to know before updating

In order to use all the new features introduced by the new firmware update, Bambu Studio and Bambu Handy should be updated to the latest version available:

- Bambu Studio: v2.0.3.54 or later

- Bambu Handy: v3.1.0 or later

¶ New Features

- Added support for multi-plate printing

- You can now select "Print all" from the Bambu Studio interface, or you can use the Multi-Plate printing operation from the printer's screen.

- Added support for AMS 2 Pro and AMS HT

- The printer now supports starting the filament drying operation from the printer's screen

- Added Portuguese language

- Added Korean language

¶ Note:

- Please update the printer firmware before connecting the printer to the AMS 2 Pro/HT

- Each P1 series printer supports up to four AMS units in total, regardless of type. You can mix and match different AMS models, such as the AMS, AMS 2 Pro, and AMS HT, within this limit.

¶ AMS version 00.01.06.62 (20250429)

¶ Improvement

Optimize AMS RFID recognition detection to improve usage stability.

¶ P1 series version 01.07.00.00

¶ New Features

- Added support for offline Firmware update from MicroSD card. How to: Firmware Upgrade via microSD Card - P1 Series.

- Added support for filament editing while printing

- Only the filament that is not in use can be edited.

- The printer will automatically remap the filament backup according to the new filament settings.

¶ Feature Optimizations

- Pause print if abnormal bed-leveling data exceed the threshold. This helps protect the buildplate from unwanted damage.

- Optimized UI Copy.

¶ Bug Fixed

- Fixed the printer screen freeze problem when user using Bambu Handy to initialize the first calibration

- Fixed the printer restarting problem caused by saving the K-factor values.

¶ P1 series version 01.06.01.02

¶ Improvement

- Improved printing stability.

- Optimized read-and-write compatibility for Micro SD cards.

¶ P1 series version 01.06.01.00 (20240722)

¶ Improvement

Improved system stability.

¶ Bug fixes

-

Fixed the intermittent time synchronization failure.

-

Fixed the intermittent manual calibration failure.

-

Fixed the issue where there was a small chance the K factor from flow dynamics calibration was not effective.

¶ P1 series version01.06.00.00 (20240611)

¶ New Features

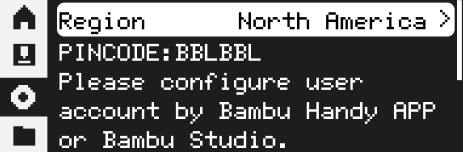

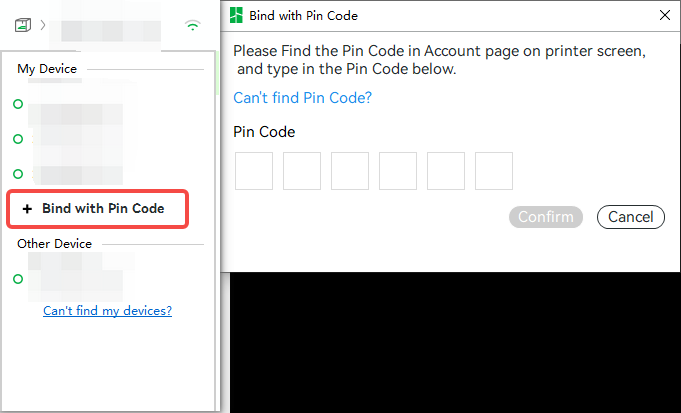

- Non-LAN binding via PIN code on the Studio side (in conjunction with Bambu Studio v01.09 and up)

Users can bind P1 devices to the computer that is not on the same local area network (LAN) using a PIN code on the studio side

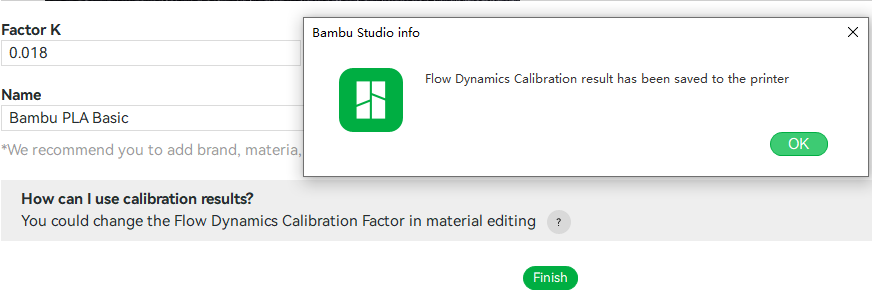

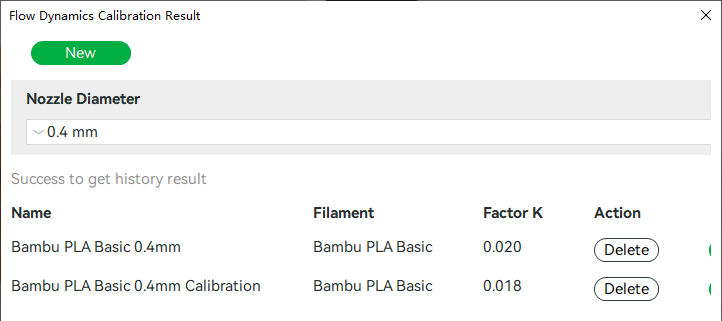

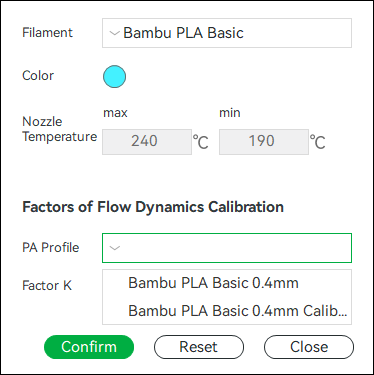

- Improved manual flow calibration parameters management

Auto-save the manual flow calibration parameters

Support creating & managing new PA parameters

Support setting PA configuration files on the filament settings page in Studio

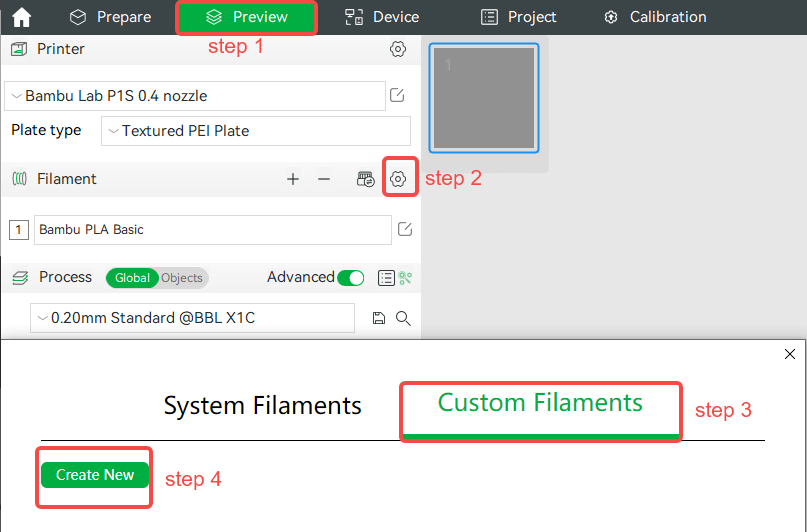

- Third-party filament support

Users can create and manage custom filament profiles in Studio. These custom filaments can then be selected in Studio Device filament slots, and then be synced to the printer and Handy.

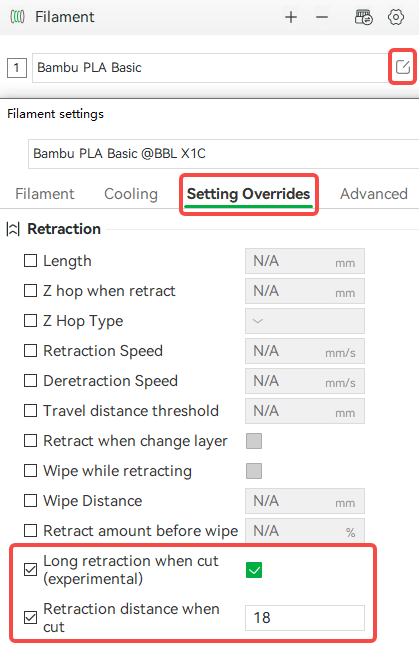

- Added filament verification for "Reducing purging through retracting filament" function

A long retraction during filament change can significantly reduce the purge volume, but it may cause clogging when the filaments assigned in the sliced file do not completely match the actual filaments in use. The filament verification function will verify the filaments match before performing retraction.

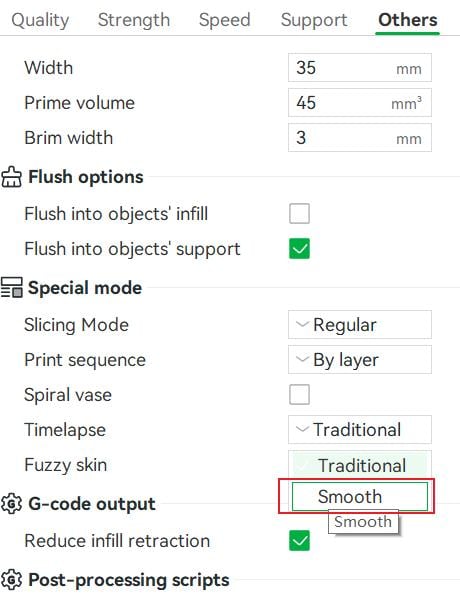

This function needs to be used with the slice files generated by Bambu Studio v01.09 and above. For more information about the "Reducing purging through retracting filament" function, please refer to the Bambu studio release notes[https://github.com/bambulab/BambuStudio/releases].

- Added heatbed abnormal protection

- Added carbon rods & lead screws maintenance notice

- Improved color display for gradient and dual-color filaments

- Added option to opt in/out of User Experience Improvement Program in Settings > Devices

¶ Feature Optimizations

- **Added secondary confirmation when stopping a print, as a safety to protect the user from accidentally canceling a print. **

- Optimized Total Print Time Calculation, add abnormal pausing time into the stat.

- Auto filament type verification when printing with 3MF files from an SD card

- Improved the Custom Device Name function to auto-save the custom name when logging out. The name will also synchronize across devices.

¶ Bug fixes

-

Fixed the button no response glitch when formatting the SD card

-

Fixed intermittent black screen after power-loss recovery

-

Optimized FW update printer status check for safer update

-

Optimized status verification when downloading a language package to avoid process conflict

-

Fixed the issue of devices being unable to send print jobs after not restarting for an extended period.

-

Prevent conflicts with Bambu Cloud service & potential damage to printer hardware by prohibiting crucial printer controls (initiating printing, heating the nozzle, and heating the heatbed) through the local MQTT Broker while the printer is logged into Bambu Cloud service.

Before this firmware update, the printer's local MQTT Broker can process control commands under cloud mode. This meant that two asynchronous channels were controlling the printer simultaneously. The commands from these two channels would execute in an overlapping manner without any order assurance, which is considered conflicting.

To ensure the stable operation of the printer and avoid malfunctions caused by control channel conflicts, we will disable certain printer control functions via the local MQTT Broker under cloud mode. These functions have higher security requirements, and we want only one channel to be able to use these functions at any given time. The restricted controls include:- Initiating print

- Heating the nozzle

- Heating the heatbed

Please note that this restriction will affect the use of software and hardware such as Home Assistant and BiQu Panda Touch. Suppose you still need to use such software and hardware to control the restricted functions. In that case, we recommend enabling the printer's LAN Only mode to continue using the restricted control functions with the Local MQTT Broker.

We will detail these restrictions in the firmware update notes to ensure users are informed in advance.

¶ P1 series version01.05.02.00 (20240122)

¶ Feature Optimizations

- Refine the log system and remove all debug logs that are not necessary for end-users. Thanks to X1plus team's feedback.

- Added a new error code to detect SD card reading errors during printing.

- Added a new handy pop-up message to prompt "Print Paused" when pausing the print (turn on system notifications to receive the message push).

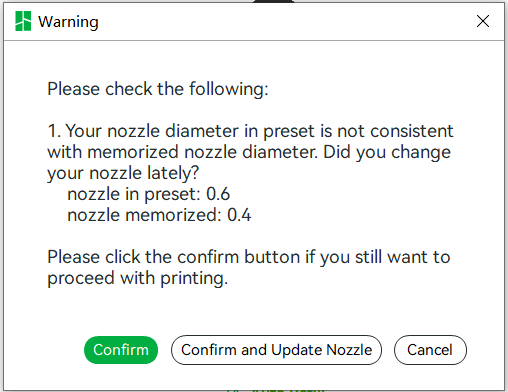

- Automatic nozzle size and type verification in conjunction with Bambu Studio(Version 1.8.3.89 and up). The nozzle type can be set on the accessory list page in the settings menu.

¶ Bug fixes

- Addressed intermittent AMS retraction failures.

- Resolved the problem of repeated startup failures.

- Fixed the abnormal display of user-defined filaments in Bambu Studio's filament settings.

- Fixed the issue where the newly generated timelapse failed to refresh when accessing SD card files from BambuStudio.

¶ P1 series version01.05.00.00 (20240102)

The V1.5 Firmware Update for the P1 series is here! This upgrade is a major feature release that introduces the popular Motor Noise Cancelation feature, SD Card remote browsing support, Print Time Statistics, and Upgrade Kit support, which were all highly demanded features. Besides that, further feature optimizations have been implemented including some bug fixes to make the experience better.

Key enhancements in V.1.5 are:

- Active Motor Noise Cancellation tailored for the P1 series.

- Support for SD Card Remote Browsing (compatible with Bambu Studio V1.8.1 or higher).

- Support for Total Device Printing Time statistic check.

¶ Added Motor Noise Cancelling Feature

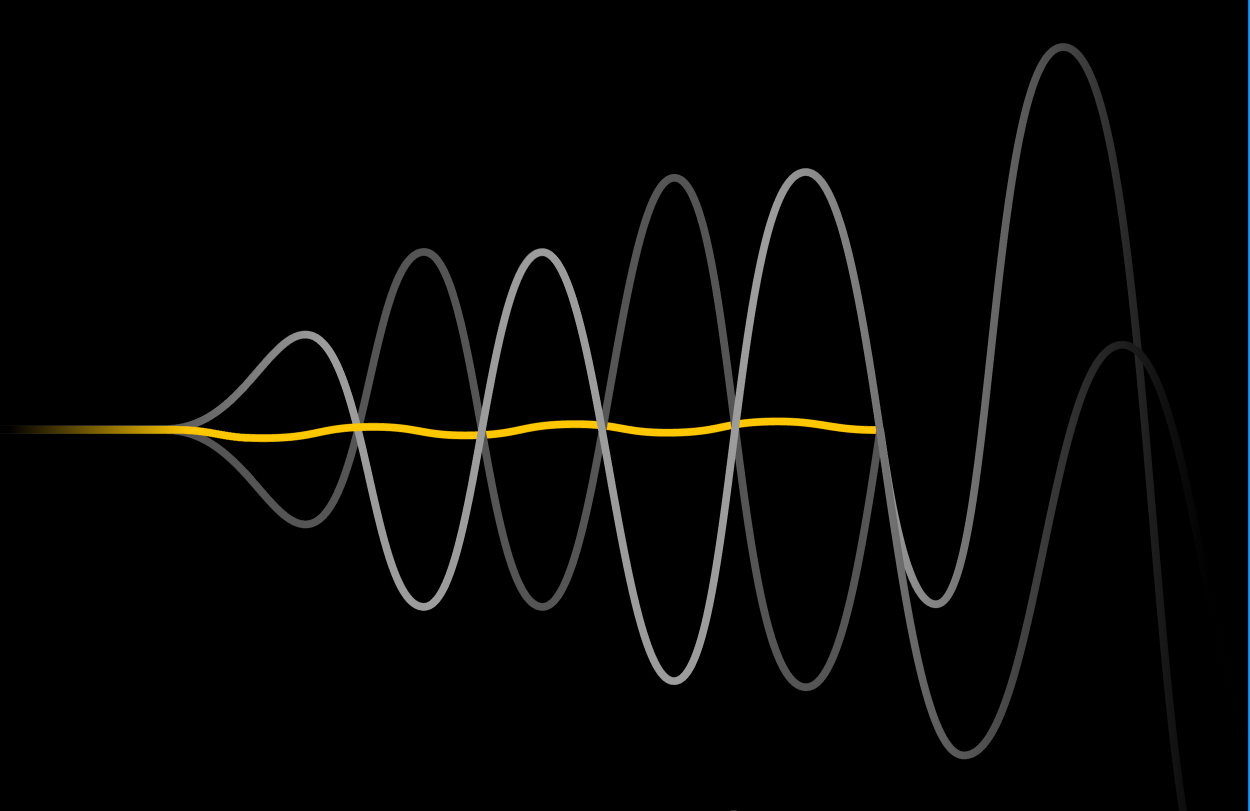

The widely acclaimed Motor Noise Cancellation feature from the A1 mini is now available for P1 series printers. This innovative feature reduces motor noise during long-line movements and mitigates the humming sound associated with high-speed printing. Additionally, it slightly improves Vertical Fine Artifacts (VFA), resulting in smoother printed walls.

In the example below, you can see the significant difference between previous firmware versions with no Motor Noise Cancelling and the latest firmware which introduces this function:

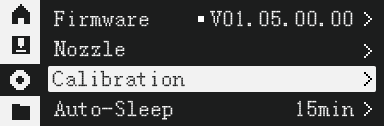

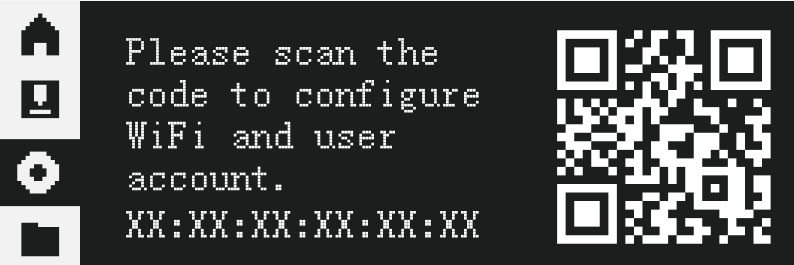

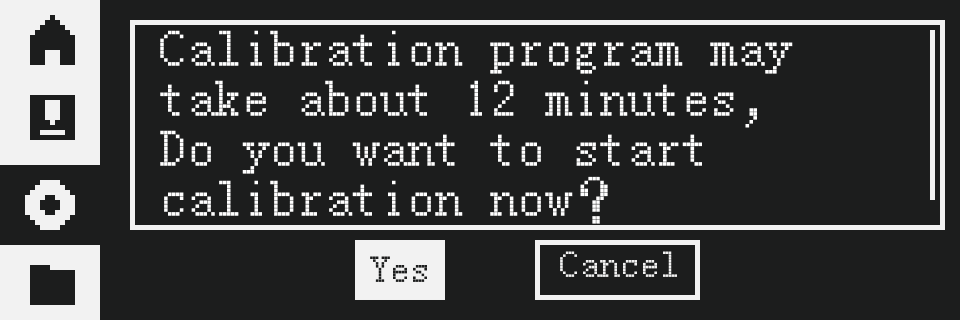

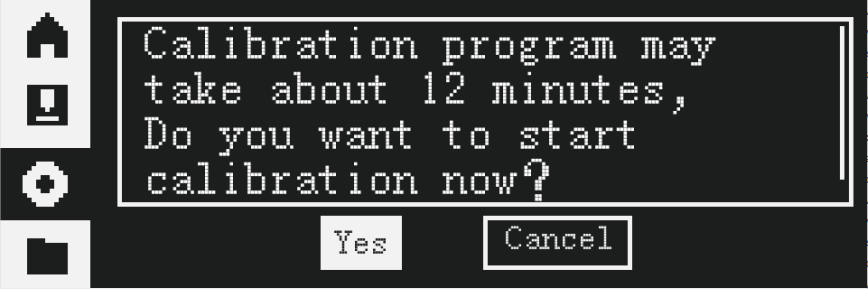

To use this feature, you need to perform a motor noise calibration after the firmware is installed. This option is available in the Calibration Menu.

The Motor Noise Calibration process will take around 15 minutes and the calibration data will be saved to the internal memory of the printer. We strongly recommend performing the entire set of calibration functions after each firmware update to ensure consistent results.

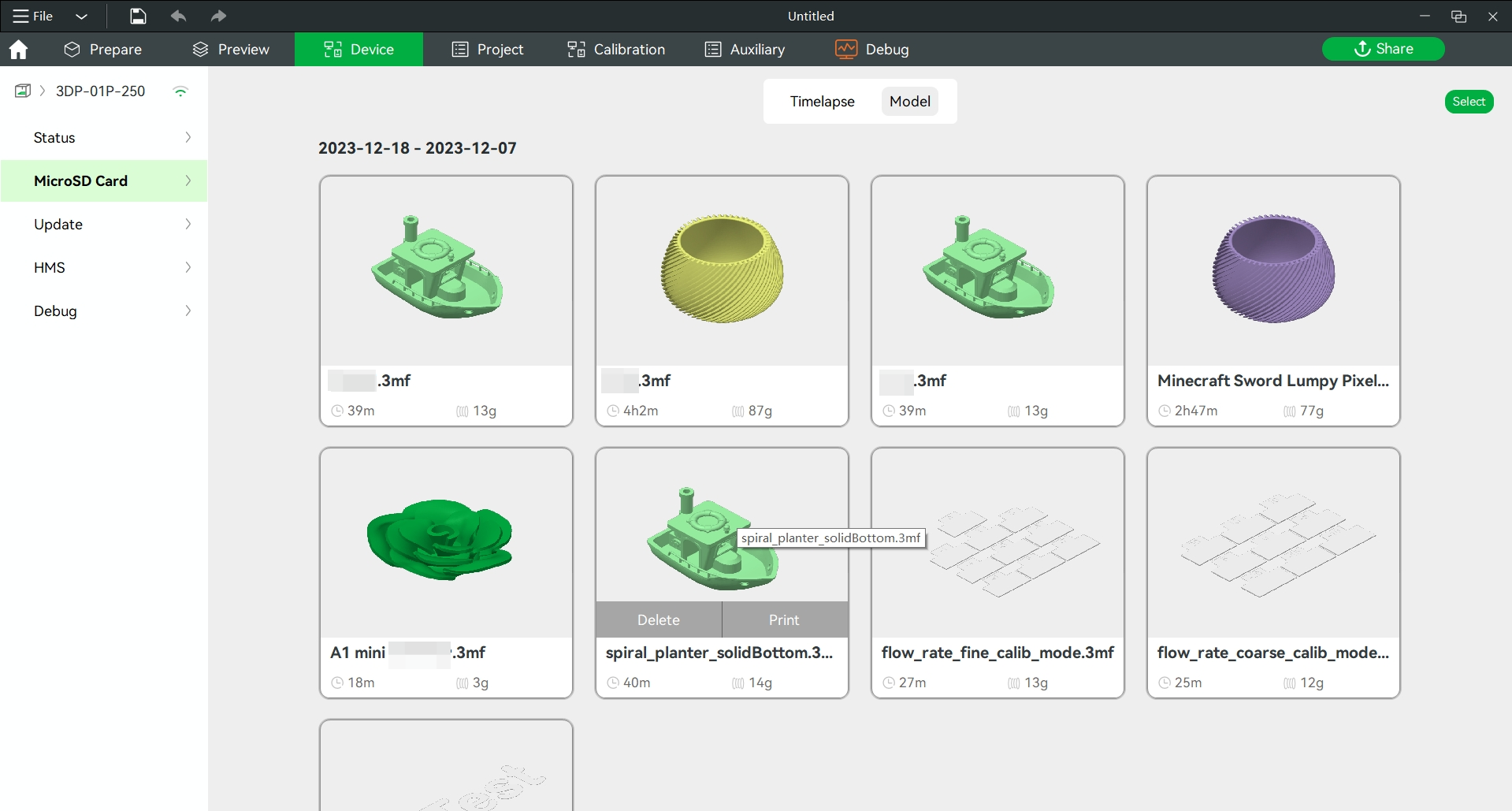

¶ Support SD card remote browsing for time-lapses and models

To improve the user experience with the printer, we introduced file management in Bambu Studio for files on MicroSD cards. You can now delete and print items from the available files on the MicroSD card right from Bambu Studio.

- Select Device -> MicroSD Card -> Model

- Hover the mouse over the model thumbnail to display options to delete, print files

¶ Feature Optimizations

- Optimized the algorithm of the quick resonance check before printing to reduce the false alarms.

- Optimized the power failure recovery function.

- Optimized the filament retraction and re-spooling when using the AMS.

- Hide the G-code file extracted from the 3mf file to prevent users from initiating a print with an incompletely extracted G-code file after canceling a print, which could result in an incomplete printing process.

- P1P now has support for the flag confirming if the P1P has been upgraded with an enclosure. It is available under "Accessories" -> "Upgrade Kit". When this option is selected, you can use the P1S Studio profiles without the prompt "Incorrect printer model". (Studio supported version: 1.8.1 and above).

¶ Bug fixes

- Fixed the problem where after a power failure, the printer would resume printing without extruding filament.

- Fixed the problem of resume printing with the wrong heatbed temperature after power failure.

- Fixed the problem of overlapping display of Chinese characters and numbers of device serial numbers on the device page.

- Fixed the problem where WIFI couldn't connect under AES-GCMP encryption.

- Fixed the problem of long print file names causing the download to stall.

- Fixed the problem of the progress bar jumping during calibration.

¶ P1 series version01.04.02.00(20231027)

¶ Overview

[New Features]

- Added support for model objects being skipped from Bambu Handy. (This is not supported when printing from MicroSD or local area network printing.)

- Added support for printer model verification of 3mf files when printing from MicroSD cards. (Bambu Studio version needs to be 1.8.0 or higher.)

[Bugs fixed]

- Fixed the problem where only a single color might be printed due to power outage during multi-color printing.

- Fixed the problem where printed parts may be hit due to power outage or similar problems during the printing process.

¶ Added support for printer model verification of 3mf files when printing from SD cards.

Bambu Studio version needs to be 1.8.0 or higher.

Due to structural differences between the P1 series and A1 mini, slicing files configured for the A1 mini will cause errors when printed on P1 series machines. In this version, we have added printer model checking for 3mf files.

Printer Configuration Selection

rules:

- If P1P or P1S is selected when slicing, there will be no prompt when initiating printing.

- If X1, X1C or X1E are selected when slicing, a compatibility prompt will appear when initiating printing, and printing can be initiated after confirmation.

- If A1 mini is selected when slicing, a compatibility prompt will appear when printing is initiated, and printing will not be allowed.

- Gcode files will not be verified.

¶ P1 series version01.04.01.00(20230927)

Dear P1 users,

To enhance the overall 3D printing experience for all users, we have made improvements to firmware version ota 01.04.01.00. These enhancements focus on improving the interaction between the device and the Bambu Handy APP, optimizing the printing process, resolving certain errors encountered during printing, and implementing additional functional protections. These measures are implemented to protect your printer while enhancing stability during printing and daily use.

¶ Improvements

[System] Added protection during the load/unload functions to avoid issues when users click load/unload repeatedly.

[System] Added handling of name exceptions when downloading models in MakerWorld. This fixes anomalies caused by model names that are too long or have special characters.

[System] Added protection for timeout when initiating print tasks to avoid abnormal responses caused by receiving timed-out tasks.

[System] Reduced the delay in the Bambu Handy APP displaying device status

[System] Added protection against calibration during the printing process to avoid device abnormalities caused by simultaneous commands being issued.

[System] Added protection to prohibit downloading of language packages during printing, and added UI prompts.

¶ Bugs fixed

- [System] Fixed the issue where transparent filament auto-refill could result in failure matching filament.

- [System] Fixed the inconsistency between the fan speed information upload and the set value.

- [System] Fixed the issue where the device status displayed on the Bambu Handy app may not match the actual device status at the end of printing.

- [System] Fixed the issue where continuing to print when using AMS after power loss may cause the AMS to be disabled incorrectly.

- [System] Fixed the issue where Bambu Handy APP still displays the "IDLE" status after canceling printing during the printing process.

- [System] Fixed the issue where HMS messages may pop up and disappear in Bambu Studio/Handy when printing is initiated.

- [System] Fixed the issue with incorrect grammar translations in the device's multilingual interface.

¶ P1 series version01.04.00.00(20230807)

¶ Summary

- Multiple language support.

- Added protection for the heatbed when homing close to the bottom.

- Canceled the secondary menu for the light switch control.

- Optimized printing pause/AMS resume function.

- Other improvements and bugs fixed

- Remaining Issues

Dear P1 users,

Further development to the P1 series firmware is constantanly in progress to add new features and fix small bugs to ensure everyone's experience is better with each new update.

In this version, we have added support for multiple languages and also brought improvements to firmware stability. We have added a fix for preventing the heatbed from generating noise when it's close to the bottom and you home the printer or start a new print and also fixed some other minor bugs.

¶ Multiple language support

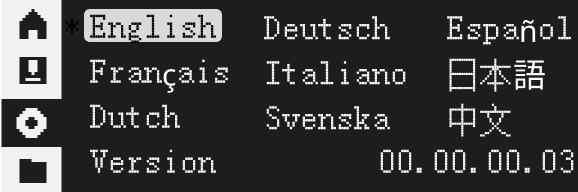

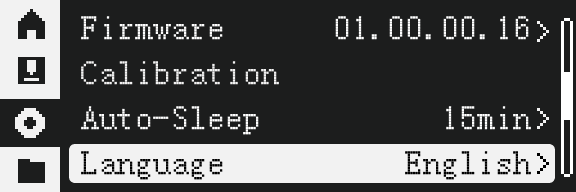

Added support for multiple languages for the homepage, control page, settings page, file page, etc.

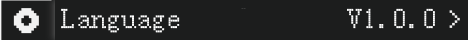

On the settings page, there is a "Language" option that allows users to select the system language. Currently, we support nine different languages.

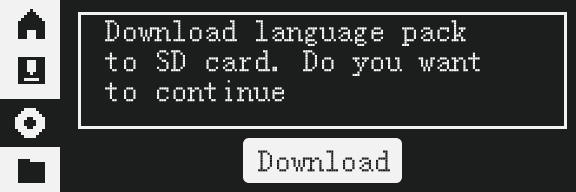

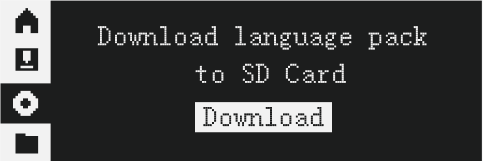

If the language option is not available upon returning to the system page, you will be prompted to download the language pack. Please click "Download" to initiate the language pack download. Make sure to have the MicroSD card inserted into the device during this process.

If the language can not be accessed, please ensure that you are connected to the internet and logged into your account.

¶ Added protection for the heatbed when homing close to the bottom.

Added G38/G380 P2 cmd , which is used to detect overload events of the Z-axis motor. Together with the latest Studio, if the heatbed is near the bottom of the printer when starting a new print, it will no longer grind at the bottom of the printer and make a terrible noise.

¶ Improvements & Bugs fixed

【Improvements】

- Improved printing stability.

- Optimized printing pause/AMS resume function. Now you can directly click the "Continue" button on the printing page to resume the AMS stalled state.

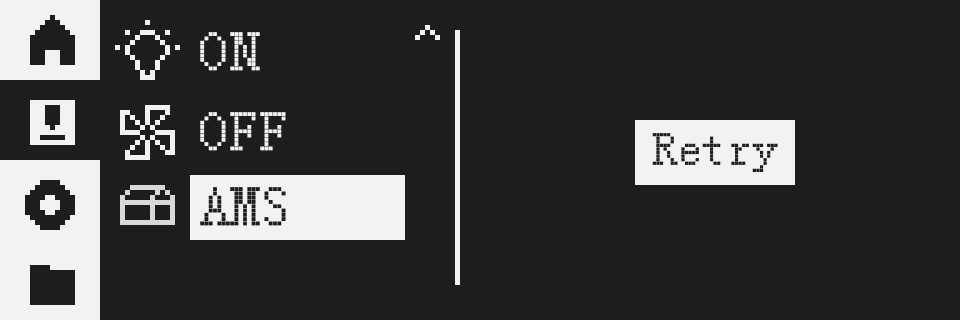

- Canceled the secondary menu for the light switch control. Now, selecting the menu item will turn the light on or off.

- Updated privacy policy.

【Bugs fixed】

- Fixed the problem of being unable to print in multiple colors from the MicroSD card.

- Fixed the problem with missing steps caused by not selecting automatic bed leveling during calibration.

- Fixed the problem where the file list does not automatically refresh when sending the sliced file to the printer.

- Fixed the printer restart problem caused by continuous reconnection of MQTT using third-party tools.

【Known Issues】

- It is possible that the printer printing built-in models will happen step loss.

¶ P1P version01.03.00.00(20230608)

¶ Summary

- Added support for downgrading to previous firmware versions controlled by Bambu Lab (Only through Handy APP V1.0.13 or above)

- Added support for remote liveview through the Internet (Handy APP V1.2.0 or above, Studio V1.7.0.0 or above)

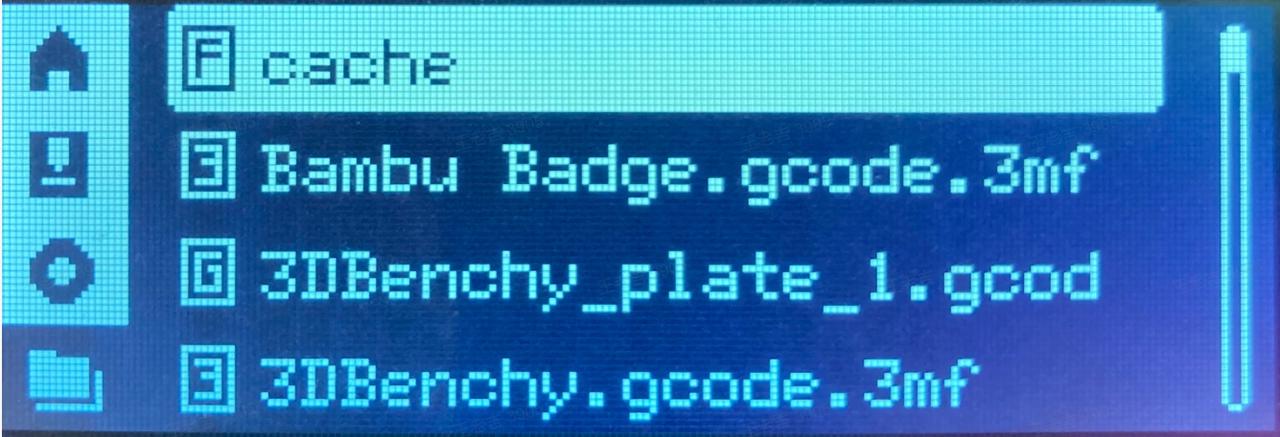

- Added support for saving history print files(limited to 20 3mf files) from cloud to the local cache folder of the MicroSD card

- Added support for smooth timelapse mode

- Added support for multi-language display of files and settings, such as file names, accounts .etc

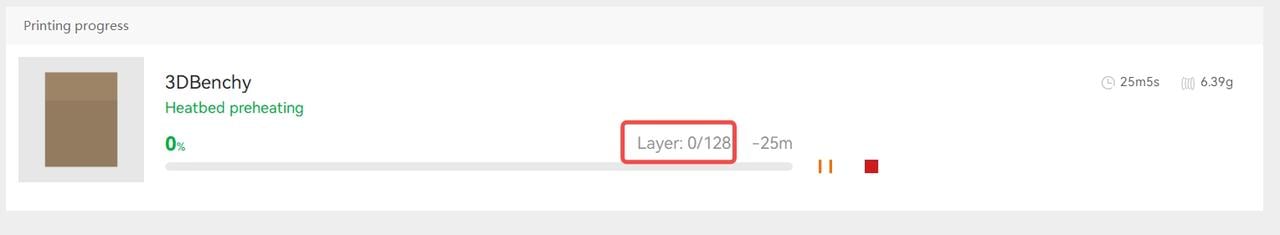

- Added support for Bambu Studio/Handy displaying the number of print layers

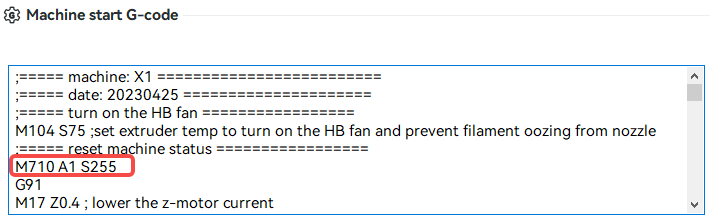

- Added support for using M710 G-code to control the MC fan

- Optimized the decompression logic of printing to allow for printing and decompressing the 3mf file at the same time

- Other improvements and bugs fixed

- Remaining Issues

Dear P1P users,

Thanks for all your support. In recent days, R&D has received many requests for new features such as downgrading firmware, liveview outside of local networks, and saving print history to the printer MicroSD card.

Firmware ota01.03.00.00 brings you all the updates that we could put together. Please enjoy it and thanks again for all your support!

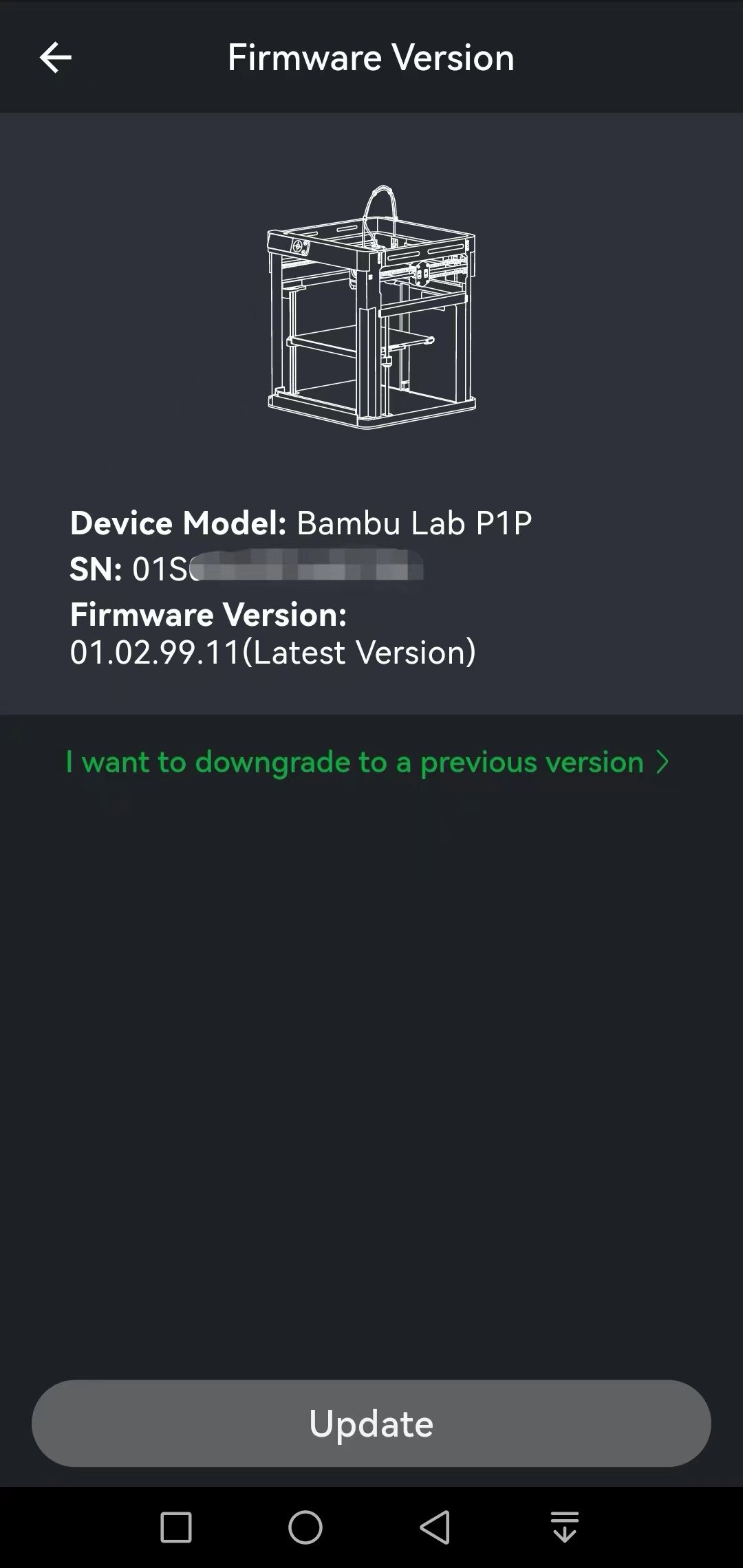

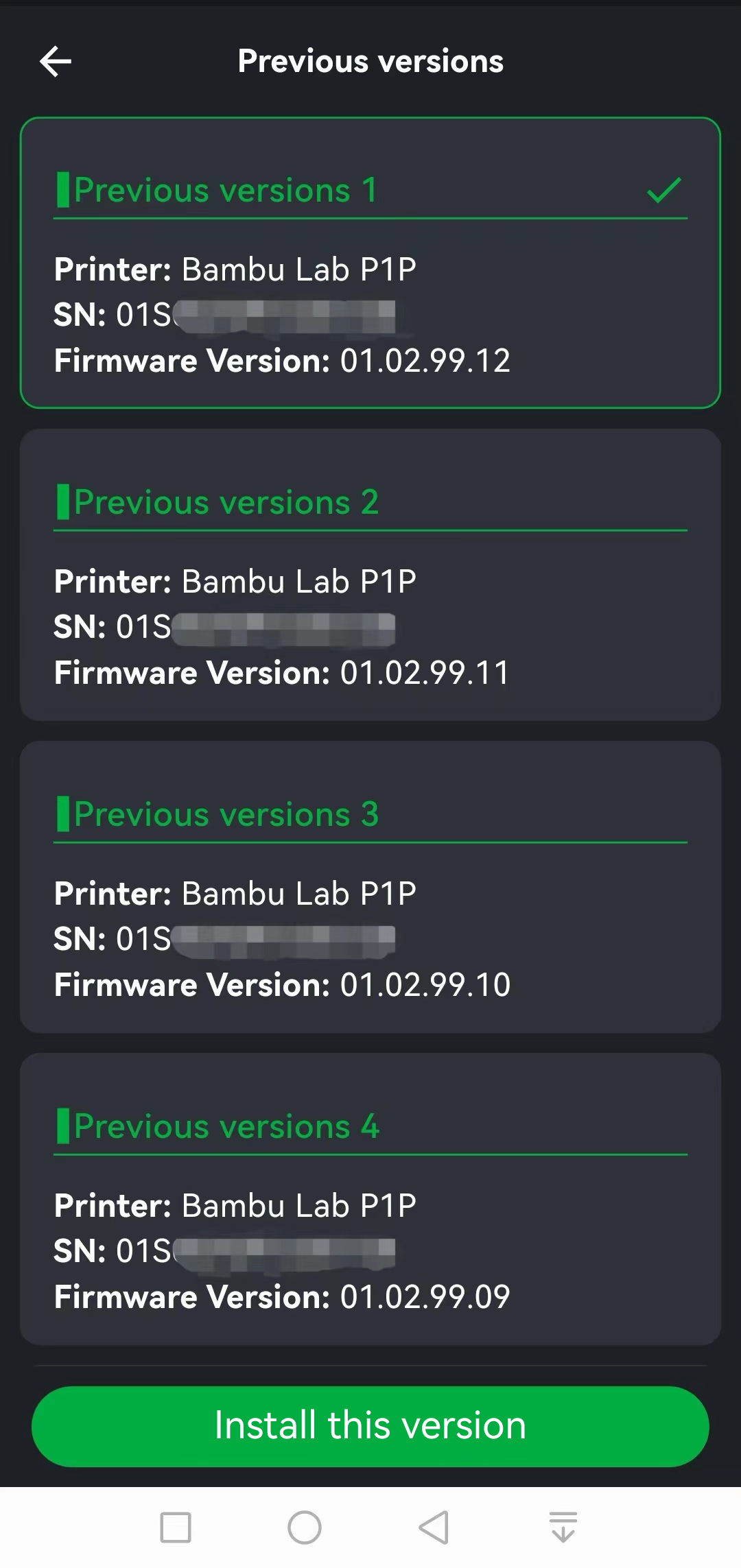

¶ Added support for downgrading to previous firmware versions controlled by Bambu Lab (Only through Handy APP V1.0.13 or above)

Steps to downgrade to a previous version:

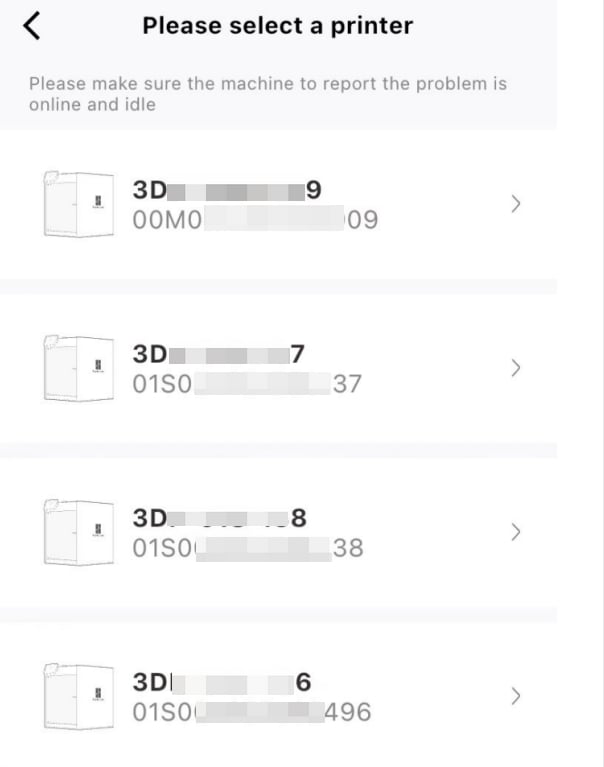

a. Go to the handy device settings page and click Firmware Version.

b. Select "I want to downgrade to a previous version".

c. Select the previous version you want to install, and then click "Install this version".

¶ Added support for remote liveview through the Internet (Handy APP V1.2.0 or above, Studio V1.7.0.0 or above).

Before this update, the P1P could only play video over a local network, which meant that PC/phone must join the same network as the printer to view live video.

From this version, we integrated 3-party tunnel lib into P1P firmware, and it can transfer video over LAN/P2P/RELAY mode, which is automatically negotiated with studio/handy according to the network capability as X1 series.

After upgrading the printer/studio/handy version to target or above, for printer cloud mode, liveview can be played without the limitation of having devices on the same local network.

The remote liveview can concurrently support a maximum of 2 clients (such as One studio + One handy)

¶ Added support for saving history print files(limited to 21 3mf files) from cloud to the local cache folder of the MicroSD card

¶ Added support for smooth timelapse mode

¶ Added support for multi-language display of files and settings, such as file names, accounts etc.

Steps:

a.Enter the settings page and click Language.

b.Download the language pack, making sure that your device is connected to the internet and the MicroSD card is inserted.

The multilingual package currently supports English, Chinese, German, Spanish, French, Italian, Japanese, Dutch, and Swedish.

Once you have downloaded the multilingual package, the files within the folder, as well as your account, will support displaying text in multiple languages.

¶ Added support for Bambu Studio/Handy displaying the numer of print layers

¶ Added support for using M710 G-code to control the MC fan

If your P1P is enclosed, the heat dissipation of the heatsink will not be as good and can lead to overheating. To avoid this, it is necessary to install and turn on the MC fan. You can add “M710" G-code once in the "Machine start G-code" and start a print, and the machine will save the settings. For more information, please refer to: https://wiki.bambulab.com/en/p1/manual/kind-reminder-for-P1P-enclosure

-

M710 A1 S255:turn on the automatic control of the MC fan,the MC fan will automatically turn on when the stepper motor is turned on and turn off when the stepper motor is turned off;

-

M710 S0:turn off the MC fan.

¶ Optimized the decompression logic of printing to allow for printing and decompressing the 3mf file at the same time

We optimized the processing of the decompression process to transmit the decompressed G-code in advance while decompressing, and shorten printing preparation time.

¶ Other improvement and Bugs fixed

-

Increased the binding success rate.

-

Fixed the issue where print shifting occurred while resuming printing after loading/unloading filament when printing was paused.

-

Fixed the issue where resuming from a power outage failed.

¶ Remaining Issues

- After canceling or completing a print job, the printer may incorrectly display "Downloading"

- When resuming printing from a power outage, the K-value of the filament in the virtual slot will be incorrectly used for printing while actually printing with an AMS.

- When sending sliced files to the printer, the file list will not automatically refresh.

¶ P1P version01.02.03.00(20230403)

¶ Summary

- Improvements

- Bugs fixed

¶ Improvements

- After loading the filament of the spool holder, the hotend will be set to the filament's temperature of the spool holder .

¶ Bugs fixed

- Fixed an issue related to the printing resume function after a power outage, such as issues after finishing printing caused by the incorrect printing process recovery.

- Fixed the issue where 3mf files download slowly when using some routers.

- Fixed unload/load typos.

¶ P1P version01.02.02.00(20230308)

¶ Summary

- Important Notes

- Bugs fixed

Dear P1P users,

We are truly sorry for the trouble caused by the latest P1P firmware update 01.02.01.00. We've received feedback that the update has caused several seams in the Z direction in some special scenarios. After reproducing the bug, our team successfully detected the issue and carried out this hotfix version. We sincerely apologize to the users who were affected by this issue.

We hope you can enjoy our P1P with the new hotfix firmware and we look forward to your further feedback.

¶ Important Notes

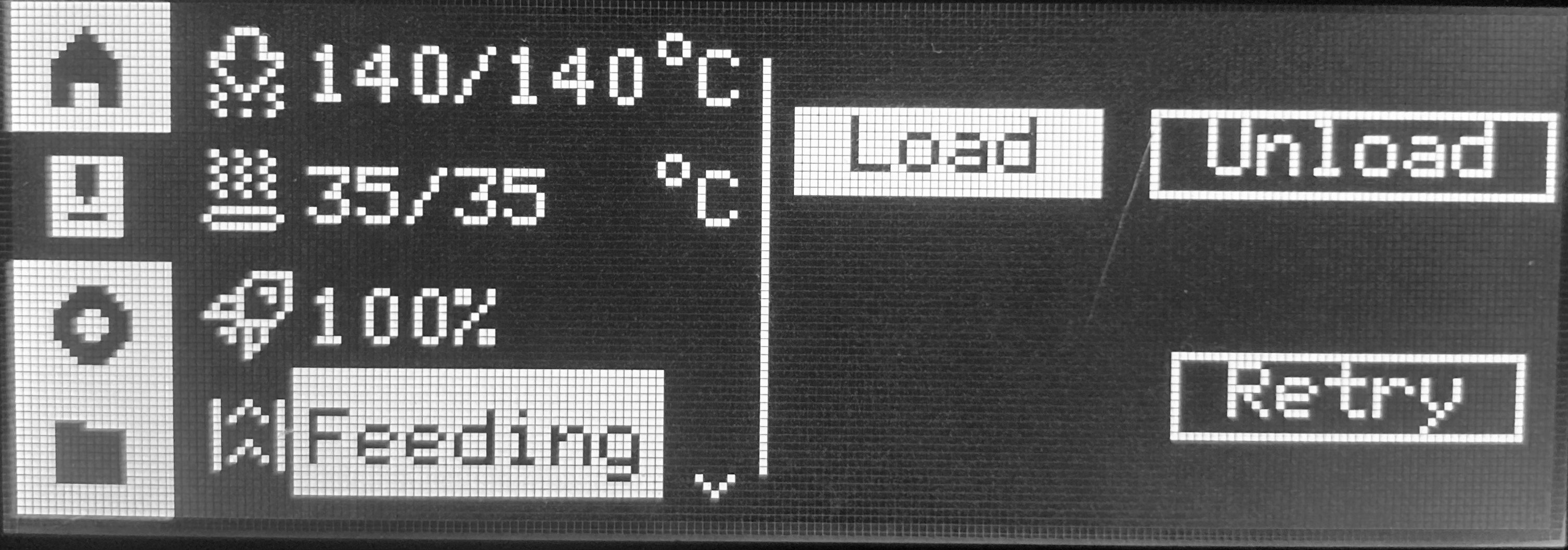

In the latest version, if the filament from the spool holder is not pulled out from the toolhead when 'unloading' is executed, the printer will prompt a message "Please remove the external filament from the extruder" on Bambu Studio and Handy APP, and set the temperature of the toolhead at 142 °C.

In this case, you will need to pull out the filament from the toolhead and then click ‘retry’ on the P1P screen or on Bambu Studio and Handy APP.

¶ Bugs fixed

- Fixed the issue of printing several Z-seams when the hotbed was uneven or warped obviously.

- Fixed the issue that printing was reported as a failure in printing history while it was successful indeed.

- Fixed the missing description of “0503c016” error code.

¶ P1P version01.02.01.00(20230302)

Some features require upgrading Bambu Studio to version 01.05.00.59, which is currently undergoing public testing on GitHub.

¶ Summary

- Added support for AMS filament backup

- Added support for traditional timelapse mode

- Added support for setting the color and type of filament on the spool holder

- Added support for LAN ONLY mode

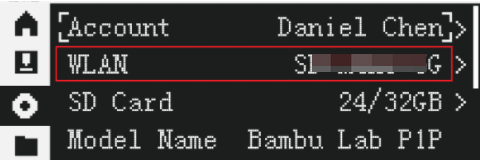

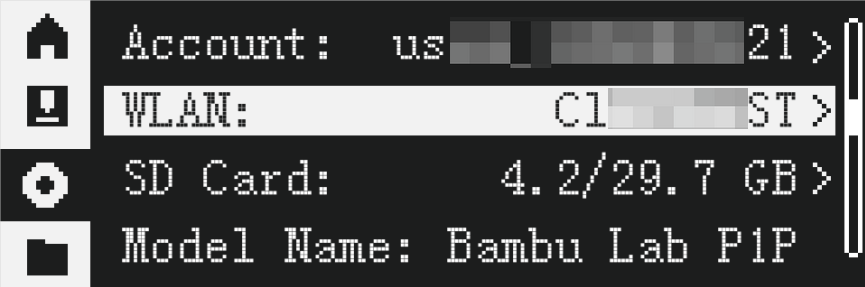

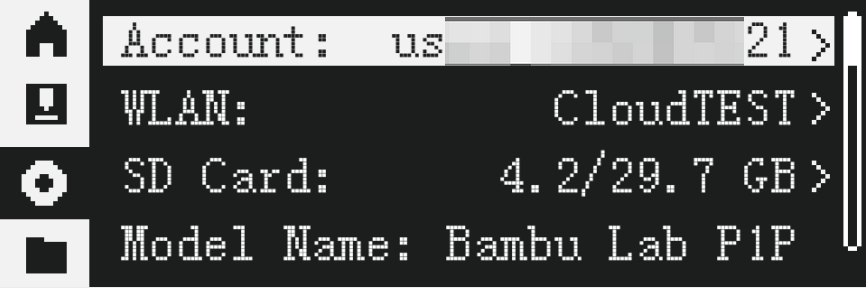

- Added support for display of device MAC address on the WLAN page which is an item on the settings page

- Added support for calibration step selection when starting calibration from Bambu Studio and Bambu Handy

- Added support for loading filament placed on the spool holder with a load button

- Added HMS messages about MicroSD

- Optimized MicroSD card data reading logic to improve print stability

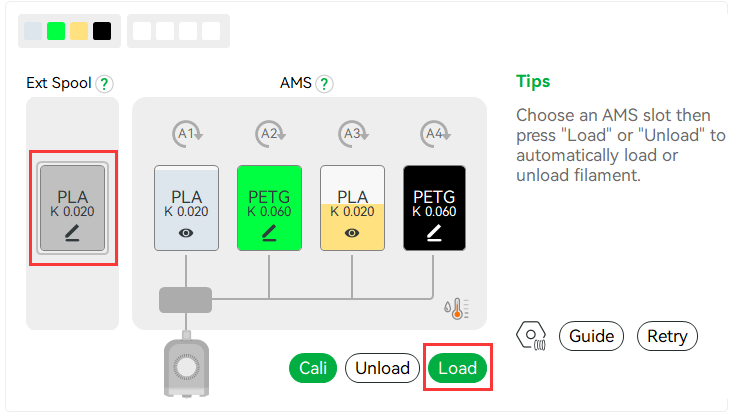

- Adjusted the filament spool holder Load/Unload function and AMS retry function to the Feeding page

- Made minor improvements and fixed various bugs (full details below)

- Remaining issues

Dear P1P users,

Long time no see! Thanks very much for all of your feedback and love. With the effort of our R&D engineers, many features that everyone has been calling for have been included in this firmware update.

In this firmware version (OTA1.2), P1P now supports AMS filament backup; the type and color of the filament placed on the external spool can also be set. In addition, traditional time-lapse mode and LAN Only mode are also supported.

Here are some big improvements, such as the optimized MicroSD card reading to enhance the stability of the printing process. For more features and optimizations in detail, please refer to the following description.

Have fun and best wishes! We're looking forward to hearing your feedback on this update.

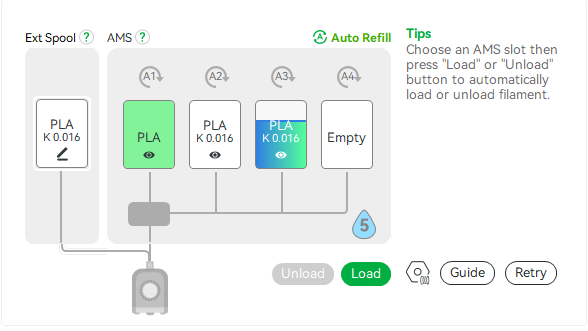

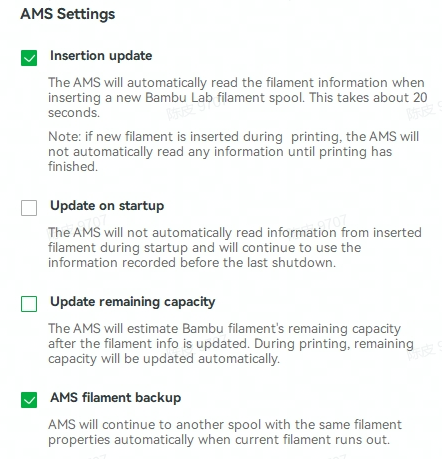

¶ Added support for AMS filament backup.

The AMS will switch to another spool with the same filament properties automatically when the current filament runs out. These filament properties include: brand, type, color, and nozzle temperature. If the AMS can not find the same filament, it will display a prompt that the current slot has run out.

To enable this feature, please check "AMS filament backup" on the AMS settings page in Bambu Studio or Bambu Handy.

Tips:

- Currently, the RFID information of filament can not be read while printing, and the information of non-Bambu filaments can not be edited while printing. Please configure filament information before printing.

- This function requires filaments with exactly the same properties. It is recommended that Bambu filament be used as a replacement for Bambu filament and non-Bambu filament be used as a replacement for non-Bambu filament.

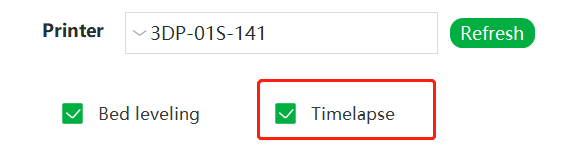

¶ Added support for traditional timelapse mode.

Traditional timepalese can now be enabled when sending a print job with Bambu Studio or Bambu Handy. While printing, the camera will get a picture on layer changes, and after printing finishes, it will generate a timelapse video. This video is stored on the MicroSD card in the "timelapse" directory.

There is an icon in Bambu Studio and Bambu Handy to display whether timelapse is running.

¶ Added support for setting the color and type of filament on the spool holder.

Filament information includes type, color, printing temperature, etc. This information will be used for the Load/Unload function and when printing from the spool holder.

¶ Added support for LAN only mode.

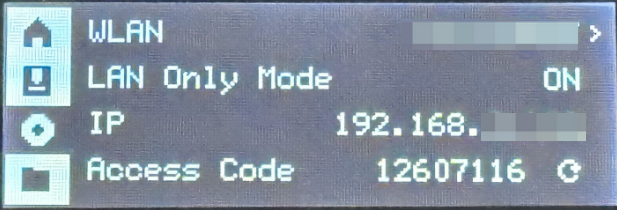

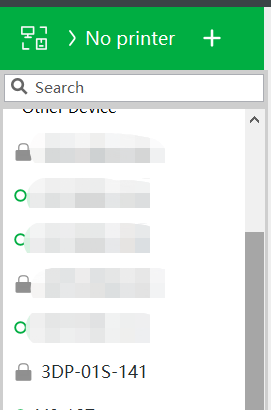

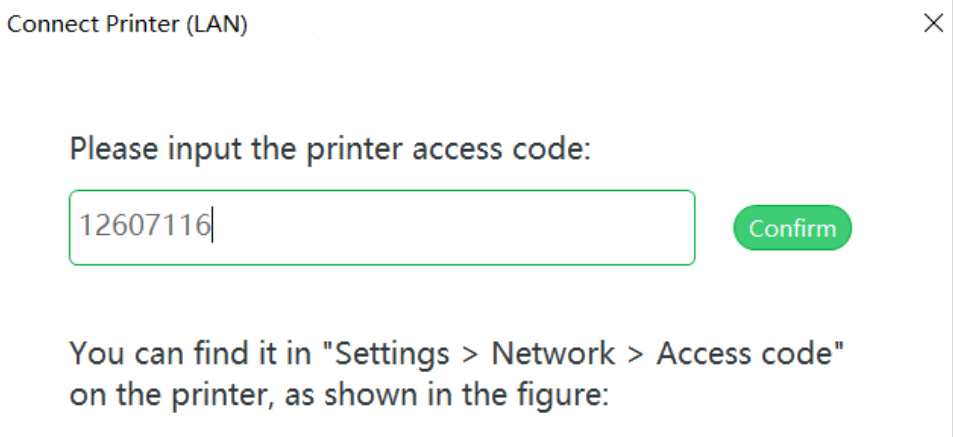

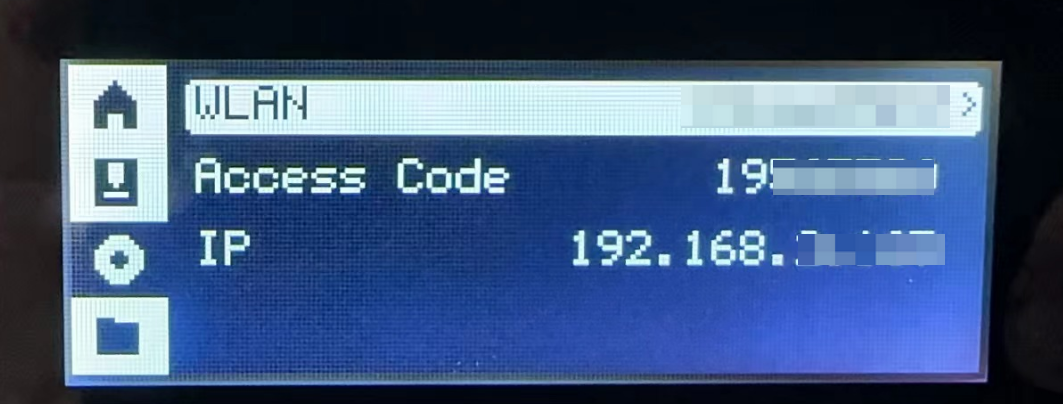

In LAN only mode, all data exchanged between printer and studio will be carried in the same LAN, without connecting to the cloud. For access authentication, Bambu Studio needs to use the access code of the printer, which is displayed on the printer screen.

Bambu Studio can detect LAN-mode printers. After user selects a LAN-mode printer, A dialog is prompted for the Access code. The access code can be refreshed on the Printer screen. After a refresh, Bambu Studio will disconnect and needs the new access code to connect to the printer again.

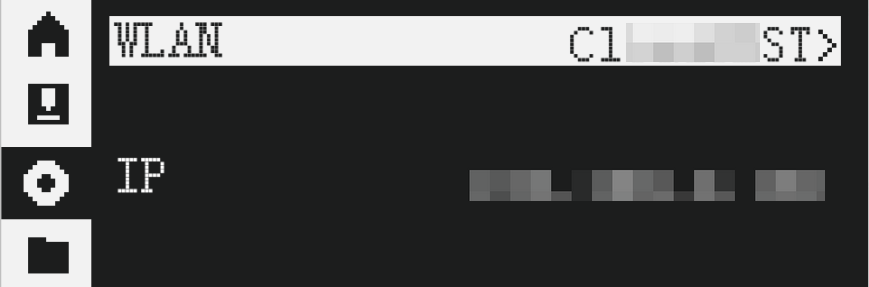

¶ Added support for display of device MAC address on the WLAN page.

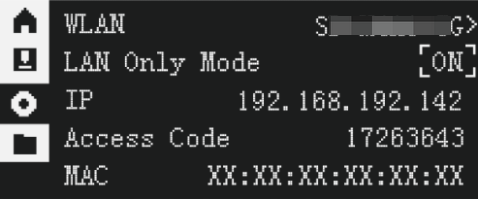

First, enter the system settings interface, select and enter the WLAN page and navigate down; the MAC address is on the fifth line.

When the network is not connected, the bottom QR code page contains the MAC address.

¶ Added support for calibration step selection when starting calibration from Bambu Studio and Bambu Handy.

¶ Added support for loading filament placed on the spool holder with a load button.

¶ Added HMS messages as follows

- MicroSD card read/write errors when downloading 3MF files.

- Paused prints caused by the MicroSD being out of place.

¶ Adjusted the filament spool holder Load/Unload function and AMS retry function on the Feeding page.

¶ Improvement

- Optimized SD card data reading logic to improve print stability and solve the issue with screen display failure caused by SD card data reading errors.

- Error codes will last until the next print begins.

- Expanded the automatic bed leveling range.

- Shortened the movement time of the tool head when changing filaments with an AMS.

¶ Bugs fixed

- Fixed the issue where the calibration process was not displayed.

- Fixed the issue where the printing process is interrupted abnormally due to the unstable connection of Micro SD card.

- Fixed the issue where the IP address is displayed as all 0 when fail to set WiFi

¶ Remain Issues

- Low probability of failing to unzip 3mf files,which is caused by the current strategy of task retransmission.

- The nozzle and hotbed settings are not reset when restoring factory settings.

- In LAN mode, the model transmission process is not displayed when sending 3mf for printing from BambuStudio.

¶ AMS version 00.00.05.96(20230207)

【Bug fixed】

-

Fixed inaccurate remaining capacity display in some cases when spool is near empty.

¶ P1P version 01.01.01.00 (20230119)

Bambu Studio will be updated on January 19, 2023

¶ Summary

- Added manual extrusion compensation calibration.

- Added access code display for wireless LAN, supports manual connection to liveview.

- Optimized thermal runaway protection for the hot end.

- Improvement and bug fixed.

- Details.

Dear P1P users,

We greatly appreciate your being a member of our community! After the P1P was released, we received a lot of feedback and suggestions, and we've been hard at work to improve the firmware. In this version, we mainly optimized common problems you may encounter during use.

In subsequent versions, we will provide more new functionality and optimization, such as cloud-based Spaghetti detection, remote monitoring, time-lapse, AMS automatic refilling and LAN mode, etc.

We are excited to introduce this firmware version to you. We hope you enjoy it, and we're looking forward to any new feedback you may have!

Our in-house extrusion compensation calibration procedure for the P1P is still in development, but we understand that users are keen to have this function, so as a temporary solution, we have derived the manual flow calibration developed by SoftFever through his fork of BambuStudio. Thanks for making this possible!

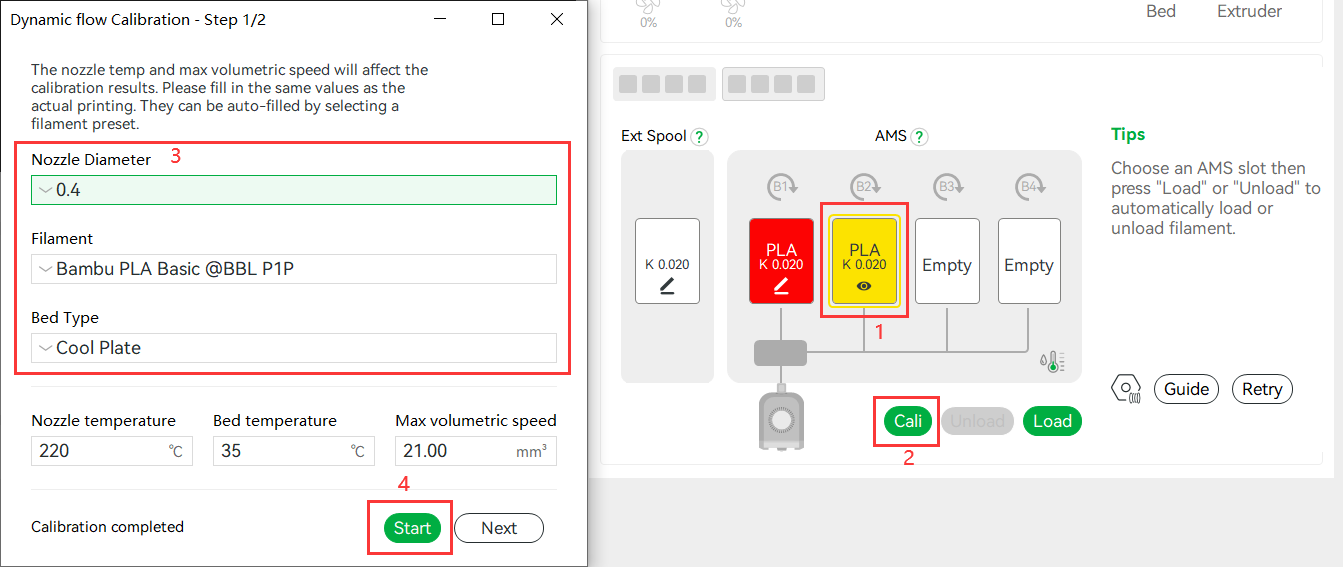

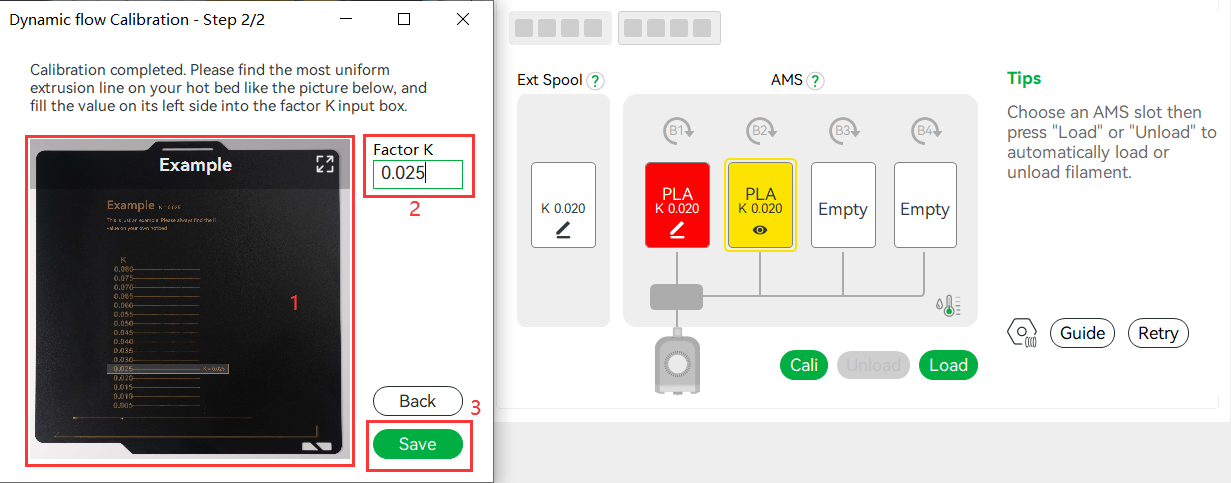

¶ Added manual extrusion compensation calibration.

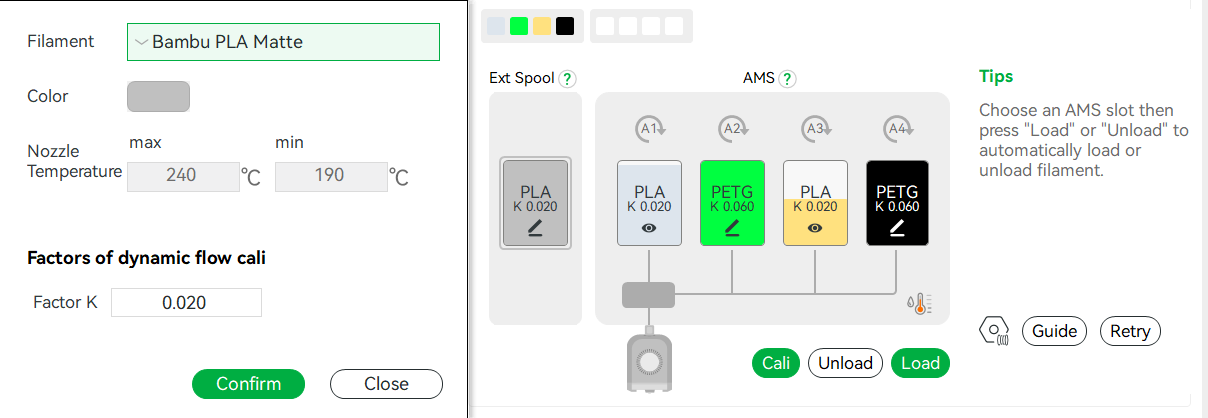

Users can initiate manual extrusion compensation calibration through Bambu Studio. To calibrate, select the material to be calibrated, either an external spool or an AMS slot, and click the "Cali" (short for Calibration) button to get started. In the dialogue box, select the nozzle diameter, material, and hot bed type. You can now click "Start" to begin calibrating.

When the calibration process is complete, select the line with the best printing effect from the printed pattern, fill the corresponding parameters into the box, and click save. The calibration of the slot is complete.

¶ Added access code display for wireless LAN, supporting manual connection for liveview.

The access coded was added from the version 01.01.00.00. and displayed on 01.01.01.00.

So if only bind on printer version 01.00.00.00, access code will NULL and did not be displayed. Need do a user logout and rebind with handy app.

Bambu Studio needs to be updated to 01.04.02.00 or higher

For Android devices, Bambu Handy needs to be updated 1.0.8 or higher

For iOS devices, Bambu Handy needs to be updated 1.0.9 or higher

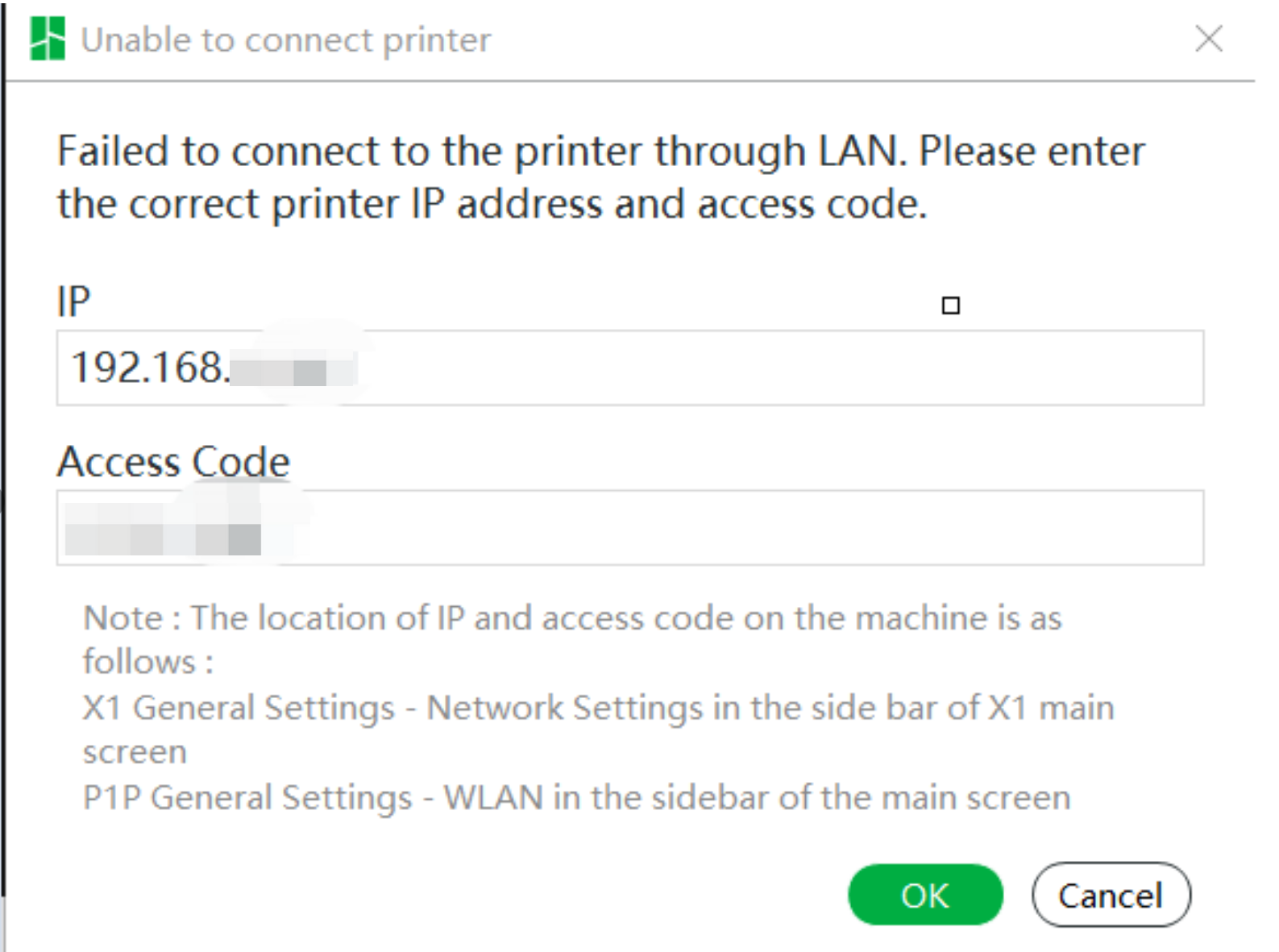

Some liveview failure issues are caused by firewall settings which block studio receiving SSDP packets , or router settings which don't forward ssdp packets to Studio/Handy. The error messages are "Missing LAN ip of printer" , or " The printer cannot be found on the LAN". To fix this, we added a manual input function, directly input Printer IP and access-code to Studio/Handy APP.

On the printer's side, IP and access-code are displayed on screen.

If auto-ip detection fails, the manual input will pop up on Studio/Handy like below:

¶ Optimized thermal runaway protection for the hot end

We implemented a new thermal runaway protection algorithm to shorten the delay before protection kicks in. For most thermal runaway cases, the new algorithm can shut down the heater and show the error prompt within 30 seconds.

We have adjusted the logic for clearing temperature errors. when the printer is idle, in the previous firmware, some errors are automatically cleared when the error is recovered (e.g. the printer will report an open circuit error when the sensor is unplugged and the error will be automatically cleared when the sensor is plugged back in); in the new firmware, the error is only cleared when the printer power cycle or a new print is initiated.

¶ Improvement and bug fixed

- Fixed the network disconnection problem

- Fix the problem that the SD card is disconnected or pulled out during the printing process, which causes the printing to stop and cannot be recovered

- performance optimization

¶ Details

Need to upgrade Bambu Studio/Handy

- Bambu Studio needs to be updated to 01.04.02.00 or higher

- For Android devices, Bambu Handy needs to be updated 1.0.8 or higher

- For iOS devices, Bambu Handy needs to be updated 1.0.9 or higher

【New feature】

- Added manual extrusion compensation calibration.

- Added access code display for wireless LAN, supporting manual connection to liveview.

【Improvement】

- [System] Optimized thermal runaway protection for the hot end.

- [System] Optimized printer performance and improved long-term print stability.

- [System] Optimized fan speed feedback, now the fan speed display is closer to the actual speed.

【Bug fixed】

- [System] Fixed the problem where "free" in the user name will cause automatic logout when booting.

- [System] Fixed the network disconnection problem.

- [System] Fix the problem that the SD card is disconnected or pulled out during the printing process, which causes the printing to stop and cannot be recovered.

【Remaining Issues】

- When using an AMS, printing a 3mf file via the SD card may fail because the AMS slots cannot be selected.

- Non-HMS error codes are not displayed on the screen.

- Steps of the calibration process are not seen by Bambu Studio.

¶ P1P version 01.01.00.00(20221215)

【Important Update Notes】

In this version, in order to ensure information security, we have included support for https to communicate with the server. It is required to update to this version before you can use the app or studio to start a print.

Summary:

- Added support for 3MF file download over https and tcp-tls connection of liveview, which is currently only available when P1P, Handy App and Bambu Studio are on the same network, to improve information security.

- Added support for BLE security connection when pairing the Handy App with the printer via Bluetooth; numeric comparison will be confirmed.

- Added support for multiple AMS and AMS-Hub.

- Added capability to switch from AMS to spool holder without unplugging cables initiated printing from Handy APP or Bambu Studio.

- Added support for the AMS retry button on the screen.

- Added hotbed protection and boundary limits.

- Supported automatically turning off the motor when the printer is idle for over 10 minutes.The idle consumption is reduced from 23W to 4.8W.

- Added support for automatic recovery after losing printing steps(Experimental).

- Added support for creating tickets and uploading logs through Handy APP.

- Added support for calibration initiated from Handy App/Bambu Studio.

- Added support for fan speed control page on the Handy App.

- Added support for WiFi clearing and account configuration.

- Added support for expansion boards displaying its sn and firmware version on the screen.

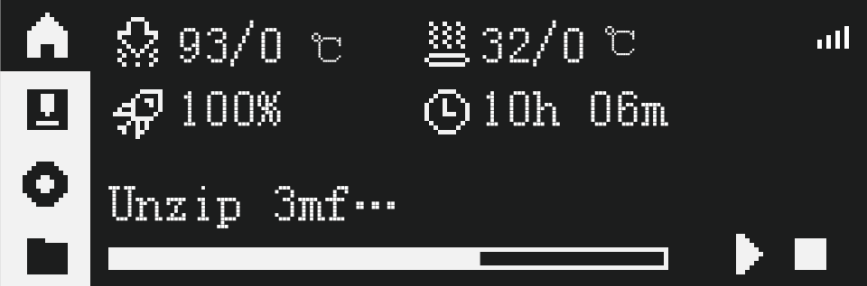

- Added progress display when decompressing 3mf files.

- Made minor improvements and fixed various bugs (full details below)

- Remaining issues

Dear P1P users,

Many thanks for being one of our valued partners. We've been working hard to make a great many improvements to bring as many of the X1 Series features as possible to the P1P. Version 1.1 of the P1P now supports Multi-AMS setups, switching to the spool-holder without unplugging cables, and now supports remaining spool amount estimation for Bambu Lab filament.

We are excited to introduce this firmware version to you. Enjoy yourself and we need your feedback!

¶ 3MF file download over https and tcp-tls connection of liveview, which is currently only available when P1P, Handy App and Bambu Studio are on the same network, to improve information security

Currently, the cloud environment has switched to https, and P1P also supports https in this version.

The liveview data will be encrypted for transmission. Furthermore, access-code checking is required. Only authorized studio accounts can obtain access codes from the cloud. These access-codes are produced during user login operation printer-side with the Handy app and are stored encrypted in the printer and on the cloud. If the printer firmware version is below 01.01.00.00, users must log out and login again after updating.

¶ Added support for BLE security connection when pairing the Handy App with the printer via Bluetooth

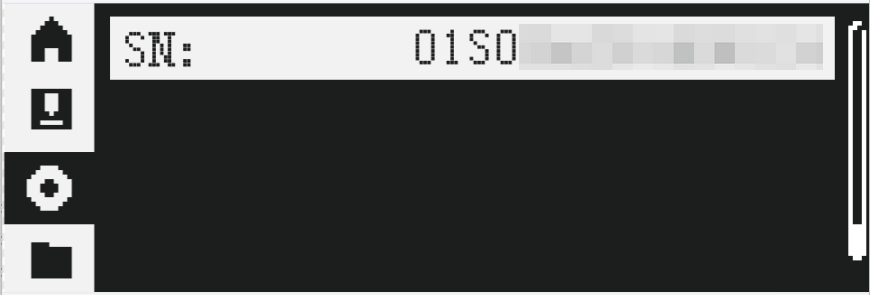

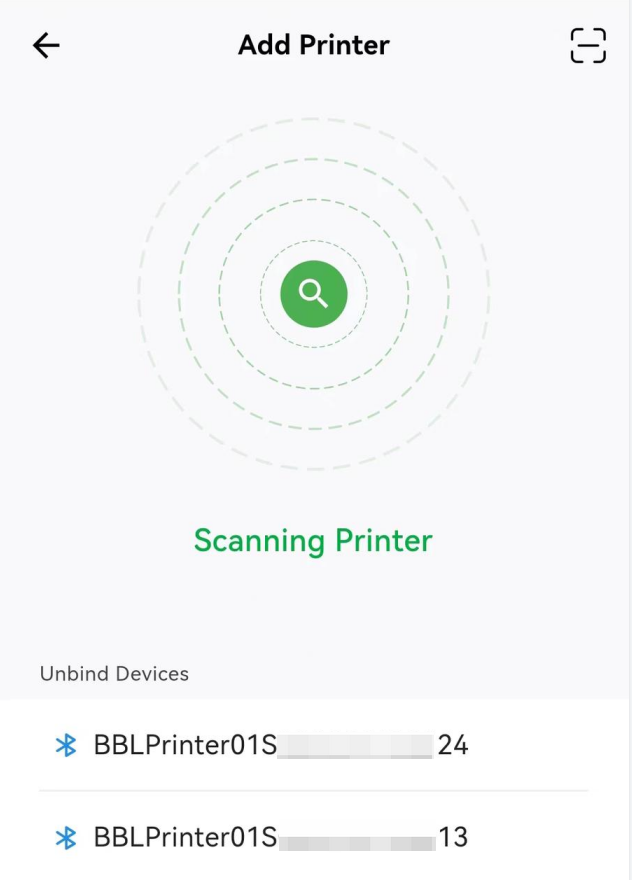

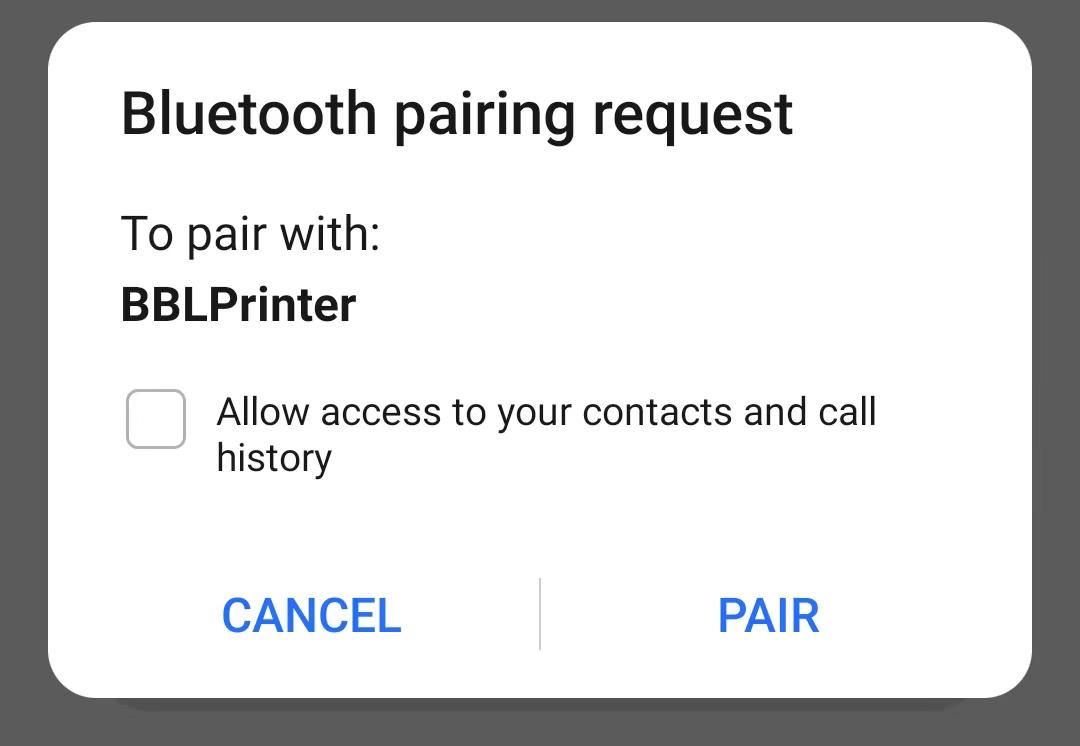

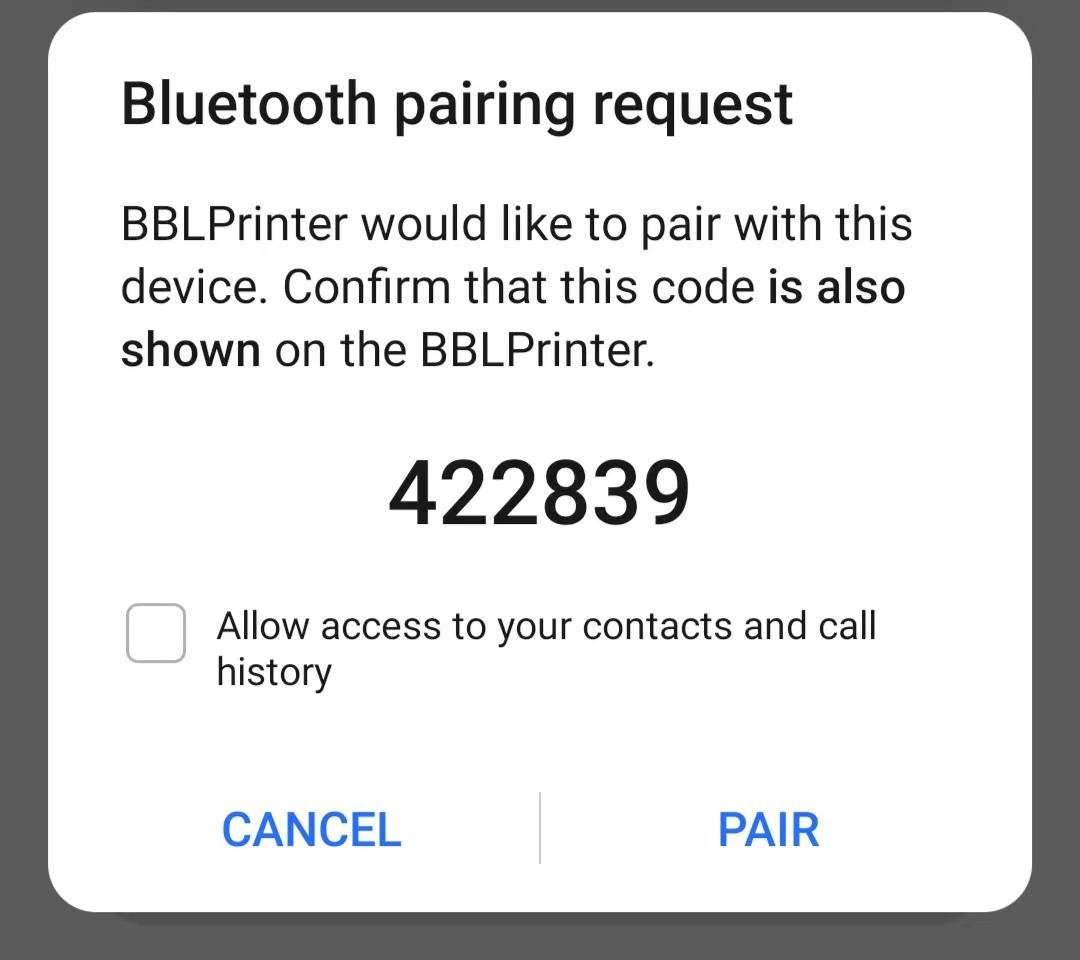

If you do a logout, use the forget wifi functionality via the UI, or delete your device from the Handy app, the printer will enable BLE advertising, so the handy app can scan for nearby printers, such as "BBLPrinter01S00XXXXX". If there are many printers, you can find the printer SN on the UI so that you can find the target printer.

The BLE link will transfer WIFI SSID and password, and printer firmware enables the ble pair-bind function, which is safe enough to prevent passive eavesdropping, man in the middle (MITM) attacks, and identity tracking. Additionally, the printer stores the wifi password using encryption.

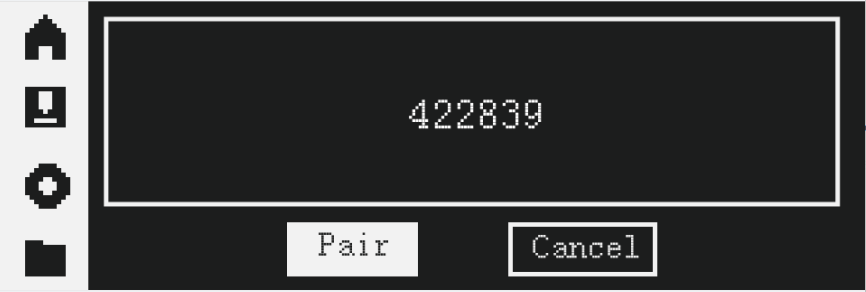

|

|

NOTE: Selecting "Allow access to your contacts and call history" is not required, it comes from the phone os, not the Handy App, so there is no need to allow it.

¶ Added support for multiple AMS units and the AMS Hub.

As promised, our printer can connect 4 AMS units to support 16-color printing from this new firmware (with an AMS Hub). We solved tons of bugs around multi-AMS setups to make the user experience more comfortable. The connection between multiple AMS units and the printer is shown in the following photo (with a X1C as an example) through the AMS HUB. The method of connecting the P1P is the same as that of the X1C.

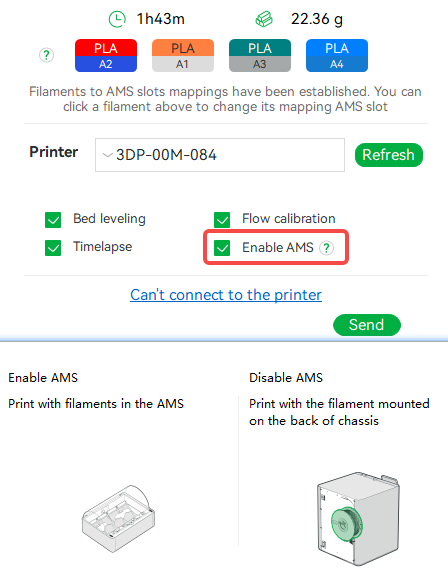

¶ Added capability to switch from AMS to spool holder without unplugging cables initiated printing from Handy APP or Bambu Studio.

Previously, AMS users needed to unplug the AMS cable before loading filament from the spool holder to print filament not supported by AMS. This was a problem for people who placed their X1 in a location where the rear of the machine was not easily accessible. To solve that problem, our new firmware provides an option to Enable or Disable the AMS when starting a print. Now, the P1P also has this capability to make it more convenient to use while initiating from Handy APP or Bambu Studio.

When the "Enable AMS" option is checked, the AMS will be used for a print. If the option is unchecked, the printer will instead pull filament loaded from the spool holder. Users can now easily switch between the AMS and spool holder without unplugging the cable.

¶ Added support for the AMS retry button on the screen.

When the AMS is stuck, such as from a filament runout or other abnormal pause, you can use this button to resume printing via AMS after solving the error.

¶ Added hotbed protection and boundary limits.

Another important feature in this firmware version is the inclusion of software end-stops. This prevents collisions when controlling the tool head manually by limiting movement to the printer's building area in order to avoid damage to the printer or its motion systems.

To benefit from this feature, users must home the printer before manually controlling the tool head. Users can home the printer or take advantage of the automatic homing that takes place at the start of a print. In some situations, users may need to move an axis before homing, so we implemented a warning when users try to manually control an axis before homing.

¶ Supported automatically turning off the motor when the printer is idle for over 10 minutes. The idle power consumption (tested after turning off the screen automatically without the AMS) is reduced from 23W to 4.8W.

All stepper motors are turned off by default when the printer is powered on, and the motors will be turned off to reduce power consumption when the printer has idled for more than 10 minutes.

¶ Added support for automatic recovery after losing printing steps (Experimental function, turned off by default).

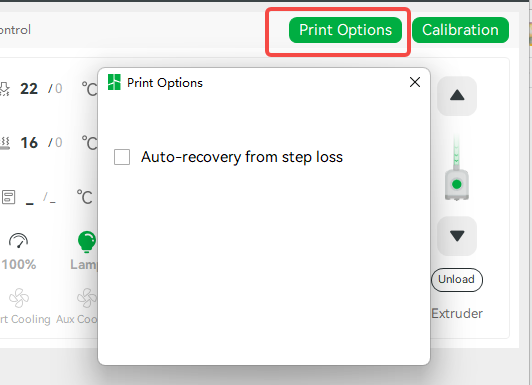

When printing under high acceleration or if the excess chute is blocked by pileup, there are risks that the XY motor will skip steps during printing. When the printer is homing, it will monitor the load of the XY motors to determine if the toolhead has reached the end stop. Now, we use the same method to monitor the step skipping during printing. If skipped steps are detected, the printer will pause the print and do an XY-axis homing, then resume the print. This is an experimental function and is turned off by default. If you want to try it, you can turn it on in the print options page.

¶ Added support for creating tickets and uploading logs through Handy APP.

Logs are on the SD card; there are three folders under the root: "logger", "recorder", and "corelogger". Log files will be written in a loop, so that the total size of all files will be kept to 600-700MB, so there is no need to worry that the log will fill the SD card.

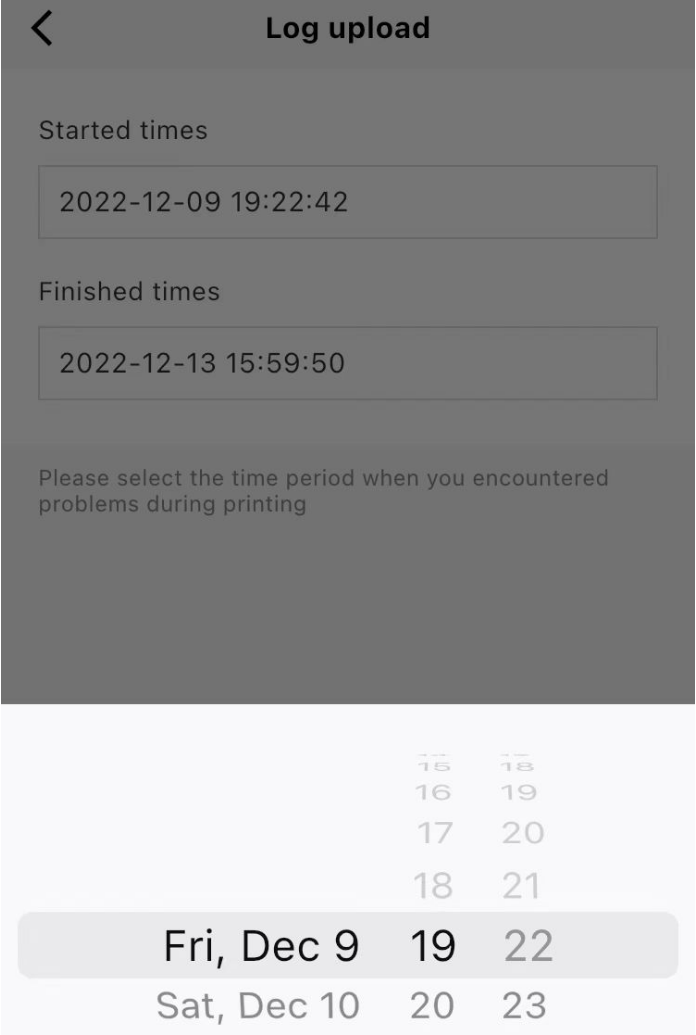

Similarly to the X1 series, logs can be submitted to Bambu Lab directly through the network. With good signal, the upload speed from the P1P should be about 150kbps. To reduce log upload times, you can select the specific time period you need to upload logs for in Bambu Handy, and only those logs will be uploaded.

You can also copy the log from the SD card and report the problem and log through Bambu Lab's official website.

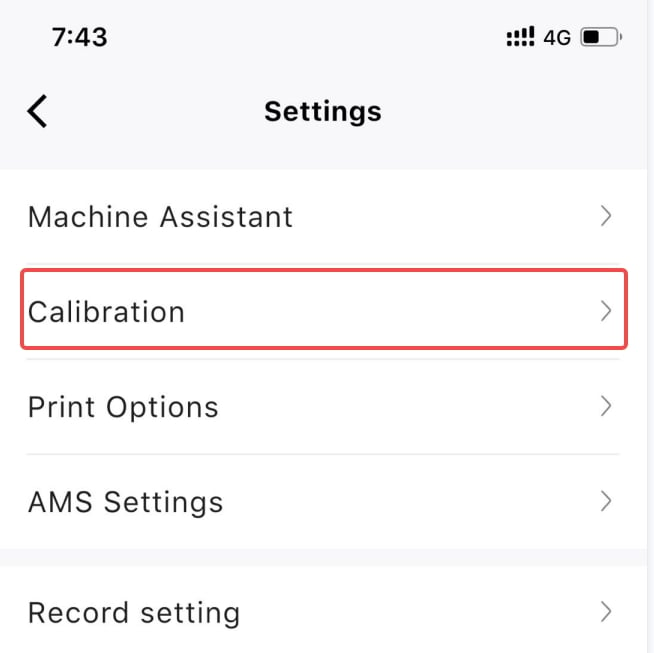

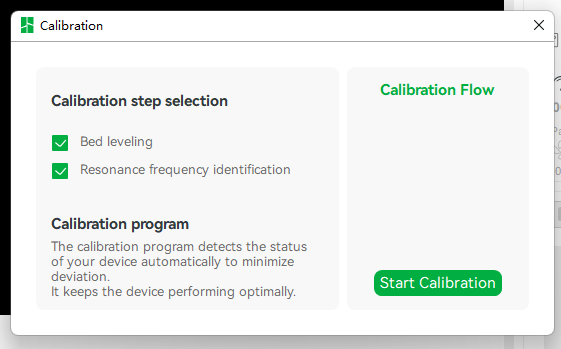

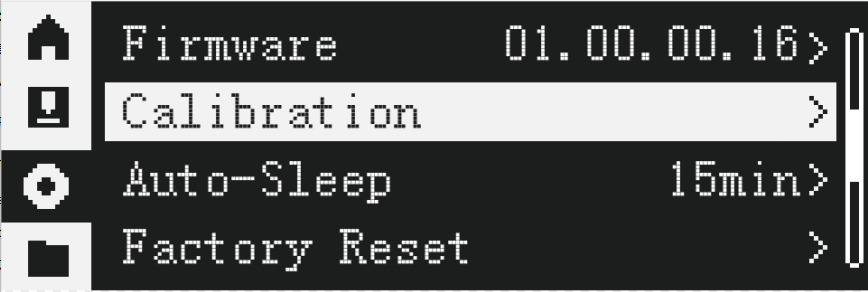

¶ Added support for calibration initiated from Handy App/Bambu Studio.

From Handy App:

From Bambu Studio:

From P1P:

|

|

¶ Added support for fan speed control page on Handy App and Bambu Studio.

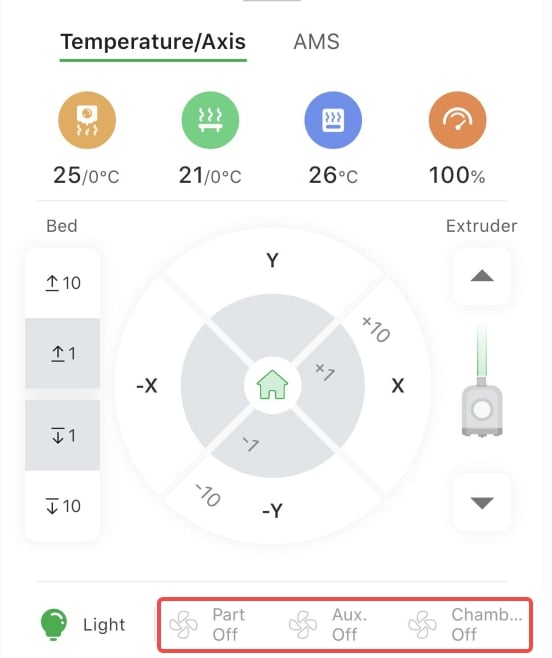

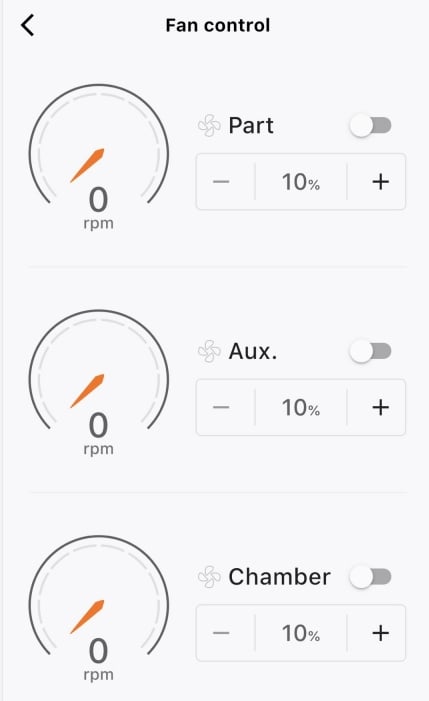

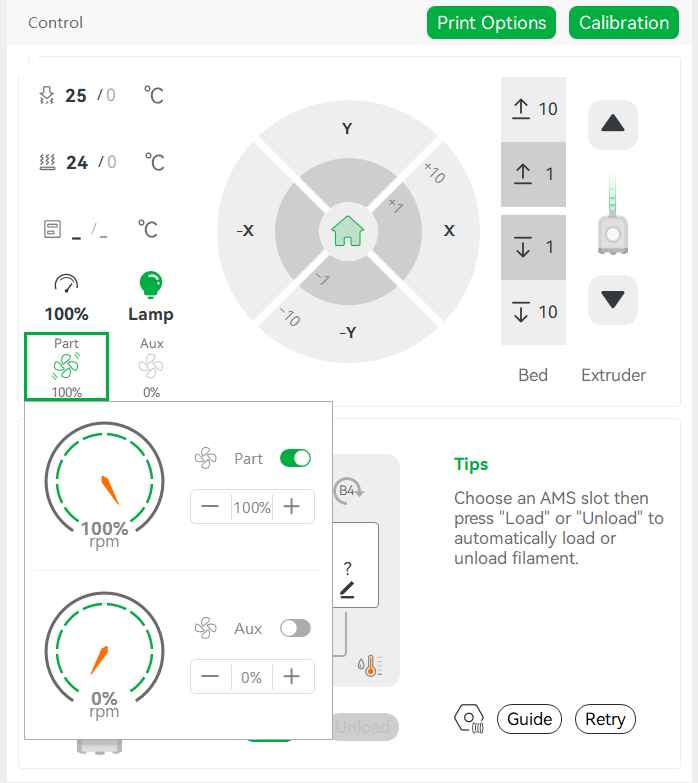

Handy App:

|

|

Bambu Studio:

¶ Added support for WiFi clearing and account configuration.

WiFi "Forget Wifi" button can forget Wifi passwords and the machine will disconnect from the chosen Wifi.

|

|

|

The "Logout" button can log the machine out of your account so that it can be bound to other accounts.

|

|

¶ Added support for expansion boards displaying its sn and firmware version on the screen.

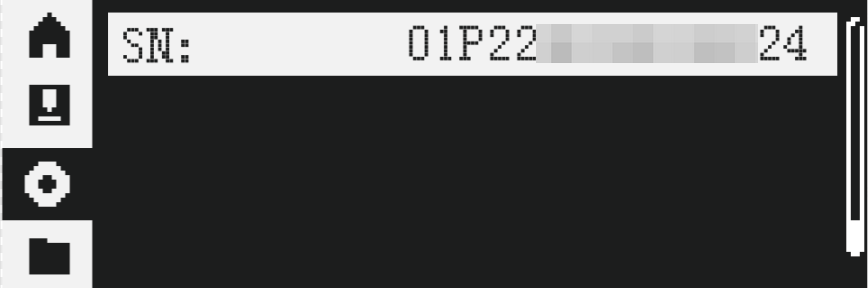

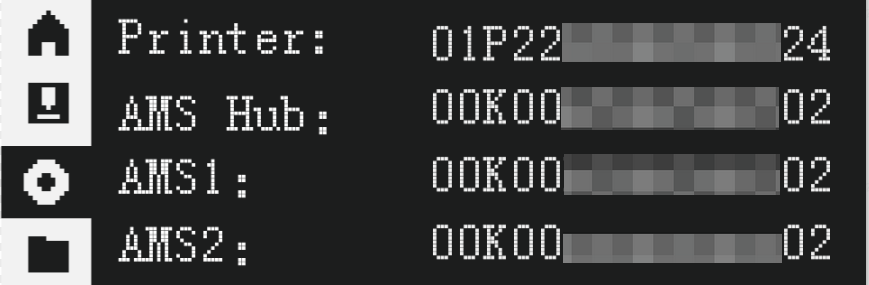

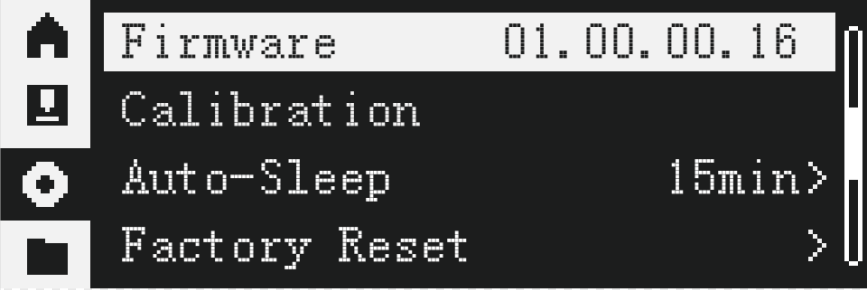

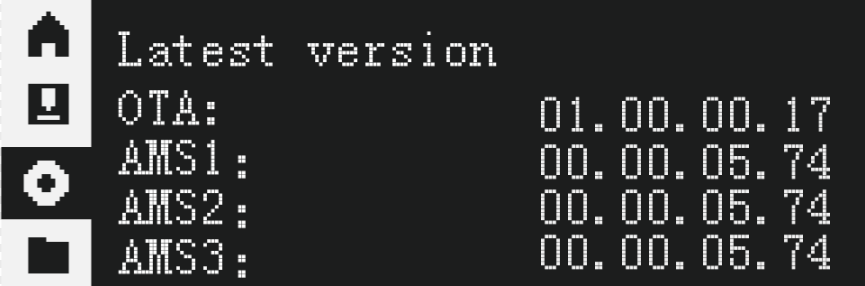

SN display at System page -> SN: ->module sn. Firmware version display at System page->Firmware:xx.xx.xx.xx ->modules version.

|

|

|

|

¶ Added progress display when decompressing 3mf files

¶ Made minor improvements and fixed various bugs (full details below)

Improvements

- [Screen] Optimized some scripts.

- [System] Optimized printer performance and improved long-term print stability.

- [System] Optimized the fluency of monitor video playback.

Bugs fixed

- [System] Fixed an issue where APP notifications of successful printing when canceling printing.

- [System] Fixed the issue that the studio and APP will show the device disconnected when the print job is named Chinese.

- [System] Fixed an issue which could lead to the printer's restart when unzipping.

- [System] Fixed an issue where there isn't any log in some cases.

- [System] Fixed an issue where some HMS messages could not be cleared.

- [System] Fixed an issue where Bambulab Studio and Handy APP unable to get and set printing speed.

- [System] Fixed the issue where Bambulab Studio and Handy APP still display printing after power failure and restart during printing.

- [System] Fixed an issue where the color of third-party consumables could not be AMS through Handy app settings.

- [System] Fixed the issue that the printer data on the Bambulab Studio is abnormal after restarting the printer.

- [System] Fixed the issue when the tool header has material, while the Handy App and Bambulab Studio display no material.

¶ Remaining issues

- Hotend temperature is not set to 0°C after unloading filament from the AMS.

- When using an AMS, printing a 3mf file via the SD card may fail because the AMS slots cannot be selected.

- Non-HMS error codes are not displayed on the screen.

- Steps of the calibration process are not seen by Bambu Studio.

¶ AMS version 00.00.05.75(20221215)

Summary:

- Supported AMS estimating remaining filament on spool.

- Supported to display AMS humidity index.

- Optimized filament stuck detection.

- Added filament stuck detection and automatic recovery during the RFID reading process.

¶ Supported AMS estimating remaining filament on spool

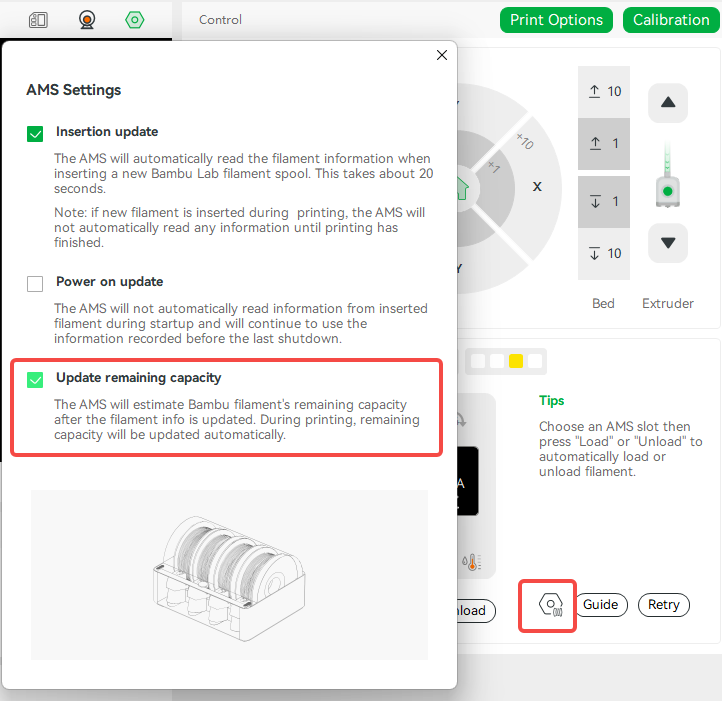

AMS can now estimate the remaining filament of the spool. This estimation is only available with Bambu Lab filament because it relies on RFID technology. To enable it, please go to the AMS setting screen and select the "Update remaining capacity" option. Once selected, AMS will estimate the spool in the NEXT filament info update, depending on how you configure when to update the info. Besides, the estimation will be updated during printing. Unplugging filament will clear the info.

Note:

Filament info must be read before AMS can estimate the remaining filament.

Please trigger a reading manually or automatically with either "Update on insertion" or "Update on startup". This function only provides an estimation of remaining capacity, it may not accurately reflect the actual capacity of the spool.

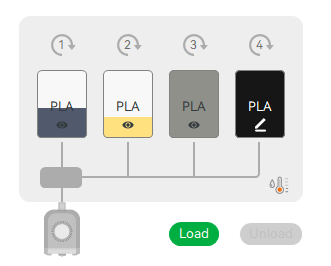

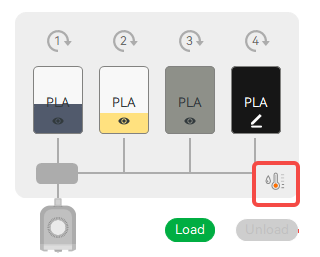

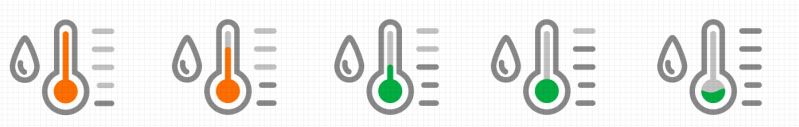

¶ Supported to display AMS humidity index

AMS can now utilize the humidity sensor to help you monitor the humidity state of AMS and the desiccants. An indicator is shown in the right-bottom corner of each AMS panel.

|

|

The indicator uses color and bars to indicate the index. Larger numbers and green color mean the air is dry and the desiccant is working effectively, while red and lower bars mean ineffective desiccants and humid air. An active desiccant can keep the indicators at 4 or 5 bars. Deactive desiccants can only keep the indicator at 1 or 2 bars. You should store your hygroscopic filament in a drybox until new desiccant packs are installed.

Notes: Newly installed desiccant can take hours or a night to absorb the moisture until the chamber is stable. Lower temperatures also slow down the process. Due to the sensor location, raw humidity measurement doesn't reflect the chamber state accurately. Instead, we applied an algorithm on raw data to estimate the effectiveness of the desiccants, which should be more reliable in a wider temperature range.

¶ Optimized filament stuck detection.

AMS will continuously detect the resistance of the filament during printing, if the resistance of the filament is too high, the filament may be tangled or the spool may be stuck. The AMS will unload the filament and retry once automatically. If it still fails, the AMS will provide the prompt "AMS assist motor overload".

¶ AMS-Hub version 00.00.00.42(20221215)

In this verion of AMS-Hub, it is compatible with printers and AMS related functions.