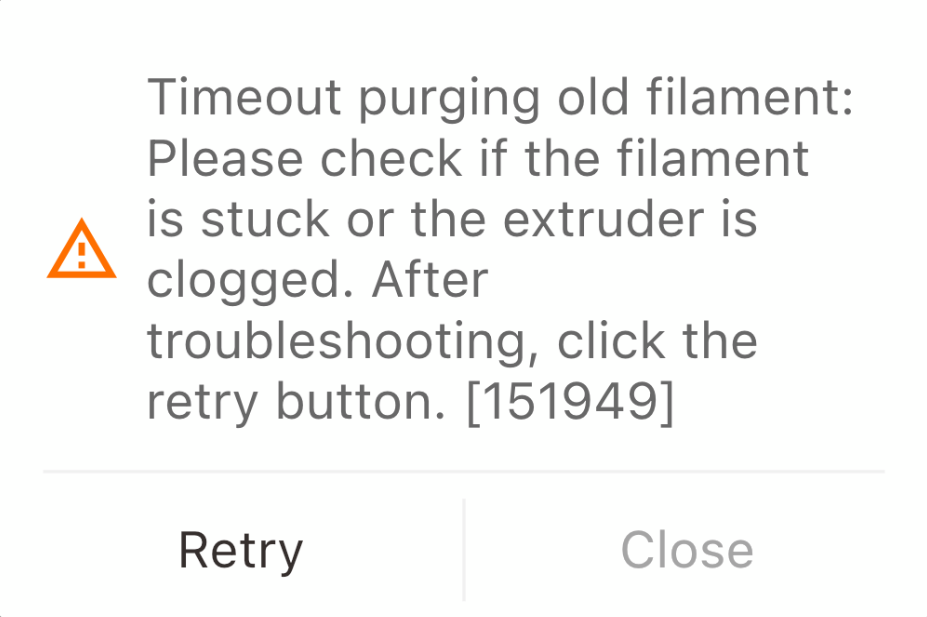

¶ Observation

The flushing of old material exceeded the time limit, triggering an alarm.

Possible reasons:

- There was an abnormality in the AMS retraction process, causing a jam (if using AMS).

- The extruder or nozzle is blocked.

¶ Troubleshooting

¶ Tools, Equipment, and Materials

- Referring the detailed Wiki in the following Actions.

¶ Actions

Operators may use discretion in determining the actual procedures used, and the order in which these steps are applied.

¶ Step 1. Check abnormality in the AMS retraction process.

Step 1.1 High unloading resistance that leads to unloading failure.

Please refer to the high unloading resistance section to reduce the resistance.

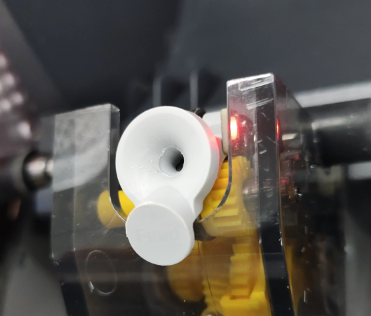

Step 1.2 The broken filament inside the AMS internal hub unit or abnormal sensors.

After the filament has fully exited the first-stage feeder, the AMS is still performing the unloading process with the LED status of the feeder in solid red (as shown below). This is possible that there is a broken filament inside the internal hub unit that leads to the unloading failure. Please refer to this wiki article to dismantle and clean the internal hub unit, and check if the sensor is normal.

Dismantling and cleaning the AMS internal hub unit

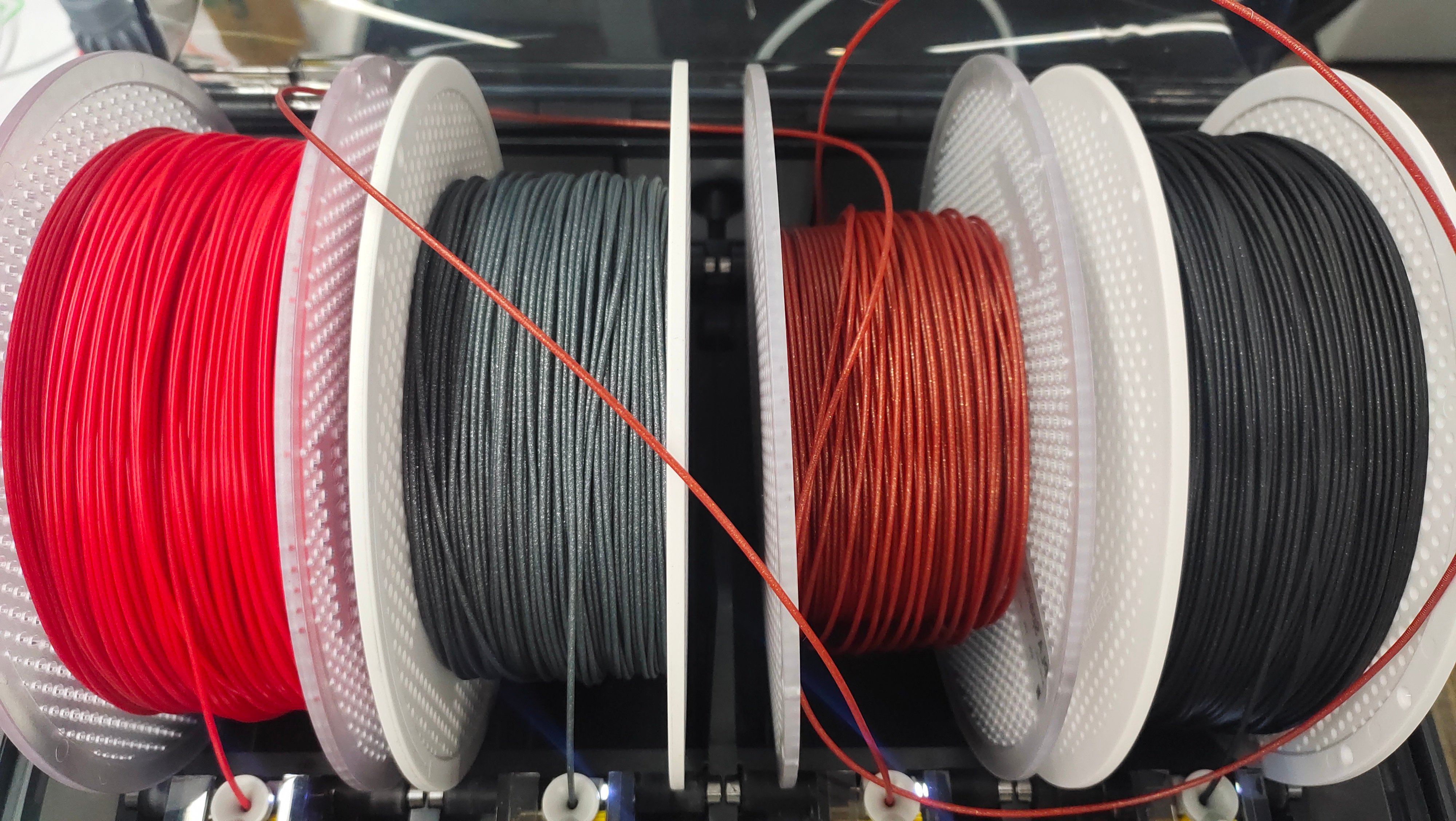

Step 1.3 Abnormal spool rotation

When unloading the filament, the AMS internal hub unit motor pulls back the filament, and the first-stage feeders rotate the spool back. If the situation in the image below happens, the spool doesn't rotate, or its rotating speed is slower than the unloading speed of the internal hub unit motor.

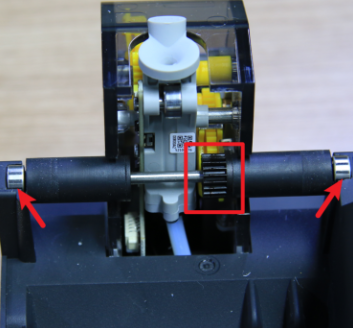

(1) The spool doesn't rotate.

It could be because the active support shaft is not fully inserted into the AMS main frame. As a result, only the yellow gear of the feeder rotates, while the black active support shaft remains stationary. This prevents the spool from rotating properly and can lead to unloading failures, which are usually accompanied by a humming sound from the gears of the first-stage feeder. Please see the image below to fully insert the active support shaft into the AMS main frame.

(2) The spool rotating speed is slower than the unloading speed of the internal hub unit motor.

During the unloading process, if the spool can rotate, but the speed is slower than the unloading speed of the internal hub unit motor, please check whether this issue only happens in a slot by swapping the first-stage feeders of different slots. If this only happens to a slot, it means that the first-stage feeder of this slot is malfunctioning. If this happens to multiple slots, please record a video and contact our customer support team.

¶ Step 2. Investigate the extruder or nozzle blocked issues.

Check which part is clogging by referring to this Wiki.

How to troubleshoot Extruder clog

How to troubleshoot Nozzle clog

If the issue persists after troubleshooting, please submit a customer support ticket.

¶ Equivalent Codes

The following HMS codes represent the same type of fault. 07[XX]-7000-0002-0006, XX means the No. of AMS which triggered this warning.

0700-7000-0002-0006,

0701-7000-0002-0006,

0702-7000-0002-0006,

0703-7000-0002-0006

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.