¶ A1 Maintenance Guidelines

Regular maintenance can minimize wear and extend the printer's lifespan while also lowering the risk of a print failure. To help ease your purchasing decision, we have listed all the commonly needed maintenance parts and offered tiered discounts. You can find the purchase link on Spare Parts Page.

¶ Tools you may need

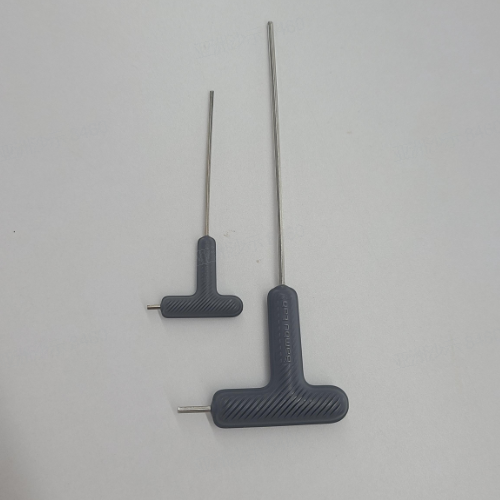

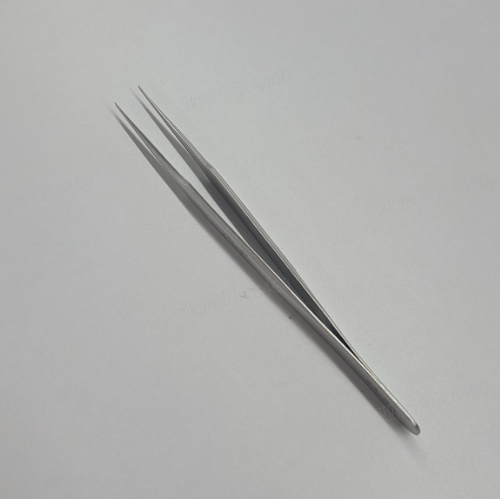

| Tools | Pic. | Tools | Pic. |

| Clean cloth |  |

Alcohol | NA |

| Lubricant Oil |  |

Lubricant Grease |  |

| Hex keys |  |

Tweezers |  |

| Heat resistant gloves |  |

Air blower |  |

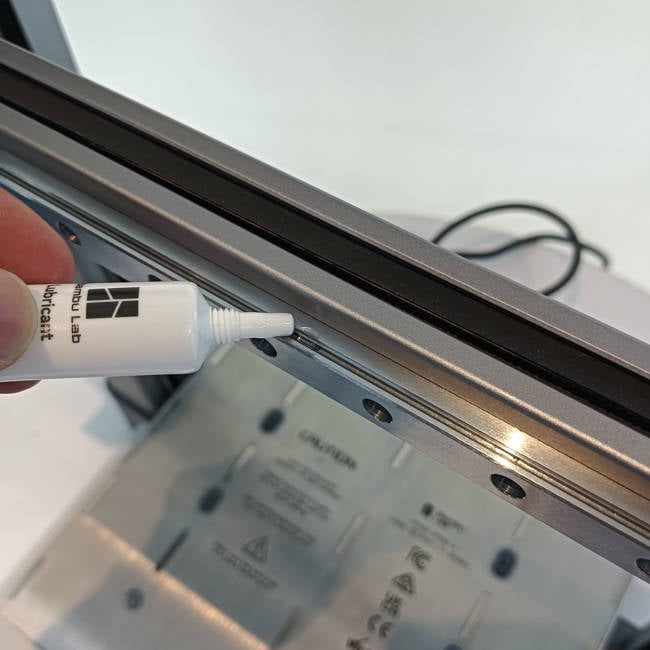

Considering user feedback regarding the stickiness of the lubricant grease and its potential to attract dust and debris, we have conducted extensive verification tests and decided to switch the lubricant for the Y-axis guide rail of the A1 model. Therefore, for the Y-axis guide rail of the A1 model, we recommend using lubricant oil for lubrication. We suggest switching to lubricant oil for future maintenance if you have previously used lubricant grease. During the lubrication process, you can also wipe off the lubricant grease on the guide rail and then follow the guide to applying the lubricant oil.

Friendly reminder:

The accessory box provides two types of lubricants, one is lubricant oil, and the other is lubricant grease. The packaging may vary depending on the batch, so please refer to the actual packaging you received. Here is an introduction to their respective applications:

|

|

Purposes of Lubricant Oil: Used for X-axis linear rail, Y-axis guide rail, and eliminating noise from idler wheels.

Purposes of Lubricant Grease: Used for lubricating lead screws and extruder wheels.

Please note that it is strictly prohibited to use lubricating grease on the X-axis linear rail.

¶ Moving parts

Refers to the components that undergo mechanical movement during the printing process, including screw rods, guide rails, sliders, couplings, belts, fans, etc. The main maintenance measures are cleaning and lubrication. Metal parts need to be rust-proofed. Rubber parts need to be checked for aging (including deformation), wear, etc., and replaced when necessary.

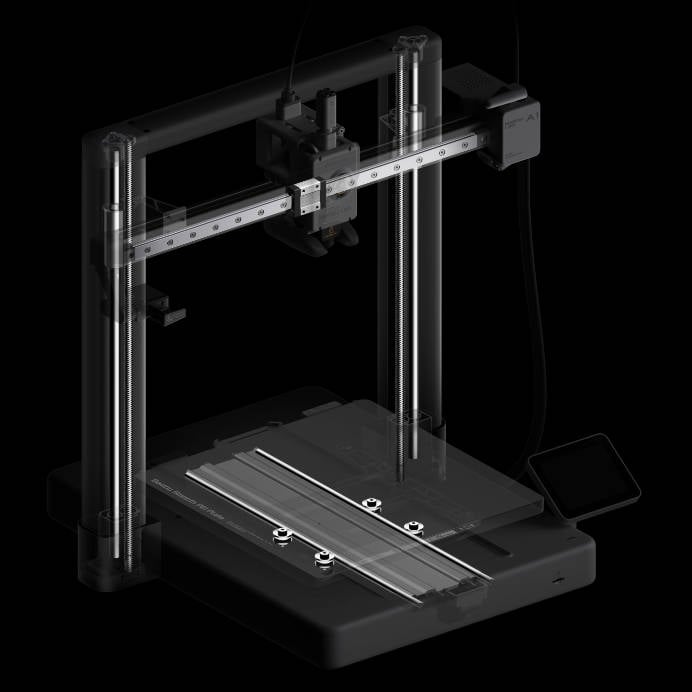

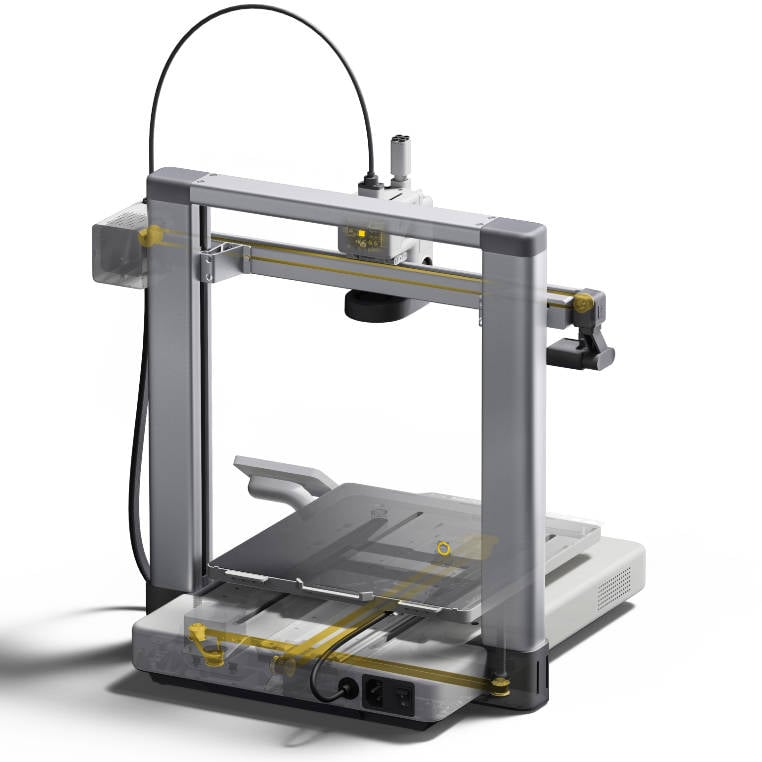

¶ Guide rail system

We spent extra to bring you the most reliable All-metal rails and cover-protected drive system. This rail system ensures that you do not need to frequently adjust the moving components of the A1, but requires regular lubrication and cleaning to reduce wear and noise, ensure the accuracy and lifespan of the printer, and effectively prevent the guide rails from rusting.

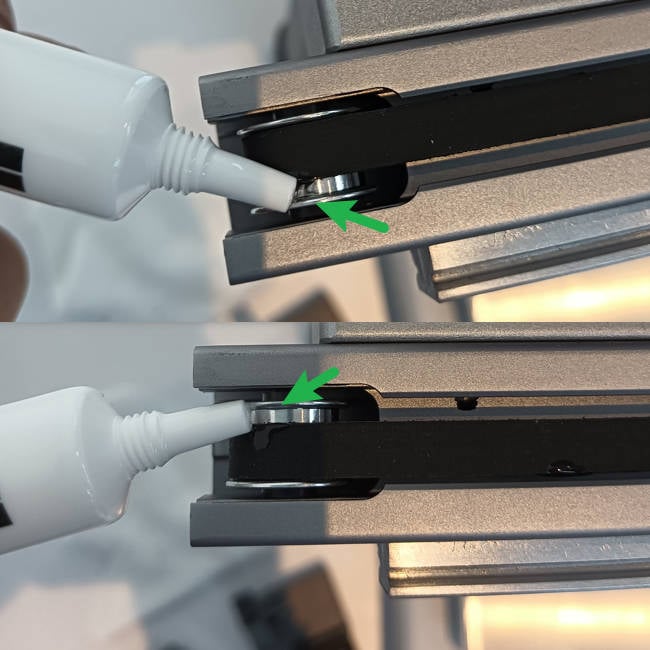

| X rail | When: Every month Materials & tools: Cloth,Tweezers, Lubricant oil Solution: Cleaning, Lubricant oil How to do: Use tweezers to clean the lumpy and filamentous foreign objects on the guide rail, and wipe the granular foreign objects and stains with a dust-free cloth; re-lubricate the X track, and slide the tool head back and forth after lubricating to ensure that the lubricant oil lubricates the entire linear rail. |

| Y rail | When: Every month Materials & tools: Cloth, Lubricant oil Solution: Cleaning, Lubricant oil Use tweezers to clean the lumpy and filamentous foreign objects on the guide rail, and wipe the granular foreign objects and stains with a dust-free cloth; re-lubricate the Y rails on both sides and slide the heatbed back and forth after lubricating to ensure that the lubricant oil lubricates the entire Y rail. Guide on how to lubricate the A1 Y-axis guide rail |

Video guide for lubricating the X-axis:

https://public-cdn.bblmw.com/wiki/A1-mini/x_guide_rail_lubrication.mp4

|

|

|

For detailed operating instructions on lubricating the Y-axis guide rail, please refer to the wiki below:

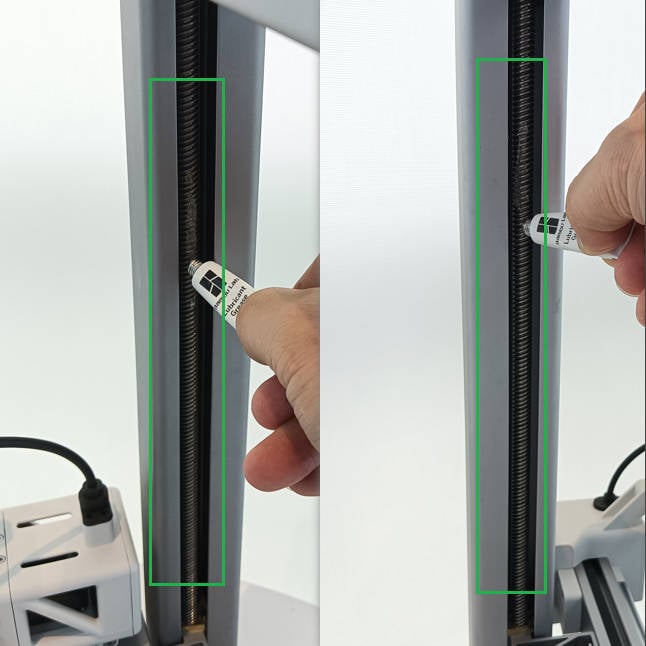

¶ Lead screw

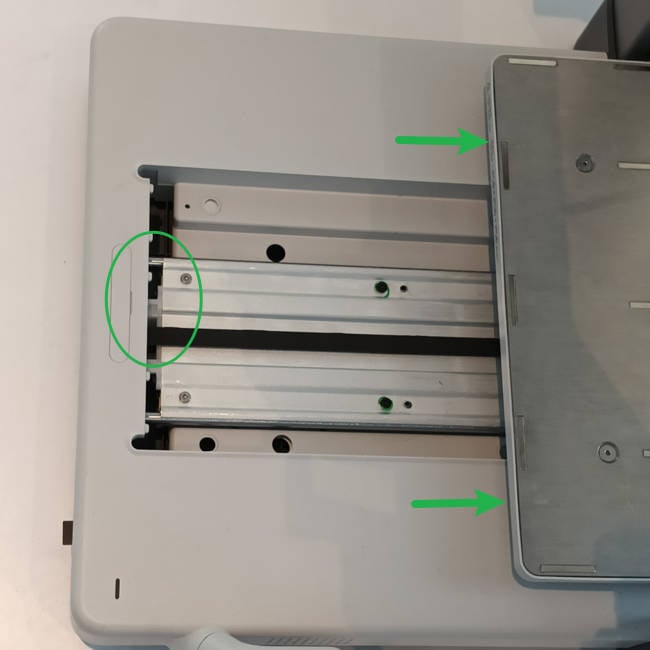

A1 uses a dual lead screw structure. Through the lead screw, the Z-axis motor can drive the X-axis to move up and down along the Z-axis direction. Proper lubrication will ensure the smooth operation of the X-axis along the Z direction, and can effectively reduce the noise caused by the movement of the screw.

| Lead screw | When: Every 3 months Materials & tools: Lubricant grease Solution: Lubricate How to do: Move the tool head to the position of the purge wiper, apply lubricant grease to the working area of the two lead screws, and manually raise and lower the X-axis to ensure that the entire screw rod working area is coated with lubricant grease. |

|

|

|

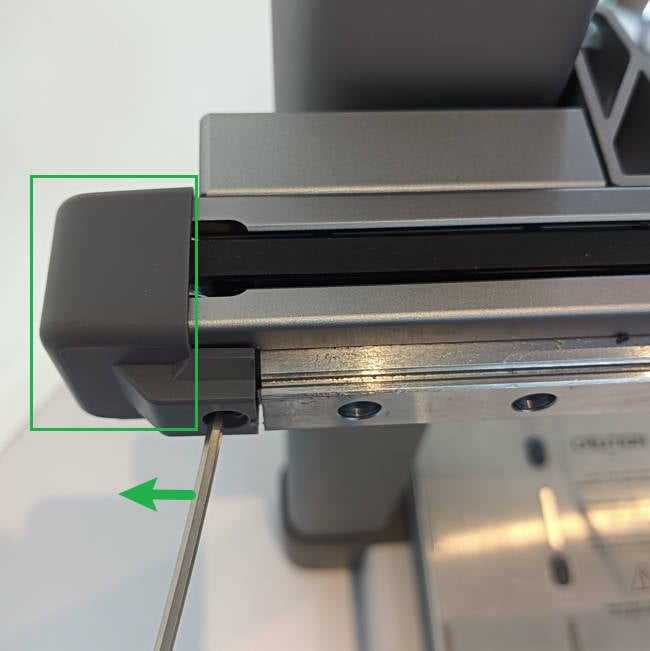

¶ X Y Z Belts

A1 can check the belt tension automatically through the vibration frequency calibration. If the belt is loose, the HMS system will notify you to use the auto belt tensioner to set the belt to the right tension.

| X Belt | When: HMS prompts Materials & tools: H2 Hex key Solution: Re-tension How to do: Loosen the tensioning screw behind the tool head, move the toolhead along the X rail 2 to 3 times, and then re-tighten the tightening screw. |

| Y Belt | When: HMS prompts Materials & tools: H2 Hex key Solution: Re-tension How to do: Remove the Y-axis tensioning cover, loosen 2 tensioning screws, slowly move the heatbed back and forth 2 to 3 times, then re-tighten the tightening screws and place back the cover. |

| Z Belt | When: HMS prompts Materials & tools: H2 Hex key Solution: Re-tension How to do: Loosen the 2 tensioning screws, operate the printer, raise and lower the X-axis 2 times, and re-tighten the tensioning screws. |

Please refer to the link for details: A1 Belt Tensioning

Note: Do not loosen or remove the Y tensioning screw completely or you will need to reassemble the Y tensioner.

If after long-term use, the timing belt has shown obvious wear and affects the print quality, please refer to the relevant maintenance guide page to replace the belts.

¶ Idler pulley

This mainly refers to the idler pulley of the X-axis and Y-axis. Regular maintenance of the idler pulley can effectively prevent abnormal noise and abnormal resistance.

| X Idler pulley | When: Every 3 months Materials & tools: Lubricant oil, hex key Solution: Lubricate How to do: Unscrew 2 screws and remove the purge wiper; Unscrew 1 screw, use a wrench to loosen the left cover, and remove it; Move the tool head, and when the timing belt deviates from the idler rib, apply a drop of lubricant oil, if there is abnormal noise from the idler gear and the rotating shaft, you can also add lubricant oil at this time. |

| Y Idler pulley | When: Every 3 months Materials & tools: Lubricant oil, hex key Solution: Lubricate How to do: Remove the Y-axis upper cover and apply an appropriate amount of lubricant oil between the belt and the idler pulley. |

|

|

|

|

|

|

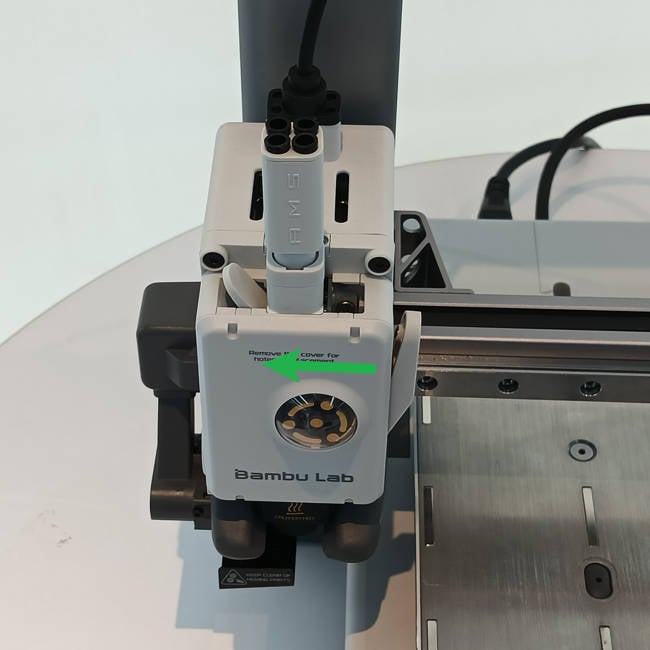

¶ Extruder

After using the printer for a long time, filament debris and dust may remain inside the extruder, which can easily cause the extrusion gear to become stuck or even unable to rotate during operation. In order to ensure the normal printing of the printer, the extruder needs to be cleaned of foreign materials in time.

| Extruder unit | When: Under-extrusion,Extruder clog Materials & tools: Tweezers, Hex key,Air blower Solution: Cleaning How to do: Remove the filament pressure block, loosen the filament cutter lever, use tweezers to clean the internal filamentous foreign materials, use a blower to blow off the residue and dust, if necessary, take out the filament hub assembly and clean it. |

Video guide for cleaning the extruder:

https://public-cdn.bblmw.com/wiki/A1-mini/extruder_clean.mp4

|

|

|

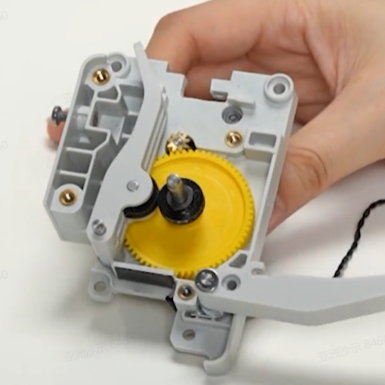

¶ Extruder Gear Assembly

When cleaning the extruder according to the above steps fails to achieve satisfactory results, you can disassemble the extruder and remove the extrusion wheel assembly for cleaning. Under normal circumstances, for printing non-carbon fiber filaments like PLA and PETG, it is advisable to clean the extruder gear every 5 spools. When printing with carbon fiber filaments, clean the extruder gear every 2 spools. If you find that the extruder gear is obviously worn, and cleaning the nozzle does not improve the extrusion, you can replace the gear assembly.

| Extruder Gear Assembly | When: Under-extrusion,Extruder clog Materials & tools: Tweezers, Hex key, Air blower Solution: Cleaning How to do: When cleaning the extruder, if you find foreign materials that cannot be removed, you need to remove the extrusion front cover and take out the extrusion wheel assembly for cleaning. For specific disassembly and assembly methods, please refer to the page for details. A1 series extruder cleaning tutorial |

Extruder module installation installation tutorial

¶ Filament Sensor

There are several Hall sensors on the filament sensor board. The attachment of foreign matter such as material fragments and dust will cause abnormal Hall values and cause false alarms. Cleaning the filament sensor board in time can effectively solve the problem of false alarms and improve the printing experience.

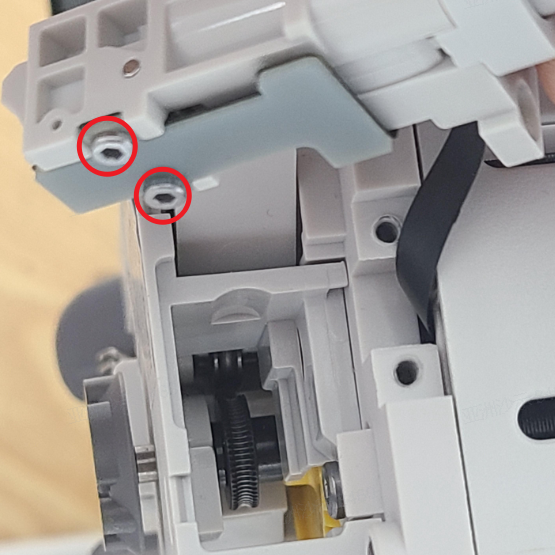

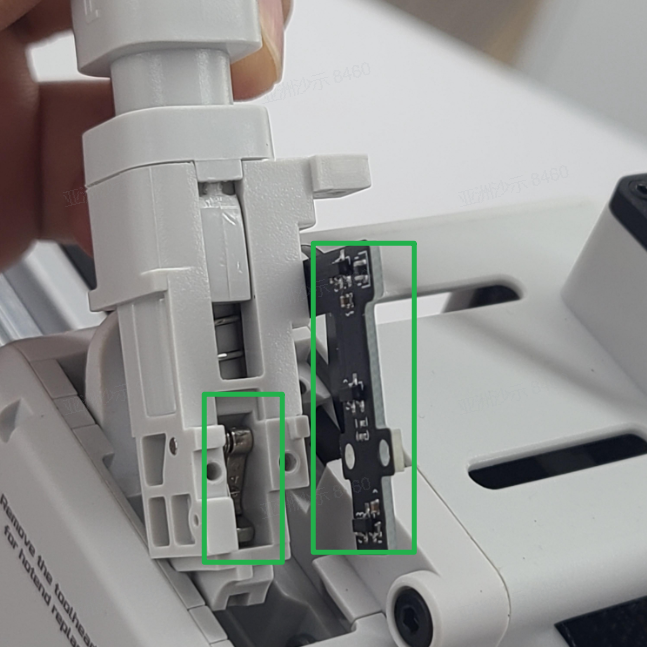

| Filament sensor | When: False alarm Materials & tools: Hex key, Air blower Solution: Cleaning How to do: Unscrew the 2 screws, carefully pull out the entire bottom bracket assembly, remove the 2 screws that lock the filament sensor, and clean with a blower. |

Video guide for cleaning the filament sensor board:

https://public-cdn.bblmw.com/wiki/A1-mini/filament_sensor_maintenance.mp4

|

|

|

Note: When disassembling, do not pull out the connecting cable too much to avoid damage and abnormal installation.

¶ Purge Wiper

The A1's purge wiper is used to efficiently process the waste material ejected from the nozzle to ensure a continuous and smooth printing process. When the movement of the purge wiper is blocked by foreign objects or the action mechanism is deformed, the purge wiper may become stuck, causing abnormal discharging or causing the printer to lose steps. Therefore, it is necessary to promptly clean up foreign objects and replace the deformed purge wiper to improve the success rate of filament exchange and enhance the printing experience.

| Purge Wiper | When: FExcess accumulation or purge wiper deformation Materials & tools: Tweezers, Hex key,Air blower Solution: Cleaning, Replacement How to do: Remove the tool head from the purge wiper , use tweezers to remove excess waste, and use a blower to blow off residue and dust. |

|

|

¶ Fans

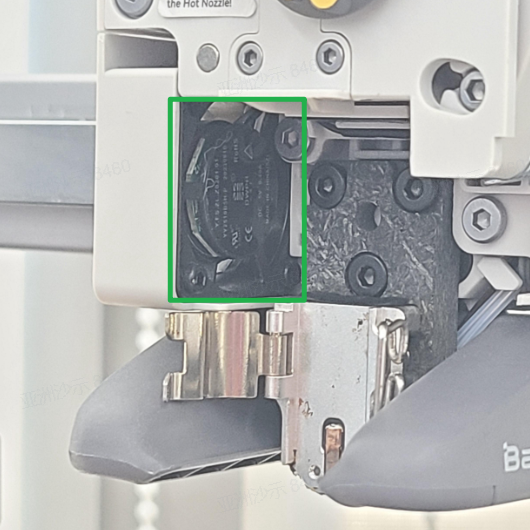

A1 is equipped with 2 fans, namely hotend cooling fan, part cooling fan. In order to ensure that the machine has a good cooling effect, it is necessary to check the status of the fan regularly and remove foreign objects in a timely manner.

Part cooling fan |

Hotend cooling fan |

| Part cooling fan | When: Every week Materials & tools: Cloth, Tweezers Solution: Cleaning How to do: Check whether there is foreign objects or dust accumulation in the air duct and clean it |

| Hotend cooling fan | When: Every week Materials & tools: Cloth, Tweezers Solution: Cleaning How to do: You can loosen the four screws at the bottom, open the lower housing, and check the air ducts for any foreign objects or dust buildup, then proceed with cleaning. |

|

|

|

|

¶ Regular Maintenance Parts

Refers to product parts or components that need to be replaced due to wear or consumption during normal operation of the product, such as PTFE tubes, hot ends, etc.

Such vulnerable parts need to be proactively cleaned and inspected to detect abnormalities and replace them promptly to avoid affecting normal printing.

¶ Silicone Sock for Hotend

The silicone sock for hotend helps maintain the stability of the hotend temperature. If there are signs of damage on the silicone sock, or the silicone sock cannot be fixed well on the hotend, the silicone sock should be replaced to avoid some print quality caused by temperature differences.

| Silicone Sock for Hotend | When: Damaged or unable to be installed Materials & tools: Silicone Sock for Hotend Solution: Replacement How to do: When the hotend temperature is below 60 degrees, refer to the hotend replacement guide attached to the extruder for replacement. |

Note: Please be sure to install the silicone sock for hotend , or it will cause some hotend temperature warning.

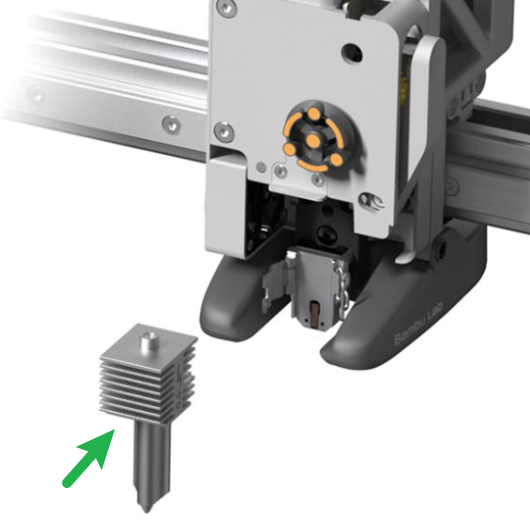

¶ Hotend

The A1 hot end adopts a quick-release buckle design. In order to ensure the normal function of the hot end quick-release, and to promptly remove the residue on the surface of the hot end and the heating assembly to ensure the accuracy of the hotend temperature measurement, it needs to be removed regularly. and clean the surface of the heating element. Under normal circumstances, for printing non-carbon fiber filaments like PLA and PETG, it is advisable to clean the nozzle every 5 spools. When printing with carbon fiber filaments, clean the nozzle every 2 spools. If you find that the nozzle is obviously worn causing material leakage, and cleaning the nozzle does not improve the extrusion, please replace it with a new spare hot end.

| Hotend Heating Assembly | When: Every month Materials & tools: Glooves,Cloth,Tweezers Solution: Cleaning How to do: After removing the silicone sock for hotend, clean the attachments on the hot end, then remove the hot end, use tweezers to roll up a lint-free cloth dipped in absolute alcohol, and wipe the surface of the heating assembly clean. |

| When: Broken structure or cable, or heating failure due to print failure or disassembling parts Materials & tools: New hotend heating assembly Solution: Replacement How to do: Refer to Hotend Heating Assembly Replacement Guide. |

|

| Hotend | When: Wear and leakage Materials & tools: Hotend Solution: Replacement How to do: Refer to the hot end replacement instructions attached to the extruder for replacement. |

Note:

1. If there is residual material attached to the hotend and the hotend cannot be removed normally, you need to set the temperature to 80 degrees to soften the residue before removing it;

2. Please be sure to install the silicone sock for hotend after the cleaning, or it will cause some hotend temperature warning.

Hotend Replacement Video Guide:

/n1/p-maintenance/nozzle_replacement_english.mp4

|

|

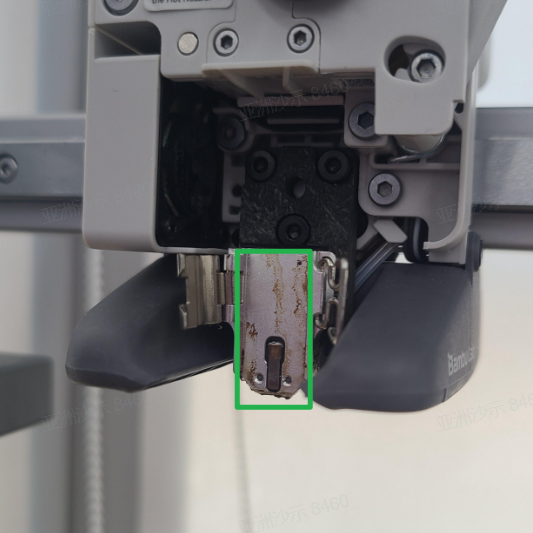

¶ Filament Cutter

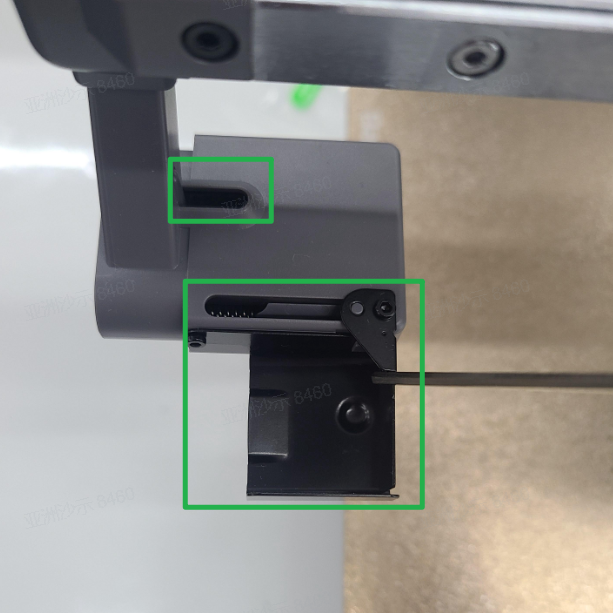

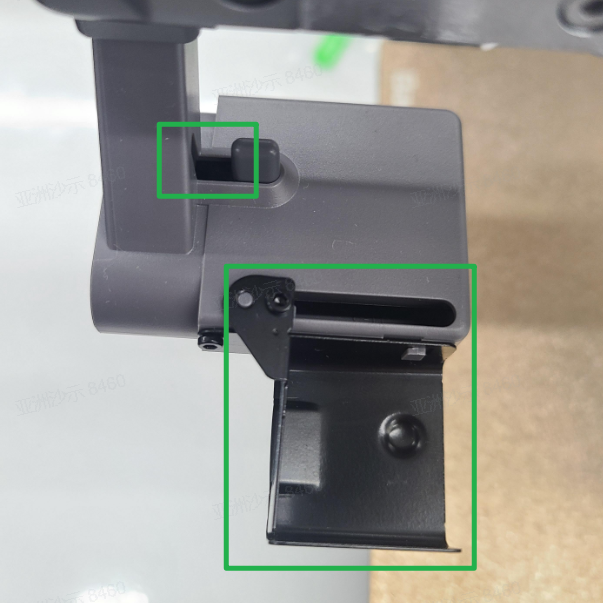

Like the X-series printers, the A1 mini is also equipped with a filament cutter to achieve automatic filament changing. If you use multi-color printing, the filament cutter blade will become dull or even chipped after printing multiple rolls of filaments. Therefore, it is recommended to check regularly to ensure that the blade is still sharp and intact to avoid losing steps due to high cutting resistance and improve printing success rate. If you find that the filament cutter is worn out and unable to cut the filaments smoothly, please replace it with a new filament cutter.

| Filament cutter | When: Check the blade once every 3 rolls of PLA\ABS\PETG Materials & tools: Hex key Solution: Replacement How to do: Disassemble the filament pressing block and check whether the blade is missing. If there is any abnormality, release the filament cutter handle and replace it with a new filament cutter. |

Video guide for filament cutter maintenance and replacement:

https://public-cdn.bblmw.com/wiki/A1-mini/filament_cutter_replace.mp4

|

|

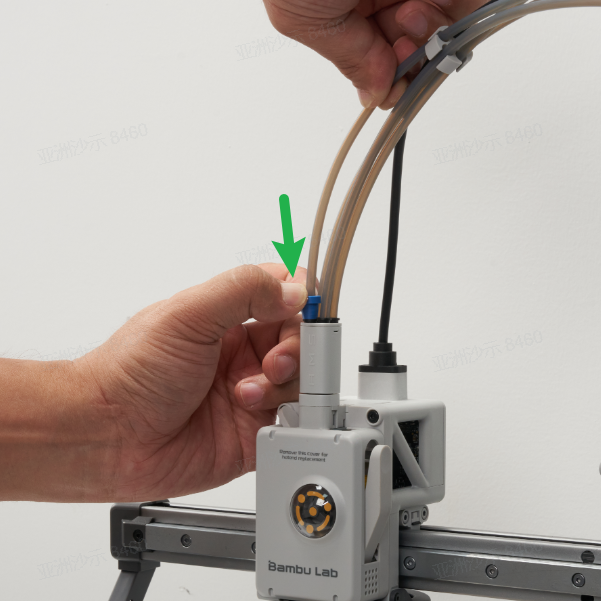

¶ PTFE Tube

We send the filament from the AMS lite (or Spool Holder) to the filament hub through a PTFE tube. After long-term friction with the filaments, the PTFE tube will wear to varying degrees and increase the filament supply resistance. In order to avoid abnormal filament transportation caused by wear of the PTFE tube, the PTFE tube should be replaced when there are obvious signs of wear.

| PTFE Tube | When: PLA and other non-carbon fiber materials, every 6 rolls; carbon fiber materials or ploywood and other high friction materials, every 2 rolls Materials & tools: With hands or with the help of auxiliary tools Solution: Replacement How to do: Press the filament hub's connector and pull the material tube upward; if it is difficult to press it with bare hands, you can use tools such as printed models or tweezers. ptfe_tool.3mf |

|

|

Note: The specifications of the PTFE tube used by A1 mini are 4mm outer diameter and 2.5mm inner diameter.

¶ Nozzle Wiper

A1 is equipped with only one nozzle wiper. The nozzle wiper is used to clean the residual filament on the nozzle. If you find that the nozzle wiper is damaged or deformed, it can result in incomplete cleaning of residual material on the nozzle, thereby affecting print quality. You need to replace it to ensure the nozzle cleaning effect. We provide spare silicone wiper, you can replace them yourself.

| Heatbed Nozzle Wiper | When: The nozzle wiper is damaged Materials & tools: Tweezers Solution: Replacement How to do: Use tweezers to pry up and remove the old nozzle wiper, then tear off the protective tape on the new nozzle wiper, align it with the installation groove, and attach it. |

|

|

|

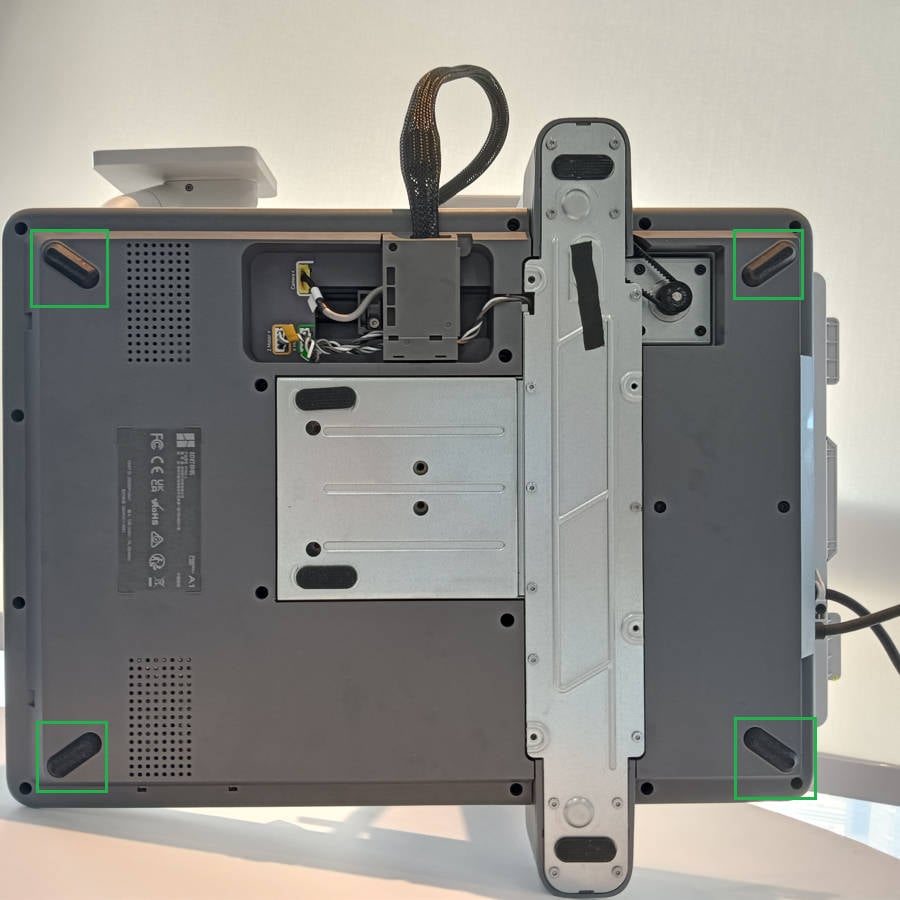

¶ Supportive Footpad

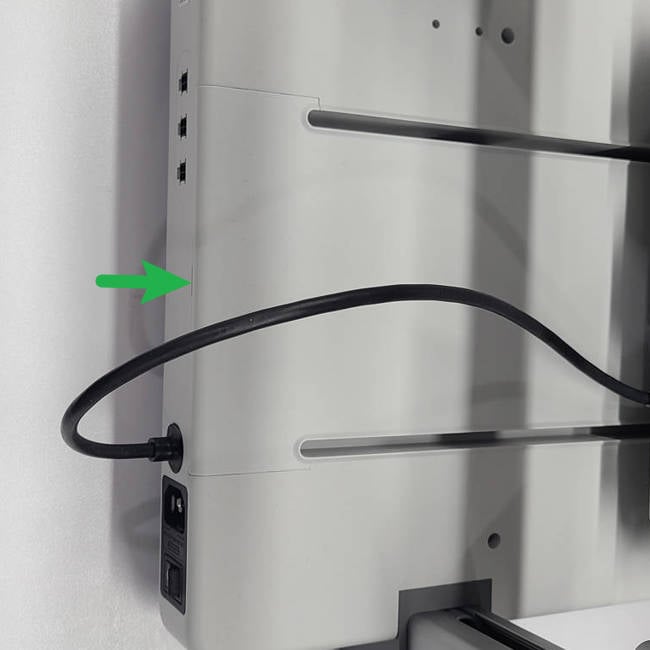

To reduce the impact of printer shaking on print quality, the A1 printer is equipped with 4 Supportive Footpads at the bottom. They are attached to the bottom cover through double-sided tape and may cause damage due to friction and extrusion during transportation. If it falls off, you need to reattach the fallen soft foot pad again. If the Supportive Footpad has been lost, please use a spare footpad or purchase it through the official store.

It should be noted that due to differences in production batches, the Supportive Footpad on your printer may be different from other people's footpads.

|

|

| Supportive Footpad | When: Footpads fall off Materials & tools: Supportive Footpad, instant glue Solution: Re-glue How to do: Drop instant glue on the hot edge of the detached soft foot, and then reattach it to the installation position. |

| Supportive Footpad | When: Footpads missing Materials & tools: Supportive Footpad,tweezers, alcohol, cleaning cloth Solution: Replacement How to do: Use tweezers to clean off the remaining glue, use a cleaning cloth dipped in alcohol to clean it more cleanly, and then stick the new pads to the installation location. |

|

|

|

|

|

¶ PEI Build Plate

A1 mini along with a textured PEI plate, which is made of PEI material sprayed on a stainless steel plate. It can be used to print various materials such as PLA/PETG without using any adhesive. In order to maintain optimal adhesion, it is recommended to clean the printing plate regularly. and please avoid direct contact of fingers with the surface of the printing plate to prevent skin oils from adhering to the surface of the printing plate and affecting the adhesion effect. Please refer to the following link for how to clean the PEI printing plate: