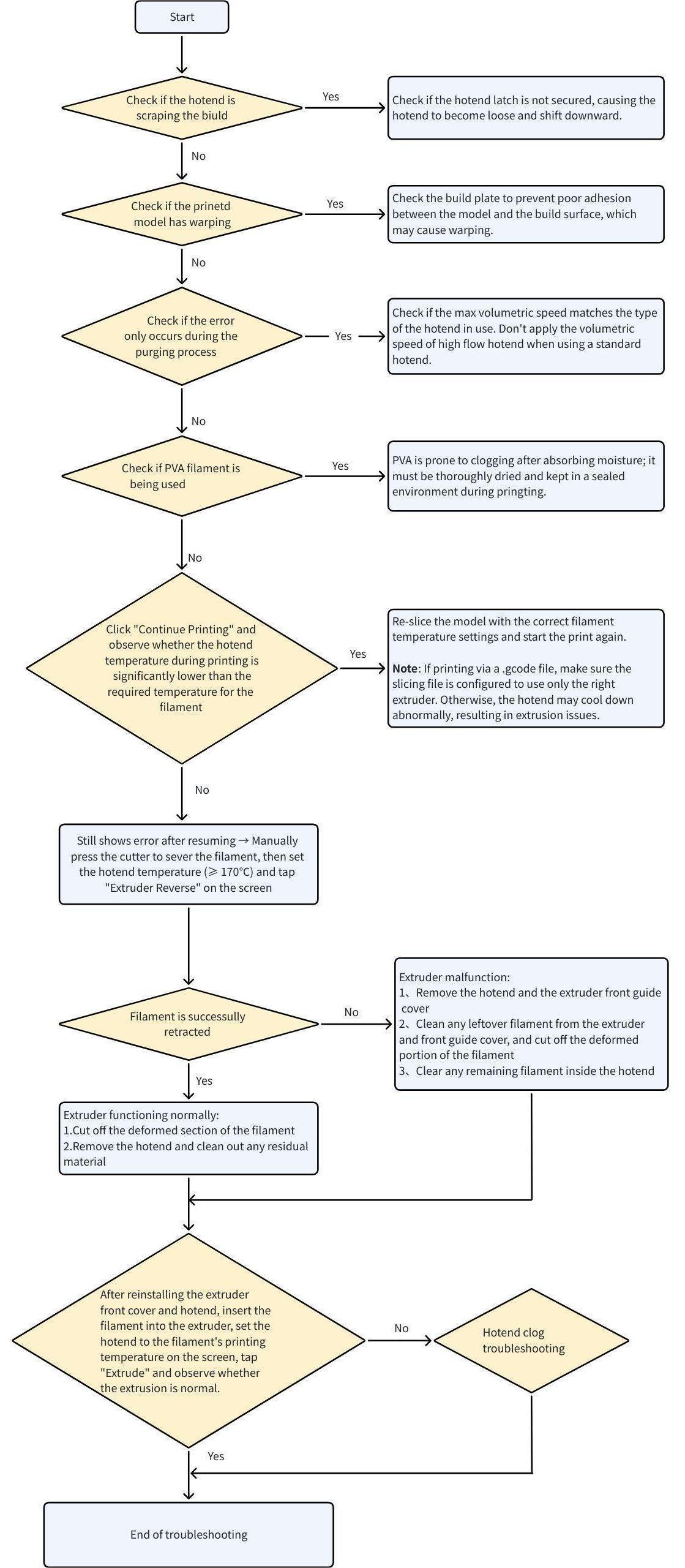

¶ Fault Description

During printing, the toolhead extruder motor continuously monitors extrusion force. If abnormal extrusion force is detected, an error will be triggered and the print job will pause. The user must resolve the issue before printing can continue.

Possible causes:

- Filament is jammed inside the toolhead

- Hotend clogging

Safety Notice: Before disassembling the toolhead, always power off the printer to avoid electric shock.

¶ Troubleshooting

¶ Tools, Equipment, and Materials

- H2.0 hex screwdriver

- H1.5 hex screwdriver

- Flush cutters / scissors

- Needle-nose pliers

¶ Potential Causes

There are multiple possible reasons for this fault:

-

The hotend retaining clip is not properly installed, causing the hotend to loosen. This may result in the nozzle scraping the build plate during the first layer,which makes extrusion difficult.

-

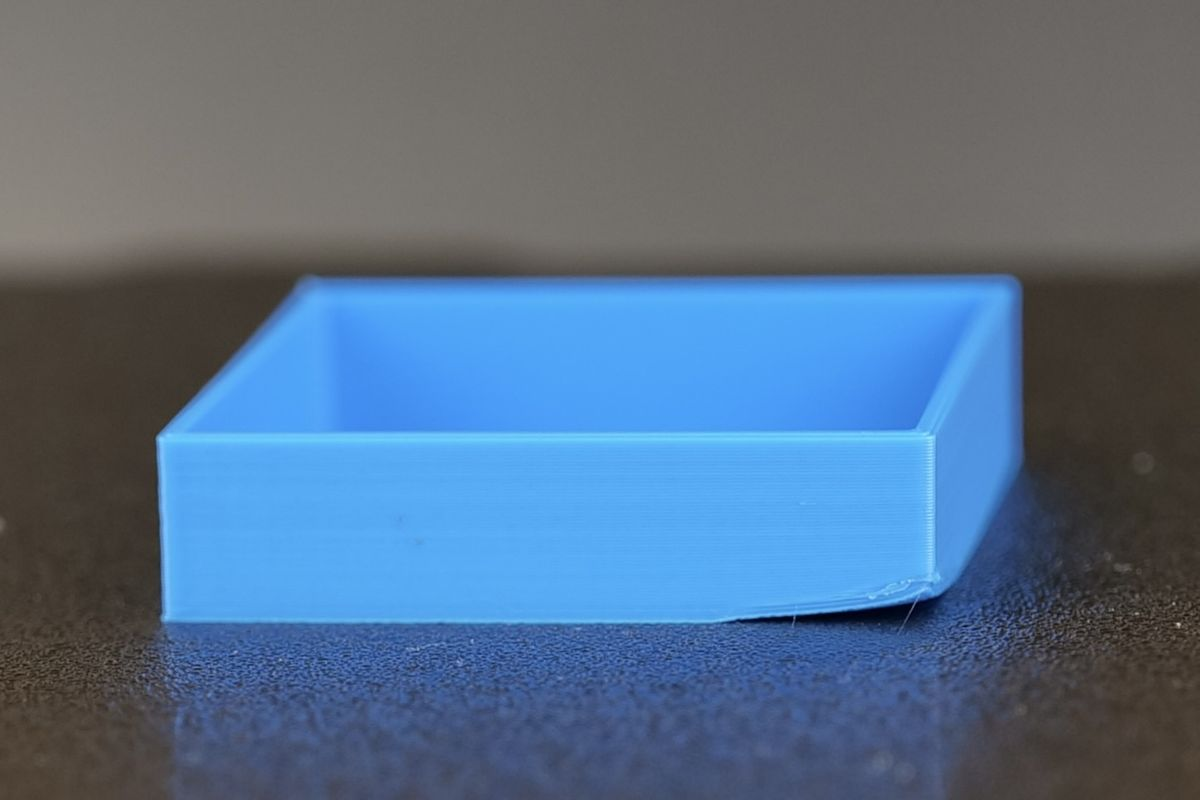

Warping of the printed model leads to the nozzle scraping the model surface, creating extrusion resistance.

-

Printing with undried PVA filament may cause severe hotend clogging, resulting in extrusion failure.

-

The hotend temperature is abnormal and far below the filament’s required printing temperature. For example, PLA-Basic requires ~220 °C. If the hotend is mistakenly set to 60 °C, extrusion will fail.

-

The hotend is partially or fully clogged, requiring cold pull or clog removal.

-

Deformed or non-standard filament with inconsistent diameters may get stuck in the extruder, causing the motor to skip (audible clicking). In such cases, the jammed filament must be removed and, if necessary, the extruder disassembled for cleaning.

¶ Troubleshooting Steps

Users may adjust the order of steps depending on their situation.

We recommend checking in the following sequence:

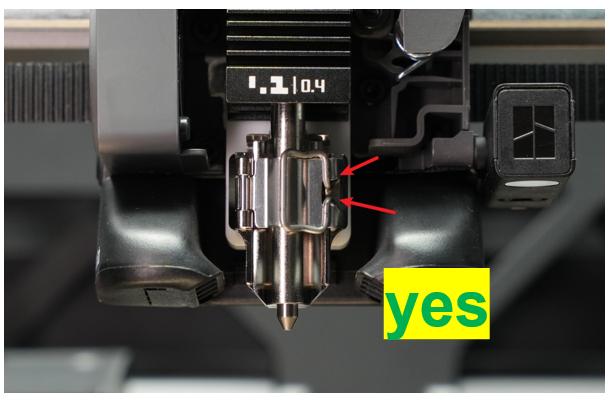

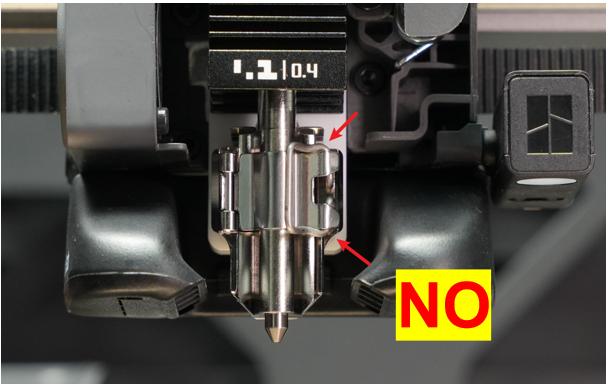

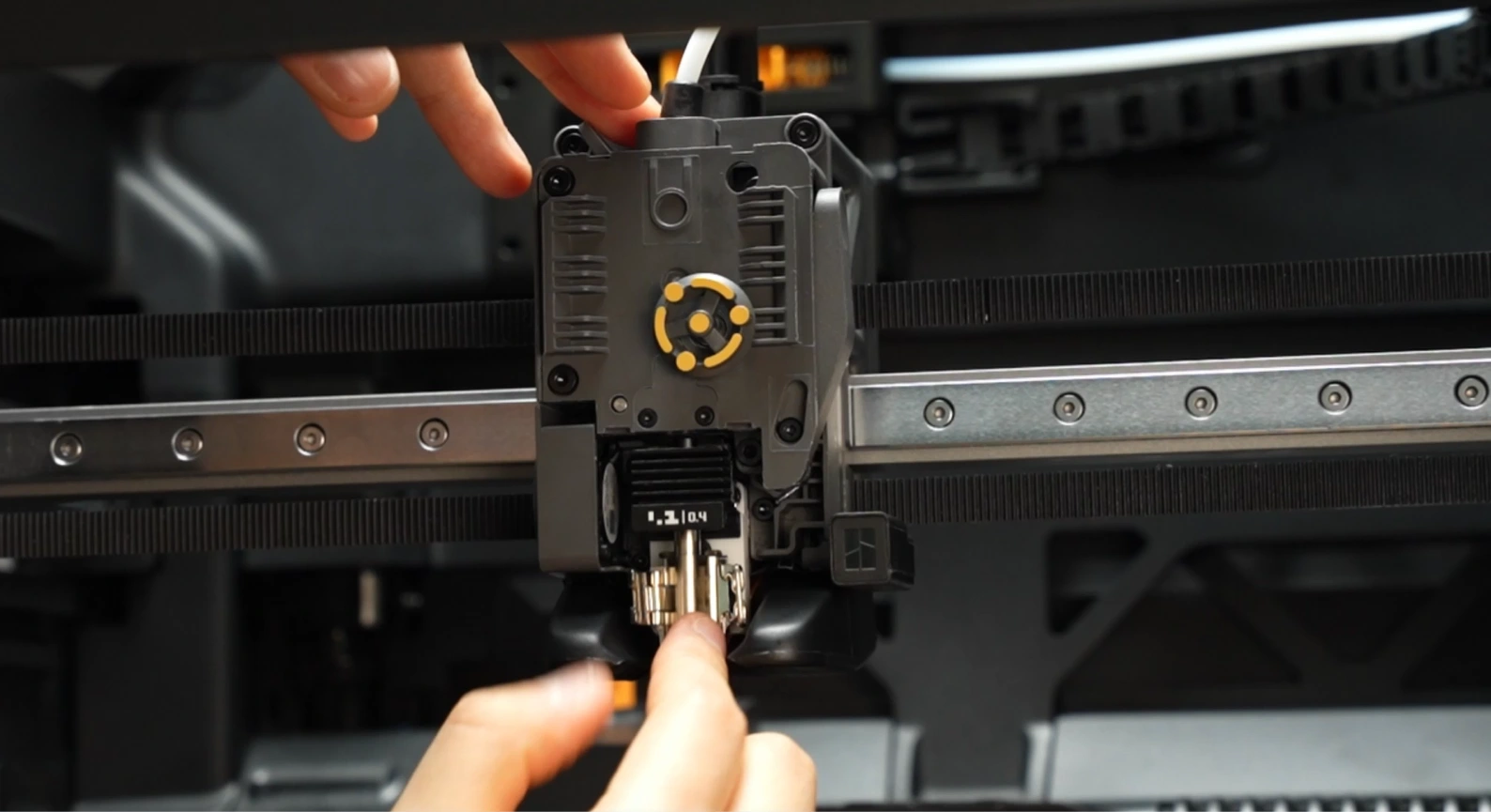

¶ Step 1. Verify the distance between nozzle and hotbed during printing the first layer

When the error occurs, please check whether the hotend is too close to the hotbed, resulting in nozzle scraping.

- In this case, it is strongly recommended to cancel the print job and allow the hotend to cool to room temperature (important to avoid burns).

- Inspect whether the hotend clip is properly secured. Remove the silicone sock and verify that the clip is locked correctly.

|

|

If the hotend is installed incorrectly, please re-install it properly.

If no downward shift of the hotend is observed, run an automatic bed leveling procedure and retry. If scraping persists in certain areas, perform a manual bed leveling adjustment. (See guide: H2S Manual Bed Leveling).

¶ Step 2: Check for model warping

Warping may cause the nozzle to scrape against the model surface, leading to extrusion problems. Refer to this wiki guide to resolve warping issues Printed Model Warping: Causes and Solutions.

¶ Step 3: Check if the Error Only Occurs During the Purging Process

Check whether the max volumetric speed matches the type of the hotend in use.

For example, the preset max volumetric speed for PLA Basic is 25 mm³/s with a standard hotend, while it is 35 mm³/s with a high flow hotend. Using a standard hotend with parameters intended for a high flow hotend may result in extruder motor overload error.

.jpg) |

.jpg) |

¶ Step 4: Check if PVA filament is being used

PVA must be thoroughly dried before printing. Even brand-new PVA can absorb moisture. There are some suggestions if you want to use PVA:

- A convection oven set at 85 ℃, baking for 12 hours.

- Avoid printing PVA with a 0.2 mm nozzle.

- For more detailed guidance, refer to PVA Printing Guide

¶ Step 5: Confirm hotend temperature settings

Verify that the set hotend temperature matches the filament’s required printing temperature. For example, PLA-Basic requires ~220 °C. Printing at much lower temperatures (e.g., 60 °C) will prevent extrusion.

¶ Step 6: Inspect for hotend or extruder clogging

Follow this guide: How to Check Which Part is Clogged in H2S to identify the clogged part and clear the blockage. Once cleared, retry printing and observe if the problem is resolved.

If the above steps do not resolve your issue, please submit a ticket and upload your printer logs

¶ Conclusion

We hope this guide will provide you with useful information and help you solve problems.

To ensure that you operate safely and effectively, if you have any doubts or questions about any steps in the guide, please contact our Customer Support team before starting the operation.

We are always happy to answer your questions and provide support.

Click here to contact online technical support (service hours 9:00-21:00)