¶ New features

¶ 1. Natively integrate MakerWorld

We have integrated MakerWorld in Bambu Studio to provide a seamless experience for you to share, search, and slice 3D models.

The homepage layout has been redesigned to display more content.

A link button to MakerLab has been added to the homepage so you can click and navigate to the web page.

And now we support displaying and searching models, and importing 3D models directly in Bambu Studio.

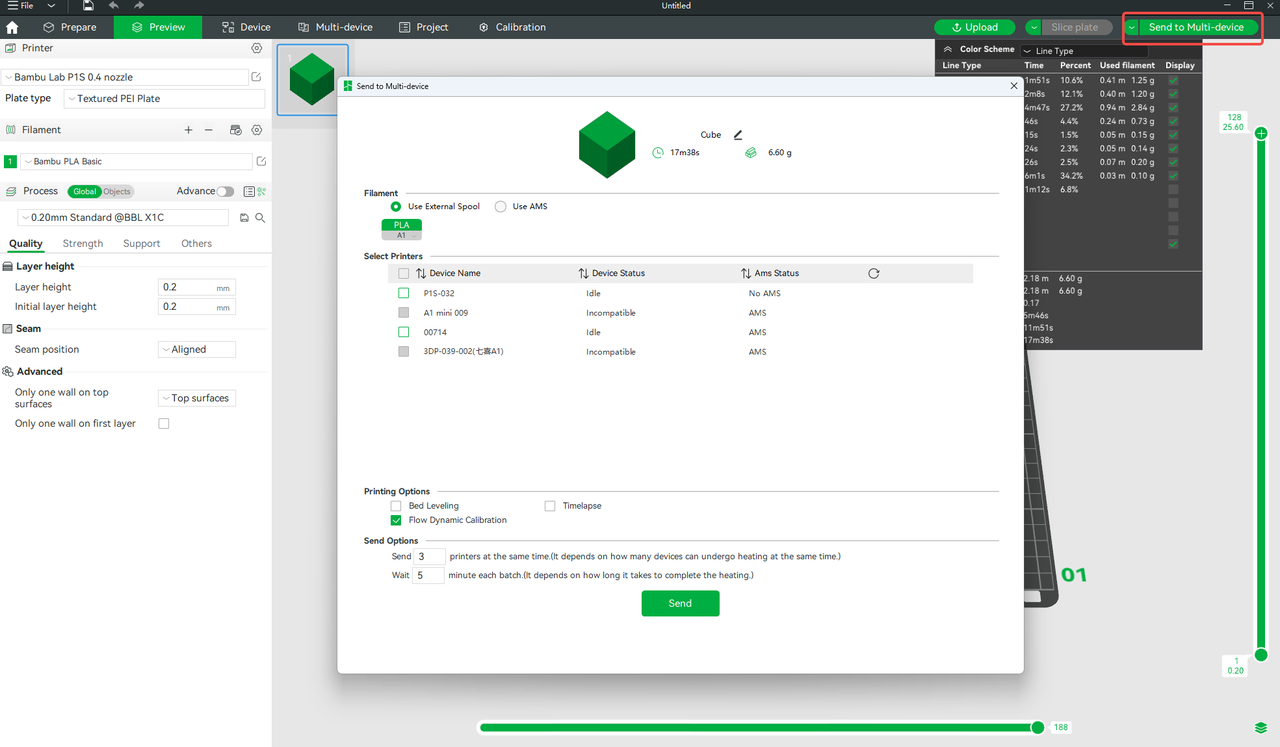

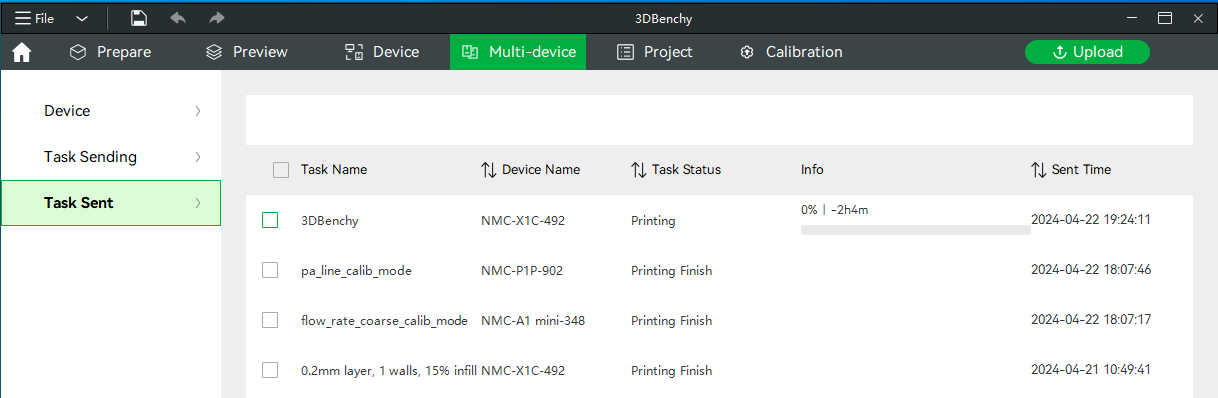

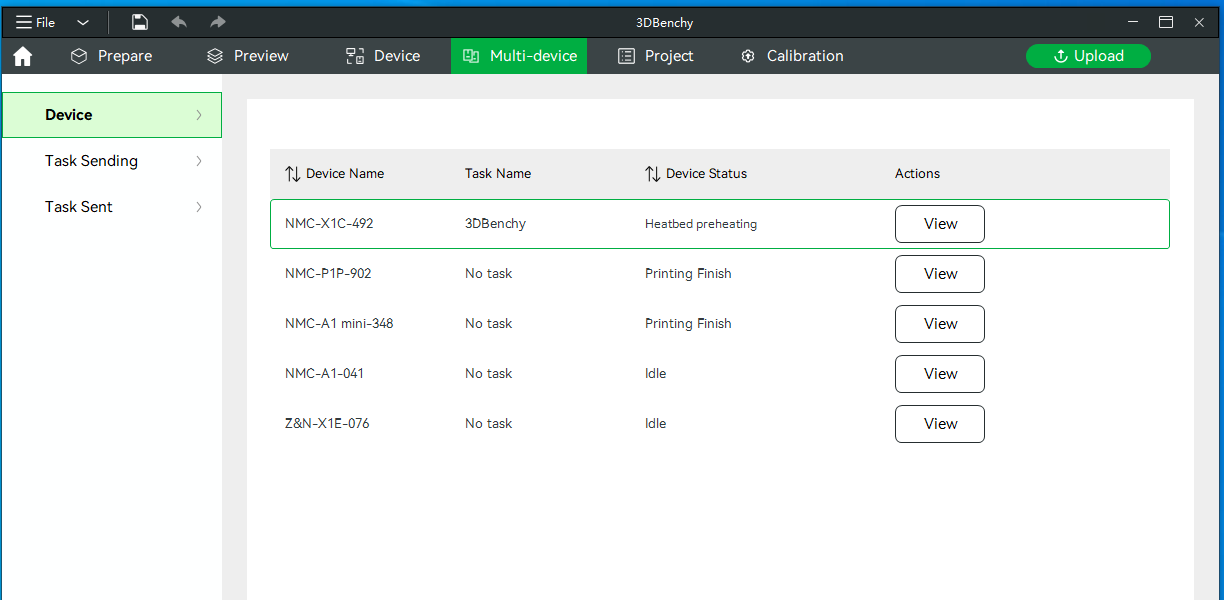

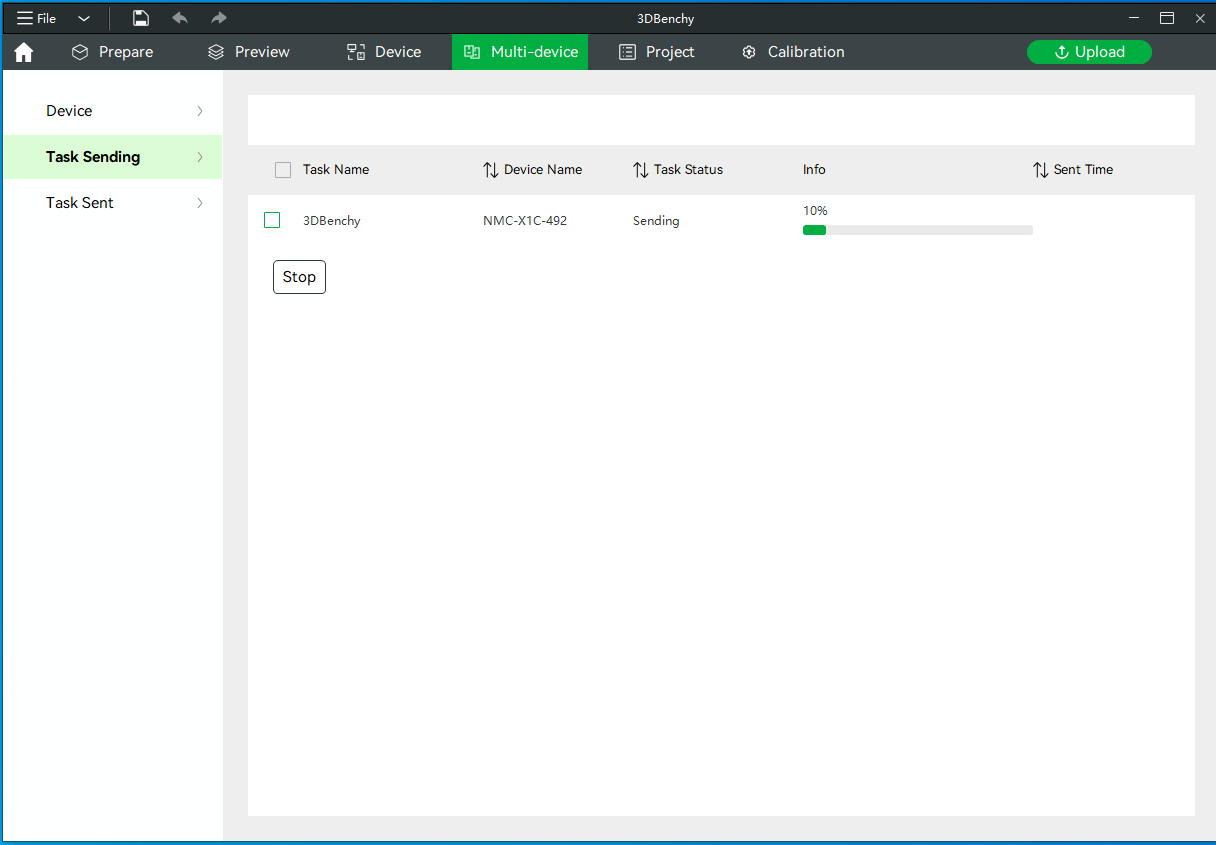

¶ 2. Support Multi-device Management.

We are excited to announce the introduction of a new feature in our latest release: Cloud Printing for Device List. With this feature, you can now send cloud-based print commands to all devices in your device list simultaneously. It provides a convenient and efficient way to manage and control printing tasks across multiple devices.

Key Features:

You have the option to choose either the External spool or AMS (Automatic Management Service). If you select AMS, please note that we currently only support simple mapping.

Customizable Sending Settings: We understand that different users have varying requirements when it comes to sending print commands. Therefore, we have included the ability to customize the maximum sending interval and quantity. You can configure these settings according to your specific needs and workload.

Edit printing parameters in the send window

View task details on the tab page of Multi-Device

For more detailed information about this feature, please click the wiki page. https://wiki.bambulab.com/en/software/bambu-studio/multi-device-management

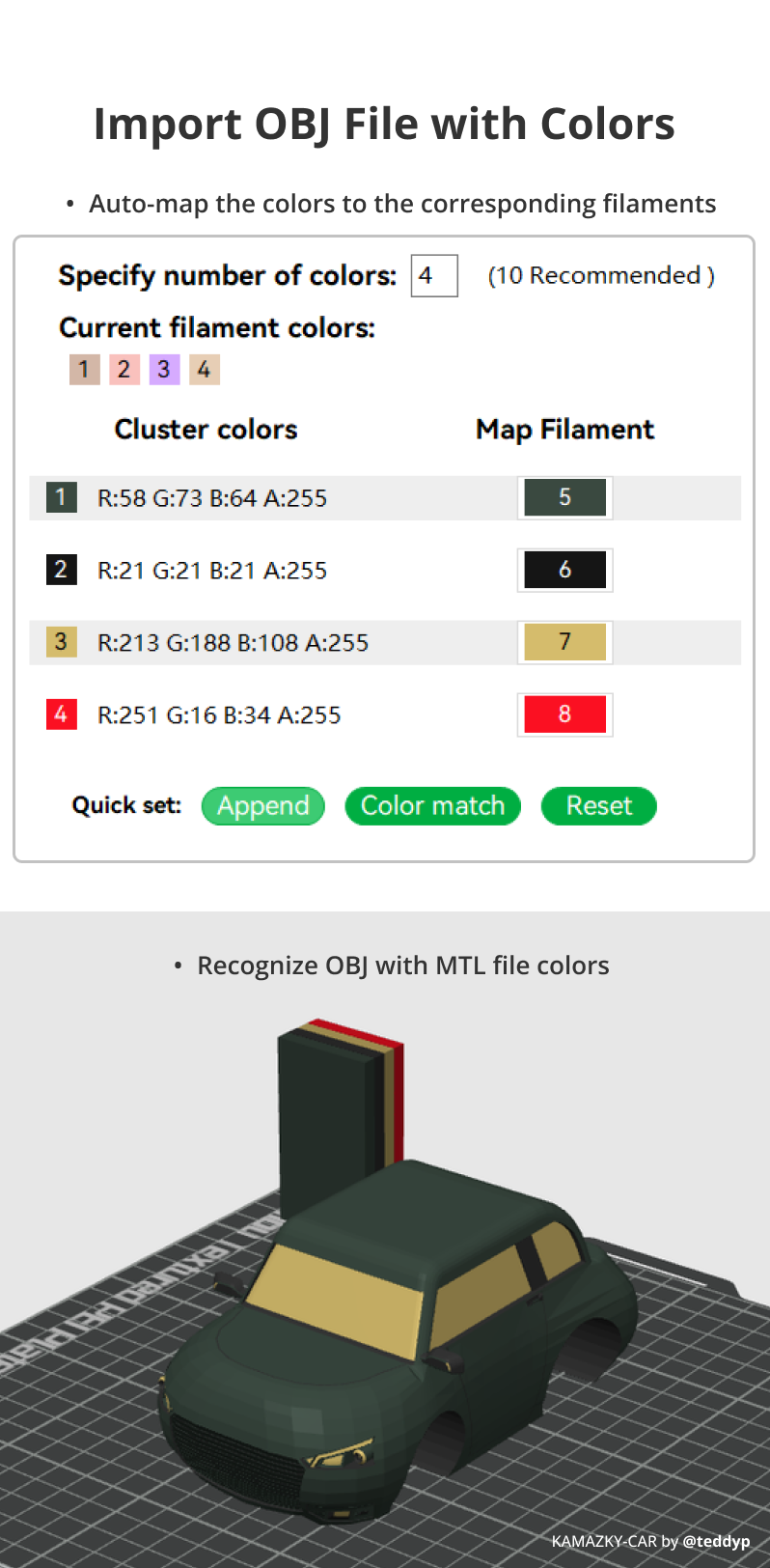

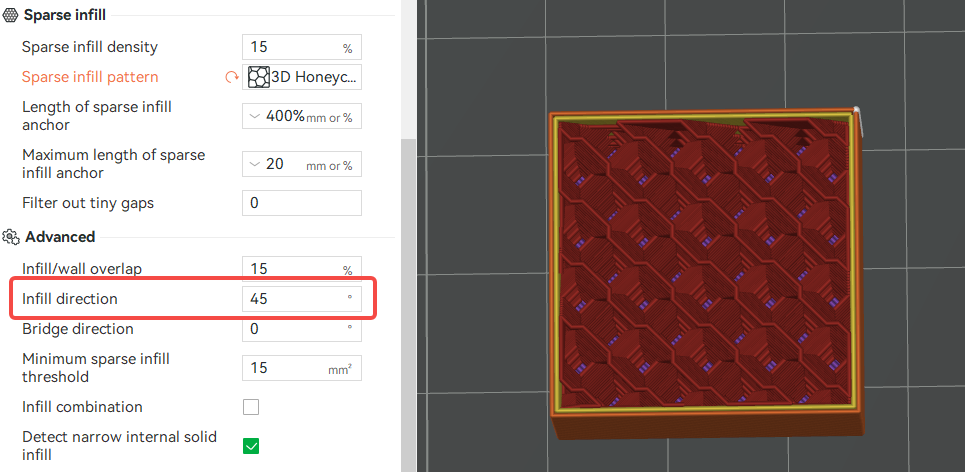

¶ 3. Imported obj file with color

Added color imported from the vertex in the .obj file, and color imported from the mtl file function.

You can use software such as Blender or Meshlab to color vertices or patches of the model.

The PNG color function is currently under development. Please stay tuned.

Note:

Please ensure that the imported obj file does not have non-manifold edges to ensure correct slicing.

After color parsing, it may not fully correspond to other rendering software. Users can continue to manually adjust the printed colors in BambuStudio.

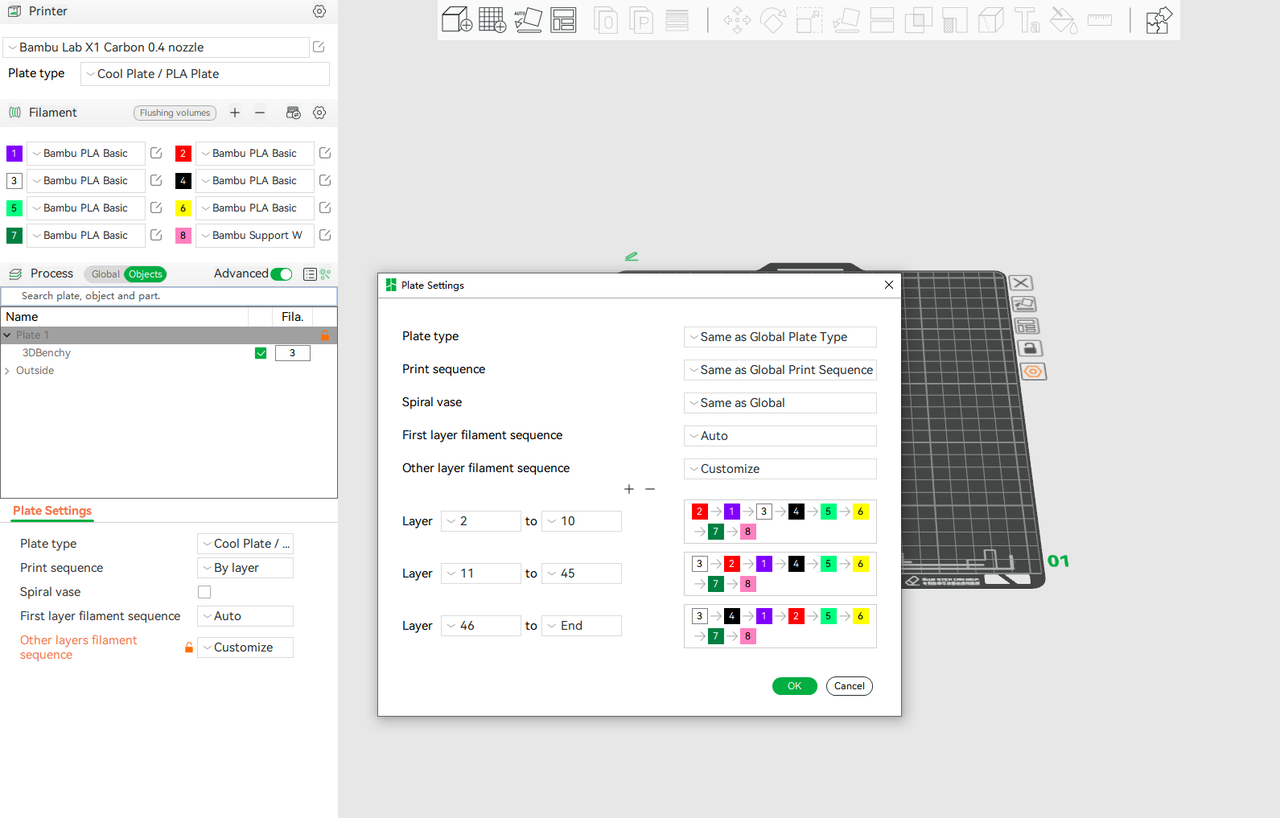

¶ 4. Support customized print sequences above the first layer

Please see this wiki page for details.

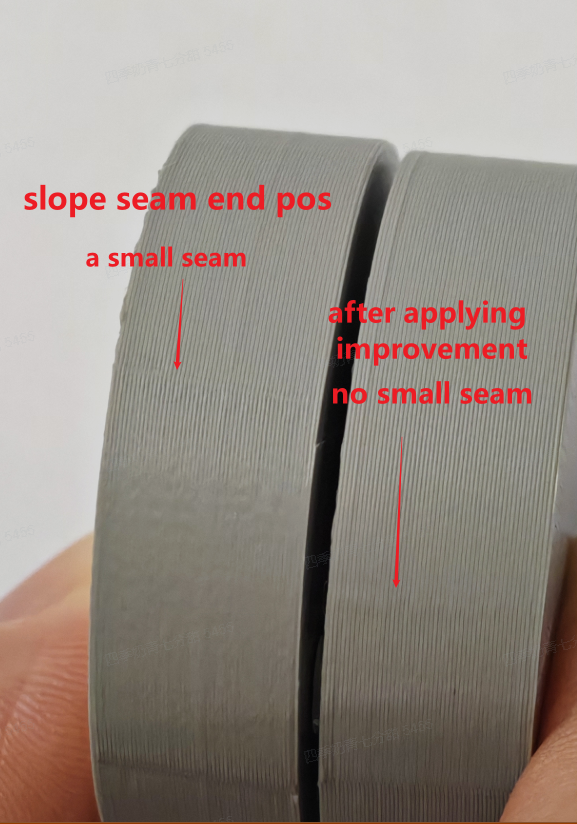

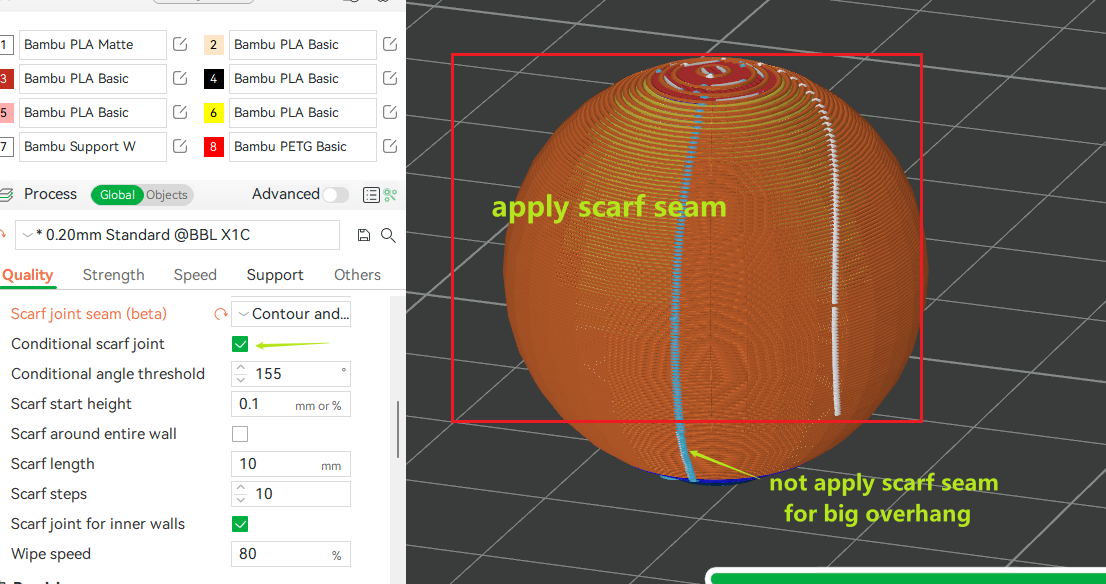

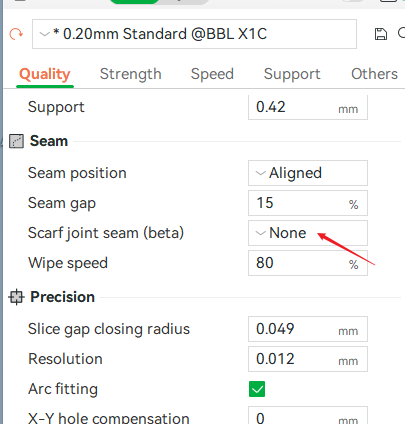

¶ 5. Improved Scarf Seam

Scarf Seam is a useful seam type to hide seams for objects with few corners, where the seam joint is not a single point as the usual seam, but a short slope. Scarf seam was first introduced in Orca Slicer by Noisyfox https://github.com/Noisyfox and fellow community contributors for their involvement and discussions, and we deeply appreciate their great contributions. We have imported and further improved Scarf Seam.

Drawing upon community contributions, Bambu Lab strives to refine seam quality for users within established parameters. This approach aims to enable users to achieve enhanced seam outcomes without adjusting line width or reducing print speed. The comparison is shown as follows:

Additionally, Bambu Lab adds the scarf seam overhang detection for conditional joints. When enabled, the scarf seams are not utilized if the overhang exceeds a certain threshold. This addresses the issue where the scarf seam becomes less effective and fails in cases of excessive overhang.

Please note: it is an experiment function and is turned off by default. Please use it with caution. The function entrance is shown in the figure below.

¶ 6. Reducing purge through retracting filament

An experimental feature in development mode, currently exclusive to the X and P series and disabled by default. This function prolongs the retraction and cutting distance of the filament during changes, aiming to reduce purging. While it significantly decreases flushing, it may elevate the risk of nozzle clogs or other printing complications. Please use it with caution. Thanks to LeonFisherSkipper

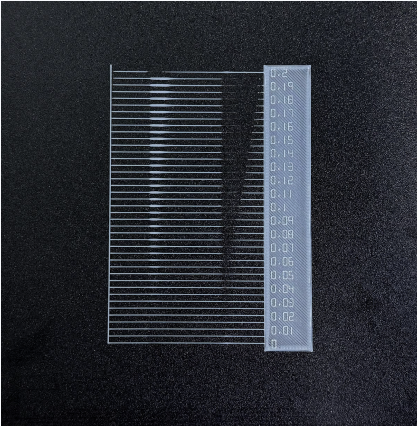

¶ 7. Improve PA calibration pattern

Improve PA calibration pattern. All calibration lines are now printed with a single base plate, facilitating easy removal. Thanks to OrcaSlicer.

¶ 8. Support manual calibration values management

Following user feedback, Bambu Studio has introduced a feature allowing users to directly input and save their specific calibration values on the printer, facilitating the customization of device settings. This update is designed to enhance the overall user experience.

¶ 9. Straight line painting (horizontal & vertical) and view enhancement

Introduced a tool for drawing straight lines (vertical and horizontal) in painting, plus a default front view and horizontal rotation feature, courtesy of OrcaSlicer. Thanks to OrcaSlicer.

¶ 10. Ported and improved measurement tools

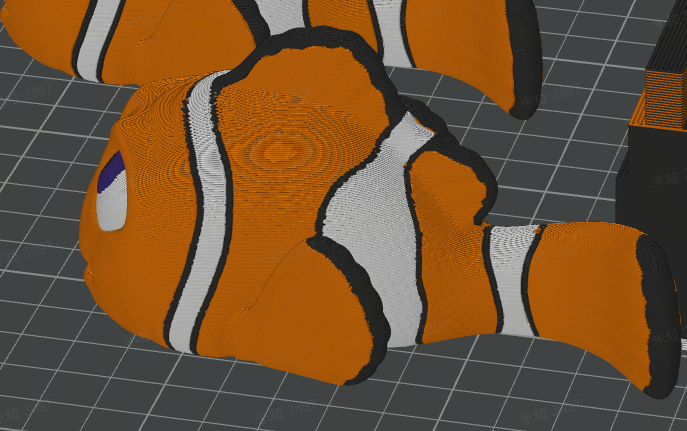

Initially created by the PrusaSlicer team and favored by numerous users, the 'Measure' feature has been adapted for Bambu Studio, with acknowledgments to both OrcaSlicer and PrusaSlicer.

We've enhanced this feature by introducing modifications that enable measurement across multiple model objects, significantly elevating its functionality.

Moreover, we've enabled setting distances between different meshes, allowing for assembly functions akin to CAD, facilitating precise distance-based assembly.

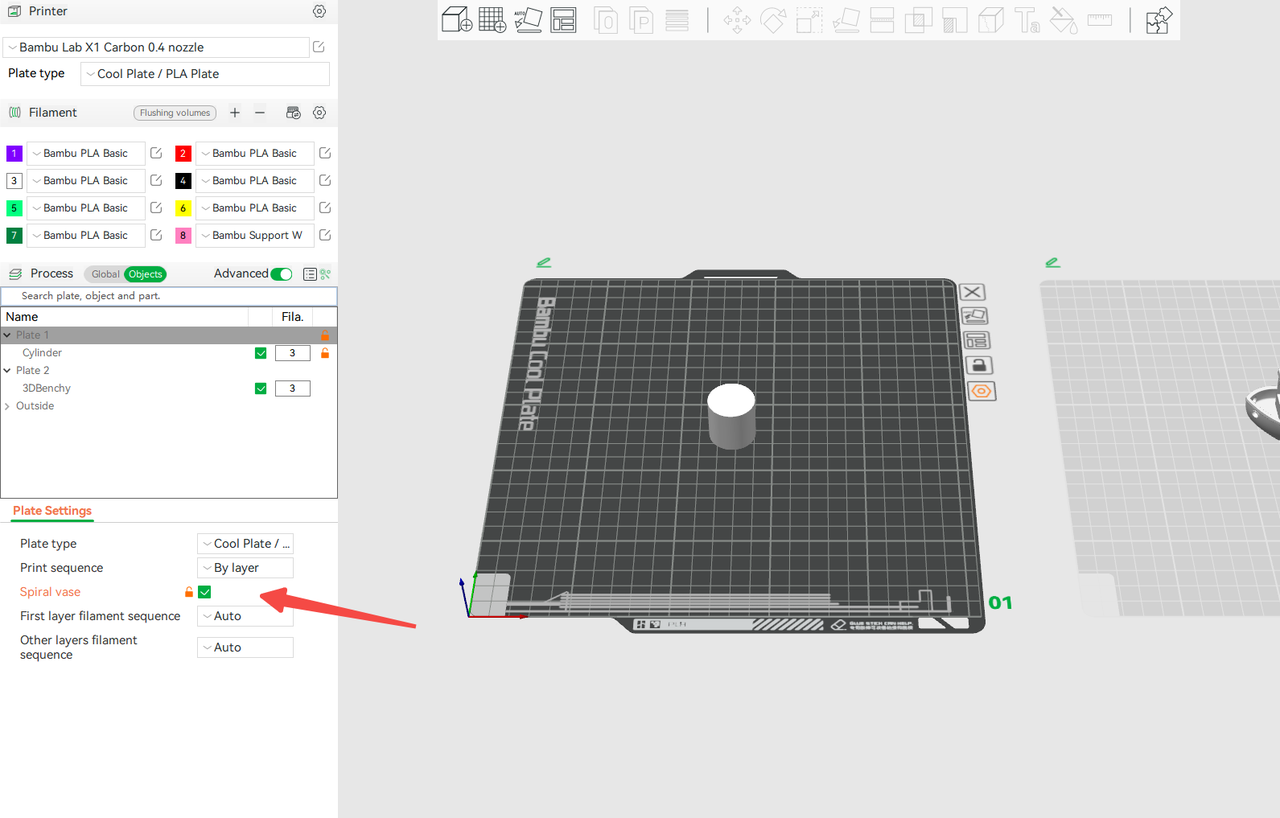

¶ 11. Enabled Spiral Vase Mode in per-plate settings.

https://github.com/bambulab/BambuStudio/issues/2079

The new per-plated 'Spiral Vase' option is added under the Plate Settings tab. With this setting, model airplane parts designated for printing in spiral vase mode can now be sliced together with standard parts as long as they are in different plates.

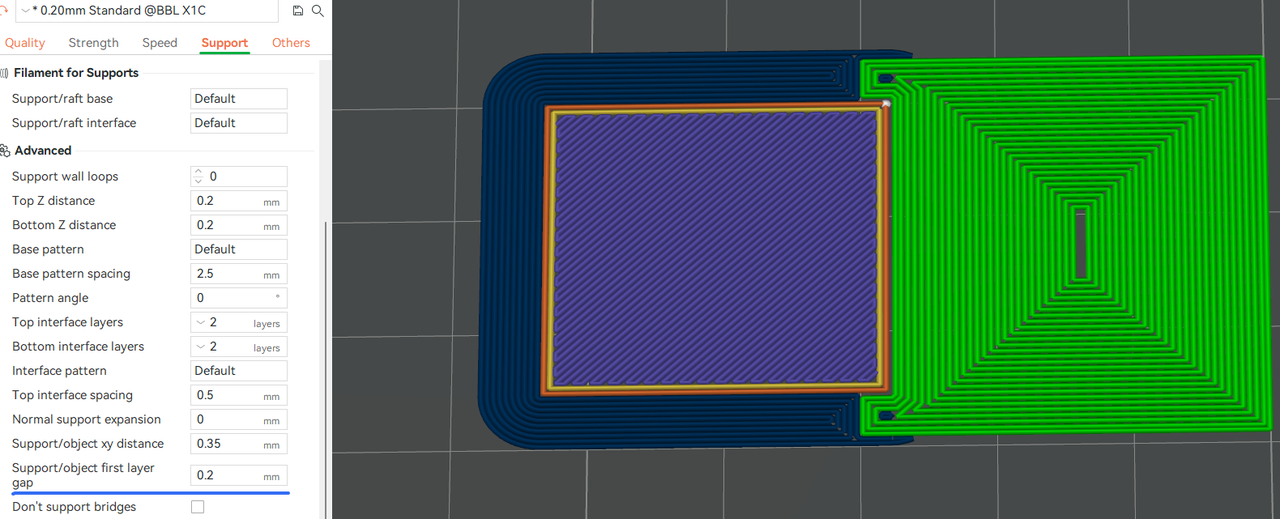

¶ 12. Added a new option "Support/object first layer gap"

Previously, the distance between the first layer of supports and objects was determined by the brim gap, a setting that could complicate support removal in some instances. Now, this gap can be adjusted independently, with a default value of 0.2mm that generally performs well on Textured PEI plates. Adjustments may be necessary for other types of plates.

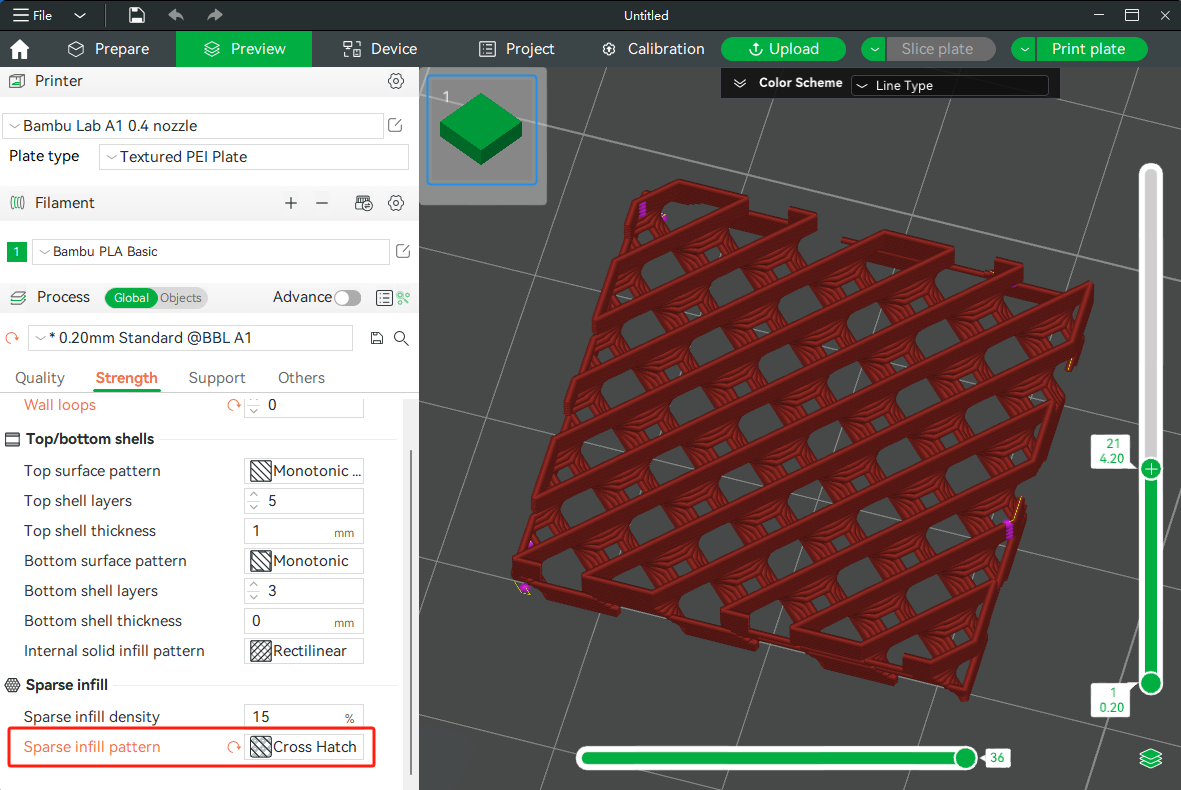

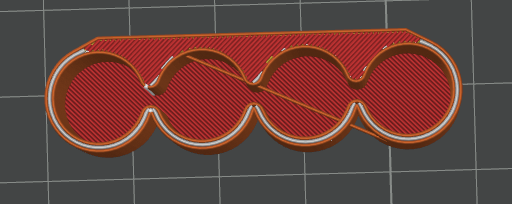

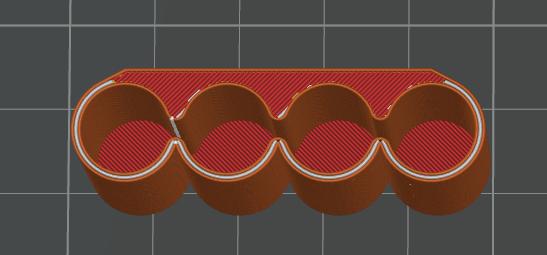

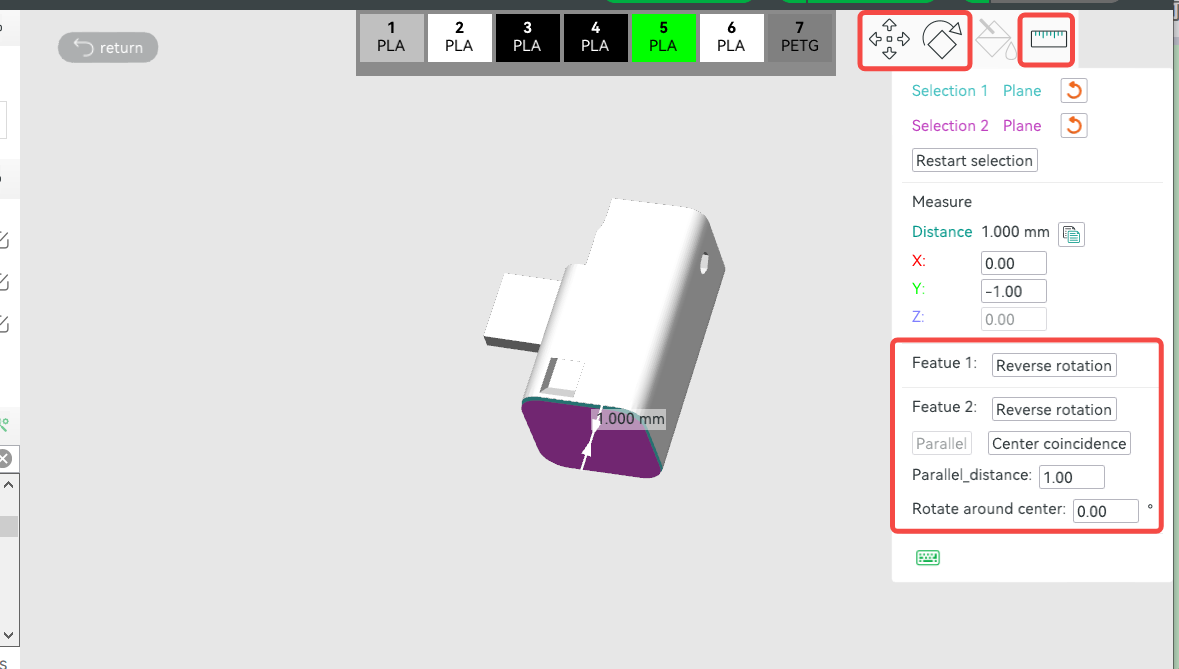

¶ 13. New CrossHatch Infill Pattern

We developed a new infill pattern called CrossHatch. As the name suggests, it primarily fills parts with lines, while periodically altering the direction of the lines through some transition layers. It dramatically improves strength compared to line and concentric infill, while achieving high speed and silent printing in most layers.

When compared to Gyroid infill, it prints 28% quicker in a test cube. When compared to Grid infill, it has a smaller grid size at the same density setting. Based on our tests, we recommend printing it with a slightly lower density setting than you normally would, such as 12%.

¶ Improvement

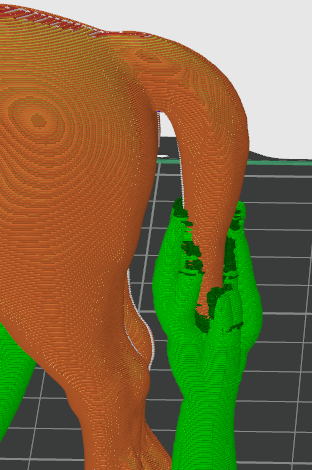

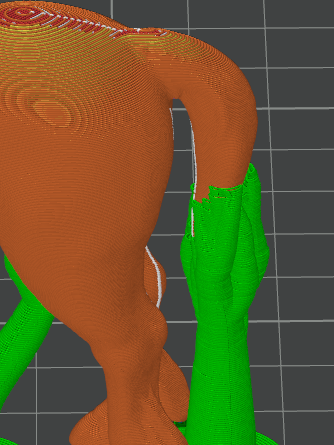

¶ 1. Improved sharp tail support

Sharp Tail is a special type of overhang that flies in the air, such as animal tails or human hair. Previously, we supported sharp tails with very tight and dense tree structures, which are difficult to remove. Now we have improved the support structure. Greatly improving the support effect and ease of disassembly of the pointed tail structure. Only a sparse set of contact nodes are added around the sharp tails, and the tree branches are separated far enough so they are easier to remove. Besides, sharp tail overhangs will no longer have support interface layers. For more details, see our wiki page.

¶ 2. Smooth overhang speed

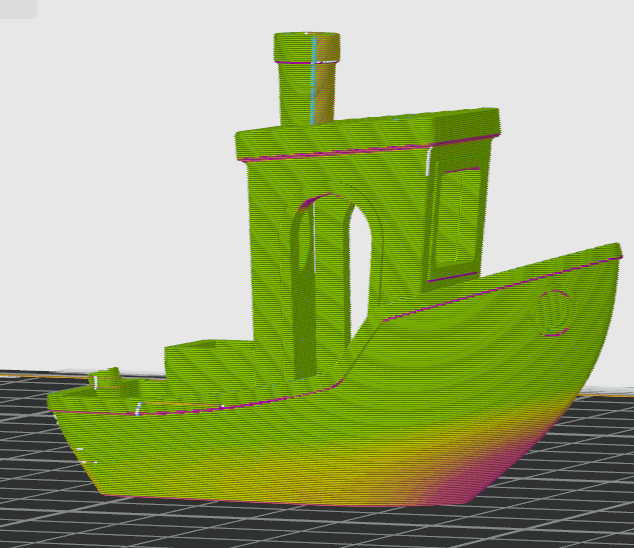

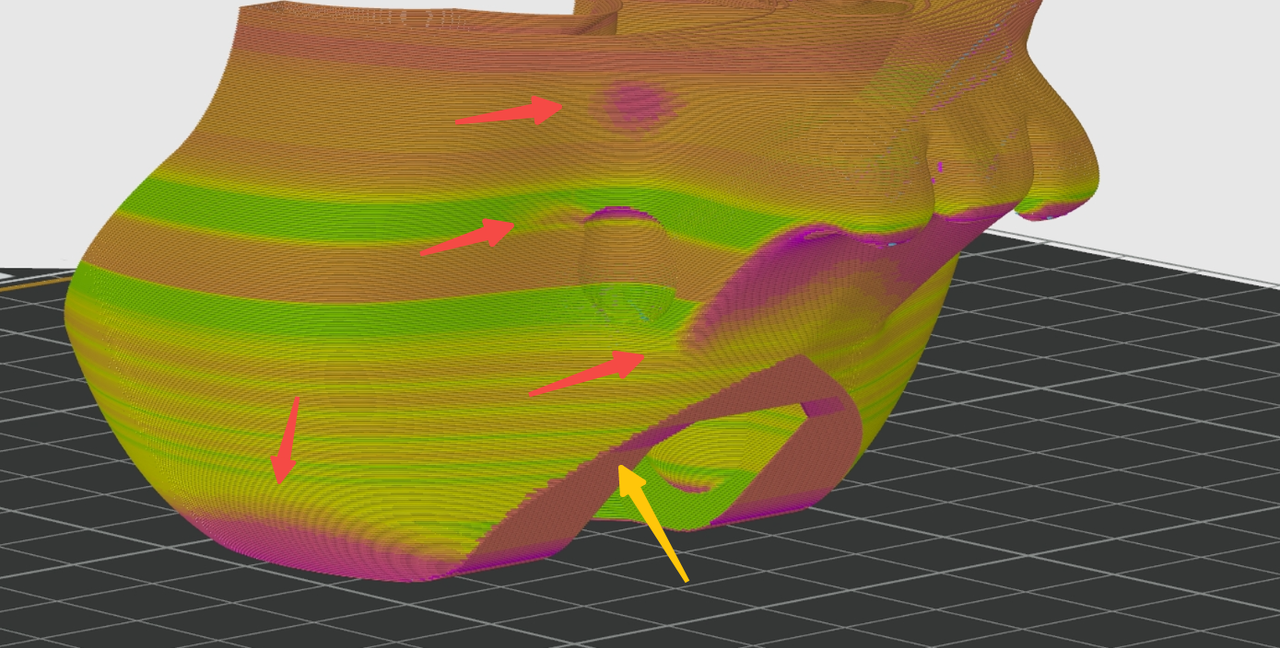

This update enhances the overhang descent speed feature for smoother transitions between speeds, thus improving the appearance of speed-transition defects. This improvement is accessible in Classic mode. The following image illustrates the effect of the smooth overhang descent speed (the cooling function was turned off to showcase the overhang speed transition).

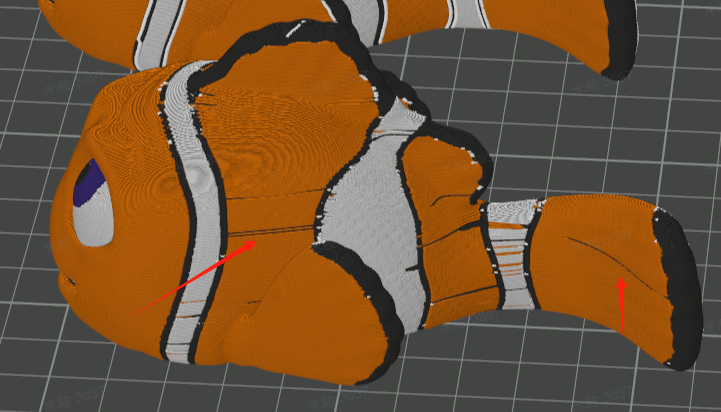

A. The overhang descent speed is smoother, and the quality of speed-dependent patterns has been improved. The test model is from wuguigui https://makerworld.com/zh/@wuguigui on MakerWorld https://makerworld.com/zh/models/12888#profileId-13005

As shown in the left image, the areas with significant speed changes have transitions (red arrows), while areas with drastic path changes do not have transitions (yellow arrows). And the printing result, as shown in the right image, demonstrates surface improvement.

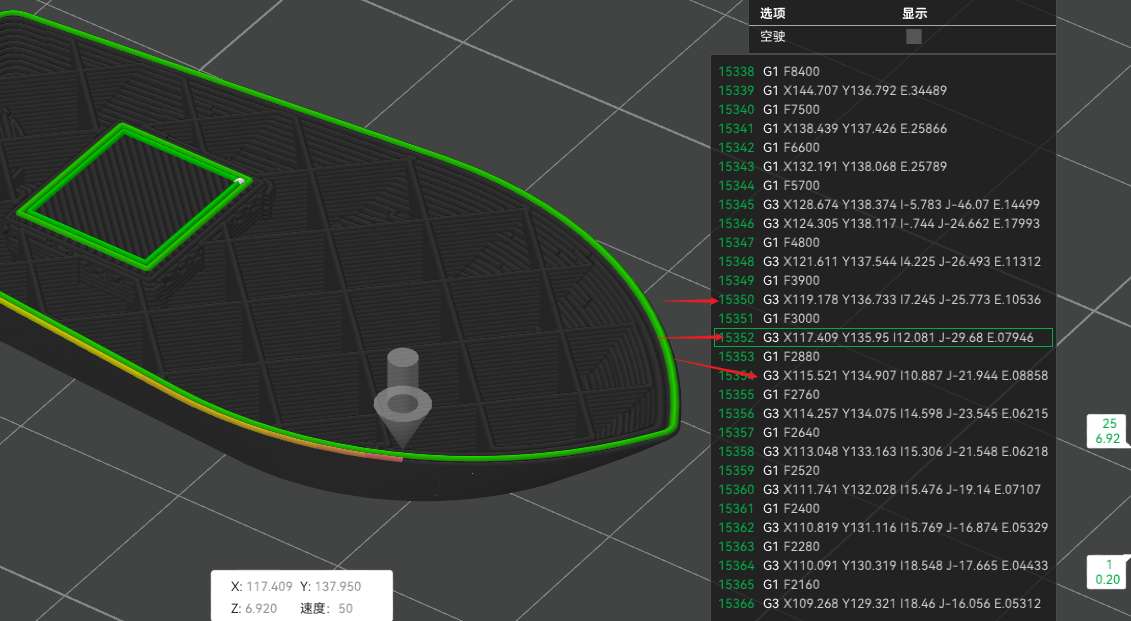

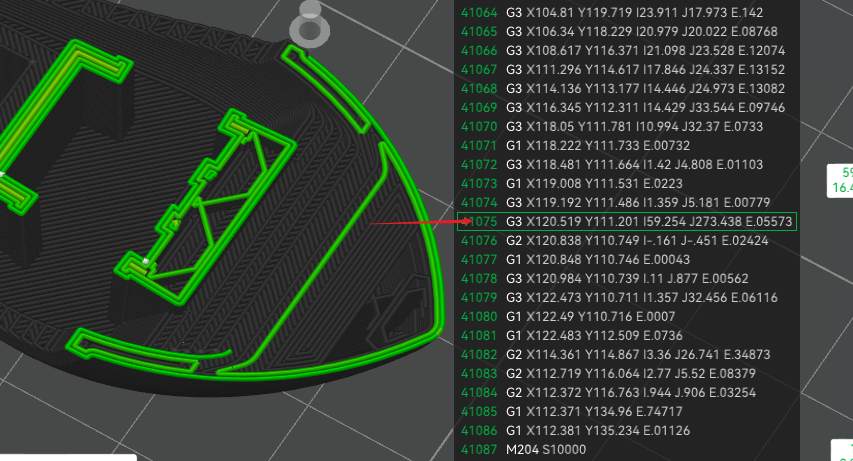

B. Additionally, the arc fitting result is preserved. Both the speed transition and non-speed transition parts retain arc fitting. The bottom-left image shows arc fitting in the speed transition part, and the bottom-right image shows arc fitting in the non-speed transition part.

¶ 3. Improved fly-wall issue

due to the improved calculation method for overhangs, there has been an improvement in fly-wall path caused by overhang calculations. The bottom-left image shows the situation before the improvement, while the bottom-right image shows the situation after the improvement.

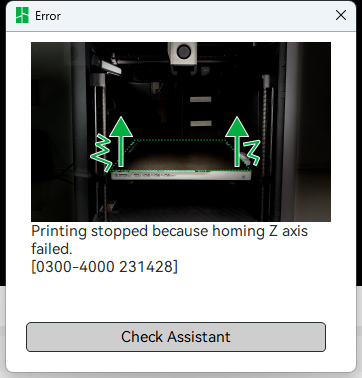

¶ 4. Error code pop-up using new UI

We have updated the error code prompts and added illustrations, making the error codes easier to understand. This facilitates users in locating and identifying issues.

¶ 4. Tooltips have been added to all gizmo tools, offering straightforward instructions for use.

¶ 5. Added Plates Stats Total Cost by niklasb22.

¶ 6. Show estimated print time in the ruler by @Noisyfox

¶ 7. Display both layer time and tick information when a tick is selected from the gcode progress bar, by @Noisyfox

¶ 8. Support remote batch file management on the machine.

¶ 9. Optimized performance and reduced lag when switching between parameter pages.

¶ 10. Optimized error descriptions and resolution methods for Liveview and file browsing.

¶ 11. Enhanced application by implementing single-instance mode, allowing only one instance of Bambu Studio to be active simultaneously.

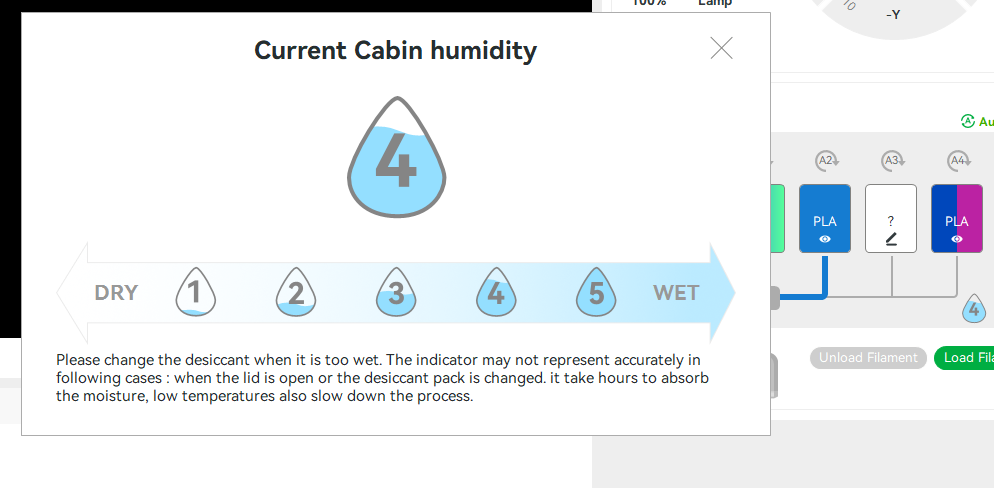

¶ 12. New AMS humidity display UI.

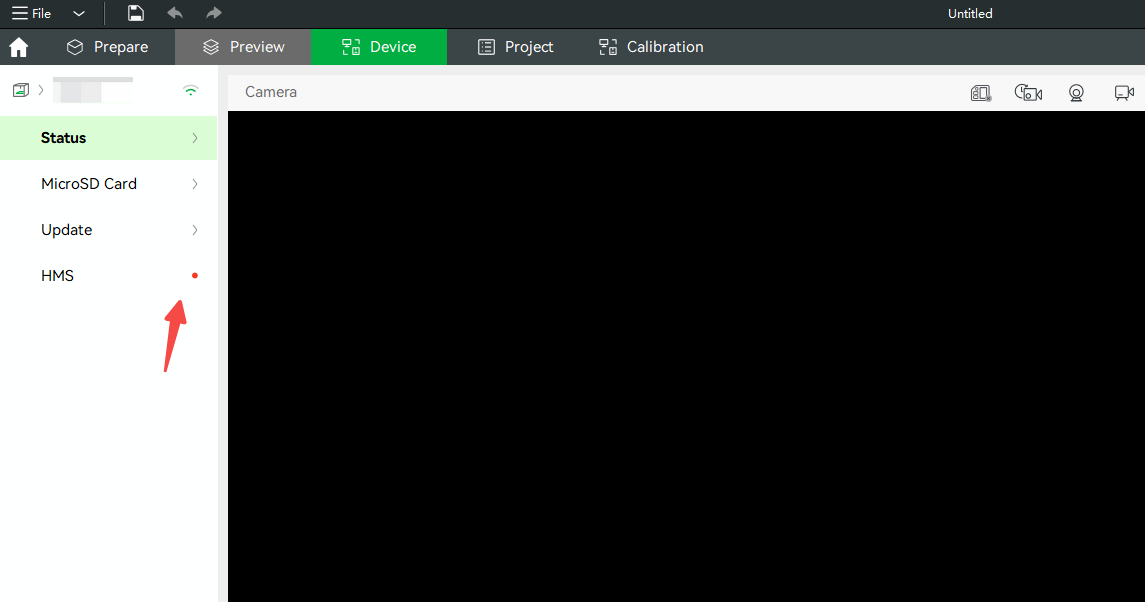

¶ 13. Add red dot notification to HMS messages.

¶ 14. Added security checks when downloading models from MakerWorld. We have implemented additional security checks, such as file type verification and download server inspection. The purpose of these measures is to prevent users from being deceived by fake MakerWorld websites and inadvertently downloading viruses or trojan programs.

¶ 15. When initiating a print from the SD card's Model view, compatibility checks are now performed between the printer and the slicing file. This helps avoid potential issues and ensures smooth printing operations. https://github.com/bambulab/BambuStudio/issues/2991

¶ 16. When printing is paused and an external filament is being used, users are now able to perform filament loading and unloading operations seamlessly.

¶ 17. Add Portuguese language.

¶ 18. Limited the input range of the multiplier in the flushing volume to [0~3].

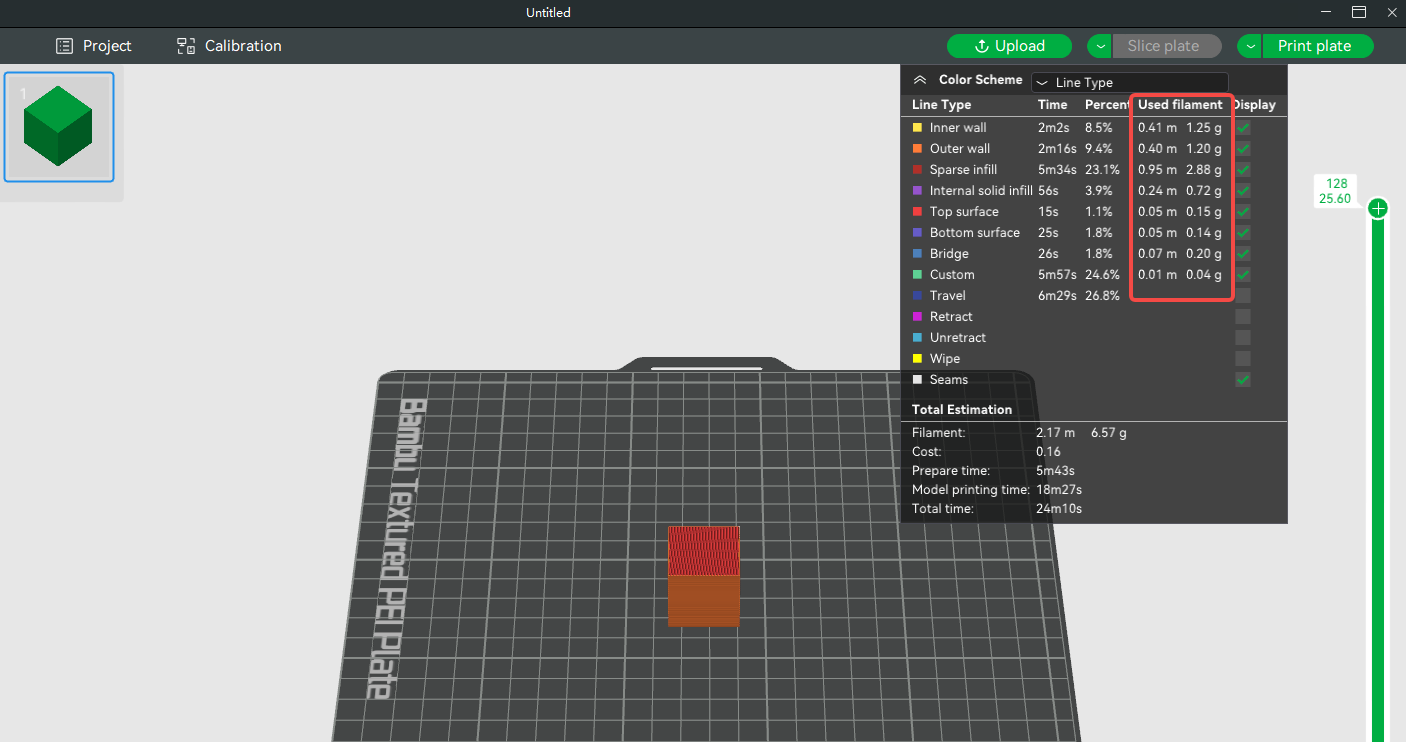

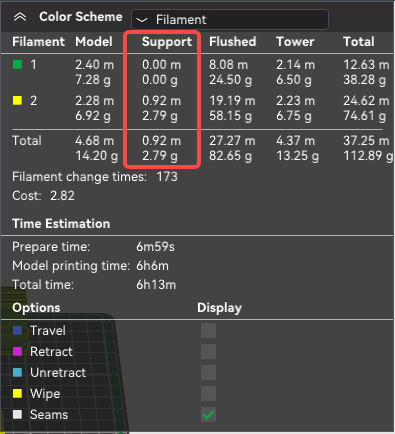

¶ 19. The filament consumption for each item used is displayed in the preview.

¶ 20. Optimized memory consumption and performance in the scenario of copying model objects.

¶ 21. Optimized loading time of 3MF files with a large number of models.

¶ 22. Security Enhancement. Bambu Studio has been updated to ensure that sensitive information, like print_host and api-key, is no longer included within the G-code files.

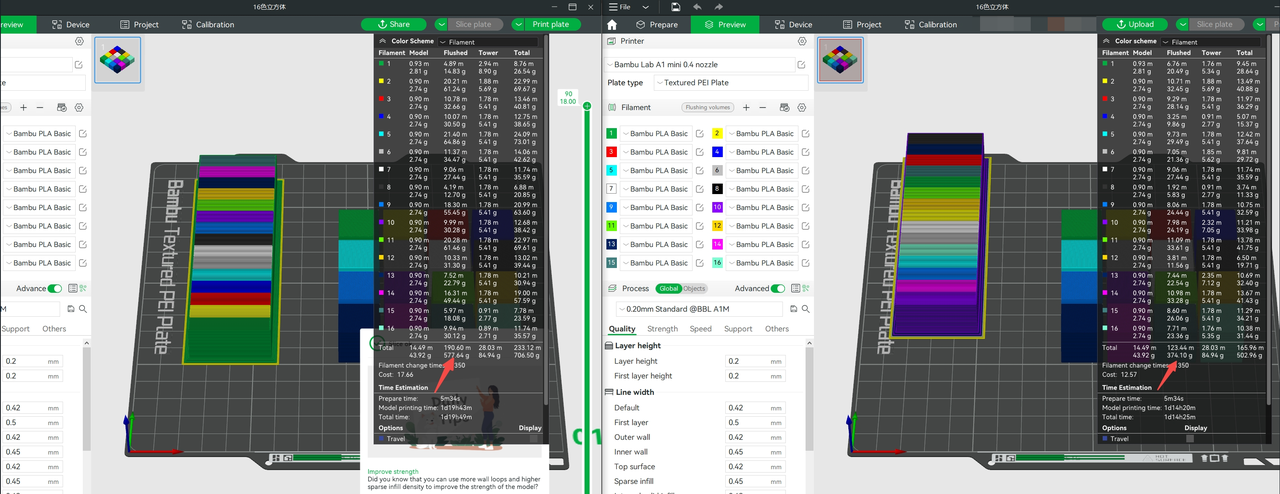

¶ 23. Optimized the material change sequence function. Optimized the material change sequence generation speed and expanded support to plan material changes with over 8 colors.

¶ 24. Added Batch file management to the Studio homepage

¶ 25. Now support adding notes to profiles.

¶ 26. Add tooltips for process profiles.

¶ 27. Support OLTP format files.

¶ 28. Support shortcut key coloring for filament slot 10 or above. You can use quick-selection of 1+other numeric keys to color, up to a maximum of 16 colors.

¶ 29. When the AMS lite version is greater than or equal to 00.00.07.89, the AMS lite will automatically read the material information when inserting materials, and the option of "Insertion update" will be removed from the AMS settings.

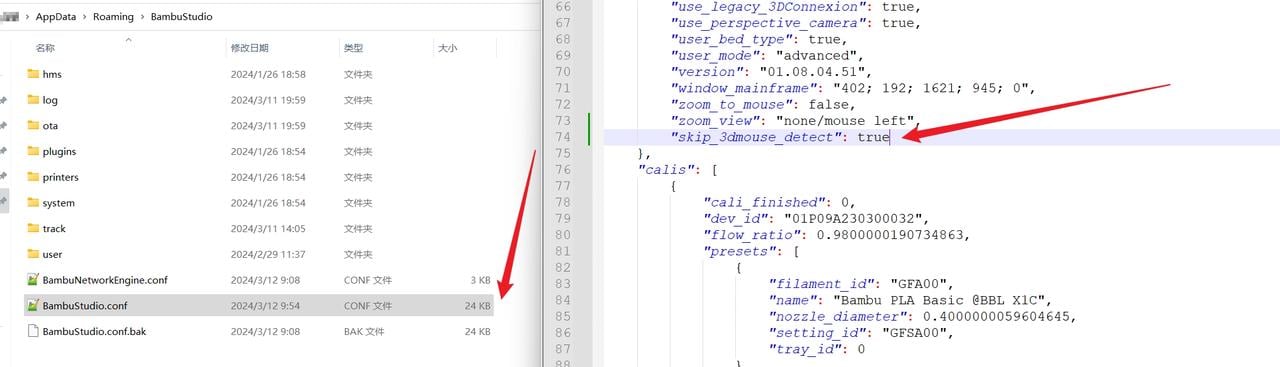

¶ 30. Some USB devices can cause BambuStudio to start slowly, such as special keyboards. You can add a line in the configuration file with "skip_3dmouse_detect": true to avoid this issue.

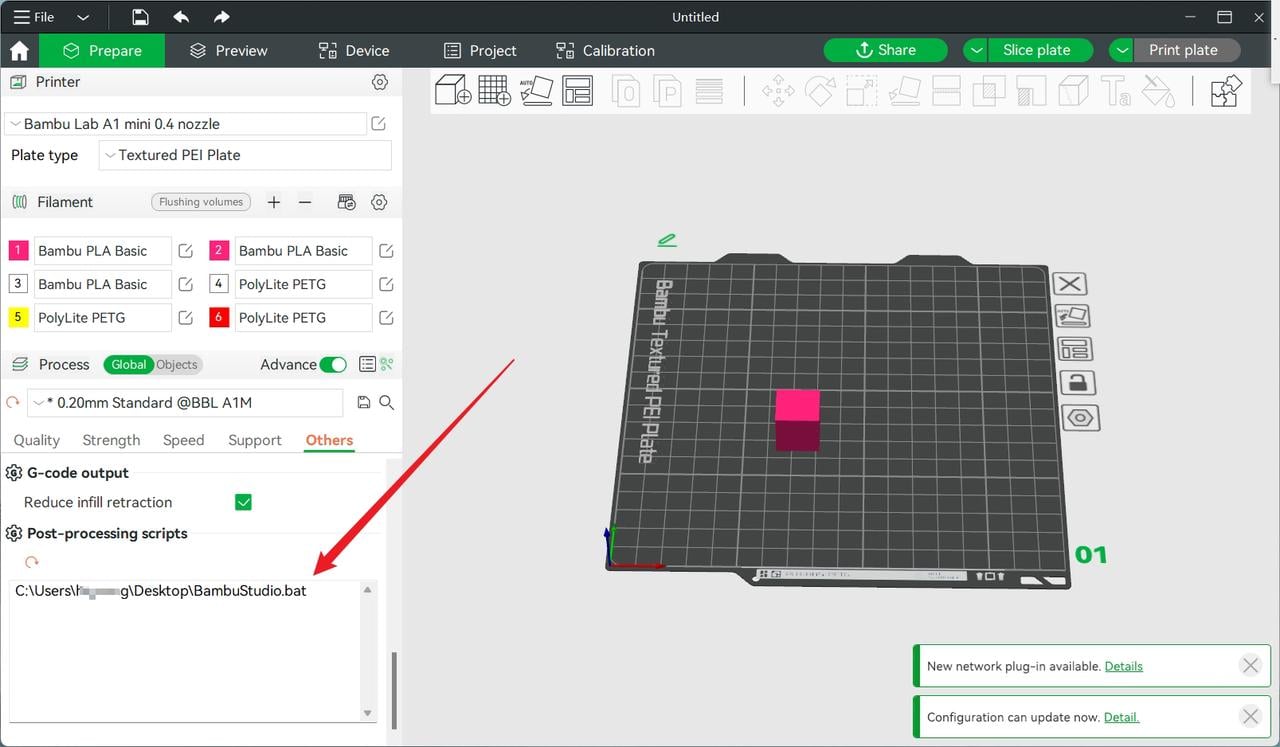

¶ 31. Before slicing, add the absolute path of the processing script as shown in the image below. After slicing is completed, the script can be automatically processed. Note: The script will no longer be called when exporting gcode, as it has already been called during slicing.

¶ 32. Optimized the prompt text for parameter transfer. https://github.com/bambulab/BambuStudio/issues/3236

¶ 33. Optimized support for Japanese characters.

¶ 34. You can now set up custom filaments in Studio without the need to operate on the printer side. https://wiki.bambulab.com/en/bambu-studio/create-filament

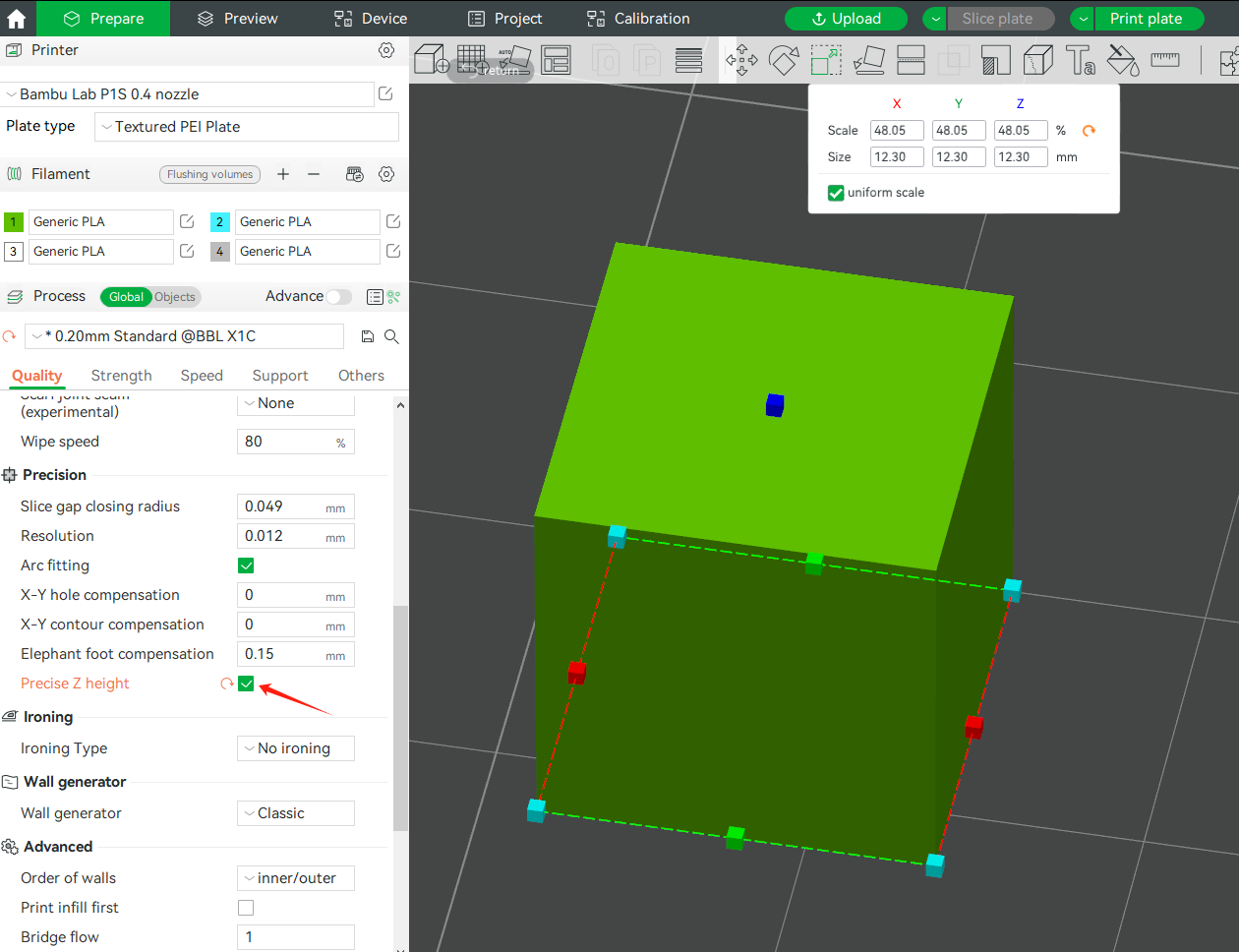

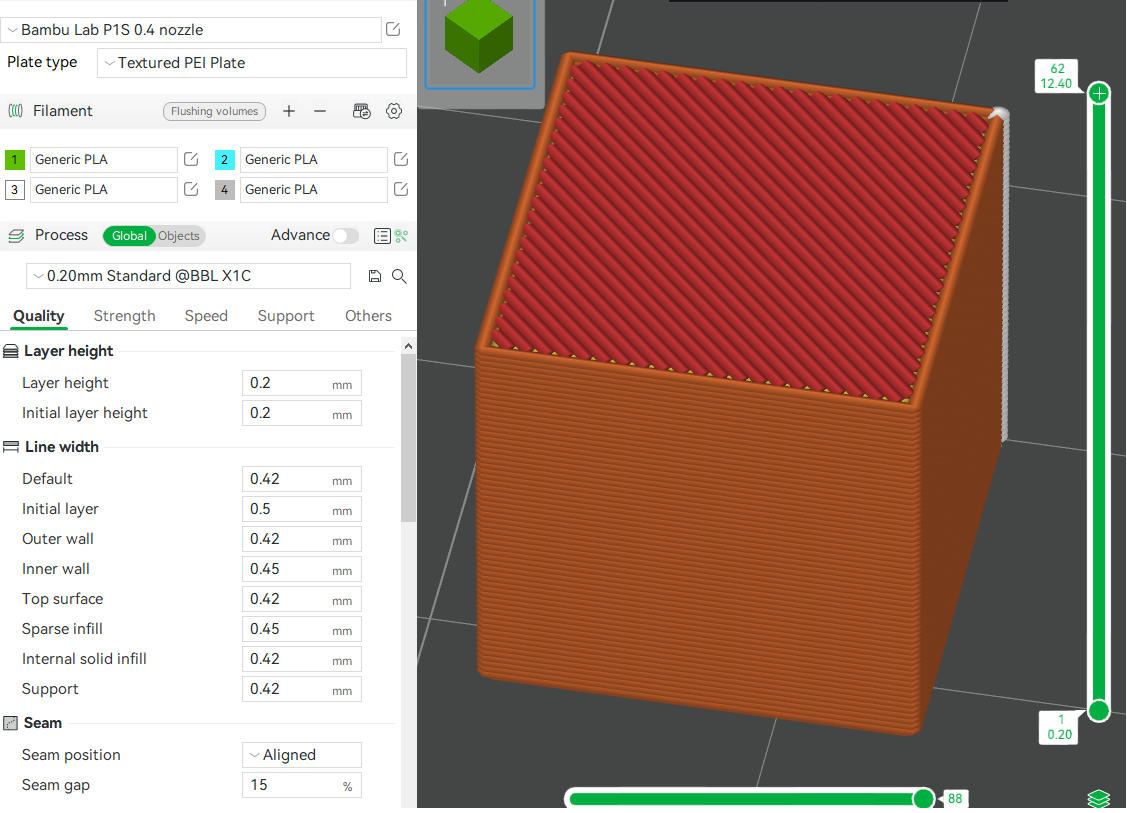

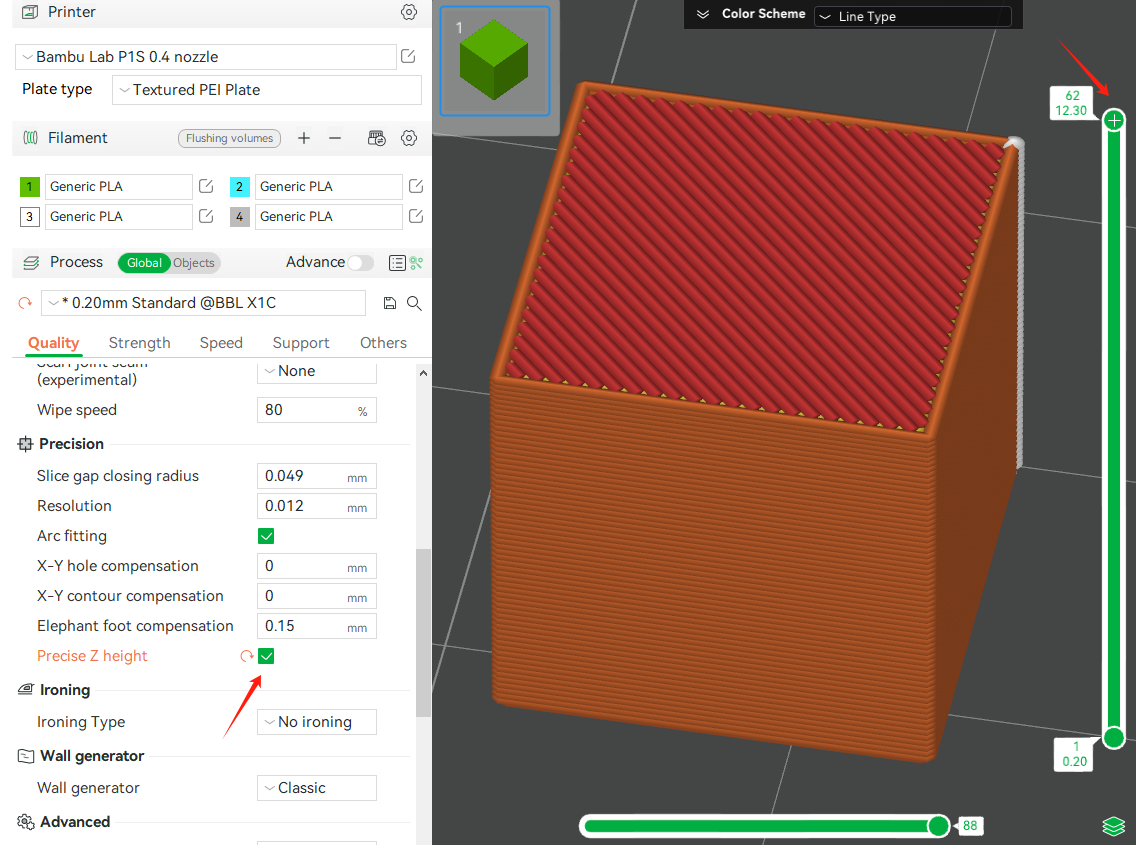

¶ 35. Precise z height

If checked, the accurate Z height will be obtained after slicing the model.

For example, We slice a 12.3mm×12.3mm×12.3mm square with a layer height of 0.2mm. The final slicing result will be a multiple of 0.2mm (As shown in the first picture, the height after slicing will be 12.4mm). After checking this parameter, we will adjust the layer height of the last 5 layers so that the height of slicing result will be consistent with the actual height of the object. (As shown in the second picture, the height after slicing is 12.3mm which is consistent with the actual height of the object)

Attention: It will not take effect when the number of object layers is less than 6

Precision z height is checked

¶ 36. Multi-material segmentation improvements

We extracted the part about Voronoi diagram detection in Arachne to a public location and applied it to multi-color area segmentation. We re-implemented the main part of multi-material segmentation and solved all the problems of the material segmentation overflow layer. This patch is cherry pick from Prusa, Thanks to PrusaSlicer.

¶ 37. More importantly, we have added translation, rotation, and measurement tools in the assembly diagram, and added face and face assembly functions in the measurement tools to facilitate the rapid assembly of two objects

¶ 38. Adapt and enhance the 3DHoneyComb infill from OrcaSlicer, credited to @gringer (David Eccles) for the initial 3DHoneyComb implementation in Slic3r. Moreover, we further implement the infill angle options, allowing for adjustments to the infill angle with this infill type.

¶ 39. Port the new "ensure_vertical_thickness" algorithm from PrusaSlicer. Thanks to Vojtech Bubnik <bubnikv@gmail.com>

¶ 40. Port the "Extend sparse infill" feature from PrusaSlicer. Thanks to @PavelMikus <pavel.mikus.mail@seznam.cz>

¶ 41. Add Bambu ABS-GF,Bambu ASA-Aero,Bambu Support for PLA/PETG

¶ 42. Add Turkish Support. Thanks to Fatih AYDIN for all the translations

¶ 43. Refine Ukrainian translation from @https://github.com/iZonex

¶ 44. Add support using filament statistics.

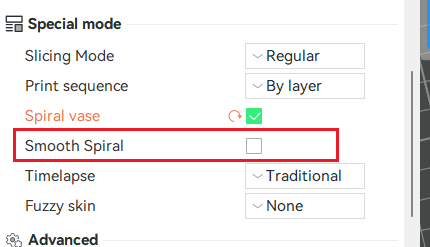

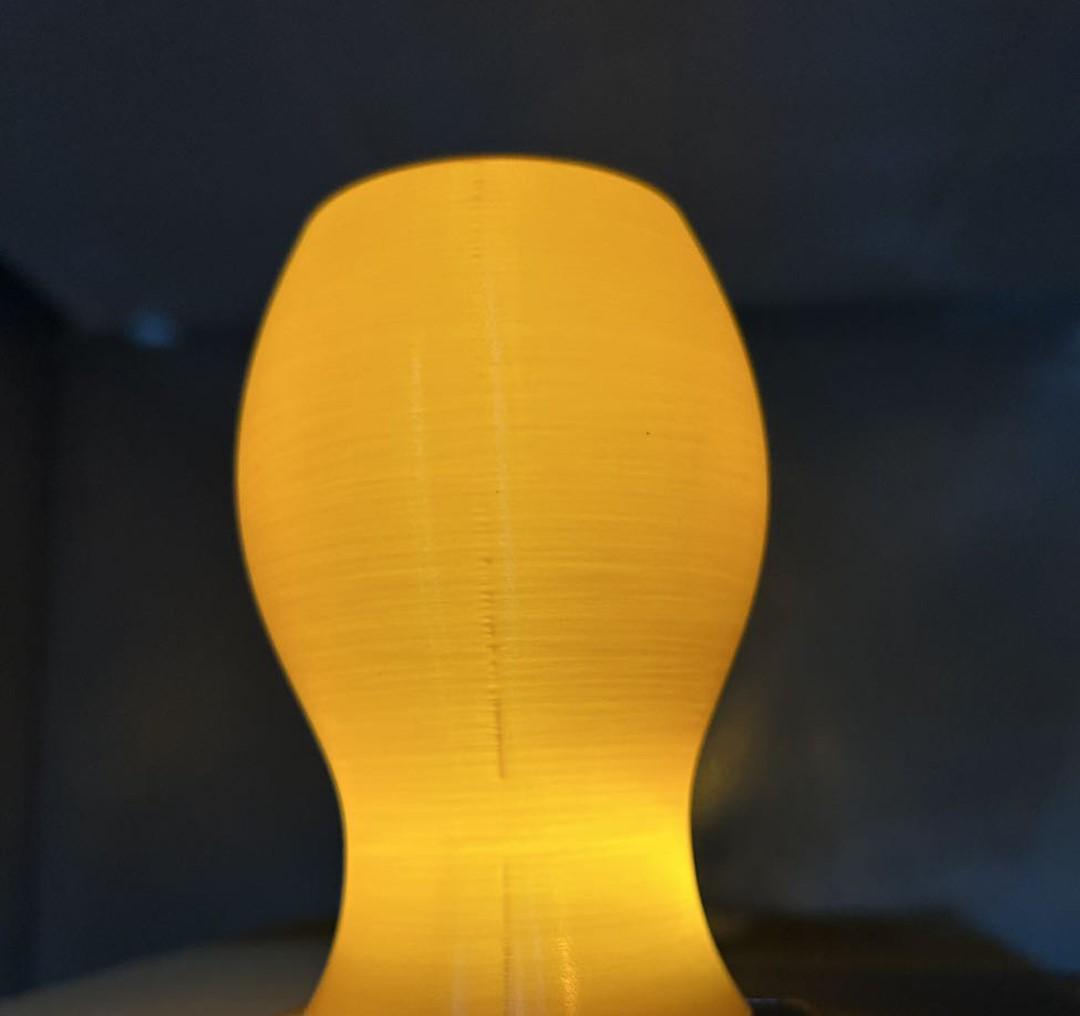

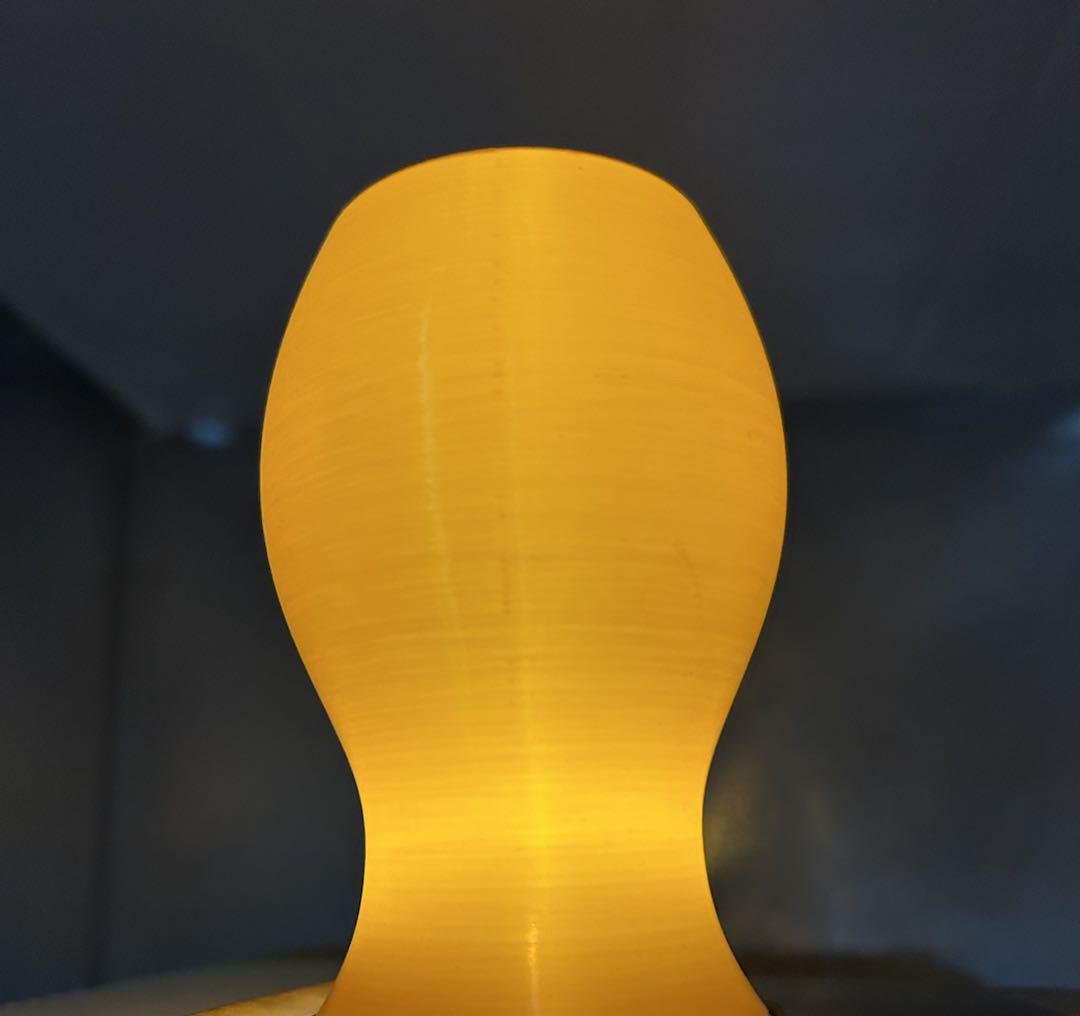

¶ 45. Full re-write of spiral vase

¶ 46. Add parameters under the rotating vase, smooth Vase. Thanks to andrewboktor

Some vase patterns have defects, such as uneven sides and vertical seams. The following are examples of defects.

After enabling smooth Vase, this defect disappears.

Attention: This radical modification is not suitable for vases with obvious edges and radical curve changes. Suitable for vases with smooth surface transitions.

¶ 47. Display filament labels in the "Change Filament" context menu, by @https://github.com/javawizard

¶ 48. We are currently optimizing to address the issue of performance degradation caused by an increase in the number of page faults. This is the first stage, and we will continue to pay attention to this issue in the future. https://github.com/bambulab/BambuStudio/issues/3702

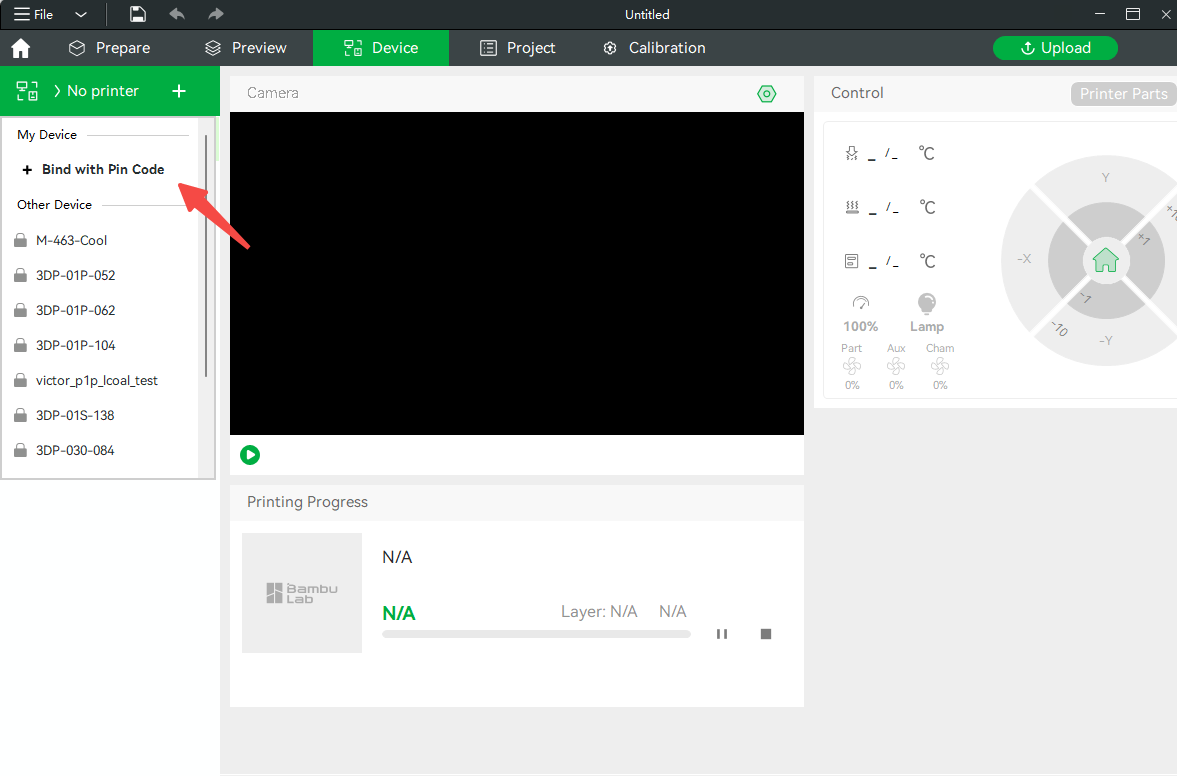

¶ 49. Added binding method for pin code We have added a non-LAN mode binding method, which allows for easy binding of printers on the Studio side by inputting the PIN code generated on the printer side.

P series starts from version 01.06

A1 mini starts from version 01.03

A1 starts from version 01.03

X series doesn't support it yet. (The firmware scheduled for August will be able to support it.)

For more information, please refer to the WIKI page https://wiki.bambulab.com/en/bambu-studio/manual/pin-code

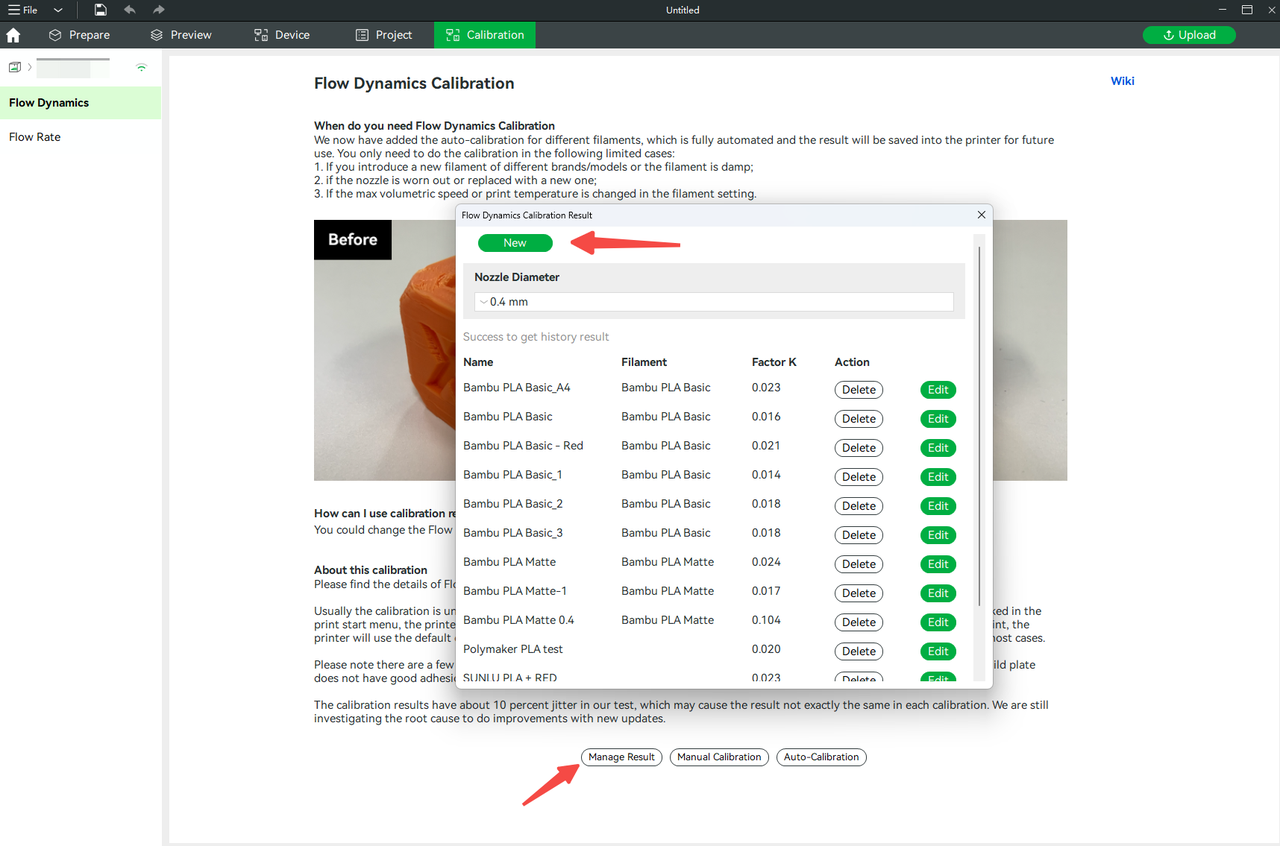

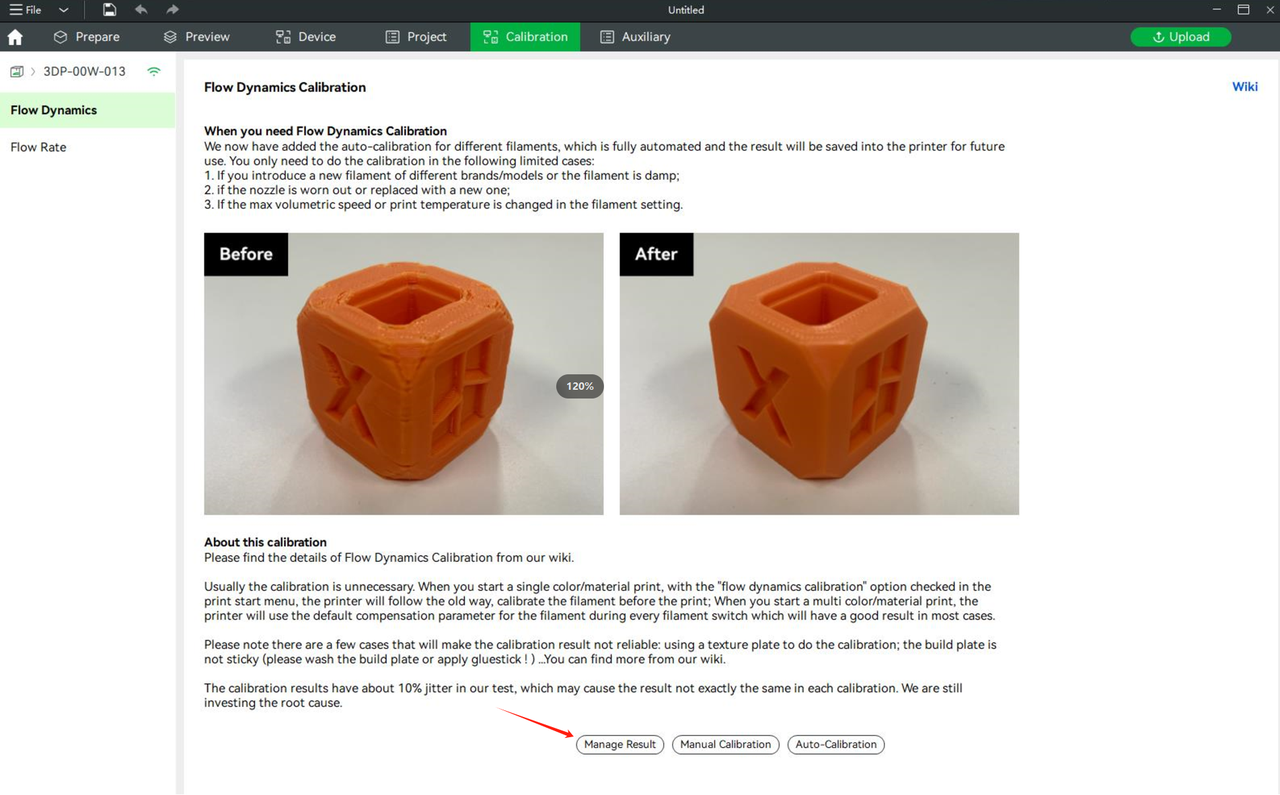

¶ 50. P series and A series printers can support saving calibration results to the printer like X series printers. The calibration results can be edited in Studio's "Manage Result", and the calibrated k value can be set for the AMS slot on the device page.

¶ 51. Load more fonts, the main idea for this improvement is borrowed from Prusa. Thanks to Filip Sykala<filip.sykala@prusa3d.cz>!

¶ 52. Add "filament long retraction when cut" for P1P and P1S. The P series firmware that supports this feature will be updated soon.

¶ 53. Some translations improvement, Russion by @https://github.com/AndylgTom , Turkish by https://github.com/fatih5228, Korean by @https://github.com/bluesoul33

¶ 54. Add partial leveling for A1 series

Check "Bed Leveling" before sending the print task, and the printer will be partially leveled according to the external outline of the sliced object, rather than the entire build plate area, reducing the preparation time before printing.

¶ 55. Fix the issue of inability to use support filament for AMS mapping

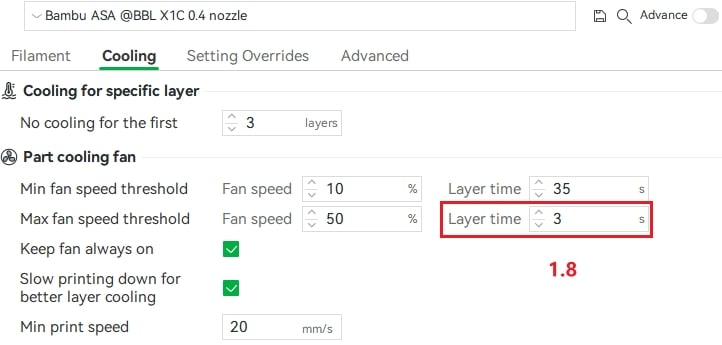

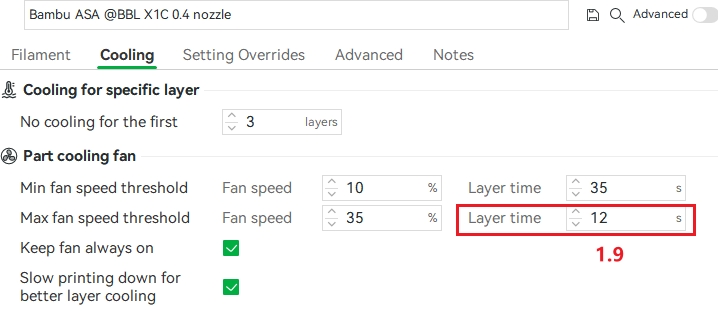

¶ 56. Increase layer time of ASA to get better cooling. Pinter time will increase

|

|

¶ BugFix

¶ 1. Fixed the issue of AMS mapping when printing with gcode.3mf

https://github.com/bambulab/BambuStudio/issues/3916

¶ 2. Fixed the wrong print sequence caused by narrow parts of the internal bridge

https://github.com/bambulab/BambuStudio/issues/3873

¶ 3. Linux building issue https://github.com/bambulab/BambuStudio/issues/3874 , by @ https://github.com/lucianoloder

¶ 4. Can't edit text

https://github.com/bambulab/BambuStudio/issues/3750

¶ 5. Slicer creates invalid color pattern

https://github.com/bambulab/BambuStudio/issues/3749

¶ 6. Fix the building issues on flathub, by @https://github.com/hadess

¶ 7. Modified the key descriptions for shortcut key combinations on macOS.

https://github.com/bambulab/BambuStudio/issues/3026

¶ 8. Misspelled word in window title "Upload Pictures" instead of "Upload Pictures" during rating of downloaded print that contains images. #3617

https://github.com/bambulab/BambuStudio/issues/3617

¶ 9. Colored filament is not matched against the same color in AMS slot.

https://github.com/bambulab/BambuStudio/issues/2190

¶ 10. Filament assignment in the AMS doesn't work #3570

https://github.com/bambulab/BambuStudio/issues/3570

¶ 11. Force .gcode.3mf file extension when saving/exporting gcode file #3375

https://github.com/bambulab/BambuStudio/issues/3375

¶ 12. Custom filaments revert to ? in the AMS #3087

https://github.com/bambulab/BambuStudio/issues/3087

¶ 13. The direction of the scaling indicator arrow is incorrect.

https://github.com/bambulab/BambuStudio/issues/3212

¶ 14. Text is invisible in the text tool while editing.

https://github.com/bambulab/BambuStudio/issues/3258

¶ 15. Color painting disables multiple object selection by shift key.

https://github.com/bambulab/BambuStudio/issues/3480

¶ 16. Fix the display of black texture.

https://github.com/bambulab/BambuStudio/issues/3484

¶ 17. Fix the bug of “Cut” function.

https://github.com/bambulab/BambuStudio/issues/3601

https://github.com/bambulab/BambuStudio/issues/3554

¶ 18. disable 'too close to others' warning.

https://github.com/bambulab/BambuStudio/issues/3647

¶ 19. Fix the problem of color bleeding multi-color slices.

https://github.com/bambulab/BambuStudio/issues/3681

¶ 20. Fix the problem that "Add Part" is not properly aligned to the parent object.

https://github.com/bambulab/BambuStudio/issues/980

¶ 21. Fix the problem of unexpected layers in multicolor print.

https://github.com/bambulab/BambuStudio/issues/3131

¶ Known Issues

- Bambu Studio crash at the open stage on some macos computer (#4050)

this is caused by an old configuration file in $HOME/Library/Application\ Support/BambuStudio/ota

please delete this directory and re-launch Bambu Studio again