¶ 01.09.01.00 (20250611)

¶ Bug fixes

- Fixed the issue that “Auto Bed Leveling” and “Auto Flow Calibration” cannot be cancelled when starting a print from Bambu Handy;

- Fixed the issue that multi-AMS can not use automatic dynamic flow calibration ;

- Fixed the issue that the AMS keeps rotating back and forth after inserting new filament when the AMS filament is exhausted during printing;

- Fixed the issue where the heated bed could not be set to 120°C on 110V.

¶ Known issues

Bambu Studio cannot set the fan speed. Please wait for the Bambu Studio update to fix it.

¶ 01.09.00.00 (20250429)

¶ Important note

- After upgrading the firmware, there is a low probability that the printer will enter the language selection interface. You can restart the printer and upgrade the firmware again to solve the problem;

- Please update the printer firmware before connecting to the AMS 2 Pro/HT. If any of the units are connected, the firmware update might not be initialized, or could fail.

- The X1 series printers support a maximum of 4 AMS units connected per printer, including the AMS, AMS 2 Pro, and AMS HT.

¶ Things to know before updating

In order to use all the new features introduced by the new firmware update, Bambu Studio and Bambu Handy should be updated to the latest version available:

- Bambu Studio: v2.0.3.54 or later

- Bambu Handy: v3.1.0 or later

¶ New Features

- Brand new 2nd-Gen user interface

- Added Support for AMS 2 Pro and AMS HT

- The printer now supports starting the filament drying operation from the printer's screen

¶ Remaining Issues:

- PPA-CF filament cannot be set as external spool.

¶ AMS version 00.01.06.62 (20250429)

¶ Improvement

Optimize AMS RFID recognition detection to improve usage stability.

¶ 01.08.05.00 (20250312)

¶ New Features

Authorization Control for Enhanced Security

- The printer now verifies whether control commands originate from official or authorized software. If not, the commands will be rejected.

- You can still:

- Use third-party slicers with Bambu Connect.

- Operate the printer completely offline.

- Send files directly to the printer in LAN mode, without cloud connectivity requirements.

- Downgrade firmware to a previous version if needed.

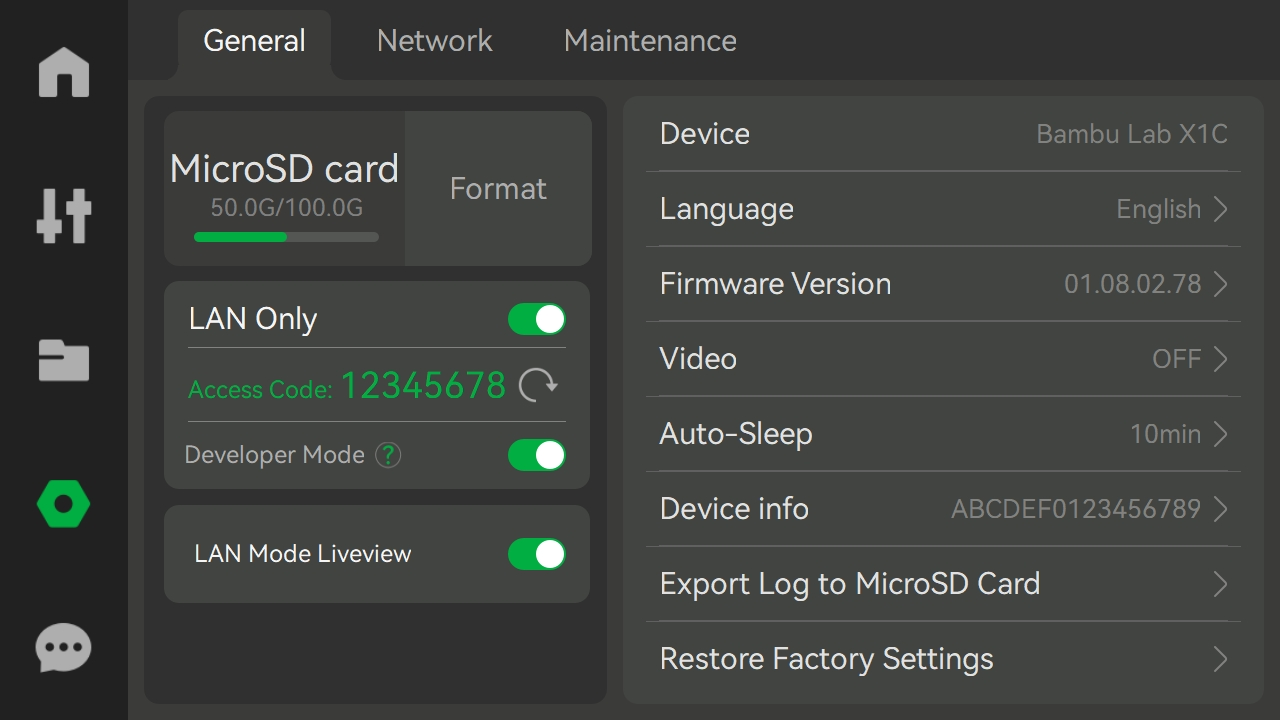

Developer Mode (Available in "LAN Mode")

- When enabled, Authorization Control will be disabled, allowing the printer to accept all control instructions without verification.

- This mode is intended for advanced users who want full control over their printer’s security.

- A dedicated guide for how to enable Developer Mode is available in How to enable Developer Mode on Bambu Lab printers.

¶ Bugs Fixed

SuperTack Build Plate Recognition

- Fixed an issue where the printer did not correctly recognize the SuperTack build plate type.

"TPU for AMS" Filament Settings in AMS

- Resolved an issue that prevented "TPU for AMS" from being set correctly in AMS filament settings.

¶ Things to know before updating

To ensure a smooth update process, please make sure to update both Bambu Studio and Bambu Handy to the latest versions before proceeding:

- Bambu Studio: v01.10.02.76 or later

- Bambu Handy: v2.17.0 or later

For more details, please visit: Third-party Integration with Bambu Lab Products

¶ Version 01.08.02.00 (20240812)

¶ New function

Supports updating the firmware from a microSD card. For detailed information, please see Update firmware from microSD card.

¶ AMS version 00.00.06.44 (20240722)

Updated the database to read the RFIDs of newly released filaments

¶ AMS hub version 00.00.00.43 (20240722)

Fixed a low chance(<0.1%) filament loading failure issue with the AMS hub

¶ OTA version 01.08.00.00 (20240507)

¶ Feature Optimizations

- Added filament verification for "Reducing purging through retracting filament" function

A long retraction during filament change can significantly reduce the purge volume, but it may cause clogging when the filaments assigned in the sliced file do not completely match the actual filaments in use. The filament verification function will verify the filaments match before performing retraction.

This function needs to be used with the slice files generated by Bambu studio v01.09.00.67 and above. For more information about the "Reducing purging through retracting filament" function, please refer to the Bambu studio release notes.

- Added support for using third-party custom filaments on the Bambu Handy side

Add third-party custom filaments to the Bambu Studio filaments library. You can set the existing filament type on the Bambu Handy side to the third-party custom filaments added in Bambu Studio.

- Optimized the AMS hygrometer Icon.

- Support the display of newly released translucent filaments in Mosaic style corresponding to the colors

- Improved firmware update issues

- Added support for network connections under the 802.11w protocol

- Optimized wifi connection stability

- Optimized the filament auto-mapping logic when printing with AMS. The color slot that cannot be mapped would need to be manually assigned filament before printing

- Optimized ntp time synchronization

¶ Bugs fixed

- Fixed the live-view lagging issue caused by a WiFi driver bug

- Fixed intermittent connection failure when switching from encrypted to non-encrypted connection

- Fixed the video resolution switch glitch problem: when switching resolutions, the resolution switch displays glitching intermittently between different resolutions

- Fixed the problem that the light on the toolhead is not correctly turned off after the print completion. In conjunction with Bambu Studio v01.09.00.70 and above

- Fixed the abrupt fan speed transition problem when the chamber cooling fan automatically adjusts the speed according to the starting Gcode of certain filaments

- Fixed the false alarms of extrusion failure caused by reducing purge through retracting filament function

- Fixed screen memory leak issue

- Fixed the problem of automatic temperature control failure after power-loss recovery

- Fixed the false report of abnormal temperature control when the heating bed is set to 120 °C.

¶ Remaining issues

After upgrading to the latest version (v1.8.0.0), Bambu Studio may falsely report that there is a new version available. Clicking on the upgrade button at this point will result in a failed upgrade. (The prompt for the new version of the device is based on the printer screen and Bambu Handy)

¶ OTA version 01.07.03.00 (20240408)

¶ Feature Optimizations

- Add filament verification for the "Reducing purging through retracting filament" function

A long retraction during filament change can significantly reduce the purge volume, but it may cause clogging when the filaments assigned in the sliced file do not completely match the actual filaments in use. The filament verification function will verify the filament match before performing retraction.

This function needs to be used with the slice files generated by Bambu studio v01.09.00.67 and above. For more information about the "Reducing purging through retracting filament" function, please refer to the Bambu studio release notes.

¶ OTA version 01.07.02.00 (20240112)

¶ Feature Optimizations

- Refine the log system and remove all debug logs that are not necessary for end-users. Thanks to X1plus team's feedback.

- Enable users to determine whether to export G-code and camera-recorded files when exporting logs from the SD card.

¶ Bugs fixed

- Fixed intermittent AMS retraction failure issue.

- Fixed the intermittent Wi-Fi connection failure when switching between encrypted and non-encrypted hotspots.

¶ Remaining issues

- The custom automatic flow calibration presets with custom names cannot be saved when powered off.

¶ OTA version 01.07.01.00 (20231222)

¶ Improvements

- Optimized the communication between printer and cloud service to provide faster notification push.

¶ Bugs fixed

- Resolved the intermittent greyed-out of the region select buttons.

- Resolved the bug where the user cannot initiate print while selecting the support filament(Support-W and Support-G) from the printer screen.

¶ Remaining issues

- The custom automatic flow calibration files with custom names can not be saved when powered off.

¶ OTA version 01.07.00.00 (20231211)

Motor Noise Cancellation and improved support for third-party filament on the X1 series printers. We have also enhanced user experience by streamlining the printer binding process and upgrading the interface.

Key enhancements in V.1.7 are:

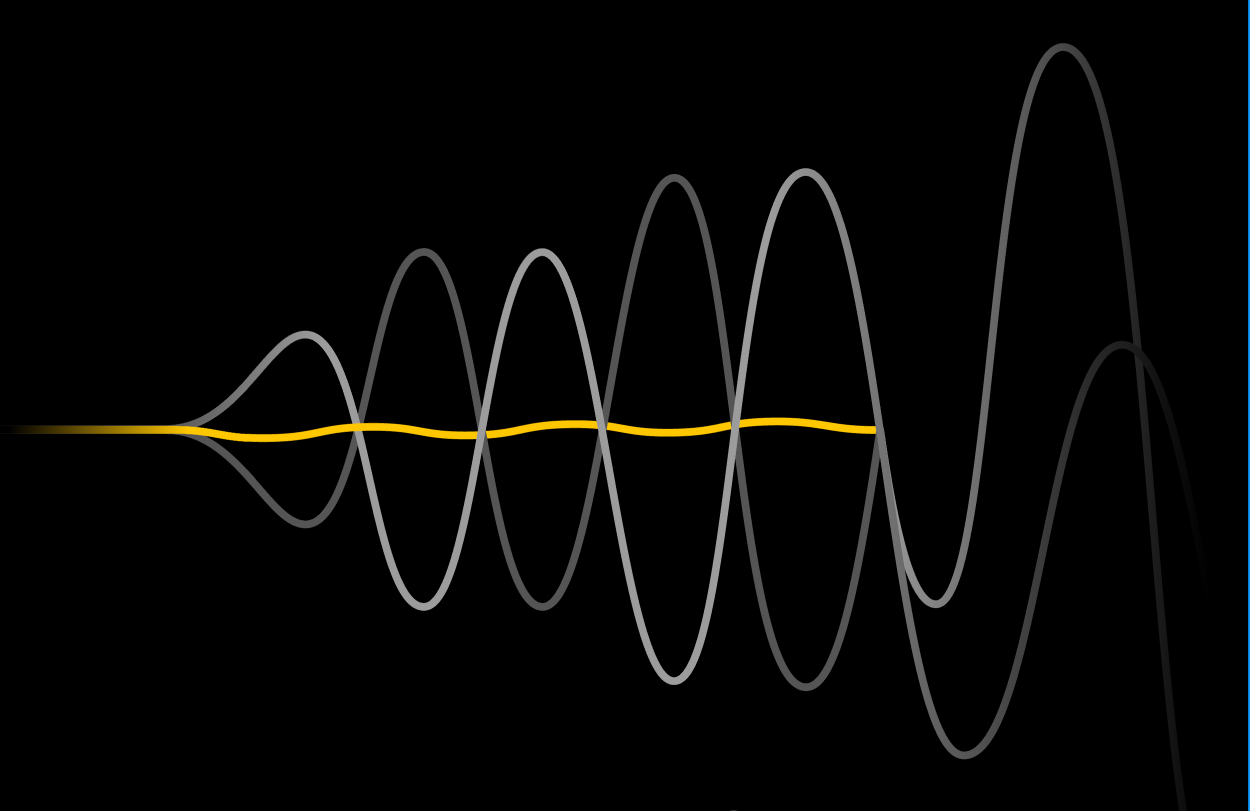

- Active Motor Noise Cancellation tailored for the X1 series.

- Import functionality for user-created third-party filament profiles (compatible with Bambu Studio V1.8.1).

- An improved UI Menu Structure, offering more intuitive navigation.

- Decreased Screen Interface Latency, ensuring faster user interactions.

- Simplified printer binding with mobile devices, eliminating the need for both devices in the same LAN.

For a more detailed overview of each feature, please refer to the information provided below.

¶ Improvements

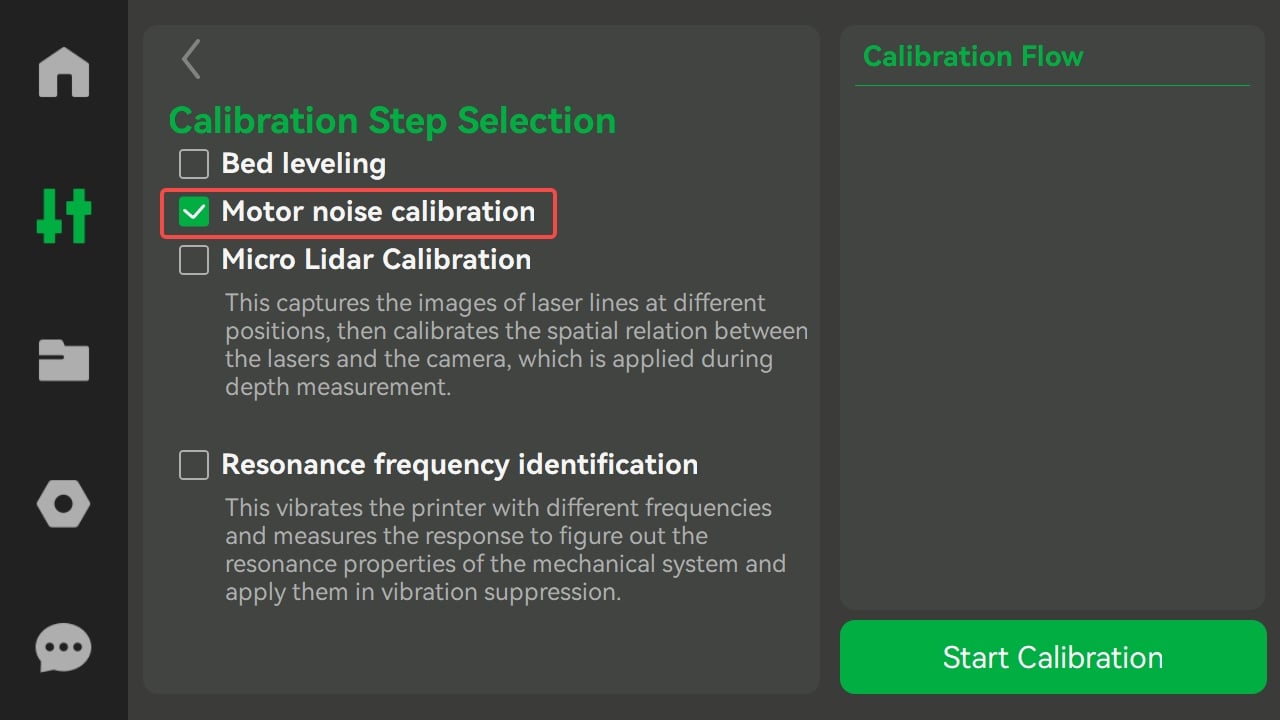

¶ 1. Motor Noise Cancellation

The widely acclaimed Motor Noise Cancellation feature from the A1 mini is now available for X1 series printers. This innovative feature reduces motor noise during long-line movements and mitigates the humming sound associated with high-speed printing. Additionally, it slightly improves Vertical Fine Artifacts (VFA), resulting in smoother printed walls. (The VFA is correlated to a lot of factors, including filament condition, print speed, and extrusion calibration. The improvement provided by Motor Noise Cancellation can vary under different circumstances.)

Please remember to run the calibration after updating the firmware to properly activate this feature. You can find the calibration option under the Control-Utilities menu. The process will take approximately 10 minutes.

We also have a short video introducing this function.

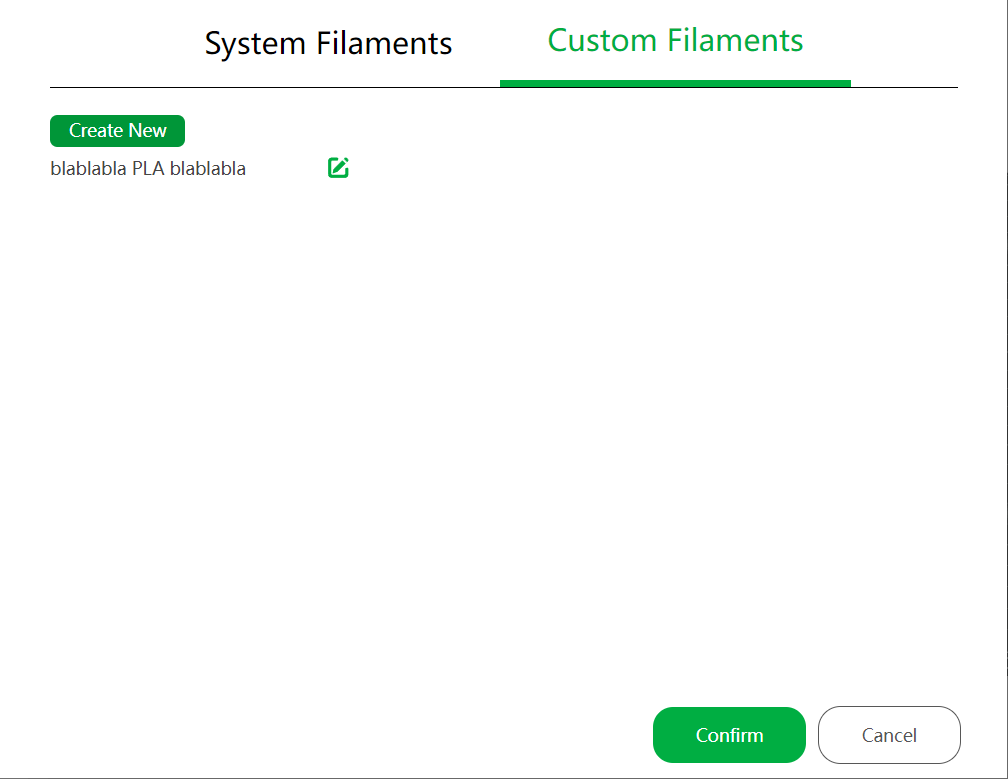

¶ 2. Enhanced third-party filament support (in conjunction with Bambu Studio V 1.8.1 and up)

With Bambu Studio v1.8.1, users now have the ability to create, modify, and delete custom filament profiles, which are saved in your Bambu account. We've created a guide detailing how to establish a custom filament preset and utilize this new feature. Please check it here: How to Create Custom Preset

Your X1 printer can now sync these custom filament presets with your account. You'll find these presets available in the filament selection slots when manually choosing your filament settings.

Please be aware that if you log out from the printer and the device is disconnected from the cloud, the custom filament information on the printer won't be immediately removed. It will only be cleared when another account is bound to the printer. The custom filament data associated with the new account will then be synchronized, assuming you follow the steps outlined in the guide linked above.

¶ 3. Improved Screen Interface Latency

The screen interface latency has been improved in this firmware version, so you can expect slightly faster interactions when using the touchscreen.

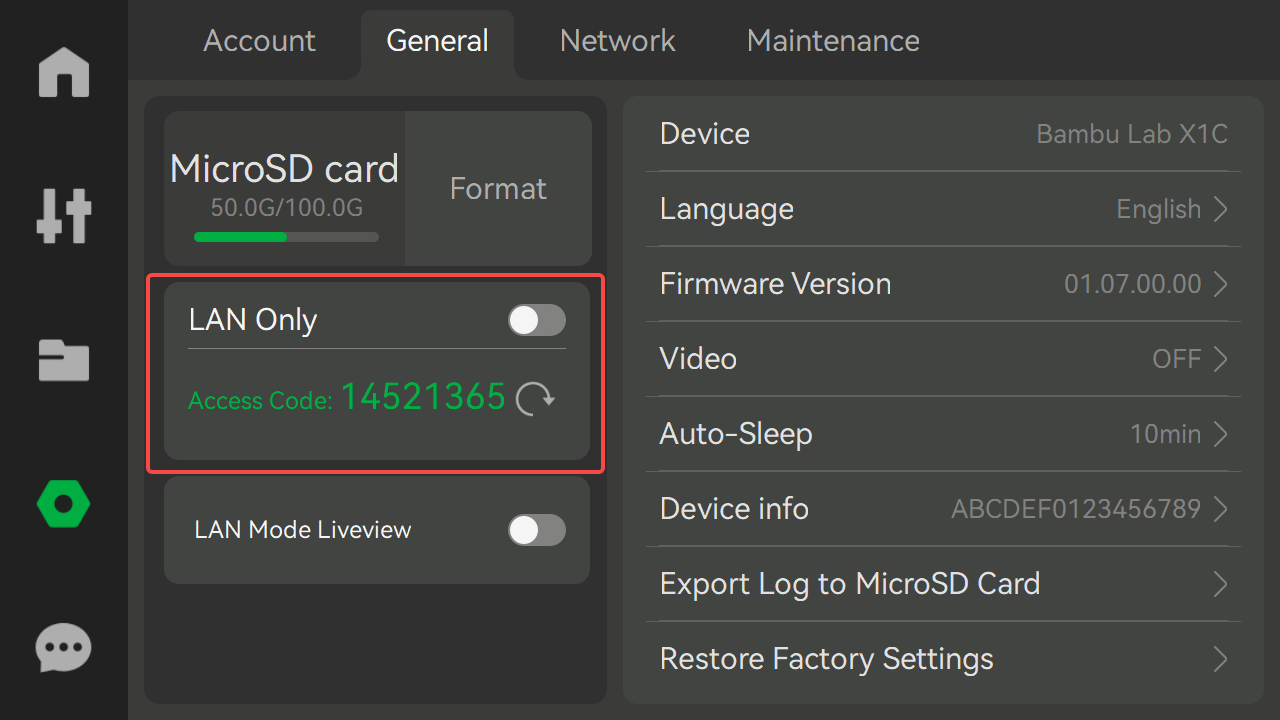

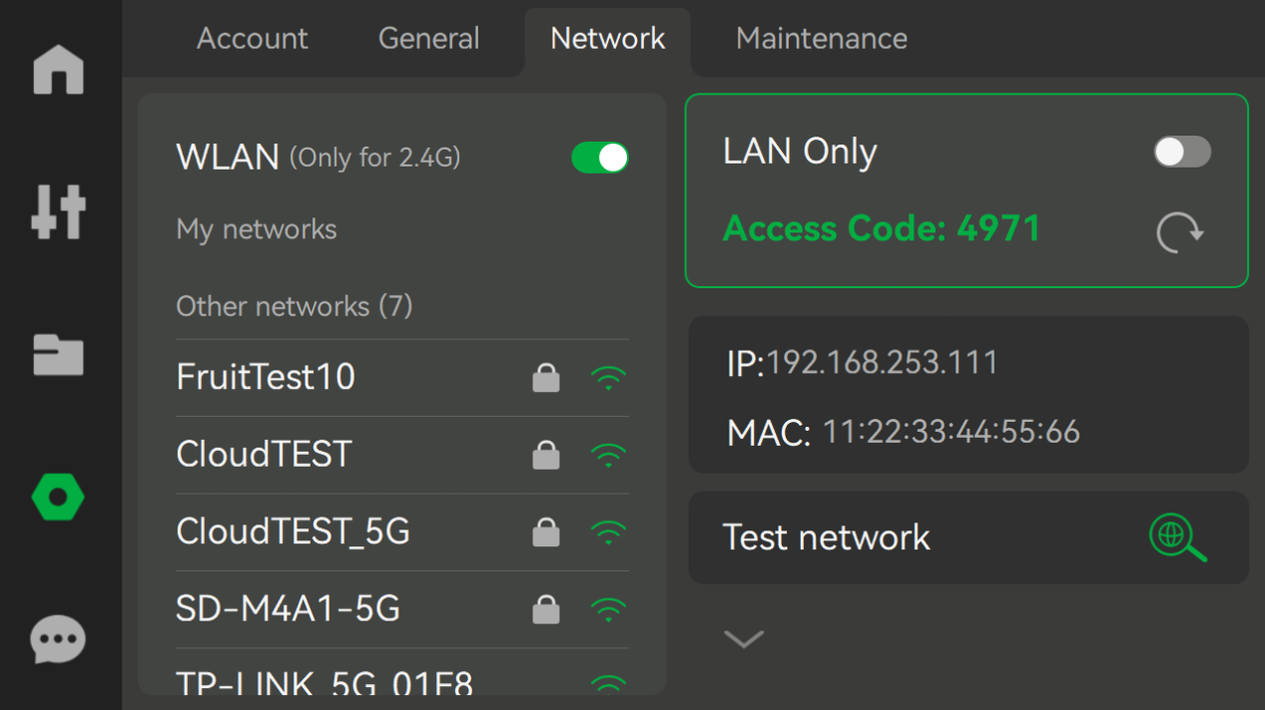

¶ 4. Improved UI Menu Structure

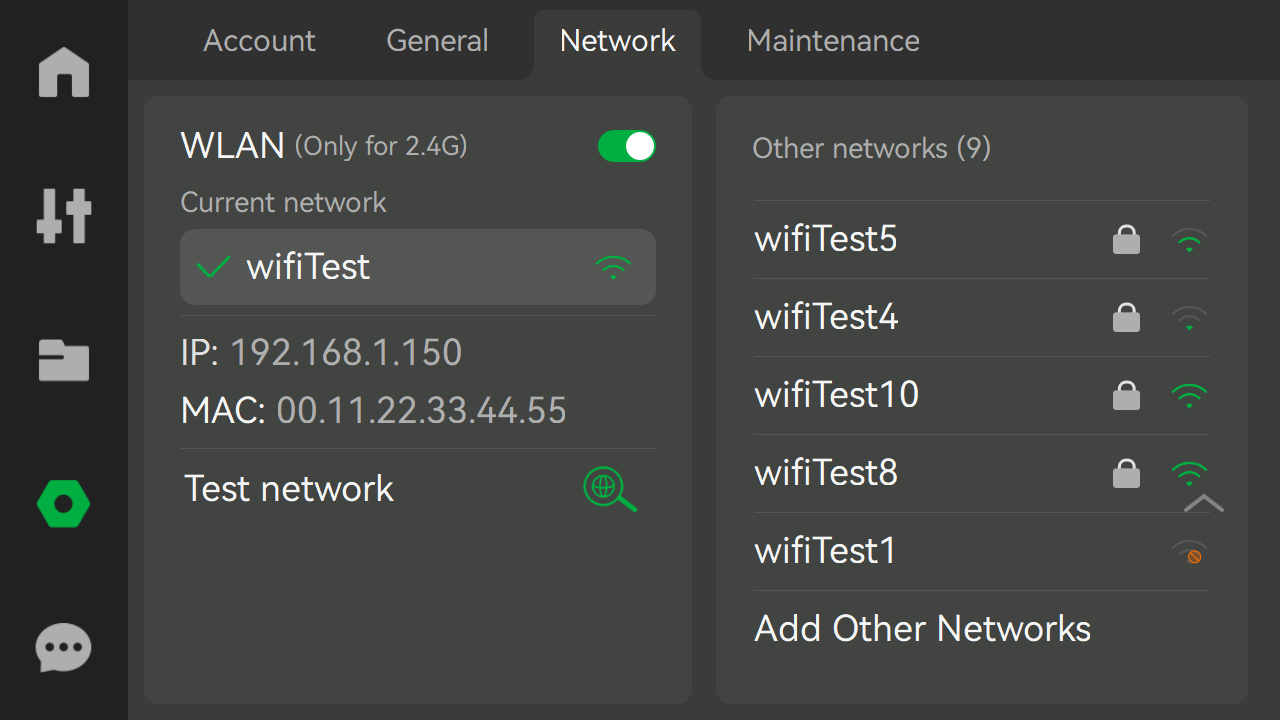

We have optimized the structure of the settings page by relocating the LAN Only mode option from the Network page to the General page, and we have optimized the UI display of the Network page.

We have also moved the access code information from the "Network" page to the "General" page, and moved the "Video" switch to the list on the right.

To provide a better display of the list of Wi-Fi networks, and the network information, we have optimized the layout of the "Network" page as shown below.

¶ 5. Simplified Binding Prerequisite.

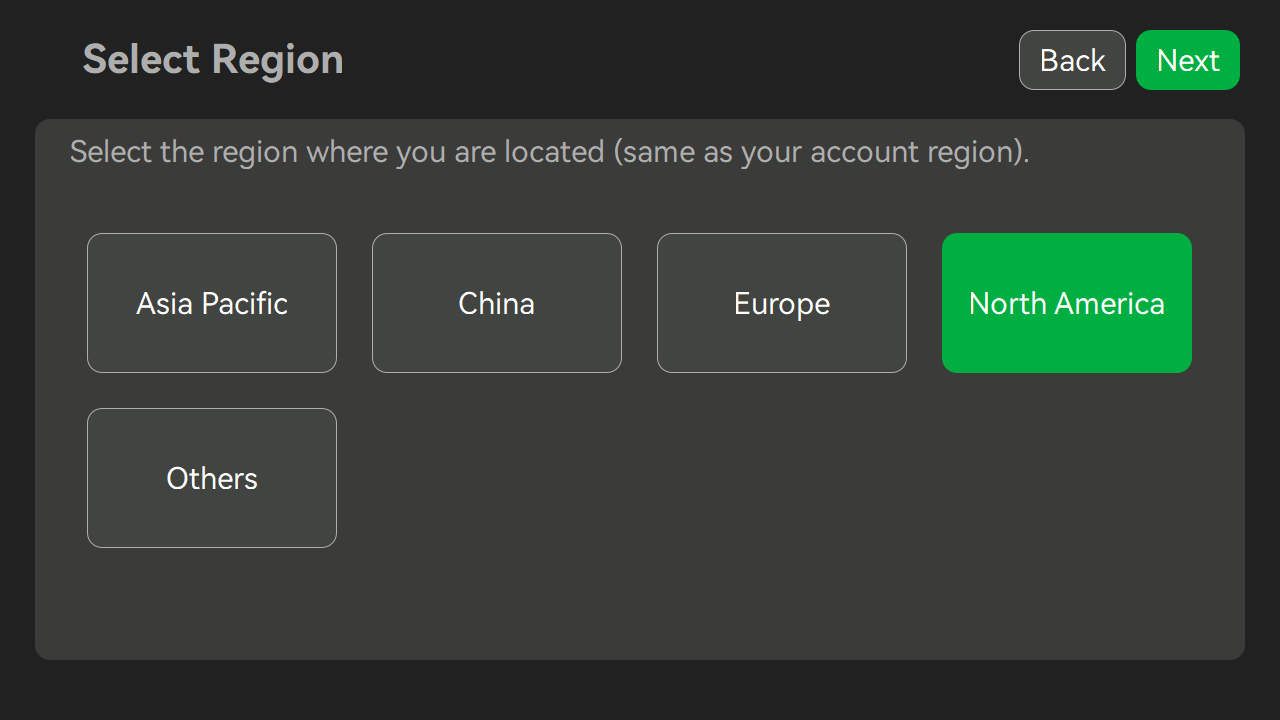

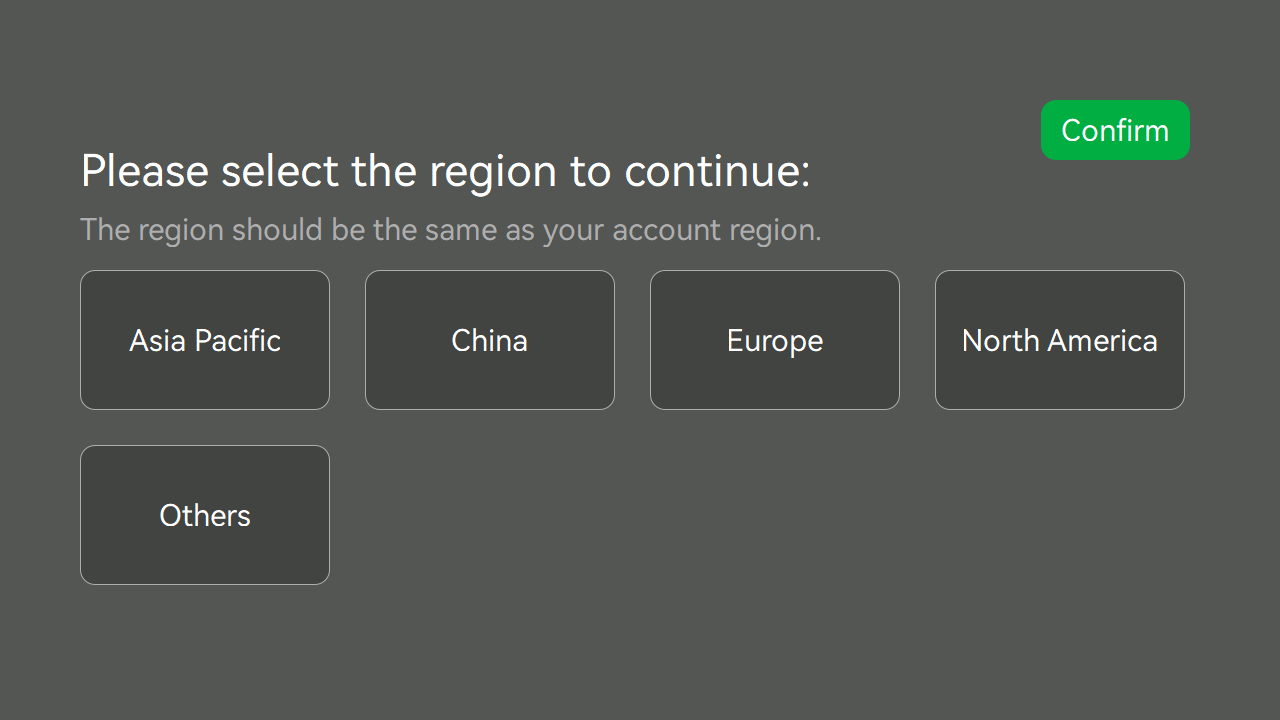

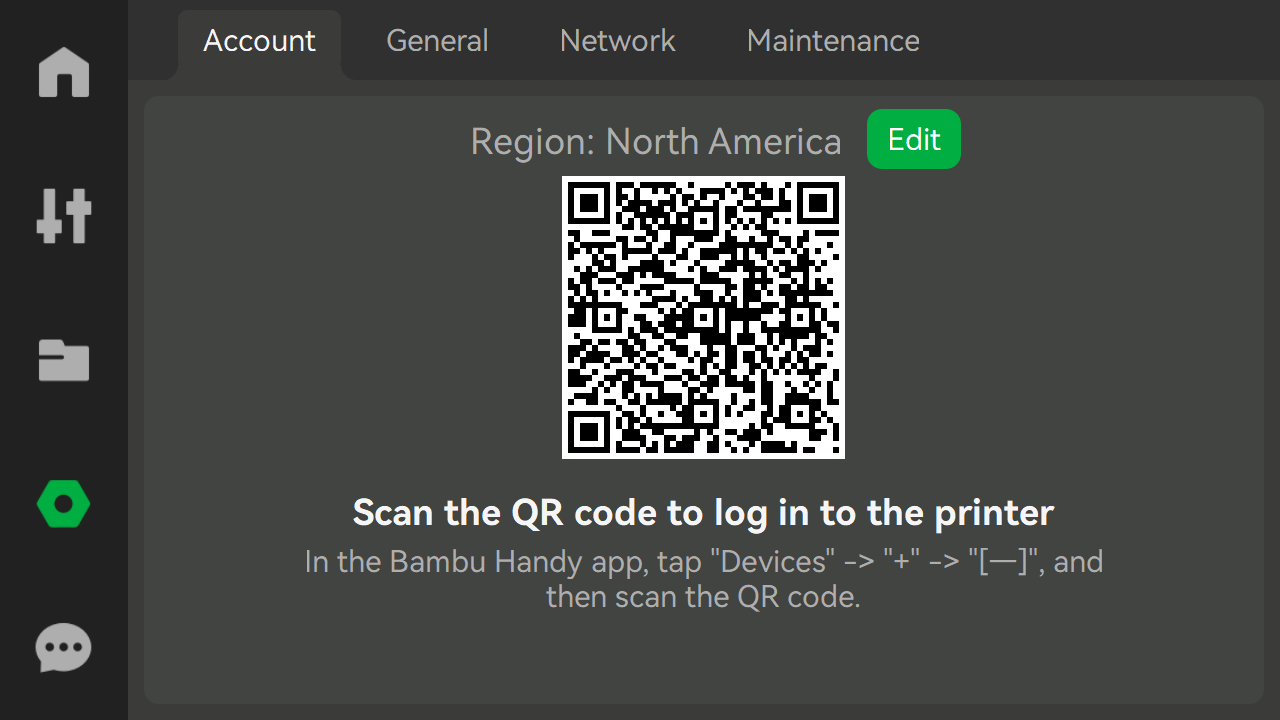

In previous firmware versions, when binding the Bambu Handy app to the printer by scanning the QR code, both devices have to be on the same LAN network. Starting with this firmware version, users can perform the binding operation without the need to have both devices on the same LAN.

For this function to work, the region selected on the printer screen must be consistent with the account region selected under the account used in Bambu Handy.

The region selection has been added on the first boot page after the update has been completed.

You can check the account user region under the Settings -> Account page. If you ever need to change the region, you can do so after logging out of the printer and performing the binding operation again.

¶ Bugs fixed

- Fixed the calibration parameters saving issue.

- Fixed the issue related to the inability to reach the desired temperature and feed filament properly after power outage and machine restart when there is a filament shortage or tangle issue in AMS.

- Fixed the issue of failed bed leveling during printing due to the lack of selecting the resonance frequency recognition option for calibration.

- Fixed the occasional issue of filament retraction failure after printing was completed.

- Fixed some incorrect text that appeared in errors and pop-up windows.

- Other minor bugs

¶ Remaining Issues

- The custom automatic flow calibration files with custom names can not be saved when powered off.

¶ OTA version 01.06.05.01 (20230921)

¶ New Features

Modify objects skip feature text to remove text that does not support multi-colours.

[Experimental] Added Flow Rate Calibration for 0.2mm and 0.6mm nozzles.

[Experimental] Added Flow Dynamics Calibration for 0.6mm nozzles.

¶ Bugs Fixed

Improved AI detection to reduce occasional false alerts of "Micro Lidar camera lens seems to be dirty".

Addressed the issue where AI monitoring occasionally fails to pause properly after detecting abnormalities.

Optimized the display issue of PLA_AERO filament on the device screen.

Optimized some issues in the printing process, such as compatibility with special character model names and fixed the problem where the Handy app and Studio still showed "printing" status after the print was stopped.

¶ Remaining Issues

The printer may appear stuck in a paused state while the AMS shows an error. There may be dropped steps if users move the XYZ axes away from the disposal chute, so please do not move the toolhead in this situation.

If the power is suddenly cut off after the detection of a filament break, the printer may attempt to continue printing without filament.

¶ Version AMS ota00.00.06.40(20230921)

¶ Improvements

Optimized the protocol of filaments with AMS

¶ OTA version 01.06.03.00 (20230822)

¶ Bugs fixed

Fixed the issue of layer shift & step loss when printing internal models.

¶ Remaining Issues

The printer may appear stuck in a paused state while the AMS shows an error. There may be dropped steps if users move the XYZ axes away from the waste chute, so please do not move the tool head in this situation.

If the power is suddenly cut off after the detection of a filament break, the printer may attempt to continue printing without filament.

¶ OTA version 01.06.01.00 (20230804)

¶ Improvements and bugs fixed

Improved printing quality and stability by optimizing the flow dynamics calibration process

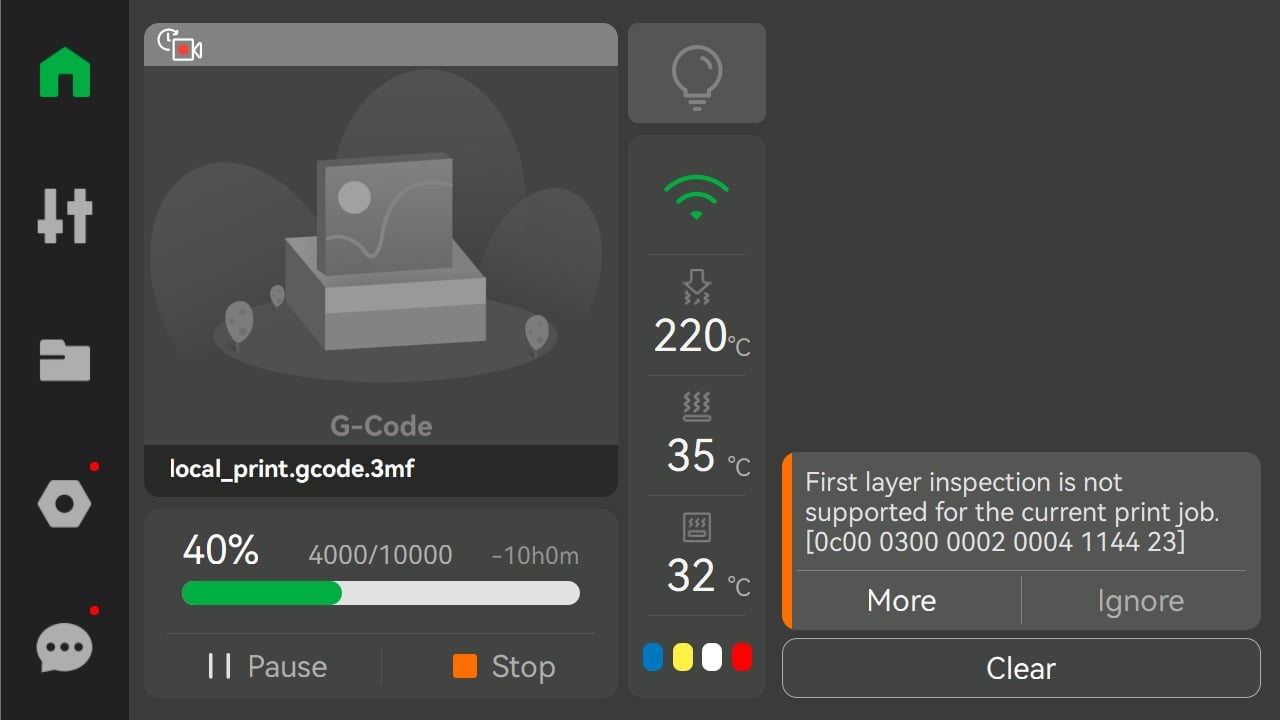

Fixed the missing "Resume" option when the first layer inspection was abnormal.

¶ Remaining Issues

The printer may appear stuck in a paused state while the AMS shows an error. There may be dropped steps if users move the XYZ axes away from the waste chute, so please do not move the tool head in this situation.

If the power is suddenly cut off after the detection of a filament break, the printer may attempt to continue printing without filament.

It is possible that the printer printing built-in models will happen step loss

¶ OTA version 01.06.00.00 (20230801)

¶ Summary

- Added protection to prevent the heatbed touching the bottom

- Added support for model objects being skipped when printing

- Added support for Liveview via LAN Mode Liveview switch when the device is in LAN mode

- Added Auto Refill page to show filaments to be used for filament backup

- Improved dynamic flow calibration on a PEI plate and reduced the print area usage as much as possible

- Added support for MicroSD file management via Bambu Studio

- Added parameters of extrusion compensation being auto-calibrated and saved

- Added absolute flow calibration

- [Experiment]Added support for first-layer detection on PEI plates

- Improvements and bugs fixed

- Remaining Issues

Dear X1 series users,

Long time no see.

After several rounds of internal iterative feature development, ota version 01.06.00.00 has finally been officially released. We will proudly introduce you to the main features of this update in the following pages. In response to your requests, we have added support for hot bed bottoming prevention to enhance the protection of the hot bed during the printing process, added automatic calibration and saving of extrusion compensation parameters, flow rate calibration to improve user experience (Studio requires v1.7.0 and above), and added support for skipping objects (Handy requires v1.2.5 and above, Studio requires v1.7.0 and above).

In addition, we have added some new features such as viewing liveview in LAN Only Mode, dynamic flow calibration for PEI plates, MicroSD file management with Bambu Studio, and an Auto Refill page to change filament backup settings. We have also made a lot of feature optimizations and problem fixes in this version of the firmware, which we hope will bring you a better user experience

We hope this update meets your expectations, and we welcome any feedback you may have!

¶ Added protection to prevent the heat bed from touching the bottom

There was a bug present in previous versions of the firmware where if a print was started when the heatbed was very close to the bottom, the bed would try to move further than possible, generating some motor skips. This issue did not cause any damage, but we have fixed it in this firmware version, with G38/G380 S2 cmd added. (this bug fix requires a file sliced with the latest version of Bambu Studio)

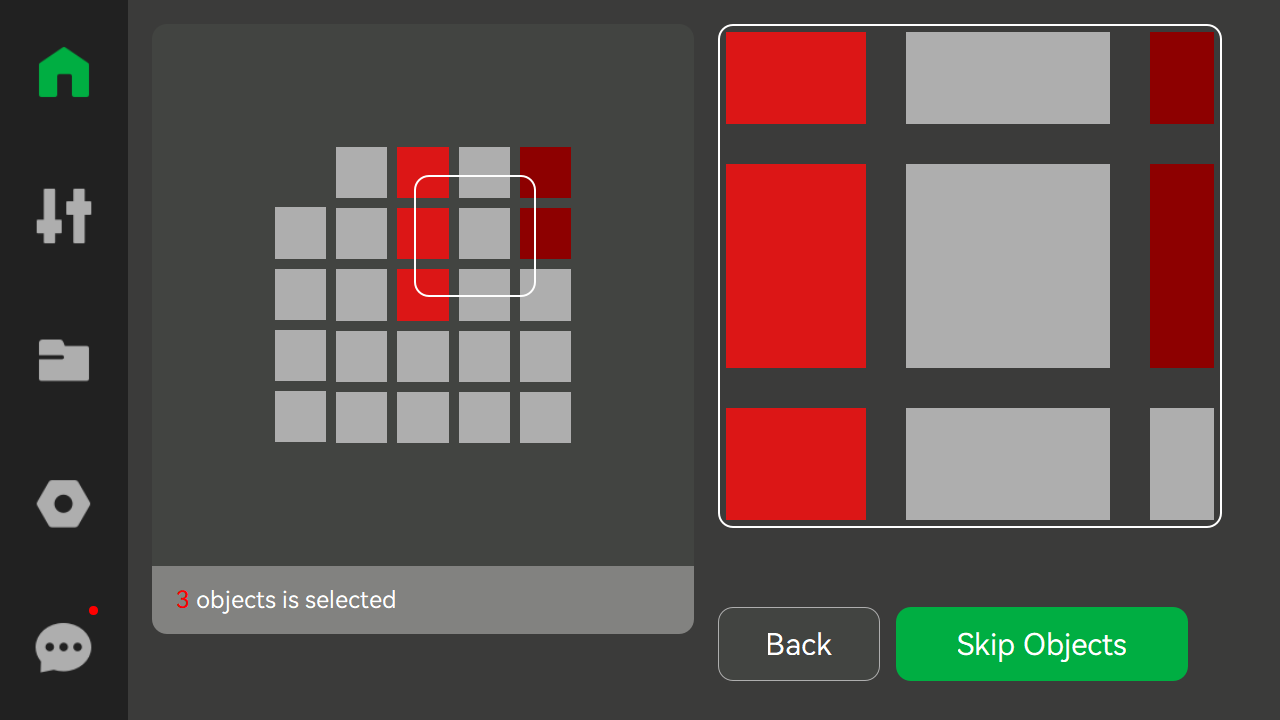

¶ Added support for model objects being skipped when printing

This feature is useful when you are printing a large number of models and one of them fails. In this case, you will be able to select that particular object and ask the printer to ignore it so you can continue printing without losing the other models.

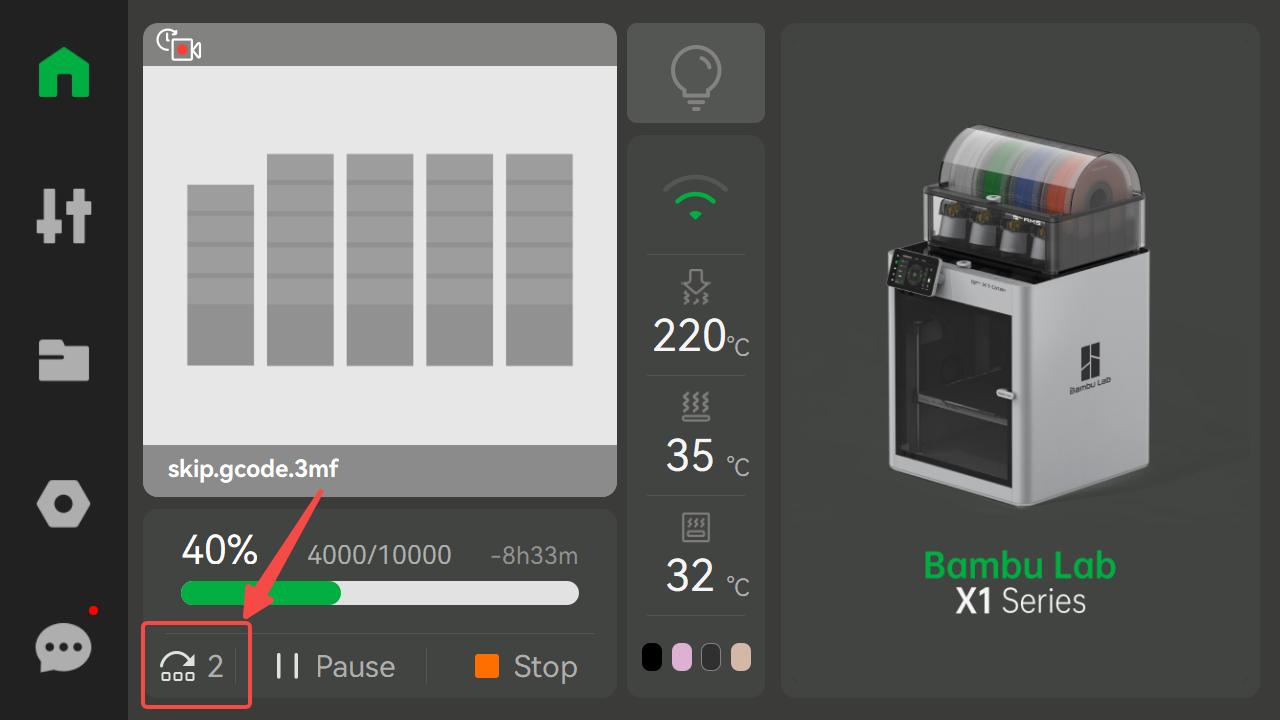

There is a new button on the screen interface, next to the Pause button, which can be tapped and an object selection will appear to allow canceling the item which is not printing as expected.

Please Note: Skipping objects is not supported in the following situations:

- multi color printing

- over 64 objects in a single plate

- Bambu Studio version is lower than v1.7

¶ Added support for Liveview via LAN Mode Liveview switch when the device is in LAN mode

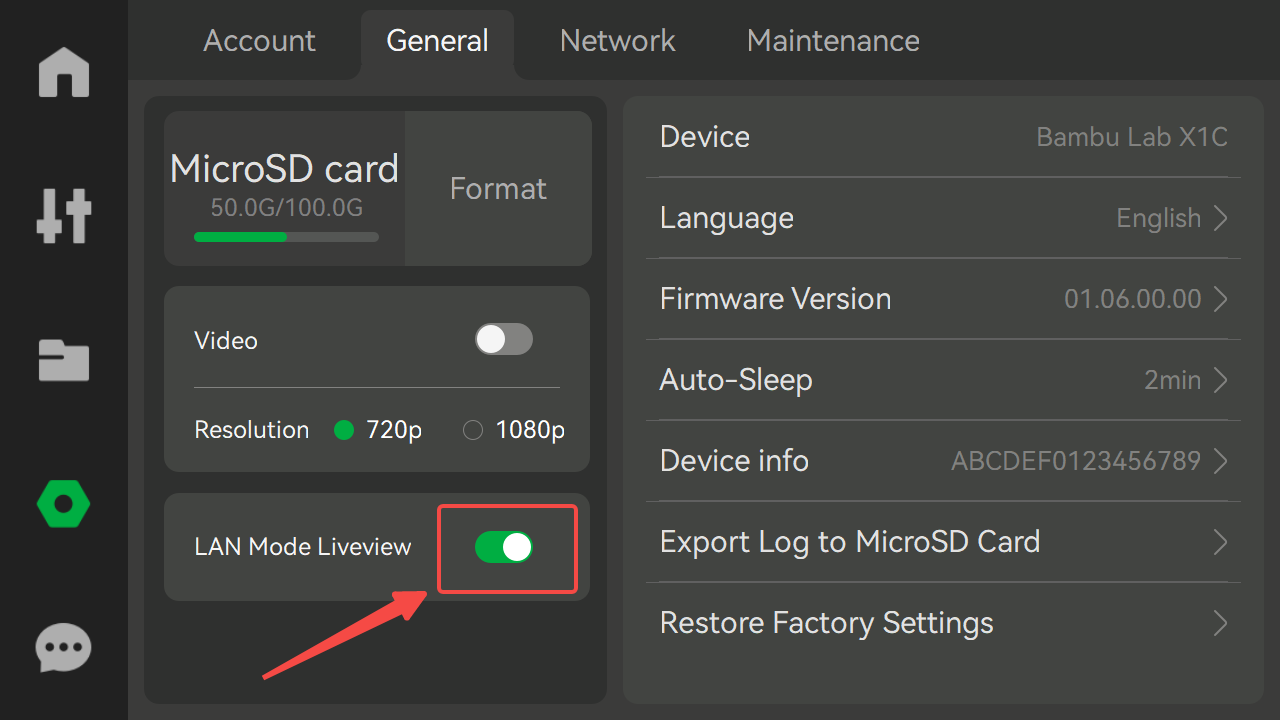

To make it easier for our customers that want to print offline, we have added support for Liveview in LAN mode. This means that you can access the video stream of the camera on your printer even if the machine is not directly connected to the internet.

To enable it, navigate to Settings -> General and enable Lan Mode Liveview.

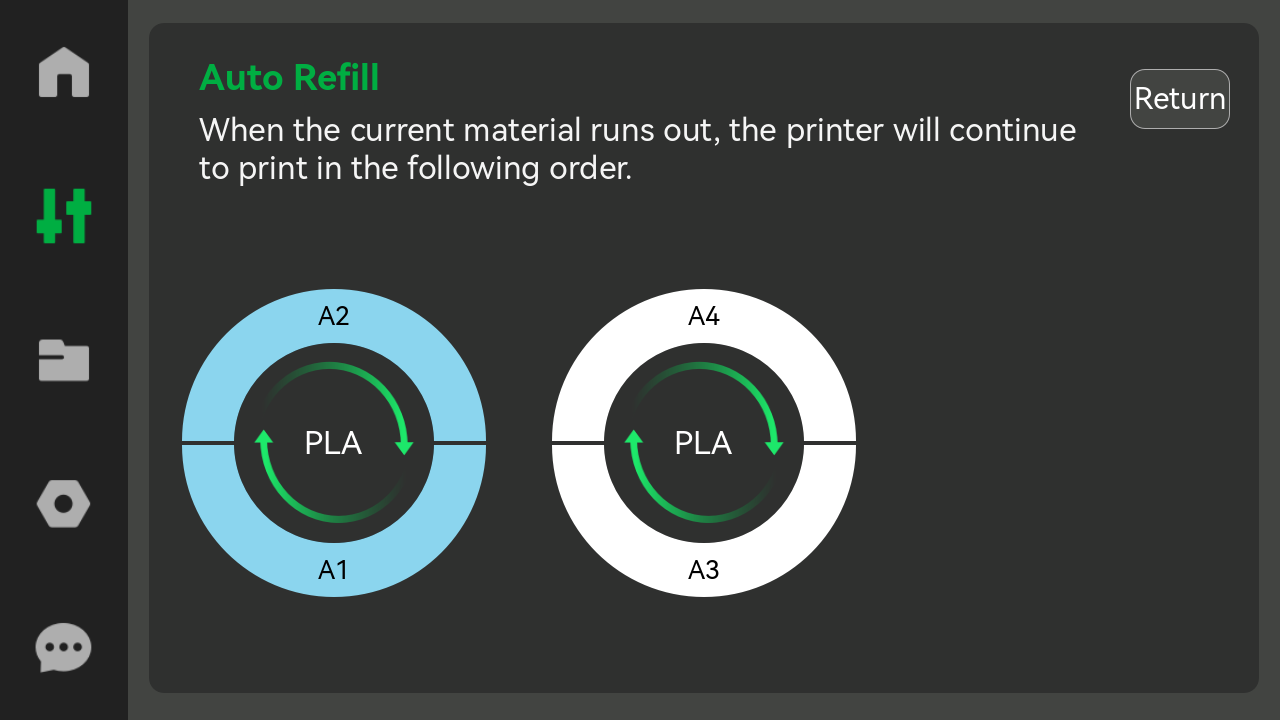

¶ Added Auto Refill page to show filaments to be used for filament backup

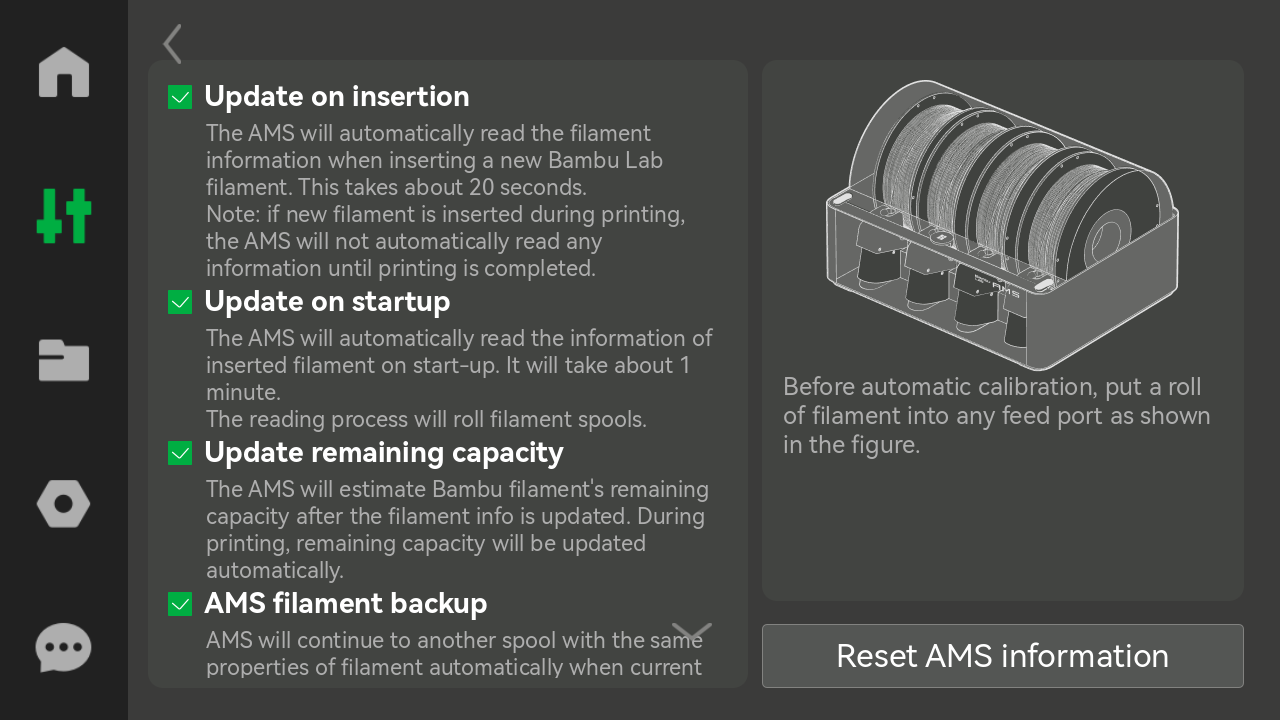

In the "AMS filament backup" feature, the AMS will switch to another spool with the same properties (brand, type, color, nozzle temperature, etc) automatically when the current filament runs out, but failures caused by the inconsistencies in filament properties may not be discovered until a "run out" error is reported during printing. The new "filament backup" page helps users to check whether the backup relationships are correct before printing.

This feature can be used by following these steps:

a. Check the "AMS filament backup" function on the AMS settings page.

b. Add two spools of the same Bambu filaments in slot1 and slot2, and add two of the same third-party filaments in slot3 and slot4 as shown in the image below.

c. Click the "Auto Refill" icon on this page. You will notice that filaments with the same properties will be displayed in groups on the new page.

Please note that this feature does not support filament on the external spool holder and only works with the AMS

¶ Improved dynamic flow calibration on a PEI plate and reduced the print area usage as much as possible

Our team has worked on perfecting the dynamic flow calibration and first layer inspection methods to include support for the Textured PEI Plates. In the past, calibrating your printer's flow rate could provide bad calibration numbers. In this version, the results should be similar to printing on a smooth surface like the Cool Plate or Engineering Plate.

Please note that there's still a very small chance for the calibration not to work as expected. If you notice the print quality is not within expectations, we recommend calibrating on the smooth sheet.

¶ Added parameters of extrusion compensation being auto-calibrated and saved

In this version of the firmware, the flow dynamics parameter (similar to pressure advance in Klipper, or linear advance in Marlin) of the filament rows in the AMS now can be calibrated and saved in batches automatically. You can also calibrate the parameter manually and save it in the printer. For more detailed information please refer to our wiki article which explains this feature.

(Please note: the compensating algorithm used in the Micro Lidar calibrated parameter is different from the manually calibrated parameter, so you may find the auto-calibrated parameter is not the same as the manually calibrated result)

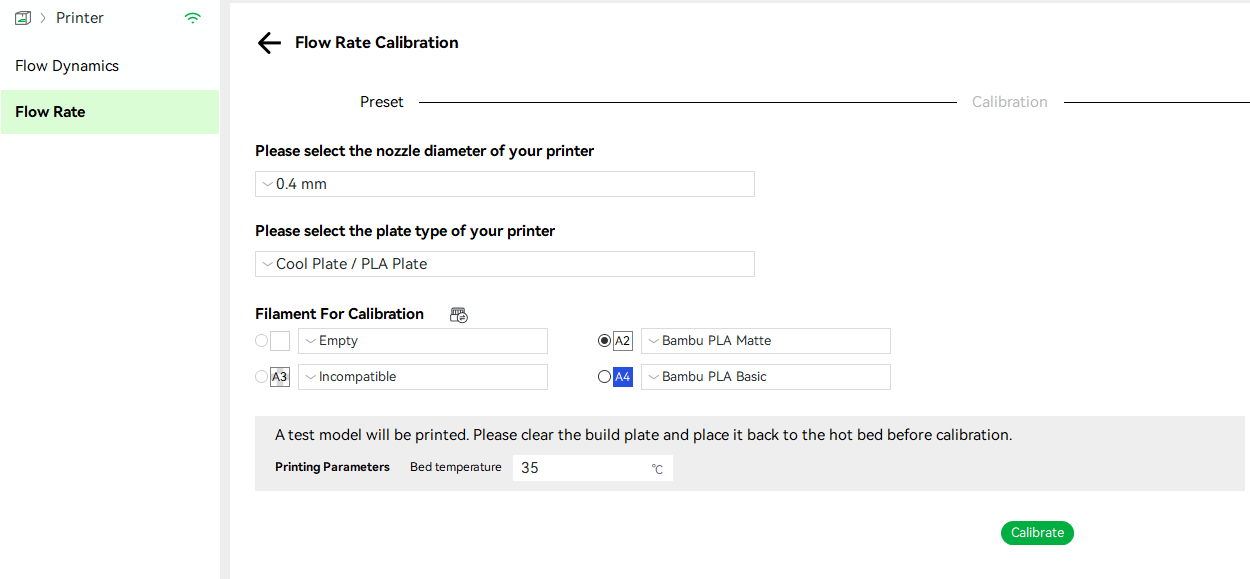

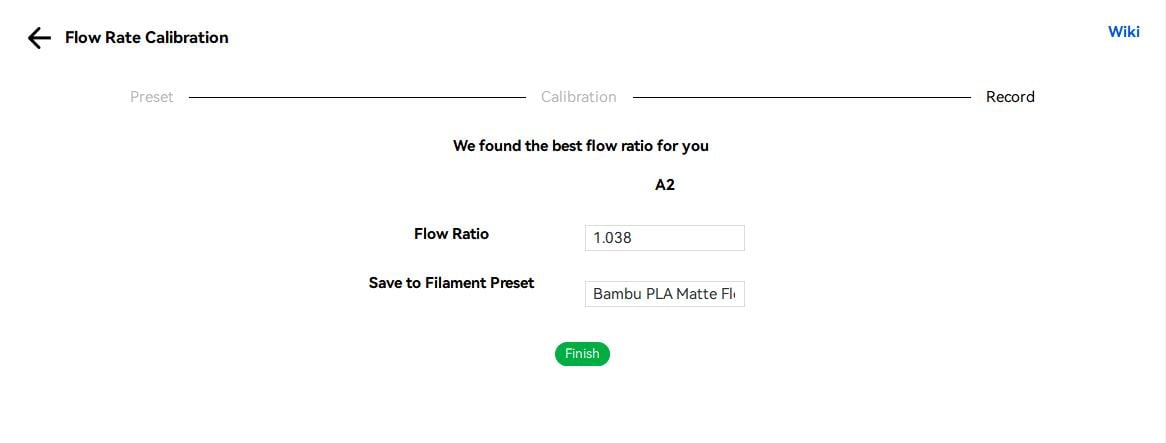

¶ Added absolute flow calibration

Starting with this version, the printer now possesses the ability to automatically calibrate flow rate using Bambu Micro Lidar. This advancement is driven by complex algorithms designed to enhance precision and efficiency.

The process involves printing a small calibration pattern, measuring the flow rate under various conditions, and smartly providing a recommended flow rate setting for improved surface quality.

You can initiate this feature from Bambu Studio by selecting the filament to be calibrated from the calibration screen. While the process takes a few minutes, upon completion, a recommended setting will appear which can be saved to a new filament profile for future use.

By using this feature, the printer can accommodate a wider range of materials. For example, it can improve print quality by calibrating for foaming materials and materials with inaccurate filament diameters.

(Please note: the compensating algorithm used in the Micro Lidar calibrated parameter is different from the manually calibrated parameter, so you may find the auto-calibrated parameter is not the same as the manually calibrated result)

This wiki page shows how to perform flow calibration from Bambu Studio and this wiki page describes more details and how it works.

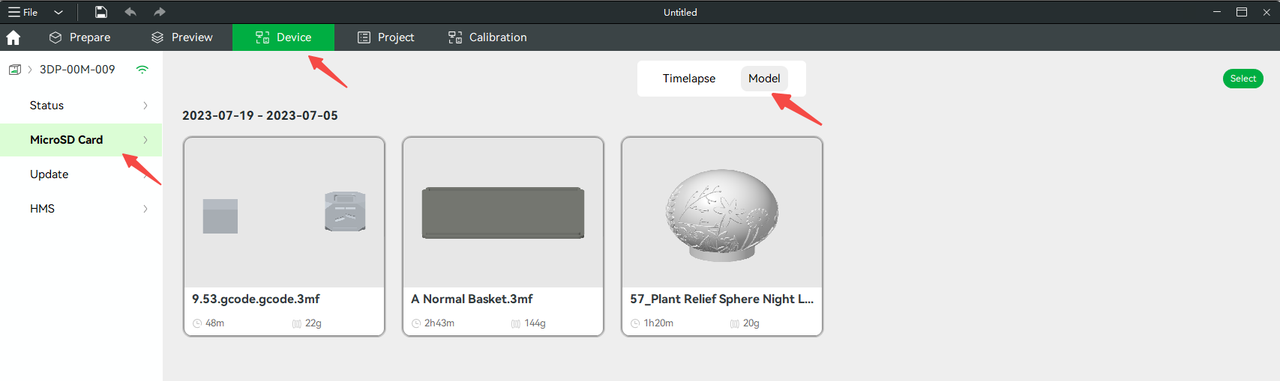

¶ Added support for MicroSD file management via Bambu Studio

We wanted to improve the user experience and interaction with the printer, so we introduced support for file management of files on MicroSD cards. You can now view, delete and print items from the available files on the MicroSD card right from Bambu Studio.

a. Select Device -> MicroSD Card -> Model

b.Hover the mouse over the model thumbnail to display options to delete, print, or download files

¶ [Experiment] Added support for first-layer detection on PEI plates

The uneven textured surface of the textured PEI build plate is not very friendly to the micro lidar, and first-layer scanning was not supported in previous firmware. We have improved the related algorithm, allowing users to take advantage of first-layer scanning on textured PEI plates, and works similarly to smooth build plates.

Please note just like the dynamic flow calibration feature, there is a chance for the detection not to work every time, depending on the first layer quality.

¶ Improvements and bugs fixed

¶ Improvements

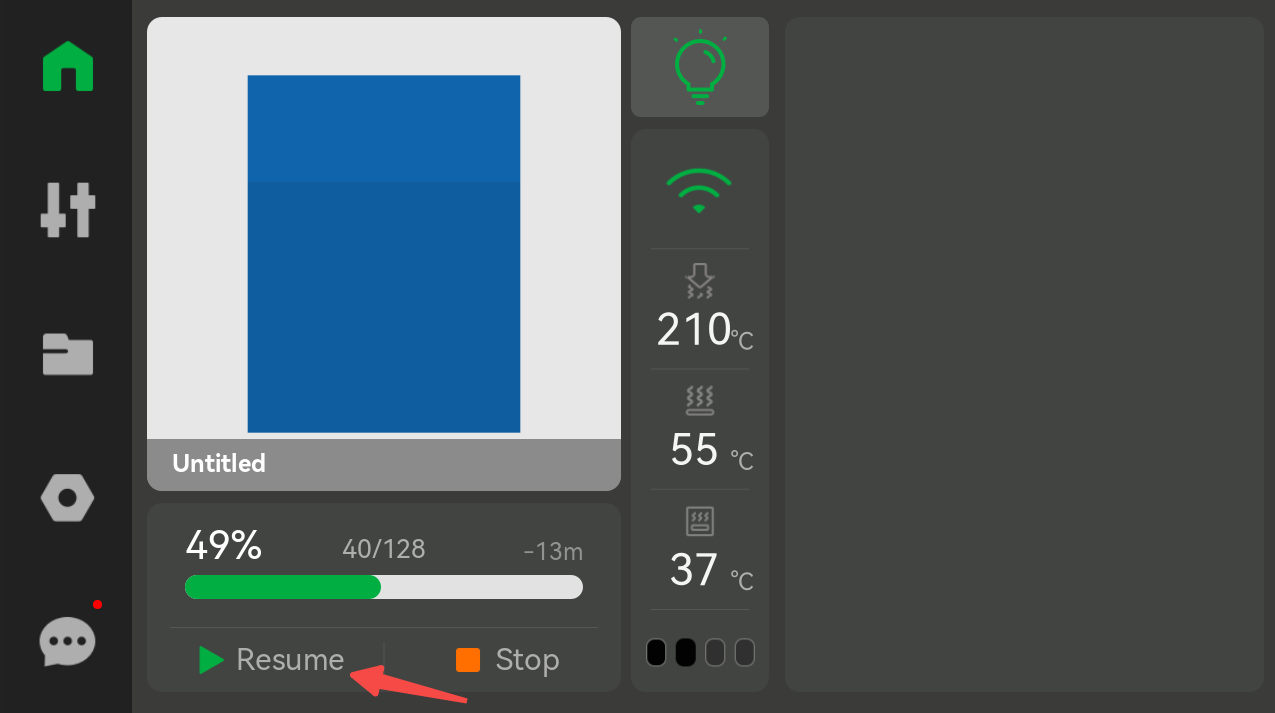

- Optimized pause and resume function. Customers can not only use the retry button, but also the resume button on the home page when the printer detects filament as being stuck.

- Added calibrate filaments when printing internal models to avoid using the wrong filament (only supported when using an AMS)

- Improved AI detection to reduce the false spaghetti detection rate

- Adjusted the listing of time-lapse videos to be displayed in reverse order (from the newest to the oldest)

- Optimized the text content for pop-ups and HMS

- Optimized the algorithm to resume the print after a power outage, reducing the probability of layer shifts when the print is restarted.

- Optimized the logic of user binding to improve the success rate

- Updated the privacy agreement

¶ Bugs fixed

Fixed some probable failure issues for resuming after a power outage

¶ Remaining Issues

The printer may appear stuck in a paused state while the AMS shows an error. There may be dropped steps if users move the XYZ axes away from the waste chute, so please do not move the tool head in this situation.

If the power is suddenly cut off after the detection of a filament break, the printer may attempt to continue printing without filament.

¶ OTA version 01.05.02.00 (20230613)

¶ Summary

- Added support for load/unload function (only with external spool holder) when printing is paused

- Optimized the filament setting and display logic

- Bugs fixed

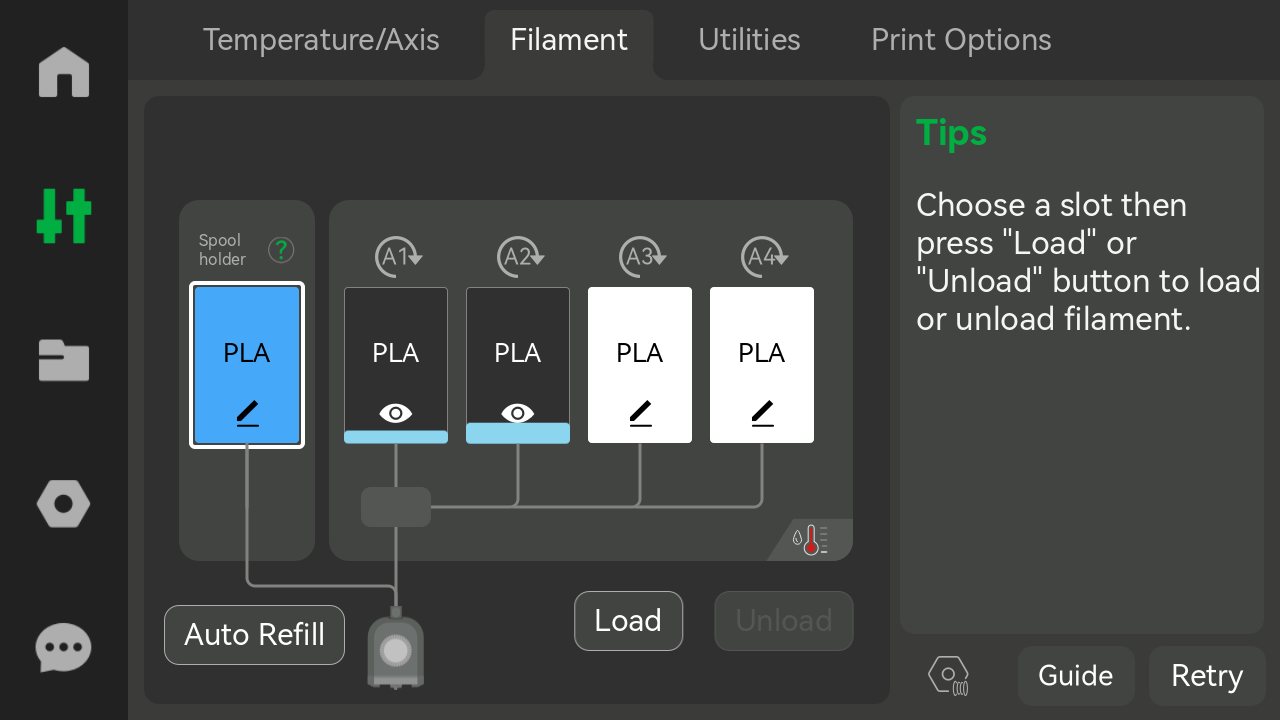

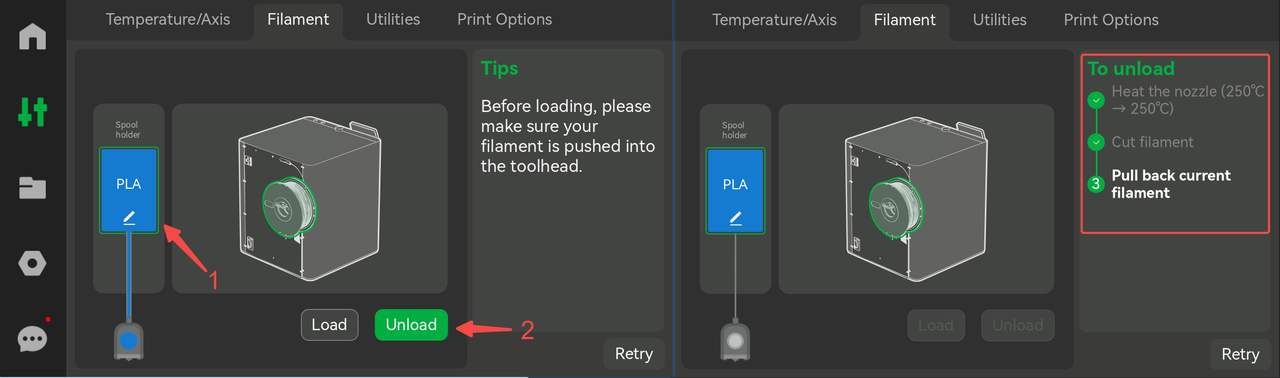

¶ Added support for load/unload function (only with external spool holder) when printing is paused

Pauses during printing usually occurs in the following scenarios:

- a. The filament on the external spool holder has run out, so the printer pauses automatically;

- b. Insert 'pause' at specific layer of the model to change filament.

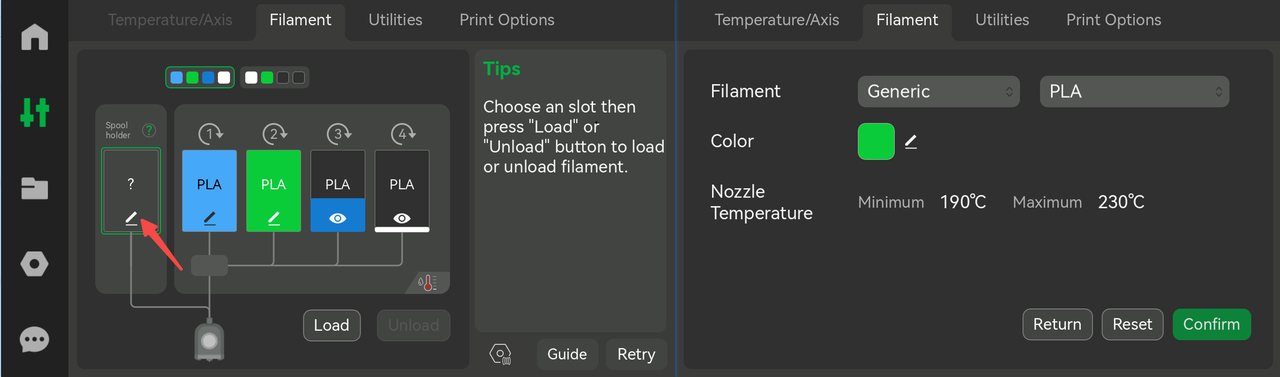

When printing is paused, please select 'spool holder' on the 'Filament' tab and click 'Load' or 'Unload' to load or unload filament on the external spool holder, and the corresponding process will be displayed on the right side.

After loading or unloading, please click the printer's 'Resume' to continue.

Tips:

- This feature currently only supports the external spool holder. Please use it in models that only use the external spool holder;

- If you need to insert a 'pause' at a specific layer of the model to change filament on the external spool holder, it is recommended to use filament of the same type to prevent abnormalities caused by mismatching printing parameters;

- For more information about the "loading/unloading filament on the spool holder" feature, please refer to the release note of OTA version 01.05.01.00 or the instructional video

https://www.youtube.com/watch?v=8Y0vCAYxvrU

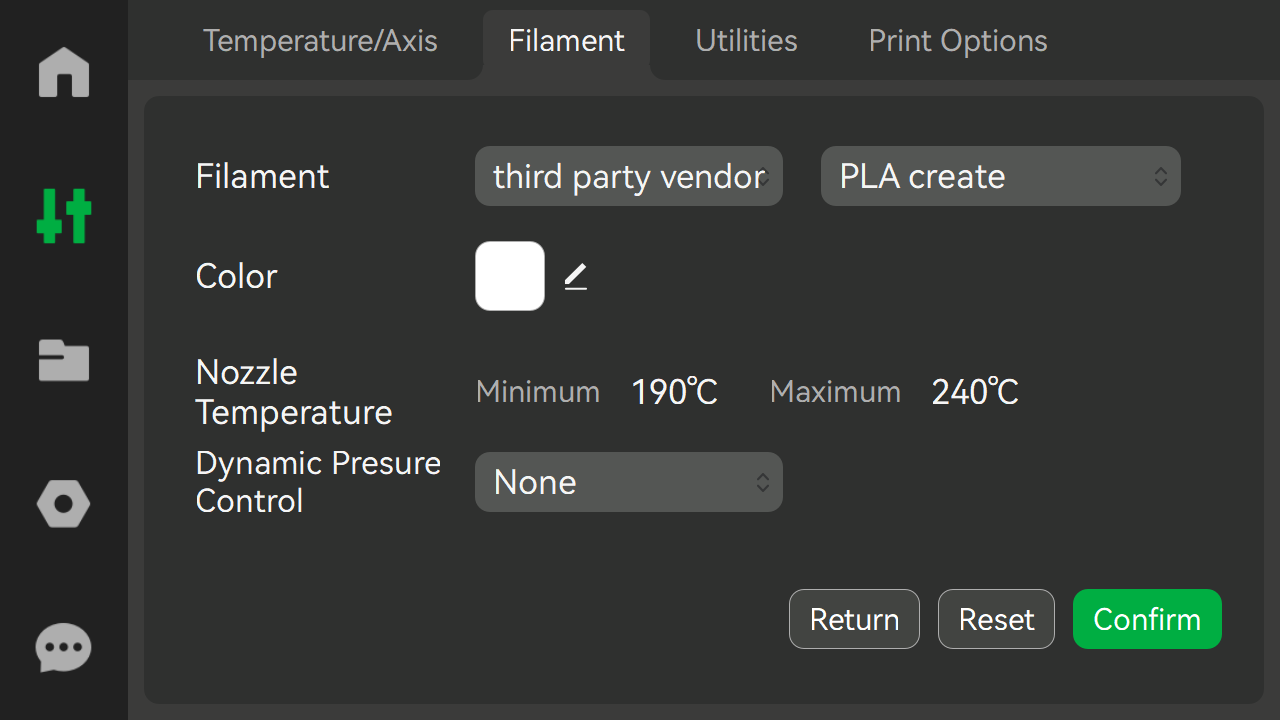

¶ Optimized the filament setting and display logic

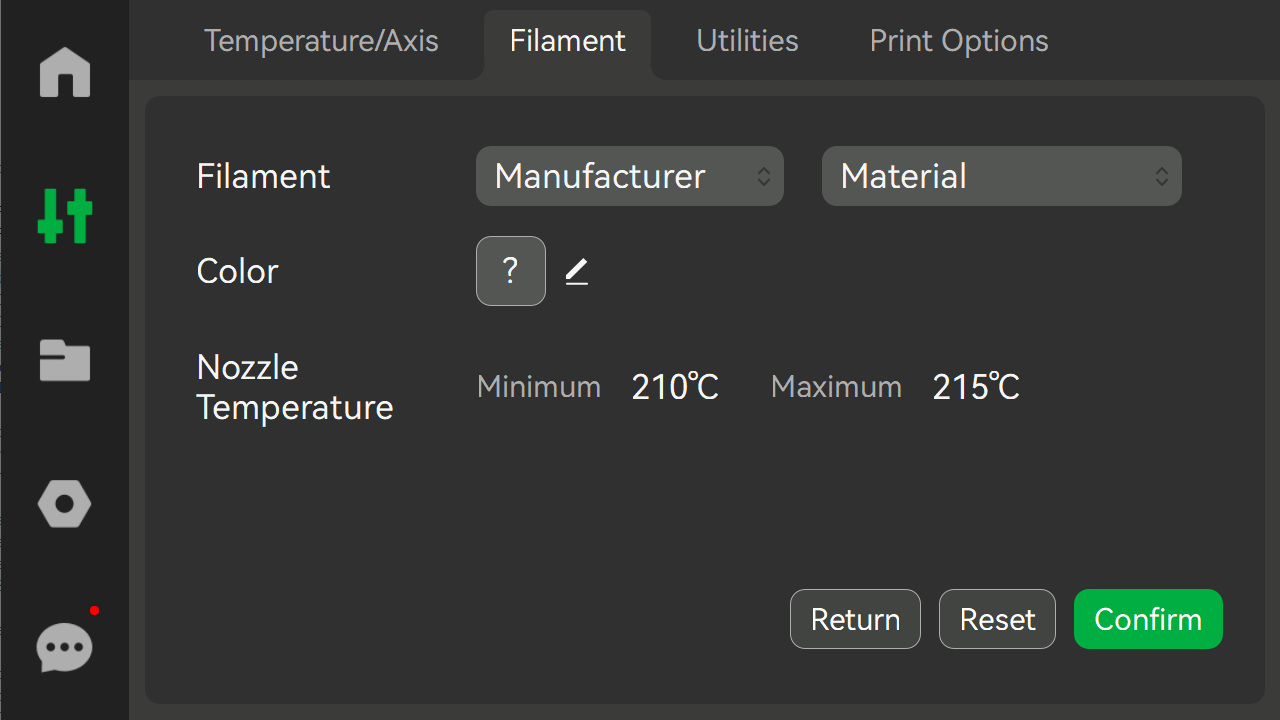

- When the filament information is not recognized or has not been set, the color box displays "?".

- When setting filament information, the manufacturer, material, and color need to be selected.

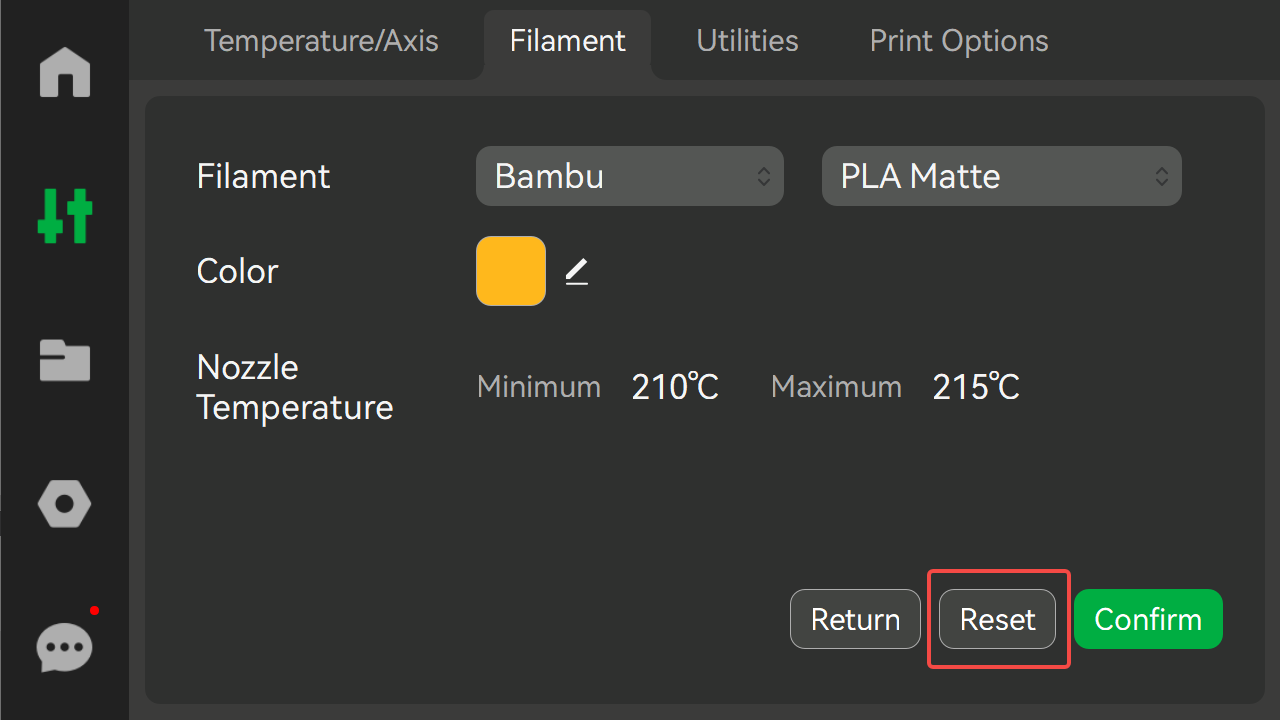

- After clicking the "Reset" button, the data on the page will be cleared, but it will not be set. You need to click the "Confirm" button again;

¶ Bugs fixed

Fixed the issue where a few frames were recorded at the end of a print even with timelapse disabled.

The drying temperature of PETG material has been adjusted from 90° to 80° to avoid deformation of the tray during drying. If you want to use the drying functionality of the printer, please check this article in advance.

¶ OTA version 01.05.01.00 (20230426)

¶ Summary

- Added support for setting properties and loading/unloading filament on the spool holder

- Added support for downgrading to previous firmware versions controlled by Bambulab (Only through Handy APP V1.0.13 or above)

- Added support for quick issue reporting through the popup window on the screen when printing is completed or stopped manually

- Added support for resetting aftermarket filament information after inserting it into a slot when the printer is idle

- Added a pop-window for filaments which are not supported or need attention by AMS when setting up and printing

- Added a QR code link to the firmware version page to view previous release notes

- Added the color setting of filament based on AMS's existing colors

- Improvements and bugs fixed

Dear X1 series users,

Long time no see.

After nearly 2 months of feature development iterations and test iterations, with everyone's efforts, the ota version 01.05.01.00 has finally been officially released. We have added several new functions for filament on the spool holder, described below. At the same time, by popular request, we have included support for downgrading to a curated list of previous firmware versions (through Bambu Handy 1.0.13 or above).

In addition, we have also added some other functionality such as quick issue reporting through the popup window when prints finish or are stopped manually, resetting a aftermarket filament information, pop-up prompts for different filaments and adjusting the filament color setting page. We also made a lot of improvements in this version of the firmware, hoping to bring you a better experience.

Enjoy this new firmware version and any feedback is welcome.

¶ Added support for setting properties and loading/unloading filament on the spool holder

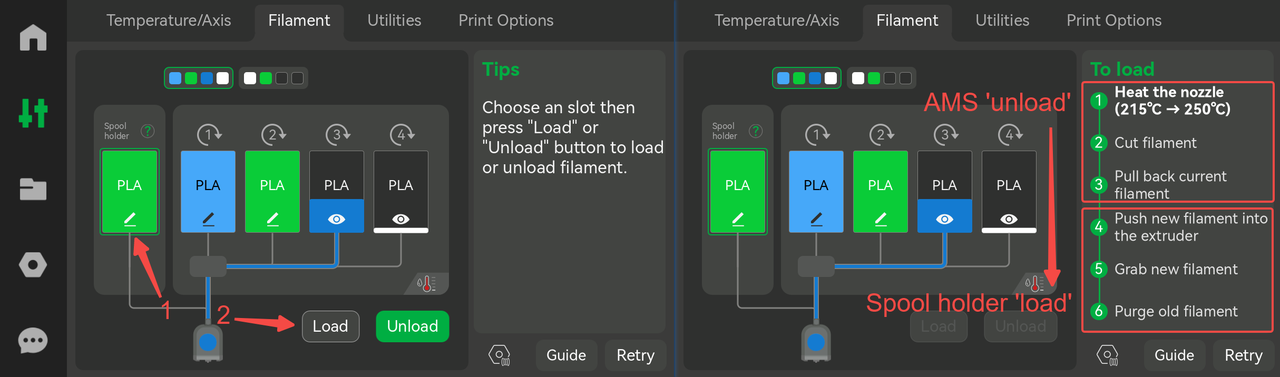

The filament on the spool holder can now be managed through an additional slot (a 'virtual slot'), this slot is managed uniformly with the AMS in the new 'filament' tab.

This slot supports setting filament properties (including type, color, printing temperature, etc), which will be used for processes such as loading/unloading filament, printing from the spool holder, etc.

Filament on the spool holder can now be loaded/unloaded by selecting this slot and pressing the 'load/unload ' button, and the load/unload process will be displayed on the right side.

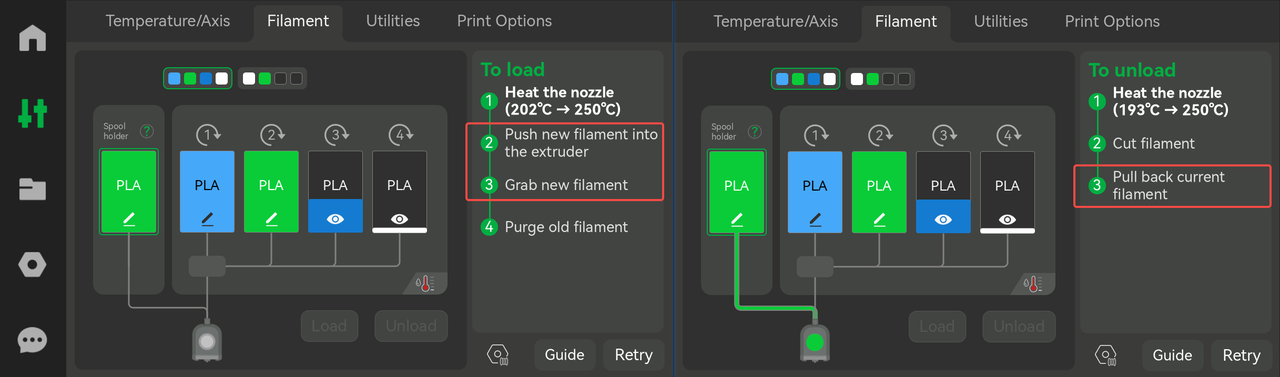

The load/unload process of the spool holder is different from AMS, which has three manual steps:

- [Load]: Push new filament into the extruder

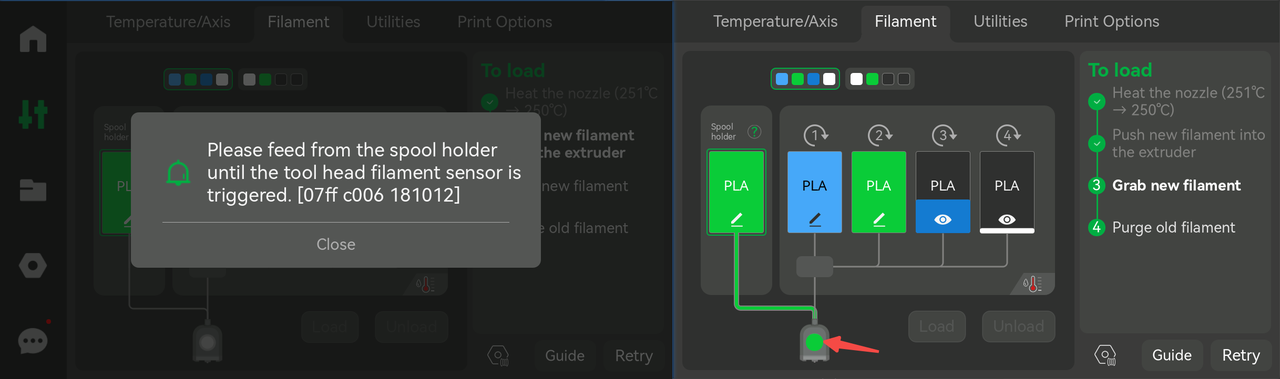

In this step, new filament needs to be manually fed into the tool head and continue to be pushed forward slightly when the filament reaches the extrusion gear. When the filament sensor detects the filament, the extruder will begin to grab the filament.

There will be a prompt during this step. When the tool head sensor is triggered, it will be automatically closed and the tool head icon on the screen will change to the color of the filament.

- [Load]: Grab new filament

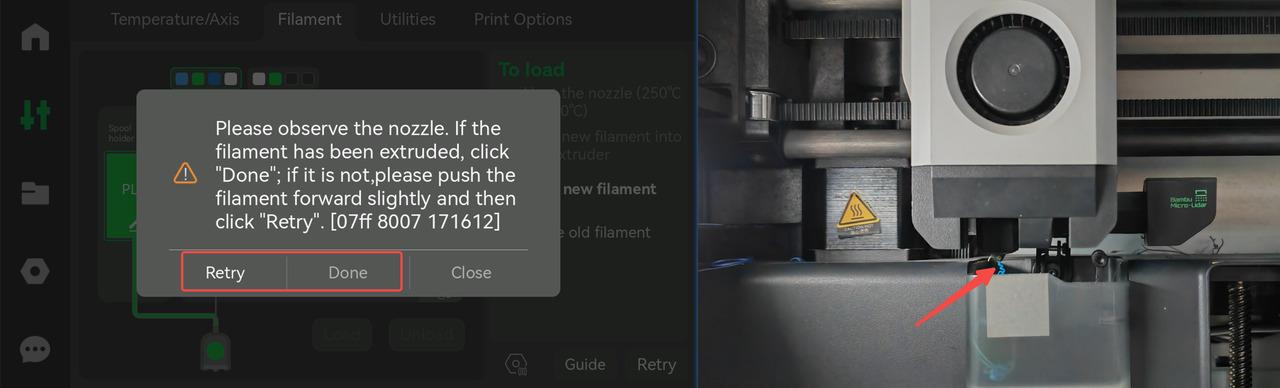

Please observe the nozzle during this step. In this step, the new filament will be extruded for a while, and a prompt will pop up if the OLD filament is extruded. Click 'Done' to complete this step and the extruder will begin to purge the old filament; otherwise, click 'Retry' and the filament will continue to be extruded for a short distance, and the prompt will pop up again.

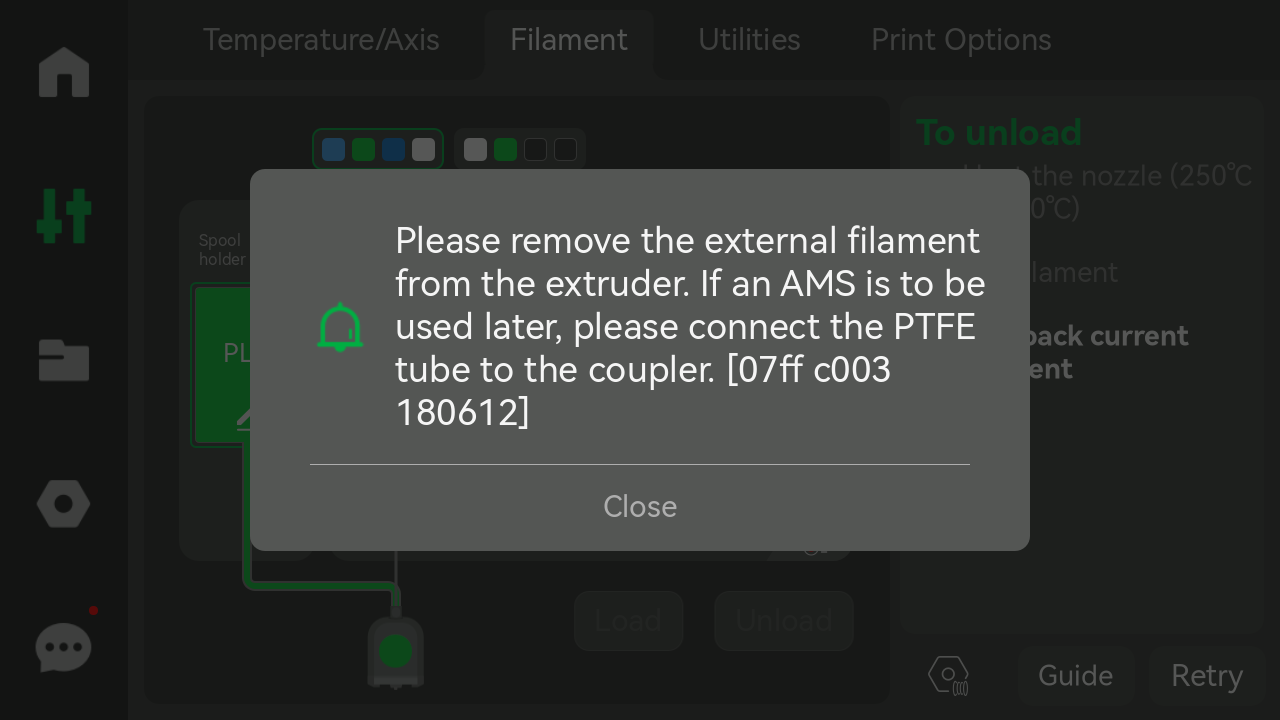

- [Unload]: Pull back the current filament In this step, the filament is cut and exits over the extrusion gear, and needs to be pulled out of the PTFE tube. There will be a prompt during this step. It will automatically be closed when the tool head sensor no longer detects filament.

Furthermore, the 'load/unload' function supports switching filament between AMS and the spool holder directly. For example, when a filament from AMS is loaded, the filament from the spool holder can be loaded directly by selecting the spool holder and clicking the 'Load' button. The spool holder 'load' process will be executed followed by the AMS 'unload' process as below.

Tip:

- The 'unload' button on the 'Temperature/Axis' tab for unloading the filament of the spool holder has been removed.

- Loading/unloading filament during printing is not supported for the moment.

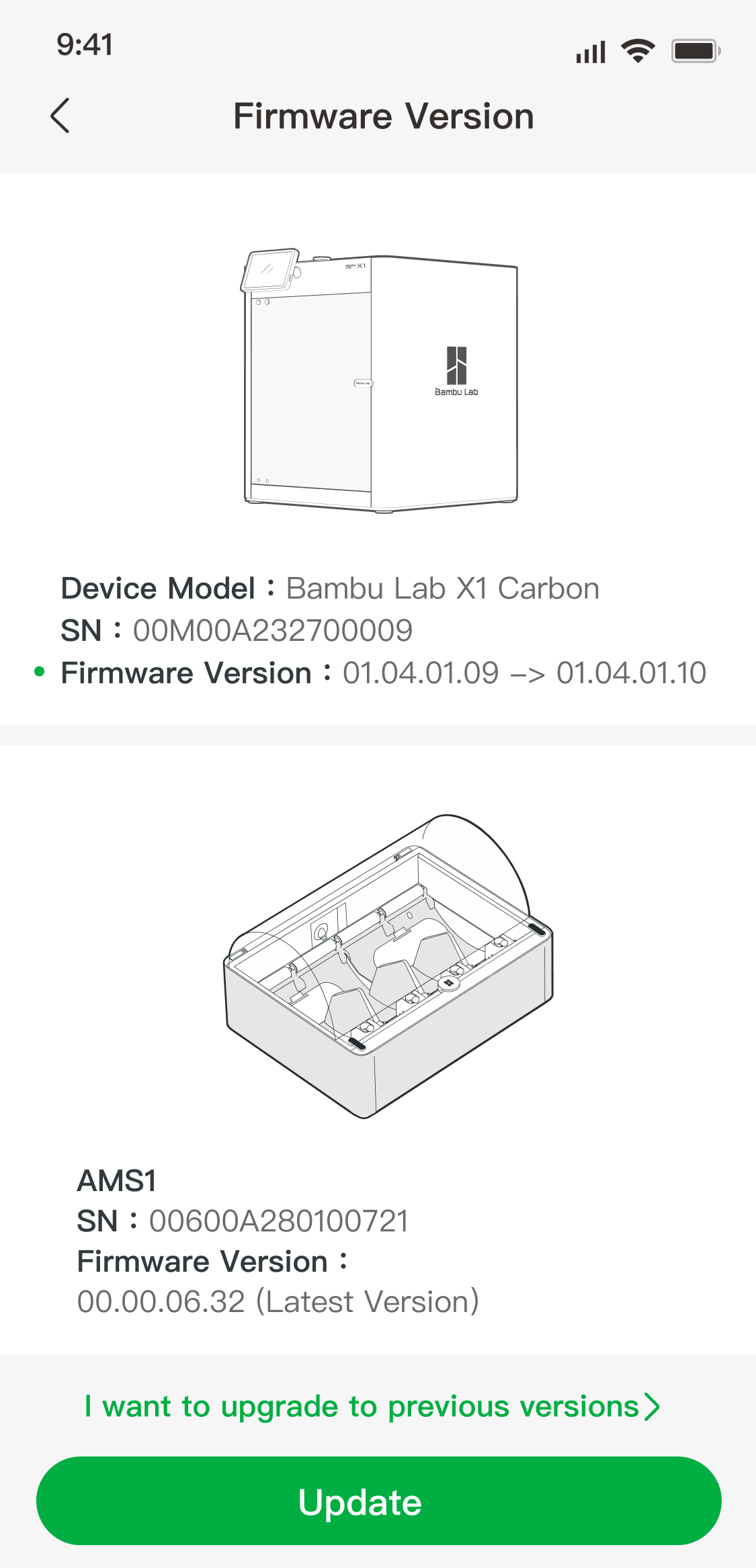

¶ Added support for downgrading to previous firmware versions controlled by Bambulab (Only through Handy APP V1.0.13 or above)

AMS filament mapping will be lost after downgrading from this version. It is suggested to set it again or just upgrade to 01.05.01.00

Steps to downgrade to a previous version:

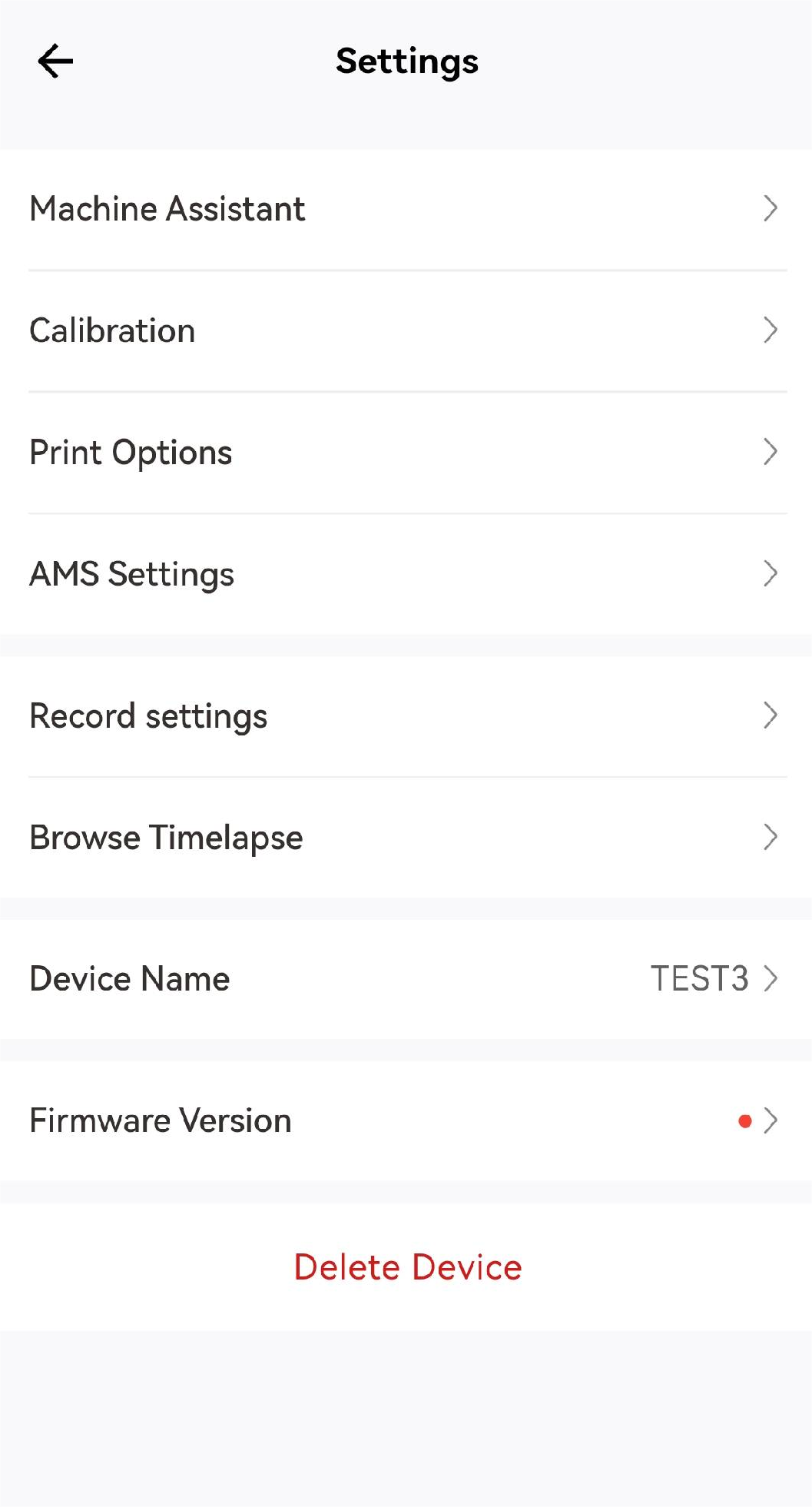

- Go to the handy device settings page and click Firmware Version.

- Select "I want to update to previous versions"

- Select the previous version you want to upgrade, and then click "Upgrade". There is only one previous version currently under maintenance, the version is v01.04.01.00, and no other previous versions.

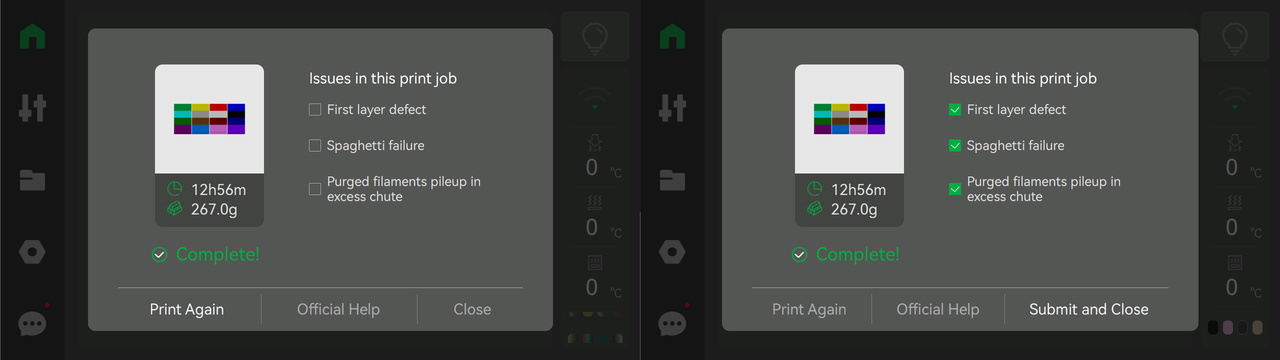

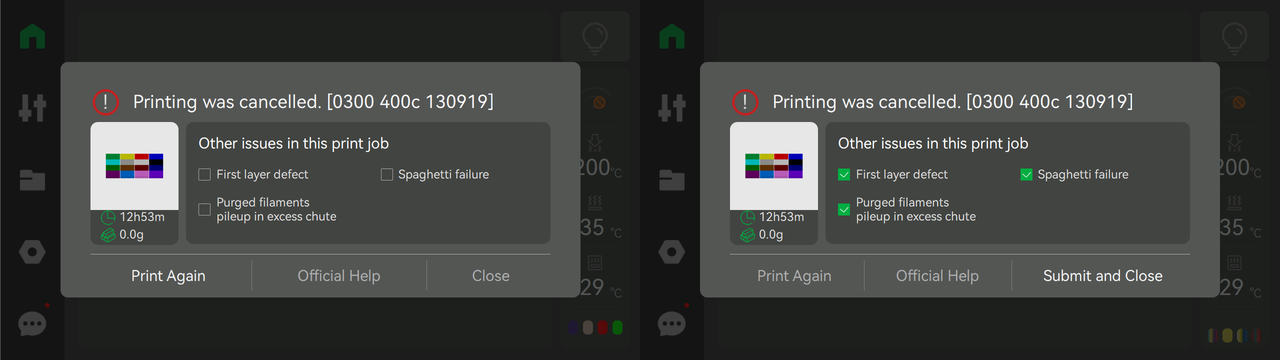

¶ Added support for quick issue reporting through the popup window on the screen when printing is completed or stopped manually

After printing successfully, users can report any missed detections during this printing process. If there is an abnormal interruption in printing, users can report it as a printing error.

¶ Added support for resetting aftermarket filament information after inserting it into a slot when the printer is idle

The "reset" button on the third-party filament information settings page is able to clear the previous filament information.

¶ Added a pop-window for filaments which are not supported or need attention by AMS when setting up and printing

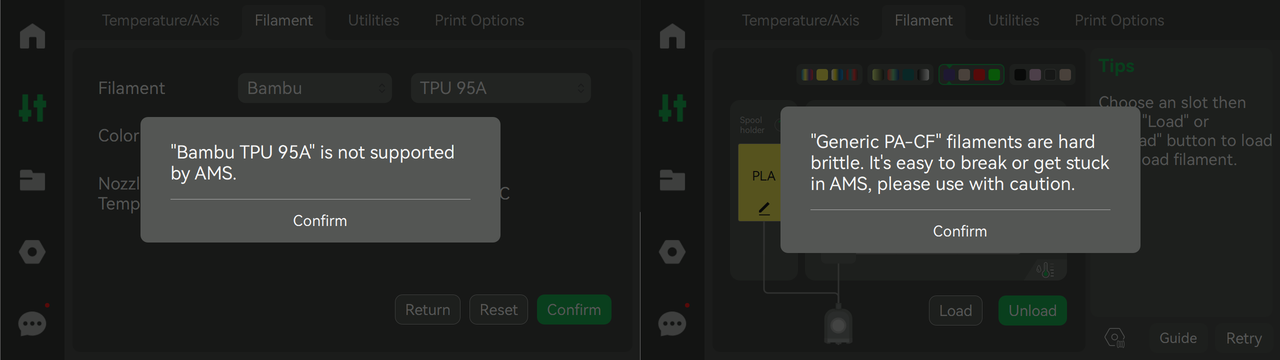

At present, AMS does not support any TPU filaments. For all PVA filaments and third-party filaments, xxx-CF filaments will pop up a box to indicate precautions. When using AMS for printing, it will pop up a box prompt and prevent printing for unsupported filaments, and also pop up a box prompt for filaments that need attention, but it will not prevent printing.

¶ Added a QR code link to the firmware version page to view previous release notes

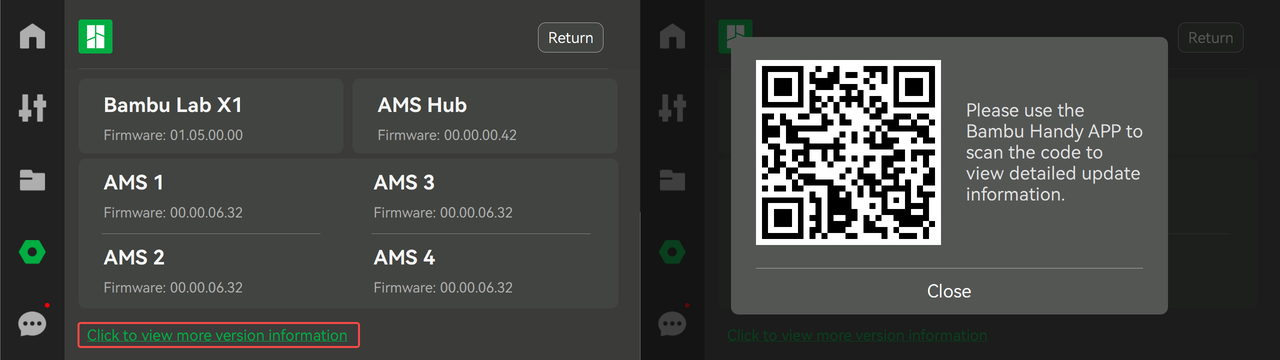

On the "General" ->"Firmware Version" page, click "Click to view more version information" below, and a QR code pop-up box will appear. Use the BambuLab Handy APP to scan the code to view the historical version information released.

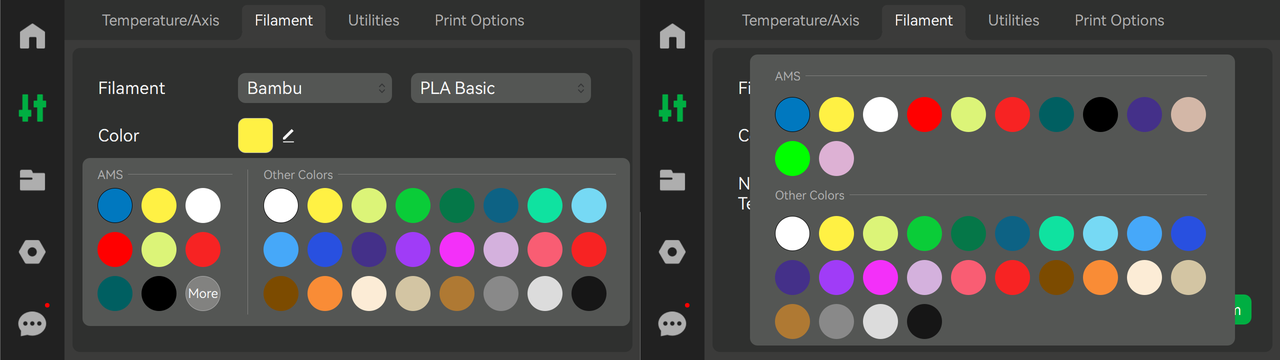

¶ Added the color setting of filament based on AMS's existing colors

When setting colors for third-party filaments, AMS can be selected to read colors from the official RFID of Bambu filaments.

¶ Improvement and bugs fixed

Improvements:

1.[Algorithm] Optimized the spaghetti detection algorithm, so that the spaghetti detection prompt message can be updated according to real-time detection results.

2.[Screen] Updated the Privacy Policy.

3.[System] Increased the user binding delay time to 30 seconds to avoid the situation where the original timeout of 10 seconds is not enough.

4.[System] Reduced the position deviation of repeated homing(G28), mitigate the issue of layer shift during power failure resume and pauses for loading/unloading of filament, etc.

5.[System] Optimized the list of filament presets, and supported the synchronization of filament presets from the cloud server.

6.[System] Optimized the heat break fan control logic and reduced the false alarm rate of fan detection.

7.[System] MC board fan is off until the tool head is moved. It will then turn on to cool the MC board components. When the print concludes and the printer goes to power save mode, the MC board fan will again turn off.

Bugs fixed:

1.[System] Fixed the issue where the printing process can not be initiated while "%" included in filenames can not initiate printing.3. [AMS] Adjusted the loading and unloading scheme to increase the output power of the booster wheel.

¶ AMS ota version 00.00.06.32(20230420)

【New features】

Added some new features.

¶ OTA version 01.04.01.00 (20230227)

【Improvements】

1. [Algorithm] Optimized the HMS prompt explaining that the PEI build plate does not support first layer inspection.

2. [System] Updated some HMS and screen content.

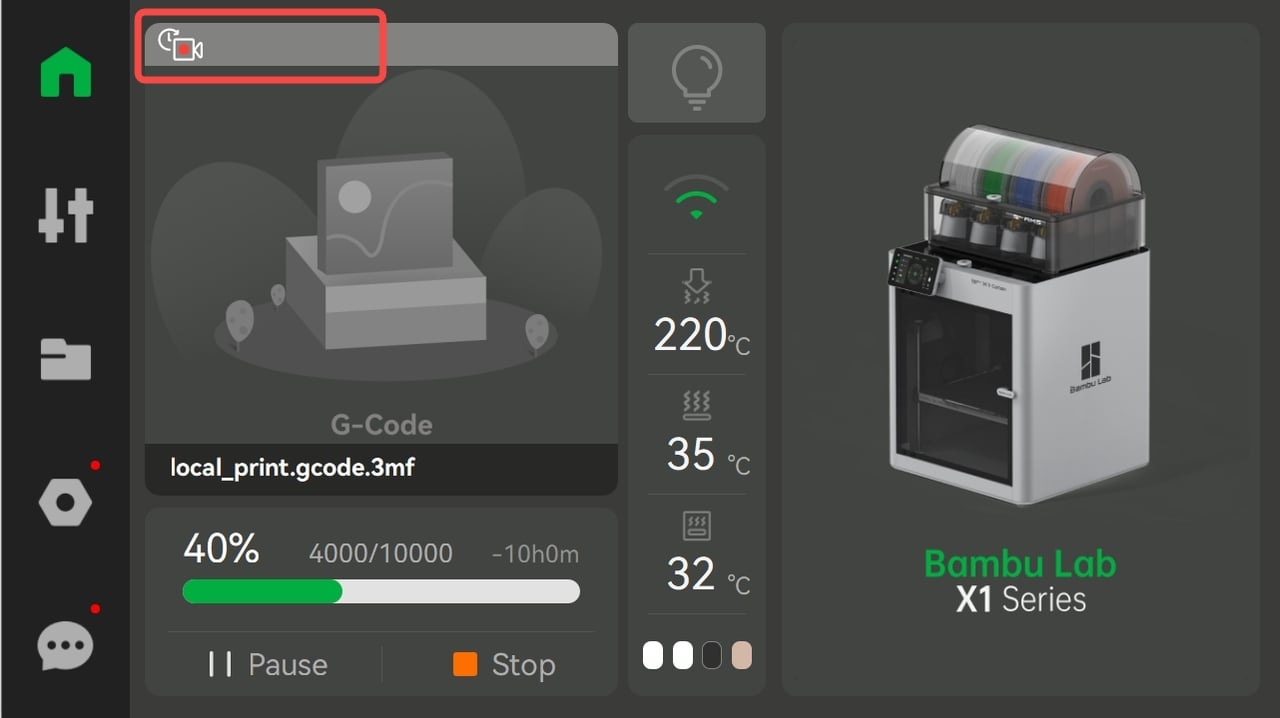

3. [System] Adjusted the page layout and deleted the video and live icon on the thumbnail of the home page during printing, only retaining the delayed photography icon.

【Bugs fixed】

1. [System] Fixed the issue of abnormal extrusion compensation caused by the large velocity difference between the inner and outer walls.

2. [System] Fixed a low probability issue where the avatar of the bound user is not displayed. If you've encountered the issue of the missing avatar in your account, please upgrade the firmware to the latest version to fix it.

¶ OTA version 01.04.00.00 (20230207)

¶ Summary

- Added a pop-up message for the first boot after updates to remind users to open AI monitoring function and remind defaultly to check if the carbon rods need to be cleaned

- Added equipment maintenance reminders when carbon rods need to be cleaned and Z-axis lead screws need to be lubricated

- Supported encryption of data and control commands between printers and Bambu Studio in LAN mode to improve security in LAN

- Added support for up to 8 cloud printing 3mf files to be cached in the MicroSD Card

- Added support for connecting to the printer by directly entering the IP Address and Access Code. This must be used with the latest version of Bambu Studio

- Added support for displaying the current layer number/total number of layers during printing

- Added secondary confirmation when stopping a printing job in a pop up window

- Optimized thermal runaway protection for the hotend

- Improvements and bugs fixed

- Details

Dear X1 Series Users,

First of all, thanks for all beta testers' contribution.

Here are some of the biggest updates in this firmware version——a pop-up message for the first boot after updates, equipment maintenance reminders, improve the security in LAN, cache cloud print files to sdcard, displaying the current layer number/total number of layers during printing, secondary confirmation when stopping a printing job, .etc. Of course, it also comes with tons of improvements, such as thermal runaway protection for the hot end, AMS humidity display icon.

We hope this firmware update can fulfill your desires! Thanks for all of your support!

¶ Added a pop-up message for the first boot after updates to remind users to open AI monitoring function and remind defaultly to check if the carbon rods need to be cleaned.

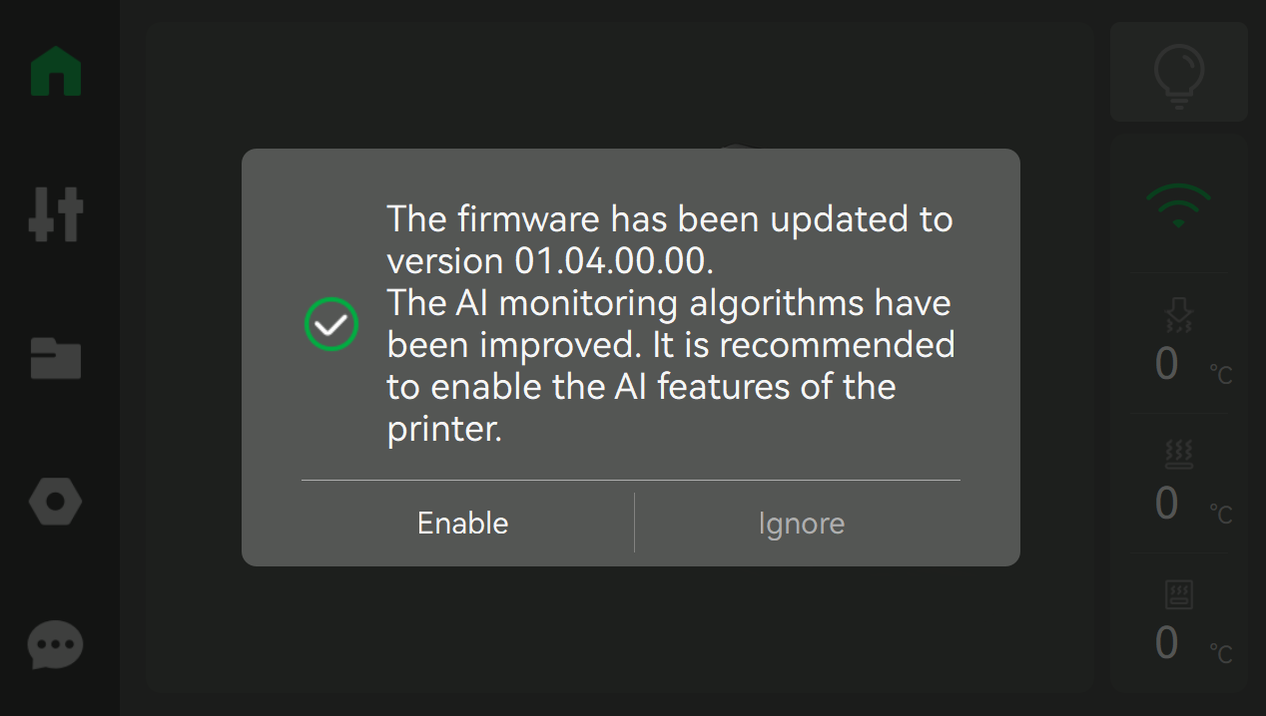

a. If it detects that the AI related functions are not turned on, it will remind you to turn them on. Click the "Enable" button to turn on AI related functions, and click the "Ignore" button to keep your previous system settings:

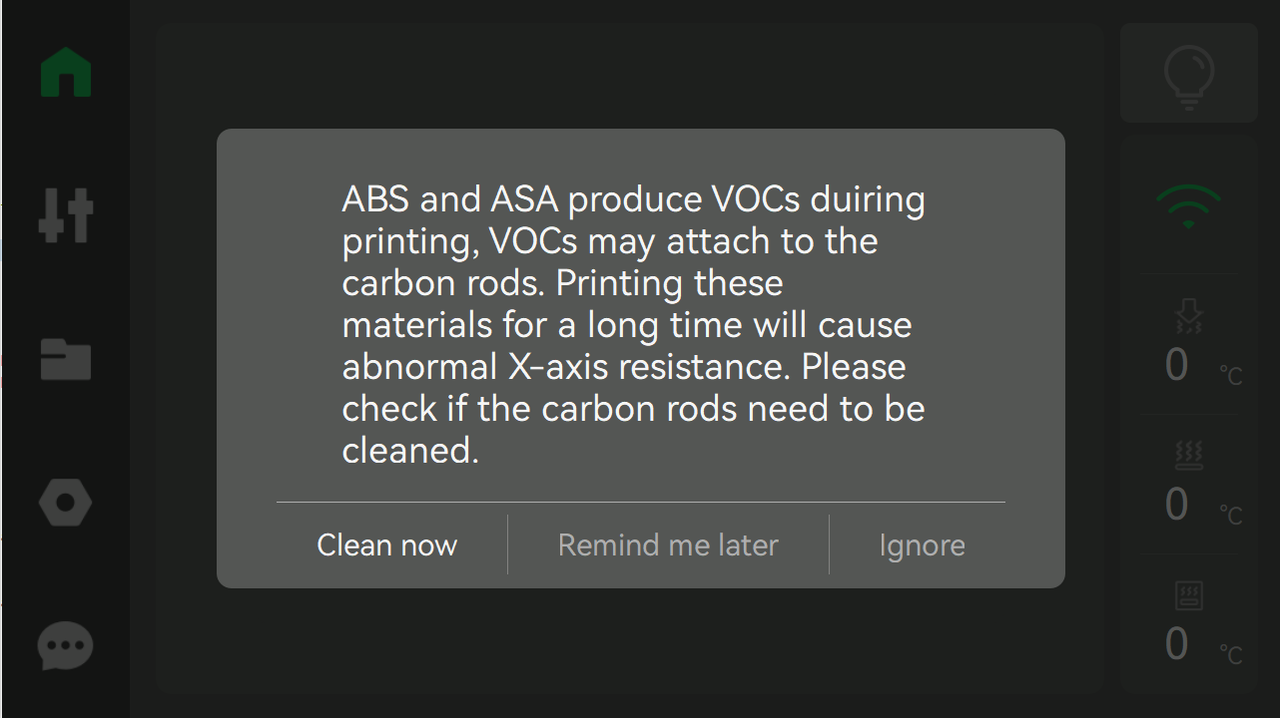

b.X-axis carbon rod maintenance reminder: If you select the "Clean now" icon, it will jump to the equipment maintenance page. If you select the "Remind me later" icon, this reminder page will pop up again when the next boot.

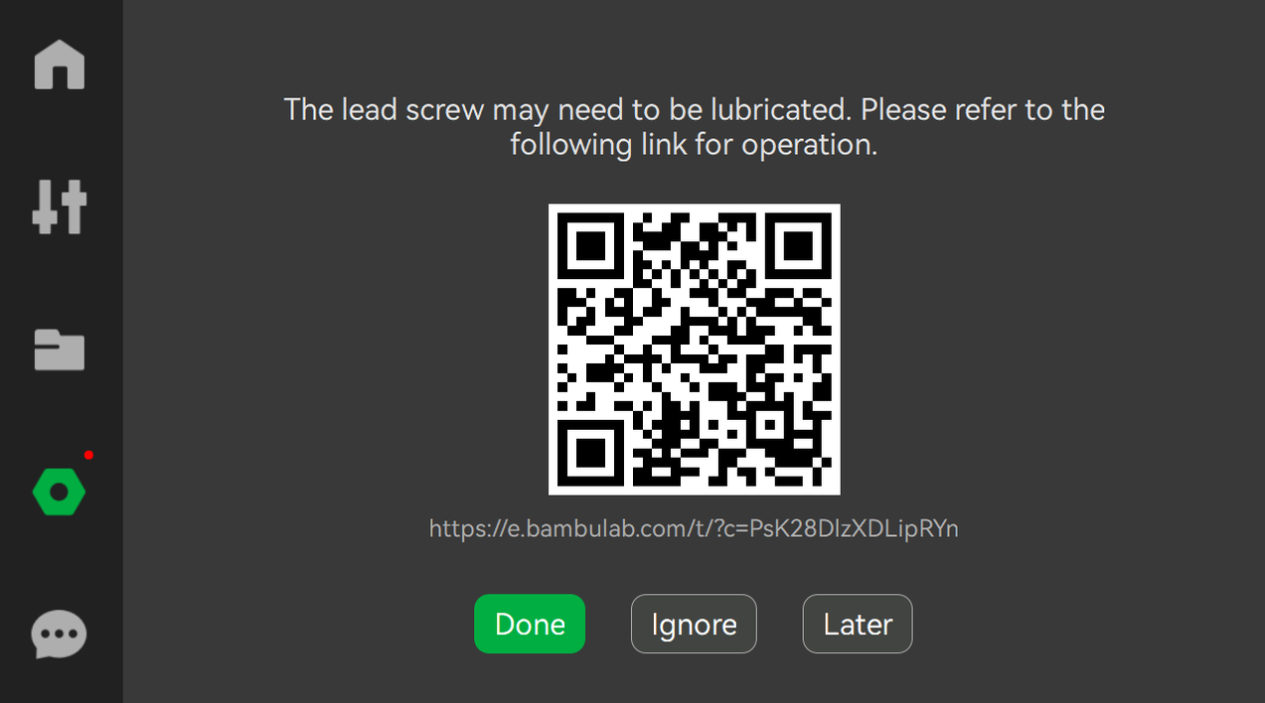

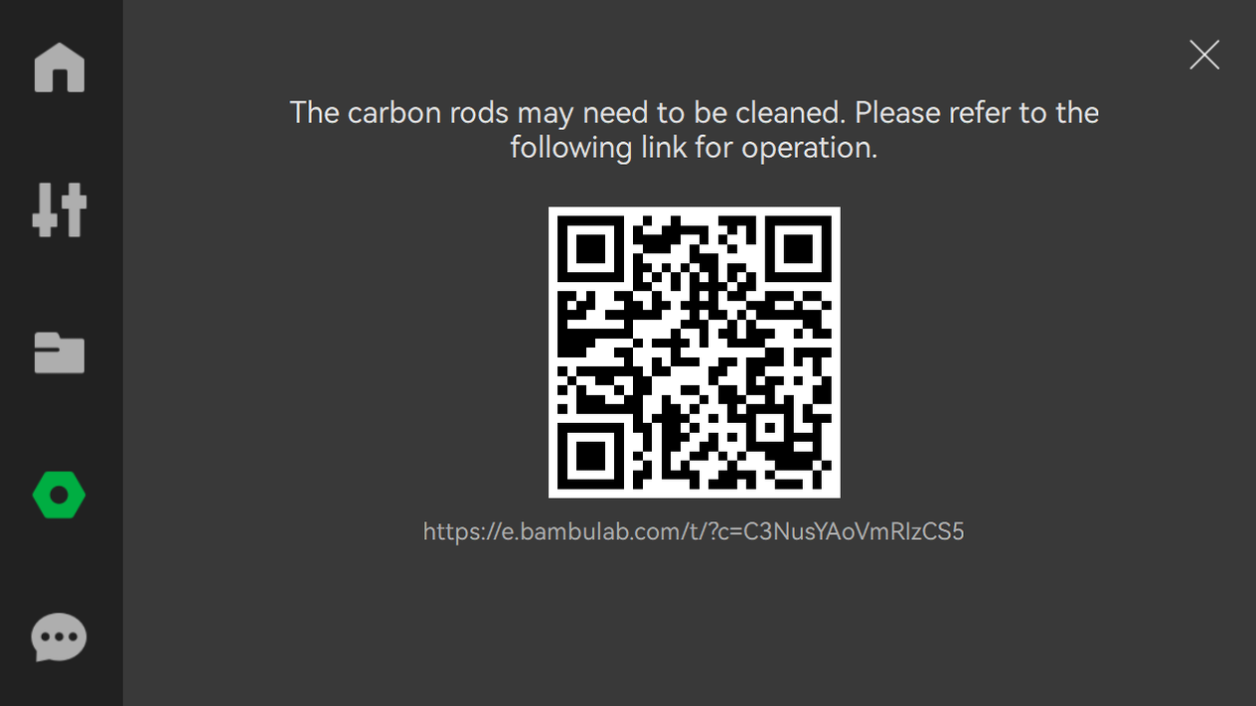

¶ Added equipment maintenance reminders when carbon rods need to be cleaned and Z-axis lead screws need to be lubricated.

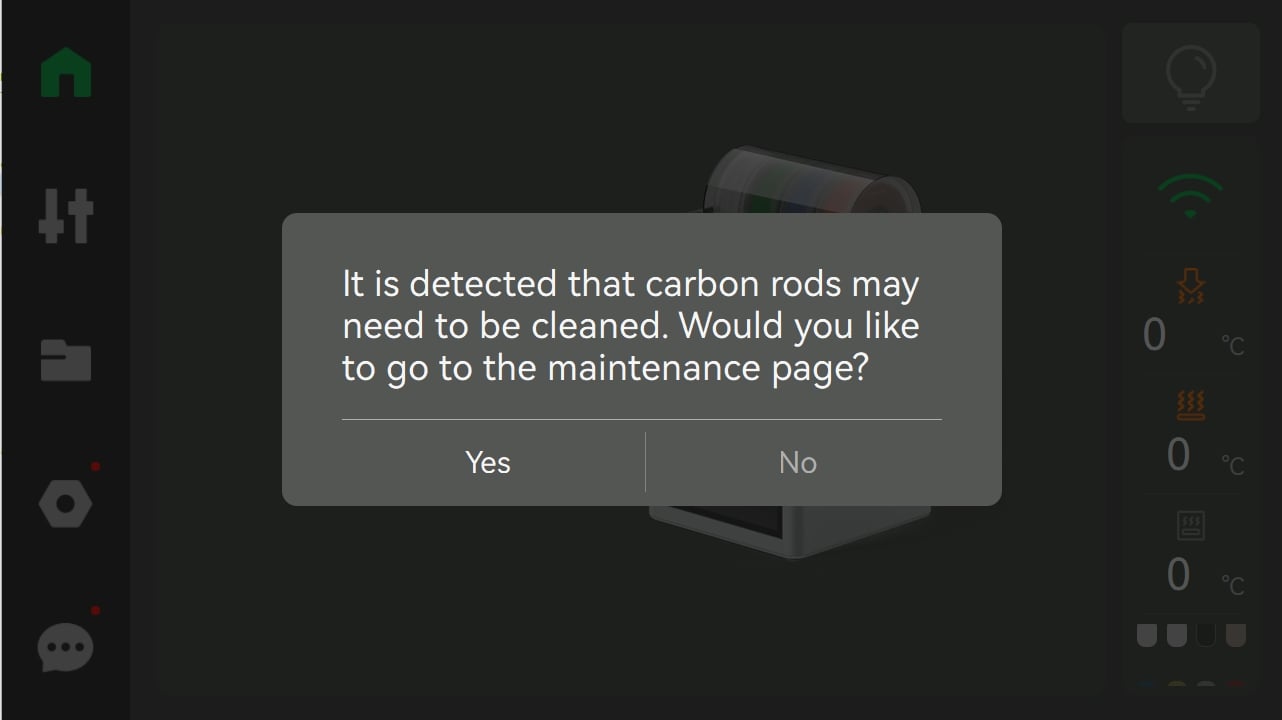

a. This popup represents carbon rods in need of maintenance. Selecting "Yes" will jump to the page described in item "c" below, and you can select "No" to ignore.

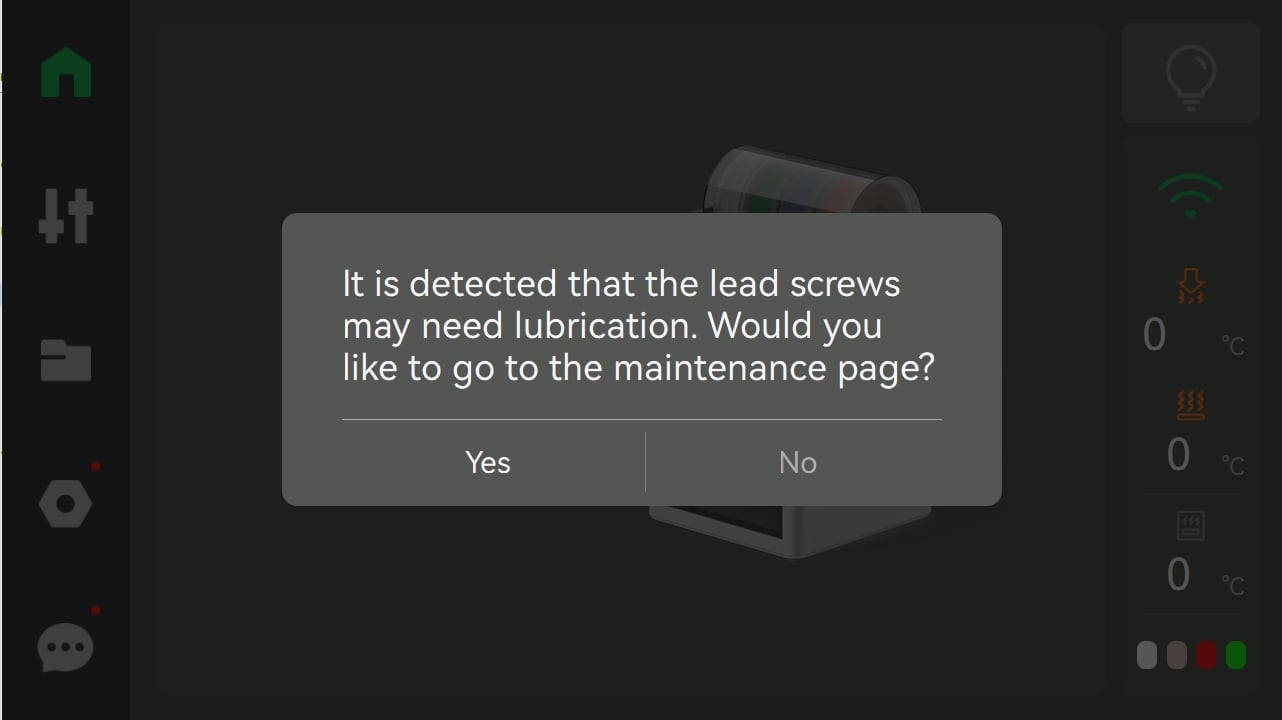

b. This popup represents Z axis lead screws in need of maintenance. Selecting "Yes" will jump to the page described in item "c" below, or you can select "No" to ignore.

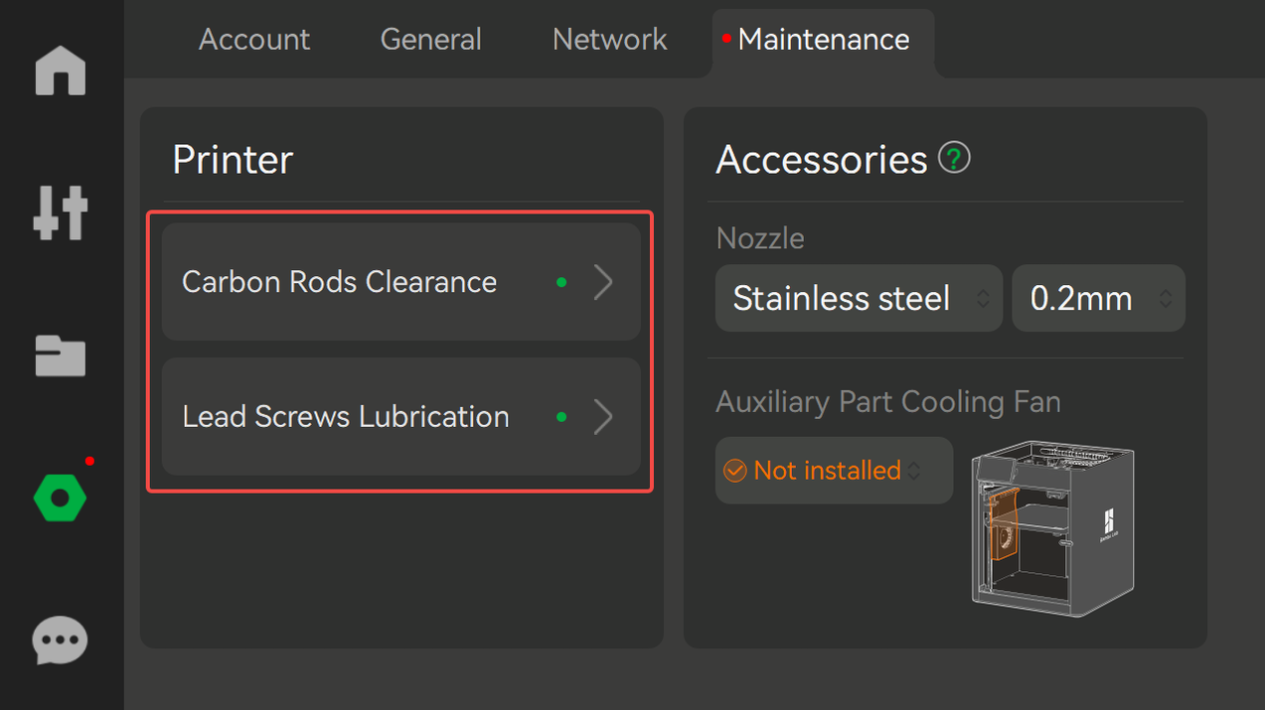

c. If maintenance is required, the test item displayed on the left side of the screen will have a small green dot prompt.

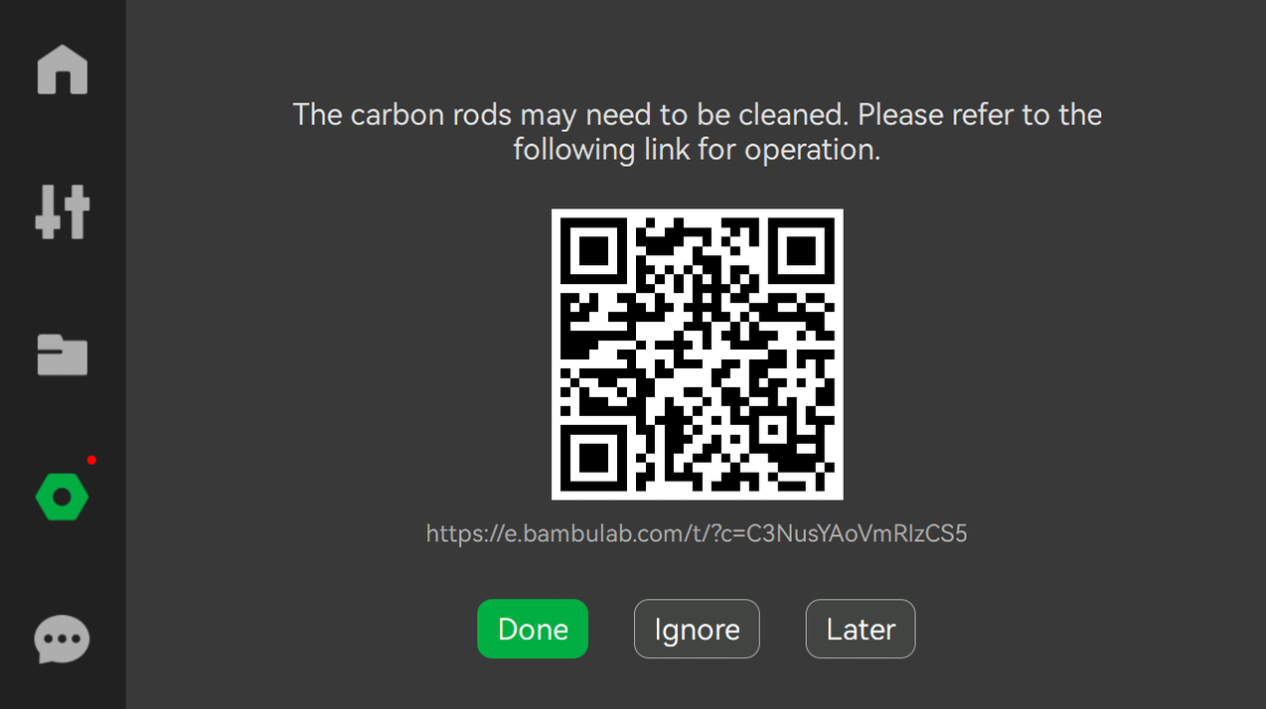

d. Selecting printer maintenances in item "C" above will take you to this page. Use the Bambu Handy app to scan the QR code to view a maintenance guide. If maintenance is completed, please press the "Done" button, and the printer will clear and re-record the print data for the next maintenance reminder. Pressing the "Ignore" button, means no maintenance is required. The printer also clears and re-records the print data. Pressing the "Later" button just exits the page, the little green dot of the maintenance item will still be present.

e.If the printer does not prompt for maintenance, only the maintenance instructions QR code will be displayed.

¶ Supported encryption of data and control commands between printers and Bambu Studio in LAN mode to improve the security in LAN.

a. In "LAN only" mode, TLS v1.2 is enabled in MQTT which is used for the direct connection between the printer and Bambu Studio. This improves LAN printer control security.

b. TLS v1.2 is enabled for FTP. FTP is used for Bambu Studio to send 3MF files to the MicroSD Card directly. This can improve the level of LAN data protection.

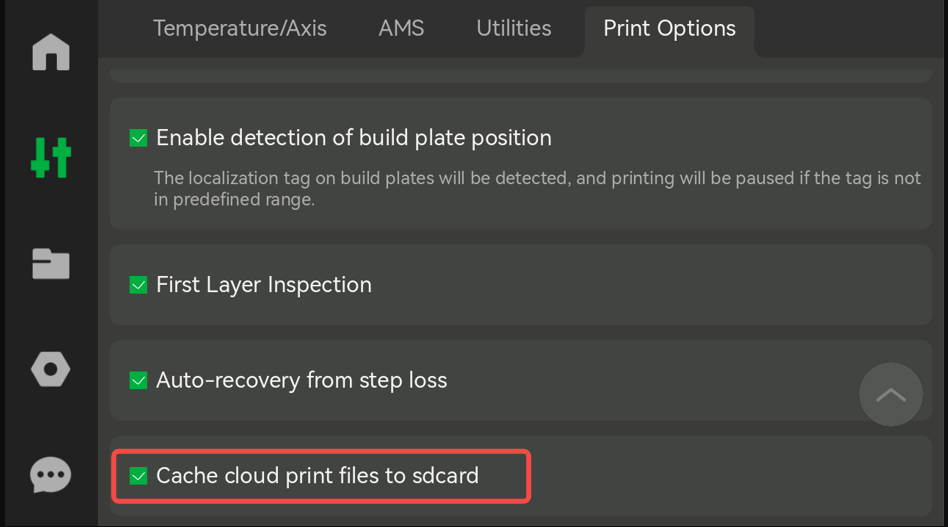

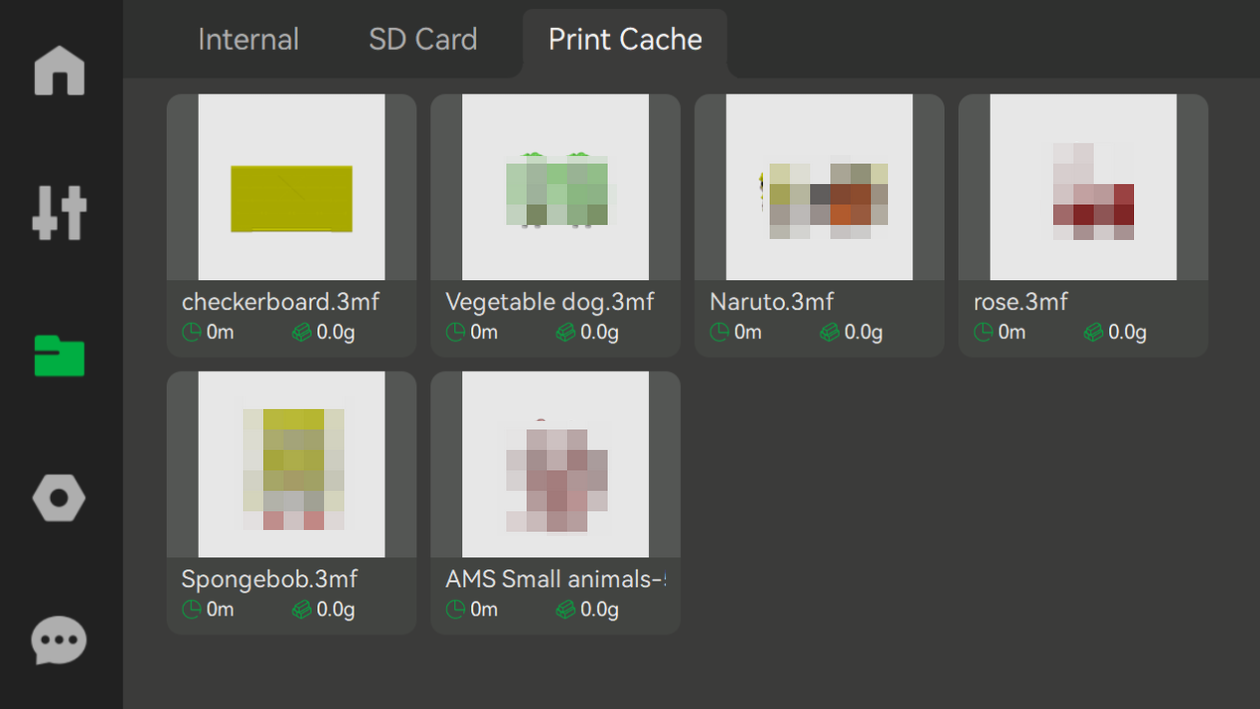

¶ Added support for up to 8 cloud printing 3mf files to be cached in the MicroSD Card.

a. Add the cloud print file caching function, which is enabled by default. If you select this option when printing through cloud, the 3mf will be stored in the cache folder of the MicroSD Card root directory.

b. The printed 3MF files will be backed up to the "Print Cache" folder if the MicroSD card has enough capacity.

c. The print cache can store up to “8” 3mf files. If it exceeds, the oldest 3mf file cached will be deleted. When the remaining capacity of the MicroSD Card is less than 500MB, some old print cache 3mf files may be deleted to ensure that the current print 3mf file can be cached. If deleting all the old 3mf files still does not meet the capacity requirements, current print 3mf file will not be cached into the MicroSD Card, and an HMS prompt message will be reported at this time.

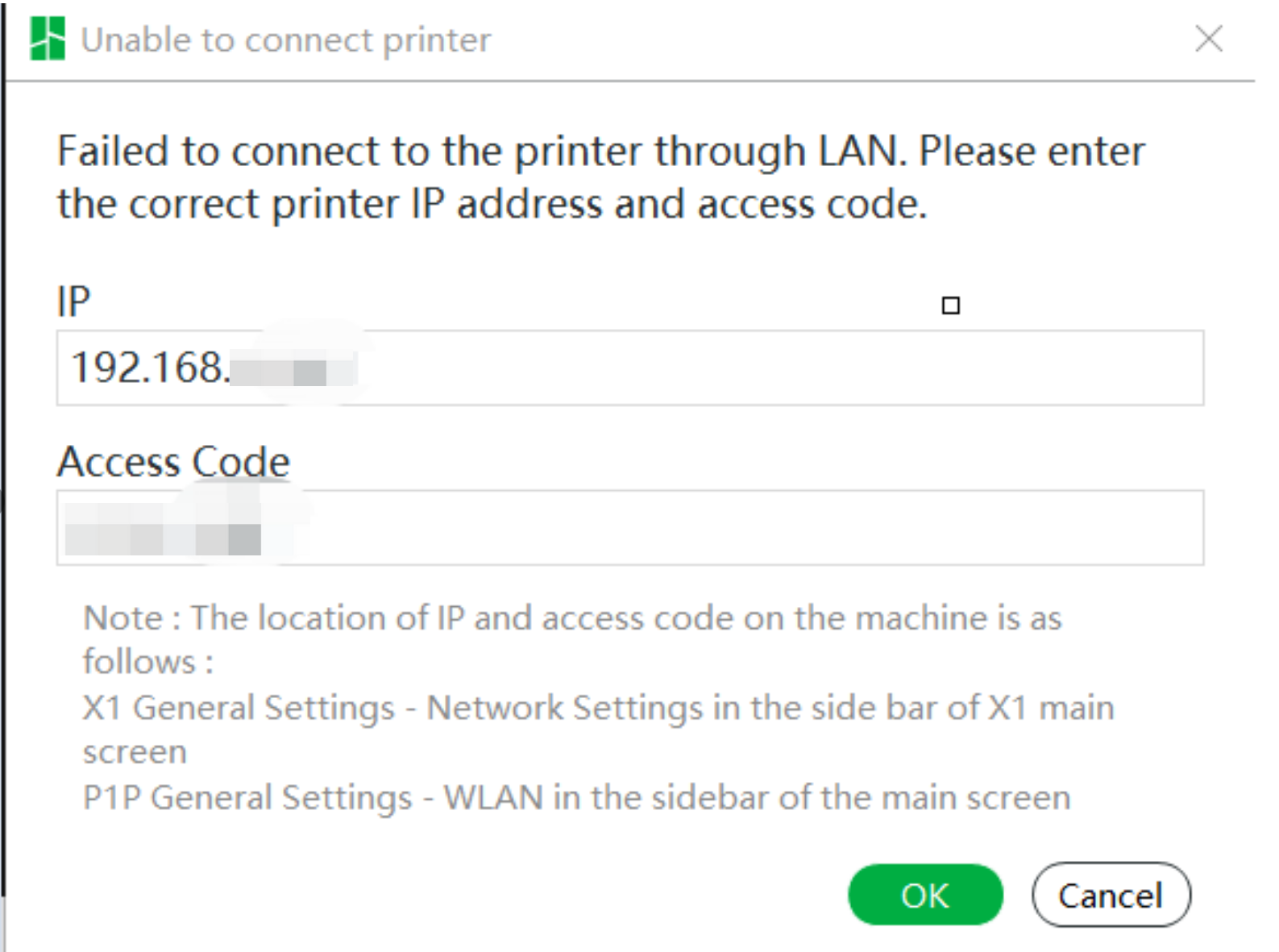

¶ Added support for connecting to the printer by directly entering the IP Address and Access Code. This must be used with the latest version of Bambu Studio( 01.04.02.00 or higher).

Bambu Studio needs to be updated to 01.04.02.00 or higher

For Android devices, Bambu Handy needs to be updated 1.0.8 or higher

For iOS devices, Bambu Handy needs to be updated 1.0.9 or higher

On the printer's side, IP and access-code are displayed on screen.

If auto-ip detection fails, the manual input will pop up on Studio/Handy like below:

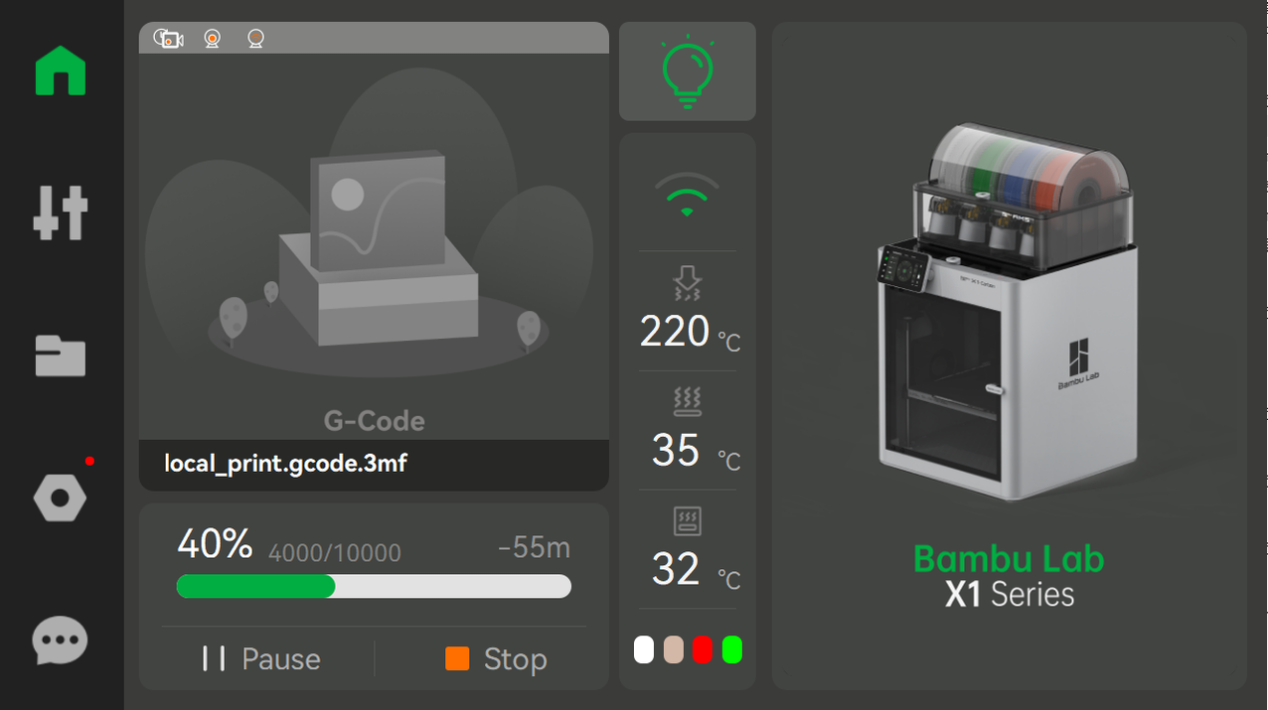

¶ Added support for displaying the current layer number/total number of layers during printing

Bambu Studio needs to be updated to 01.04.02.00 or higher

The current number of layers and the total number of layers are displayed to the right of the print progress percentage on the lower side of the print home page.

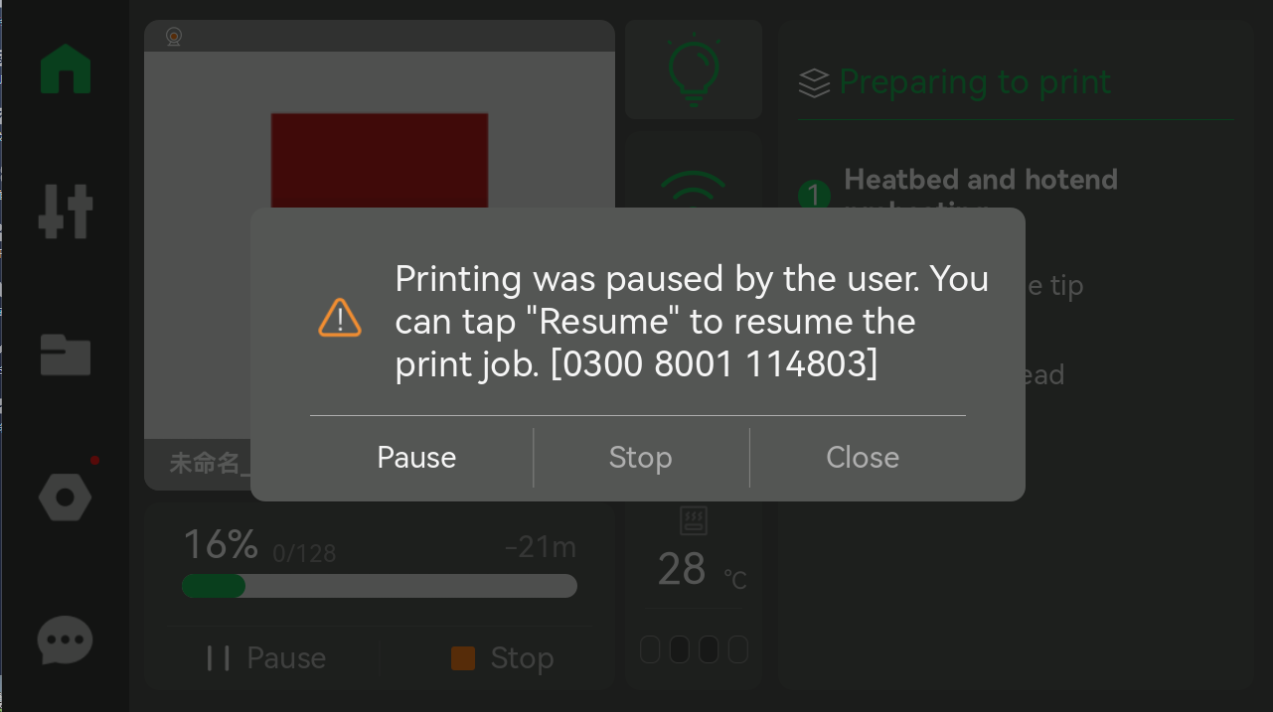

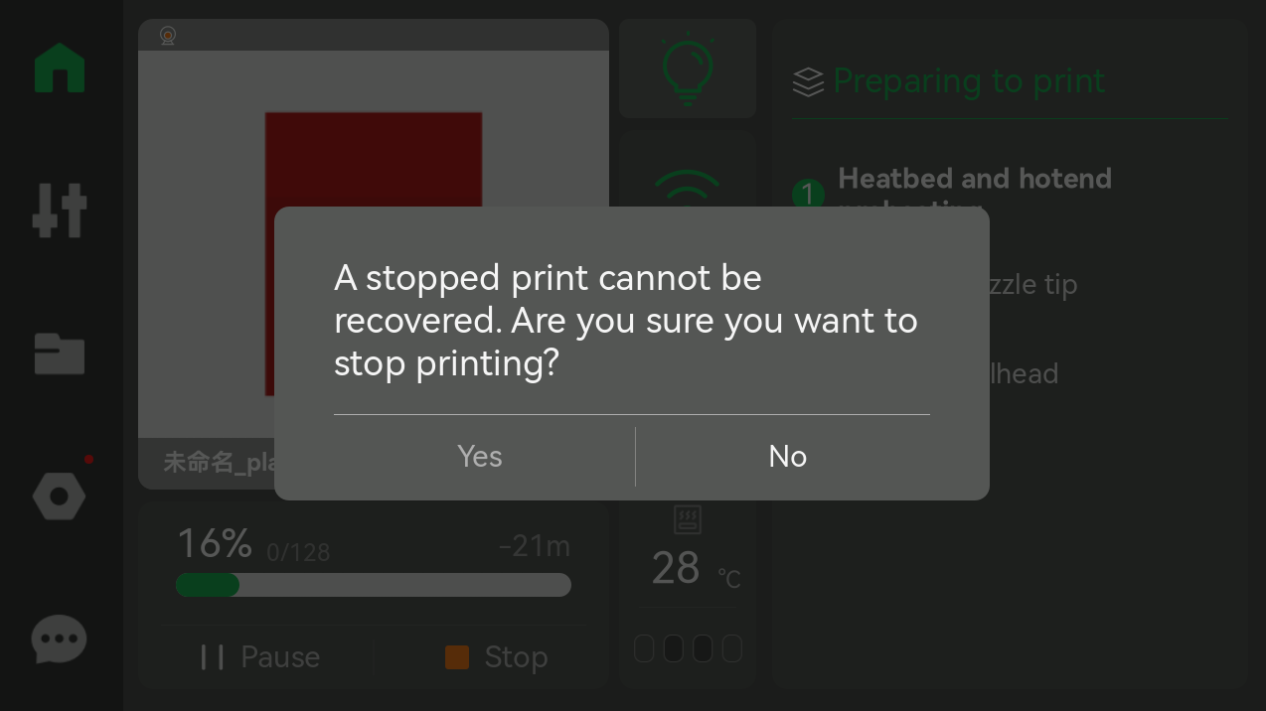

¶ Added secondary confirmation when stopping a printing job in a pop up window.

When a user clicks to stop printing after a printing error pop-up appears, a second confirmation pop-up will appear to prevent accidental cancelation.