¶ Observation

This error occurs when the extruder can still detect filament even after the AMS has completed the unloading process for a while.

Possible root causes:

- Extruder clog

- Extruder hall switch abnormal

- High unloading resistance

¶ Troubleshooting

¶ Tools, Equipment, and Materials

Please refer to the info inside each detailed troubleshooting wiki.

¶ Fault Isolation Procedure

¶ Actions

Operators may use discretion in determining the actual procedures used, and the order in which these steps are applied.

¶ Step 1. Check extruder clog

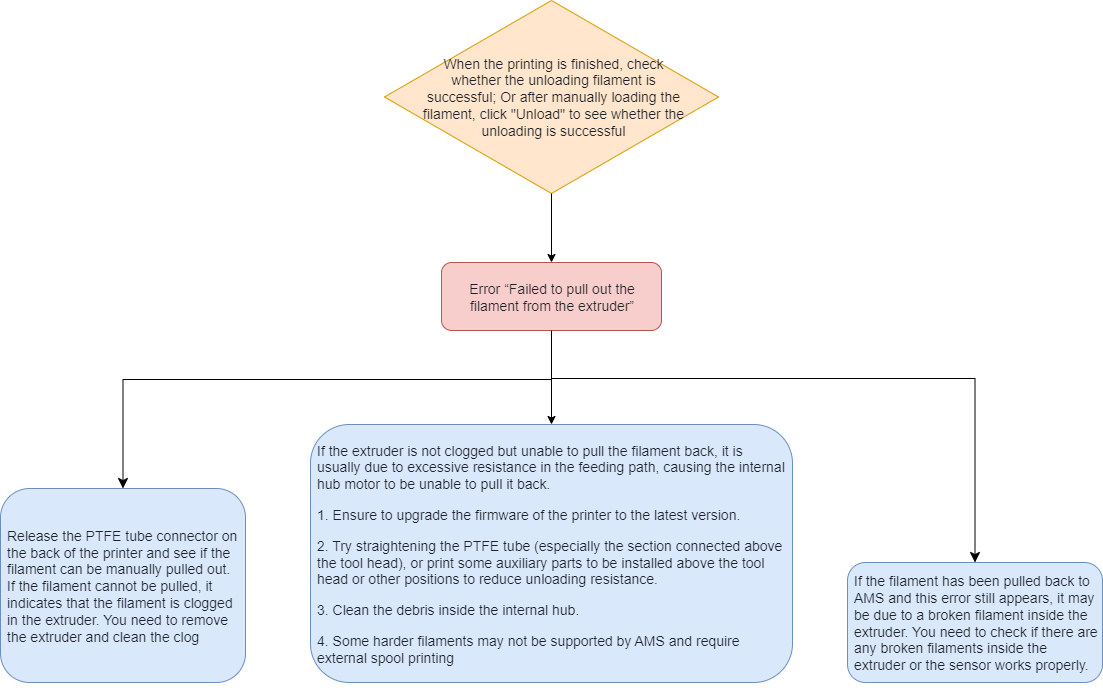

When filament cannot be successfully unloaded from the extruder it leads to an unloading failure, it is likely due to a clog in the extruder or high unloading resistance.

In this case, press the PTFE tube connector on the back remove the PTFE tube first, and then manually pull out the filament. If you can't pull out the filament, it indicates that the filament is stuck inside the extruder; if you can easily pull out the filament from the toolhead, it indicates high unloading resistance, please see the high unloading resistance section below for troubleshooting. If the extruder is clogged, please refer to this Wiki article to clear the clog:

¶ Step 2. Check extruder hall switch abnormal

If the filament has been successfully unloaded from the extruder, it still reports a failure to exit the extruder. Please refer to the abnormal extruder sensor section to check whether the green dot of the extruder is on.

If the green dot is on, it may be:

- A broken filament inside the extruder.

- The extruder hall switch is abnormal.

Please refer to this wiki article for detailed troubleshooting procedures: HMS_0700-2000-0002-0004: The AMS slot1's filament may be broken in the tool head

¶ Step 3. Check high unloading resistance

Usually, excessive bending of the PTFE tube of the toolhead, or debris accumulation in the AMS internal hub unit, can create high unloading resistance for filament unloading. First, please make sure to update the printer firmware to the latest version where the unloading failure issue is fixed.

(1) The PTFE tube is bent too much

If the PTFE tube of the toolhead is bent too much, it can create high resistance for the filament in the tube so that it can't be pulled back, and leads to unloading failure.

You can click here to download a PTFE tube bracket that can be mounted above the toolhead to prevent the PTFE tube from bending too much.

See the image below to install the bracket:

On Makerworld, there are more models to help straighten the PTFE tube to reduce unloading resistance.

Extruder AMS Filament Pull Back Fix by SPStudio - MakerWorld

AMS Filament Pull Back Fix V2 Upgraded by SPStudio - MakerWorld

AMS Fix Stack The AMS on Top and Fix For Failed To Retract Filament Error by SPStudio - MakerWorld

(2) Debris accumulation in AMS internal hub unit

After using the AMS for a long time, excessive accumulation of filament debris inside the internal hub unit can result in increased resistance and potential unloading failure.

You can refer to this wiki article for instructions on how to clean the internal hub unit:

Dismantling and cleaning the AMS internal hub unit

(3) Unloading failure of special filament

If you have an unloading failure for a special filament, such as PLA-CF or other hard filament, we recommend using the spool holder at the back of the printer when printing with the filament.

If the issue persists after troubleshooting, please submit a customer support ticket.

¶ Equivalent Codes

The following HMS codes represent the same type of fault on different AMSs.

0700-7000-0002-0001 AMS1

0701-7000-0002-0001 AMS2

0702-7000-0002-0001 AMS3

0703-7000-0002-0001 AMS4

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.