¶ Visual Detection of Live Camera

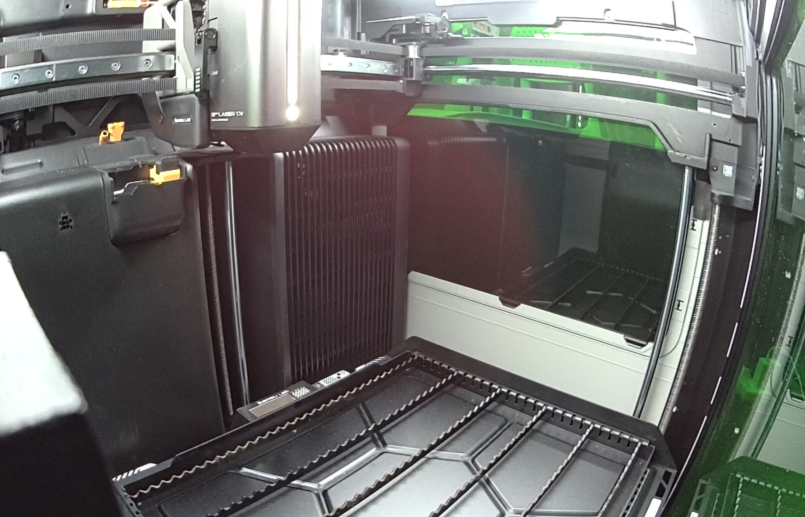

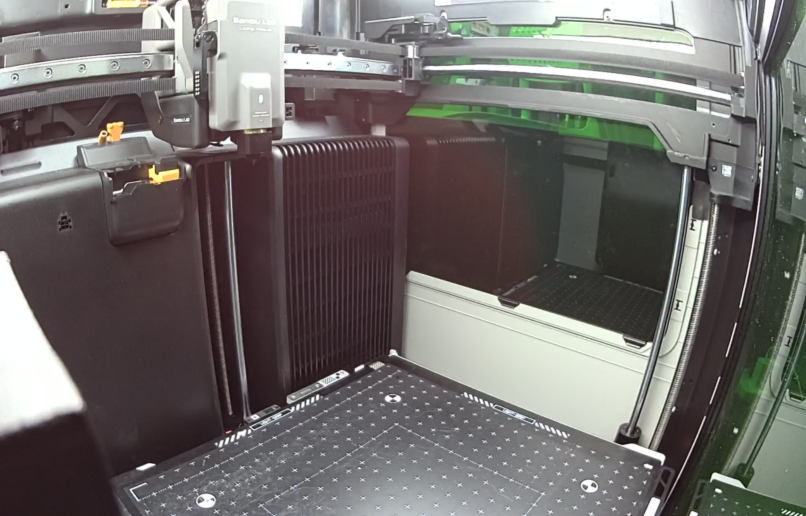

We have equipped a live camera in the corner of the H2S printer chamber. This live camera enables various visual detection functions such as spaghetti detection, foreign object detection, build plate detection, and nozzle clogging detection.

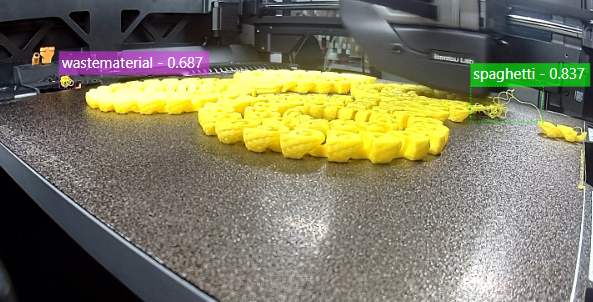

¶ Spaghetti detection

Similar to spaghetti detection on the X1 series, after a print failure, timely spaghetti detection helps prevent further losses such as wastage of filaments and damage to the printer.

Please note that Spaghetti Detection is not a foolproof method to avoid print failures. There can be some false positive detections, or cases when the Spaghetti Detection feature might not work as expected, especially when using black/dark filament.

To ensure the highest chances of success, it is recommended to always wash the plate with warm water and detergent to avoid adhesion issues, and to ensure the slicer settings are correct.

¶ Working Steps of Spaghetti detection

The working method is consistent with the X1 series spaghetti detection:

- Take a frame of the Live Camera every T sec.

- Send the image to the AI detector running on the local on-device NPU inside the device

- Postprocess the detection results. We accumulate the results for the latest 10 frames. If there are enough positive candidates, and they are spatially consistent, then a spaghetti failure is detected.

¶ Prerequisites for Spaghetti detection

To have the detector work properly, there are a few requirements.

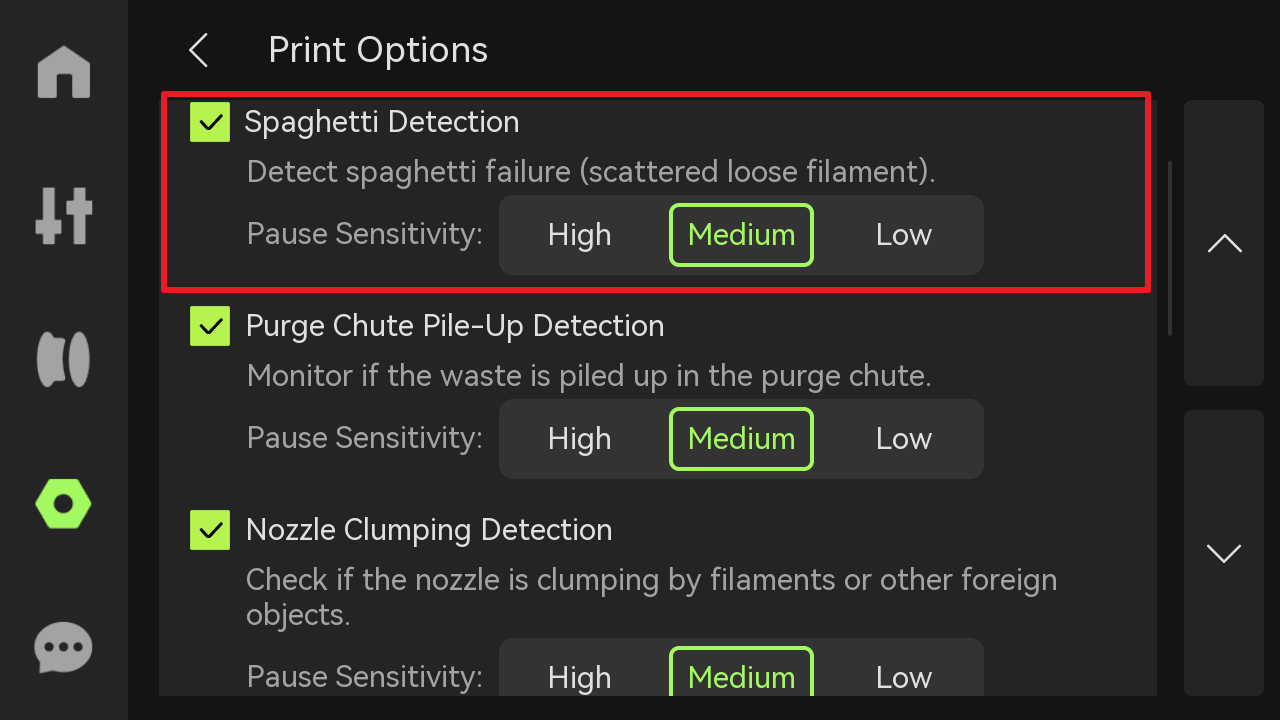

- The detection function needs to be enabled in the print options. You can adjust the sensitivity from {low, medium, high}. If you are off the printer for a relatively long time (e.g. a whole night), you can set the sensitivity to low, so it's less often to pause the printing for small defects.

- The chamber light needs to be on. The spaghetti detection needs a good lighting condition to capture the details of prints. By default, we switch on the light when the first layer starts to print. If the light is shut down manually, it will not be turned on again.

¶ Error Alarm for Spaghetti detection

¶ Related error codes

| Error code | Copywriting |

|---|---|

| 03008003 | Spaghetti defects were detected by the AI Print Monitoring. Please check the quality of the printed model before continuing your print. |

¶ Related HMS error

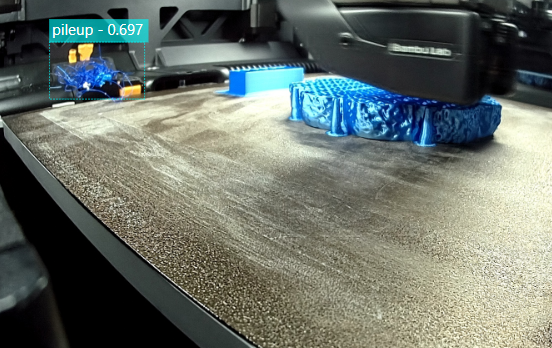

¶ Pile-up Detection

Similar to the spaghetti detection principle, pile-up detection is used to identify whether there is accumulated waste material around the extrusion assembly. Excessive accumulation may cause the toolhead to collide or skip steps, which can further lead to other printing issues.

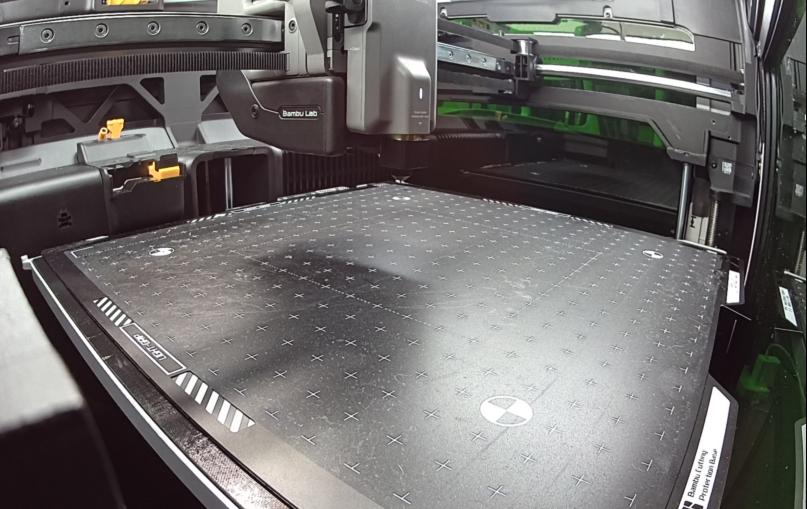

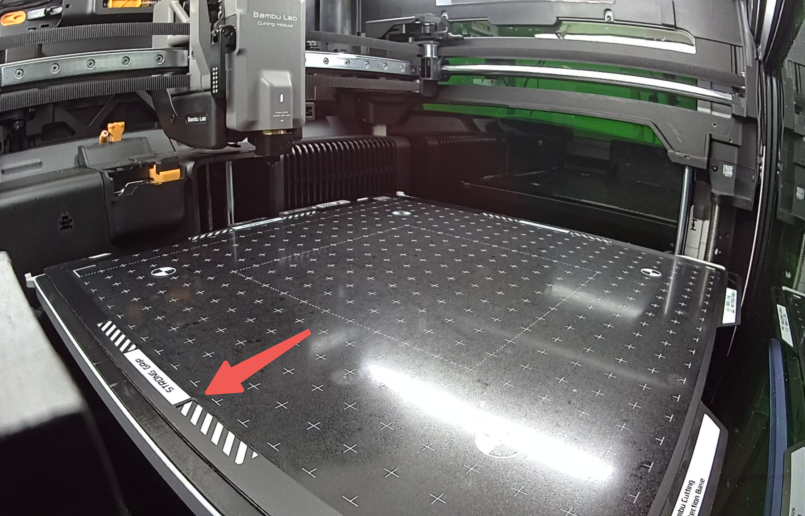

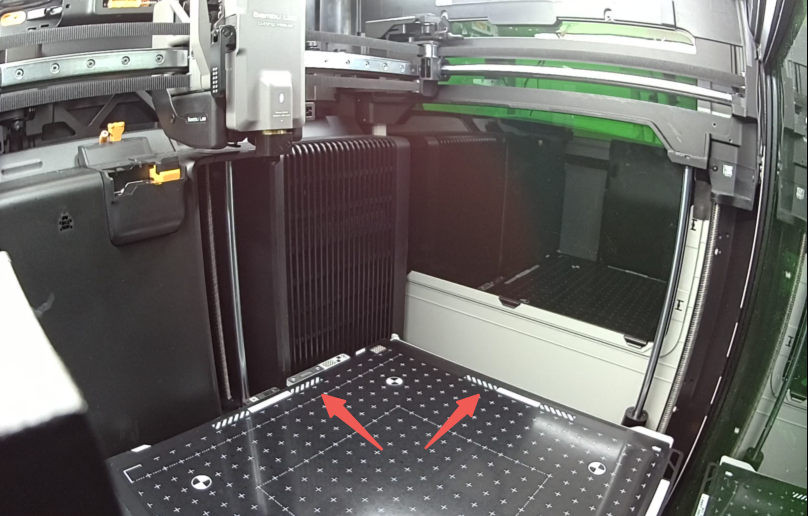

¶ Foreign Object Detection

Detect foreign objects on the laser platform based on the live camera. Control the heatbed's up-and-down movement, capture two images to simulate binocular vision for scene reconstruction, then obtain the area where the heatbed is located through plane segmentation.

¶ Foreign Object Detection Triggering Scenario

The laser platform detection phase of laser module mount calibration. The foreign object detection before the laser module operation is primarily to ensure that there are no foreign objects near the homing platform to interfere with the homing operation during mount calibration.

The cutting platform detection phase of cutting module mount calibration. During the leveling process of the cutting module, it is necessary to clear the cutting platform. Therefore, foreign object detection is required to ensure that there are absolutely no foreign objects placed on the cutting platform.

After initiating a 3D printing job, it is essential to ensure that there are no foreign objects on the build plate, especially confirming that any previously printed models have been removed from the build plate before starting a new printing job.

¶ Performance Metrics for Foreign Object Detection

¶ 🔹 Laser Module Mount Calibration

¶ Recognizable Object Size

- Close proximity: ≥ 3cm × 3cm × 1.5cm

- Distant area: ≥ 5cm × 5cm × 2cm

- Distance definition: the area outside the diagonal of the laser platform (the region on the top right away from the camera) is defined as "distant," while the area inside the diagonal is defined as "close."

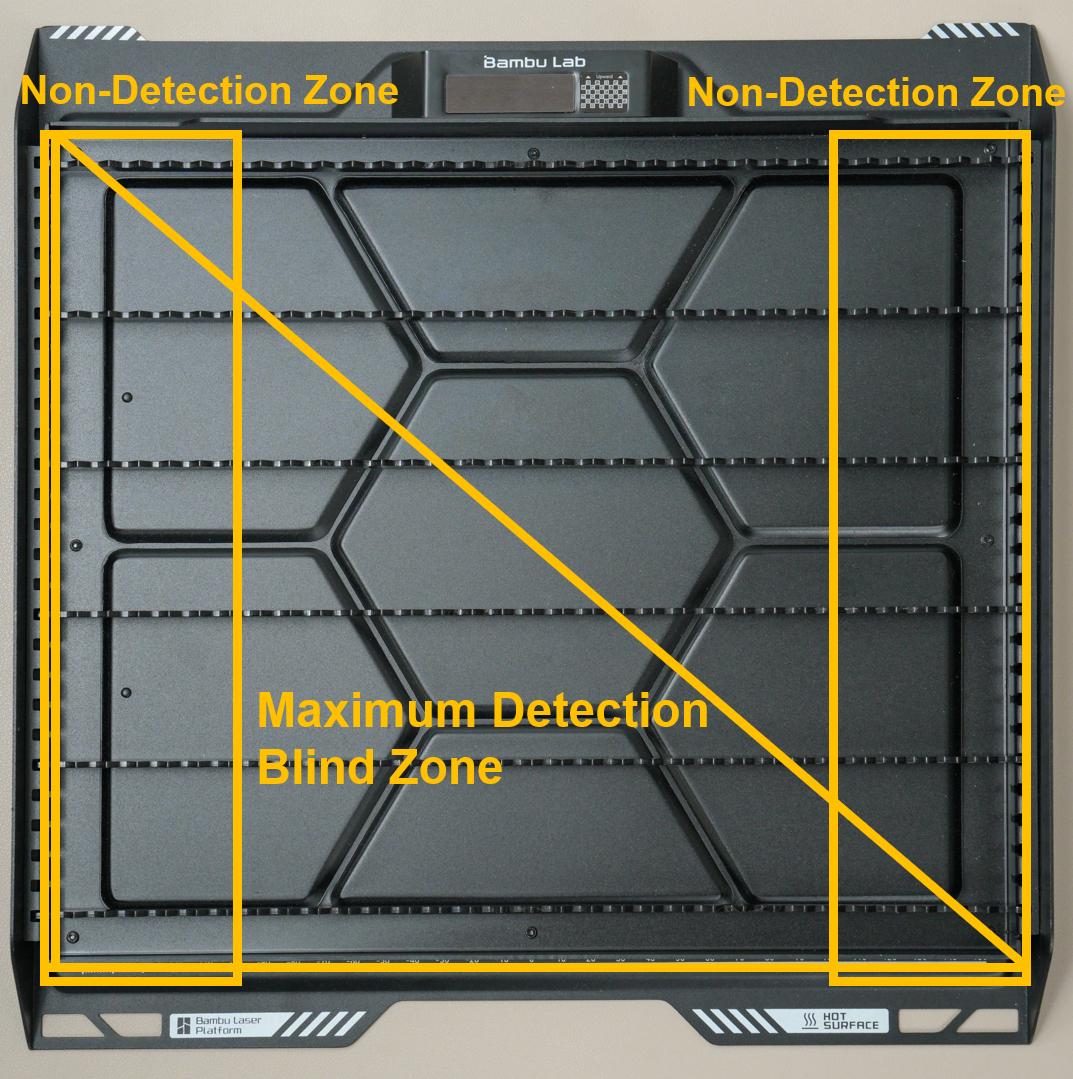

¶ Detection Blind Zone and Non-detection Zone

Detecting Blind Zone: Zones that the live camera cannot detect, with the maximum detection blind zone occupying half of the bed (from the perspective of the live camera, the 45° diagonal area near the camera side of the bed will be obstructed).

When the bed is positioned low, a significant portion of it will be obstructed, leading to blind zone.

Non-detection zone: There are approximately 6cm non-detection zones on the left and right sides, where foreign objects within these zones are not detected. The purpose of setting non-detection zones is to eliminate interference from the platform pins.

¶ Detections

- 1 time

¶ Scenarios that could potentially lead to detection failure

Large flat objects (objects whose surfaces almost entirely cover the bed, which may lead to potential missed detections)

¶ 🔹 Cutting Module Mount Calibration

¶ Recognizable Object Size

- Close proximity: ≥ 3cm × 3cm × 1cm

- Distant area: ≥ 5cm × 5cm × 1cm

¶ Detection Blind Zone and Non-detection Zone

- Same blind zone as the laser module.

- No additional non-detection zones.

¶ Detections

- 1 time

¶ Scenarios that could potentially lead to detection failure

Large flat objects (objects whose surfaces almost entirely cover the bed, which may lead to potential missed detections)

¶ 🔹 3D Printing

¶ Recognizable Object Size

- Close proximity: ≥ 3cm × 3cm × 1cm

- Distant area: ≥ 5cm × 5cm × 1cm

¶ Detection Blind Zone and Non-detection Zone

- The maximum detection blind zone is a triangular zone measuring 6cm x 6cm near the live camera.

- No additional non-detection zones outside of the blind zone.

¶ Detections

Up to 2 times.

Perform object detection without raising the heated bed first (to prevent prints left on the bed). Once it is confirmed that there are no foreign objects, lift the heatbed for a second detection.

¶ Scenarios that could potentially lead to detection failure

-

Large flat objects (objects whose surfaces almost entirely cover the bed, which may lead to potential missed detections)

-

Large flat objects (objects whose surfaces almost entirely cover the bed, which may lead to potential missed detections)

¶ Error Alarm for Foreign Object Detection

¶ Related error codes

| Error code | Copywriting | Troubleshooting |

|---|---|---|

| 03008046 | Foreign object detection timed out, please restart the printer. | Restart the printe |

| 0500807A | Foreign object detection did not take effect. You can continue the task or view the assistant. | Access the assistant to view specific HMS notifications |

| 0500806E | Foreign objects detected on heatbed; please check and clean up the heatbed. | After clearing the foreign objects, click "Continue." |

¶ Related HMS error

Most HMS error code solutions are provided in the text below. For some codes, you can find more details on the HMS home page.

- 0C00_0100_0001_000F: The Live View Camera calibration failed. Please restart the devices or update the firmware.

- 0C00_0100_0001_0010: The Live View Camera calibration failed. Please check if the heatbed is clear and ensure the camera image is clear and dirt-free. After these steps, please recalibrate.

- 0C00_0100_0001_0011: The Live View Camera calibration failed, please recalibrate. Ensure the build plate is empty, and the camera view is clear and properly oriented. Please contact customer support if repeated failures occur.

- 0C00_0100_0001_0012: The Live View Camera calibration failed and the calibration result could not be saved. Please try recalibrating. If calibration fails repeatedly, please contact the customer support team.

- 0C00_0100_0001_0013: The Live View Camera calibration failed and the Liveview camera serial number cannot be read. Please contact the customer support team.

- 0C00_0300_0002_0012: Foreign object detection is not working. The Live View Camera needs calibration. Please tap "Settings > Calibration" on the printer screen. If a laser or cutting module is installed, please remove it before calibration.

- 0C00_0300_0002_0013: Foreign object detection is not working. Please restart the devices or update the firmware.

- 0C00_0300_0002_0014: It's recommended to calibrate the Live View Camera to improve the accuracy of foreign object detection. Tap "Settings > Calibration" on the printer screen. If a laser or cutting module is installed, please remove it before calibration.

- 0C00_0300_0002_0015: Foreign object detection is not working. Detected the Live View Camera has been replaced. If a laser or cutting module is installed, please uninstall the module, tab "Settings>Calibration" on printer screen and re-calibrate the Live View Camera.

- 0C00_0300_0002_0016: Foreign object detection is not working and the Live View camera serial number cannot be read. Please contact the customer support team.

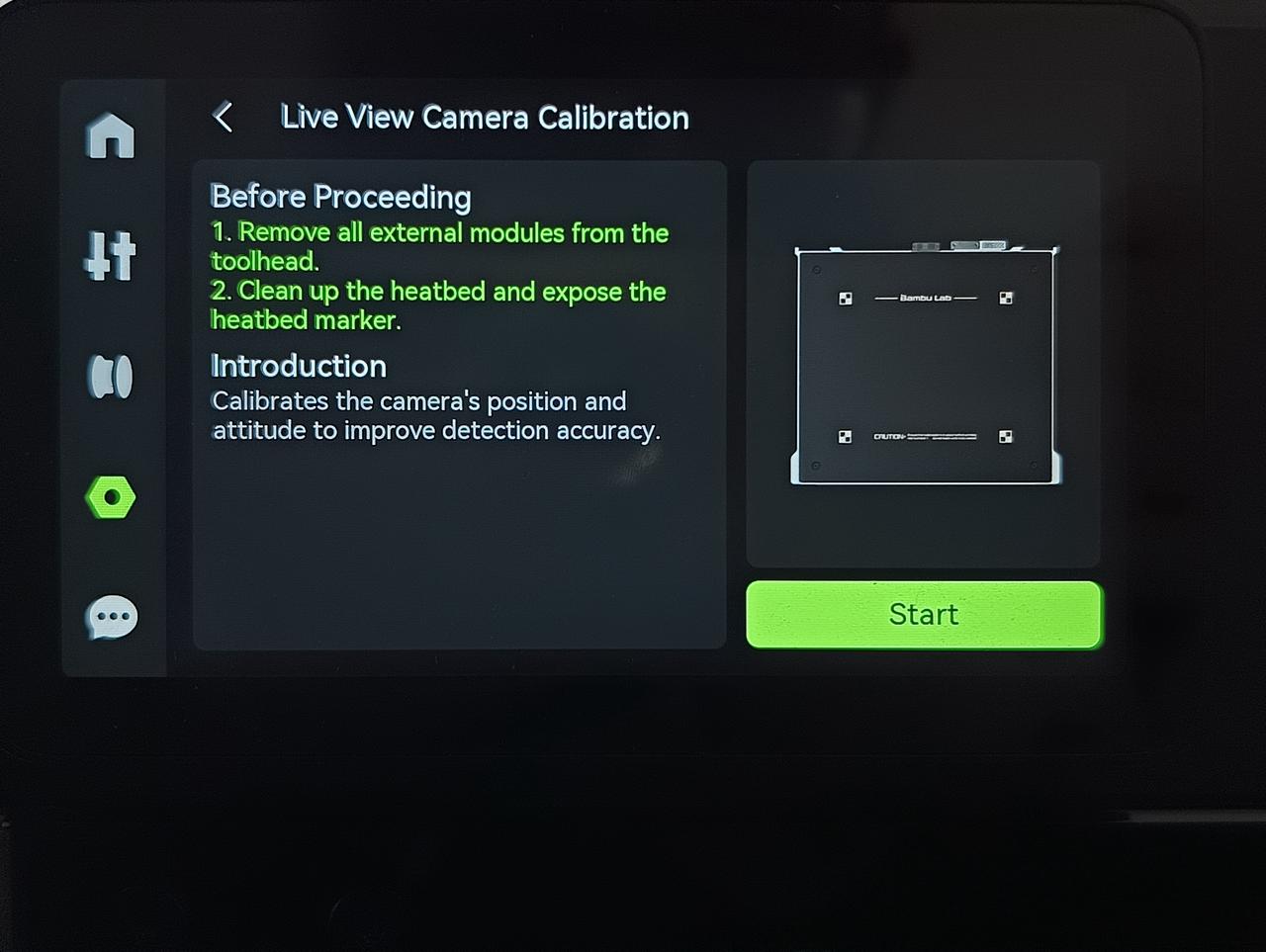

¶ Scene requiring live camera calibration for foreign object detection

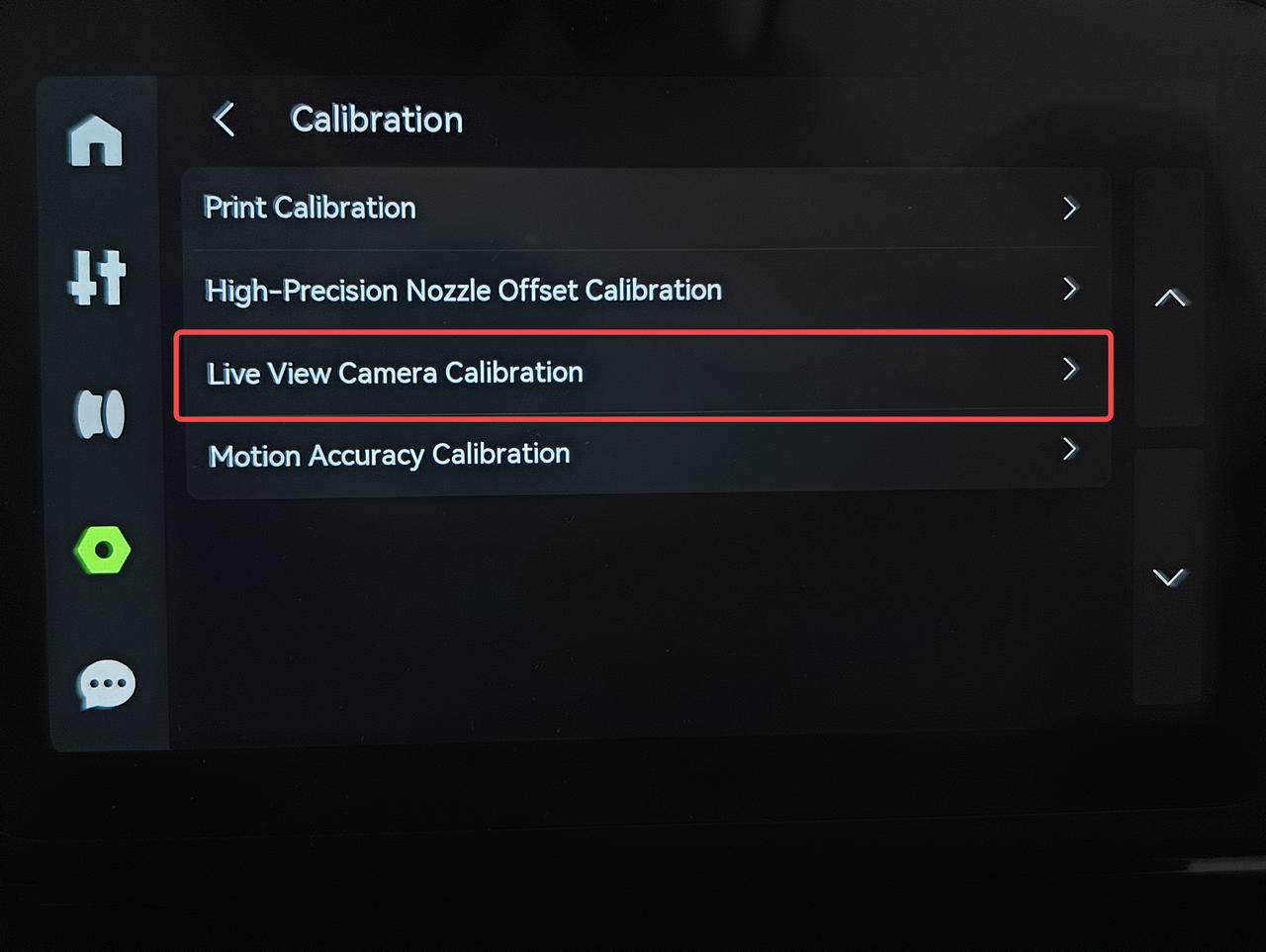

After replacing or reinstalling the live camera, it is usually necessary to calibrate the live camera before conducting foreign object detection.

Calibration is performed before the machine leaves the factory, and camera calibration is typically not required during normal use.

If the live camera is replaced, the system will detect SN changes during machine startup or before foreign object detection runs and prompt for calibration.

If the live camera is reinstalled (without SN changes), it is also recommended to recalibrate once, and during the foreign object detection process, it will also determine whether recalibration is necessary. However, foreign object detection has a high tolerance for live camera, and if the angle deviation does not exceed ±3deg, no prompt for calibration will be given.

To calibrate, the laser or cutting module installed on the tool head needs to be removed, and then the live camera calibration can be run in Settings -> Calibration to complete the calibration process.

¶ Actions during foreign object detection

Foreign Object Detection at the Start of 3D Printing: Foreign object detection is conducted up to two times to reduce blind zones. When the initial heatbed height is greater than 135, two detections will be performed. The first detection occurs with the heatbed at its initial position. During the second detection, the heatbed will be raised, and the bed height during detection will range between 70 and 90.

Foreign Object Detection Before Initiating 2D Processing: If the heatbed is too high, it will be lowered for detection. If the heated bed is too low, it will be raised for detection, with the bed height ranging between 70 and 240 during detection.

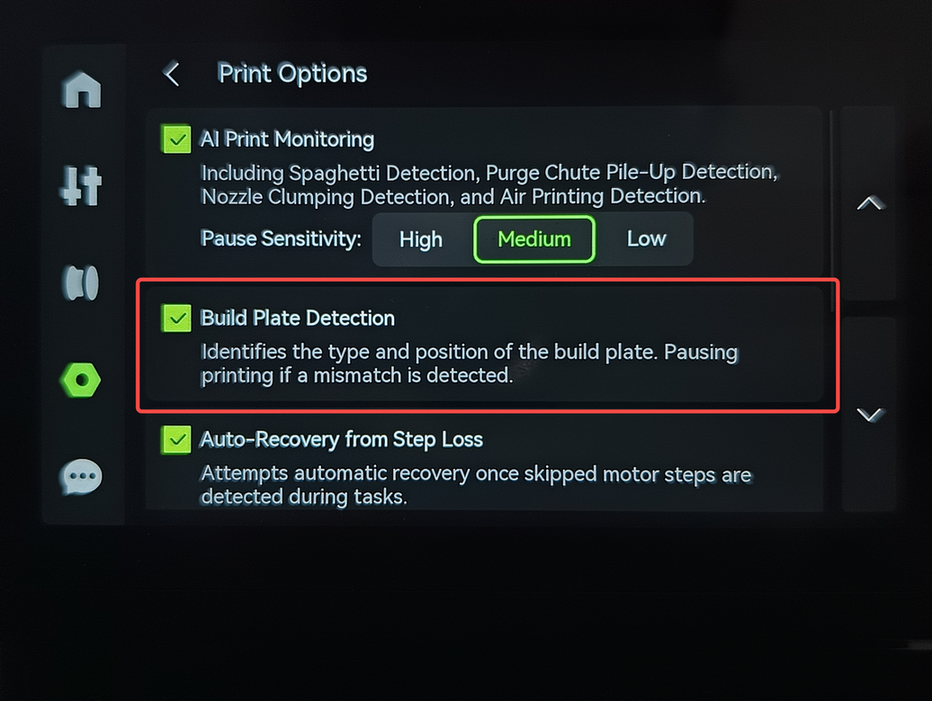

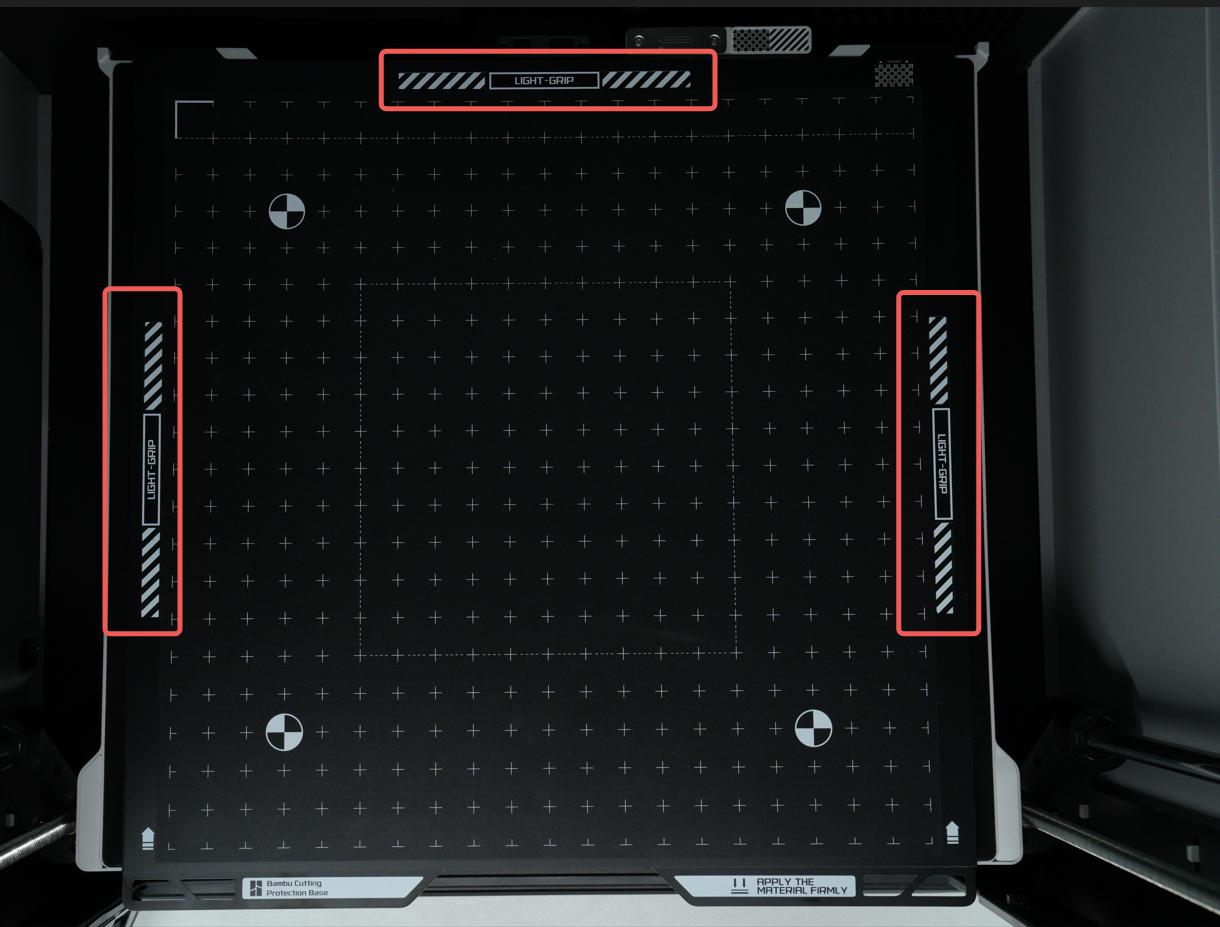

¶ Build Plate Detection

In-place and type detection of the build plate based on the live camera. If the actual build plate being used does not match the one specified in the slicing file, promptly stop the print to prevent printing failures.

¶ Trigger Scenarios for Build Plate Detection

After each print job is initiated, the print file is sent to the printer, and the printer checks the type of the build plate and the position information on the current heatbed according to the plate type of the slice file.

¶ Detection Actions

Build plate detection occurs after the heatbed homing. Then the heatbed will move to a fixed Z height, utilize the live camera to capture an image for detection.

¶ Detection Button

Enabling this function means that after the print job is initiated, it will detect whether the build plate matches according to the type of build plate in the slice file; turning off this function means that it will not detect the build plate after the print job is initiated.

¶ Error Alarm for Build Plate Detection

¶ Related HMS error

0C00_0300_0002_000C: The build plate localization marker was not detected. Please check if the build plate is aligned correctly.

¶ Laser and cutting module quick-release lever Detection

When using the laser and cutting modules, during the mount calibration and initiation of processing stages, the live camera will identify whether the quick-release levers of the laser and cutting modules are securely locked. If they are not locked, an error will be reported, and printing will be paused.

|

|

|

| Lever is locked | Lever isn't locked | Lever isn't locked at all |

¶ Related HMS error

- 0300_9500_0001_0006 : Laser Module not detected: the module may have fallen off, or the quick-release lever may not be locked.

¶ Cutting Platform Position Detection

The live camera can also confirm whether the cutting platform is placed on the heatbed by recognizing the markers on the cutting platform. There are a total of three markers on the cutting platform, and the camera can detect the markers at different positions when the heatbed is at different heights.

Timing of Detection: During mount calibration, after opening or closing the front door of the machine, when taking photos and initiating production in Bambu Suite.

|

|

|

| The heatbed is in a higher position | The heatbed is in a lower position |

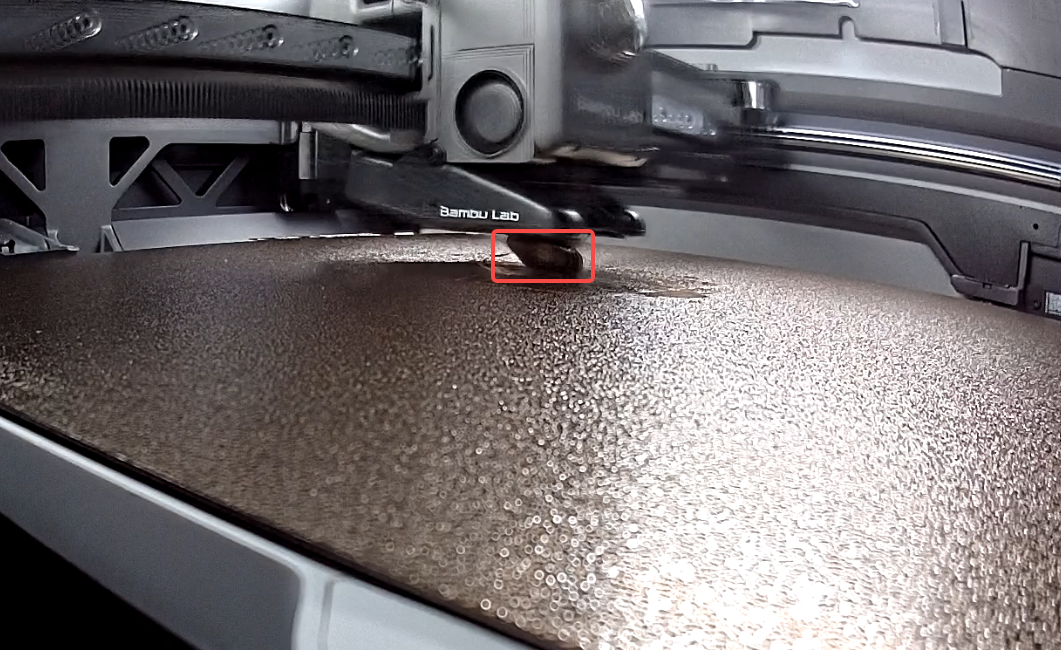

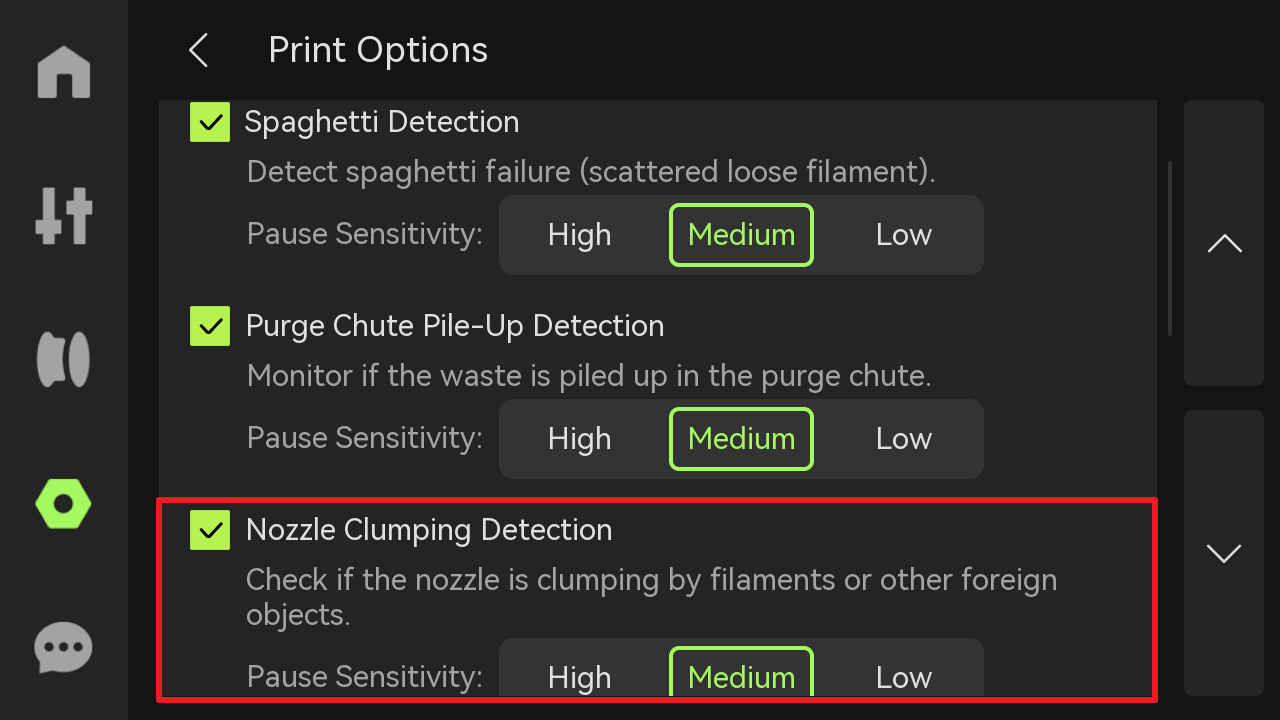

¶ Nozzle Clogging Detection

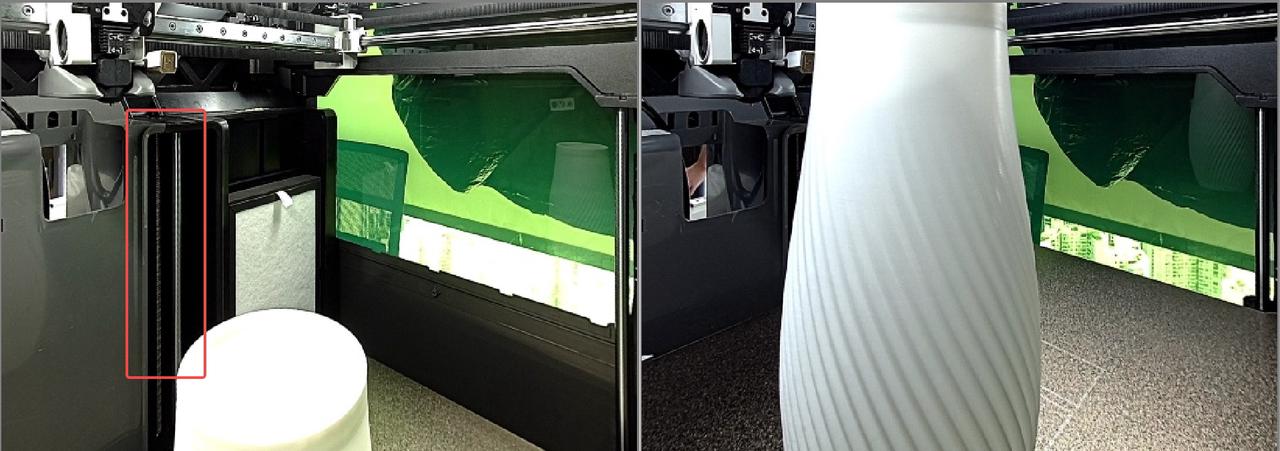

The nozzle clogging detection function uses the live camera to capture images in real time and monitor whether material has accumulated and wrapped around the toolhead. When the detected clog reaches a certain size, the system will usually issue a notification within 2 minutes and automatically pause printing to prevent damage to the toolhead.

Please note that there may be a delay in the response of the clogging detection. This function is mainly intended to prevent further damage to the device, and generally cannot protect the model being printed.

¶ Workflow of Nozzle Clogging Detection

- During printing, the live camera captures an image sequence every 60–120 seconds

- The image data is processed by the machine’s built-in NPU

- If the system identifies clogging in two consecutive detections, it will automatically trigger a notification and pause printing

¶ Notes on Nozzle Clogging Detection

- Keep the camera cover open, and ensure the lens is clean and free of dirt or glare

- It is recommended to turn on the enclosure light; the detection still works without it, but accuracy may decrease

- Detection accuracy may decrease in Ludicrous Mode or when printing with black filament

- Each print task triggers only one notification. If the user ignores the prompt and continues printing, no further clogging alerts will be issued

- Ensure that the nozzle clogging detection function is enabled

¶ Error Codes for Nozzle Clogging Detection

| Error code | Message |

|---|---|

| 0c008043 | AI has detected a nozzle clog. Please check the hotend status. You can open the Assistant for troubleshooting solutions. |

Related HMS Notification:

- 0c00-0300-0002-001c: Possible nozzle clogging detected.

¶ Intelligent Detection of Birdseye Camera

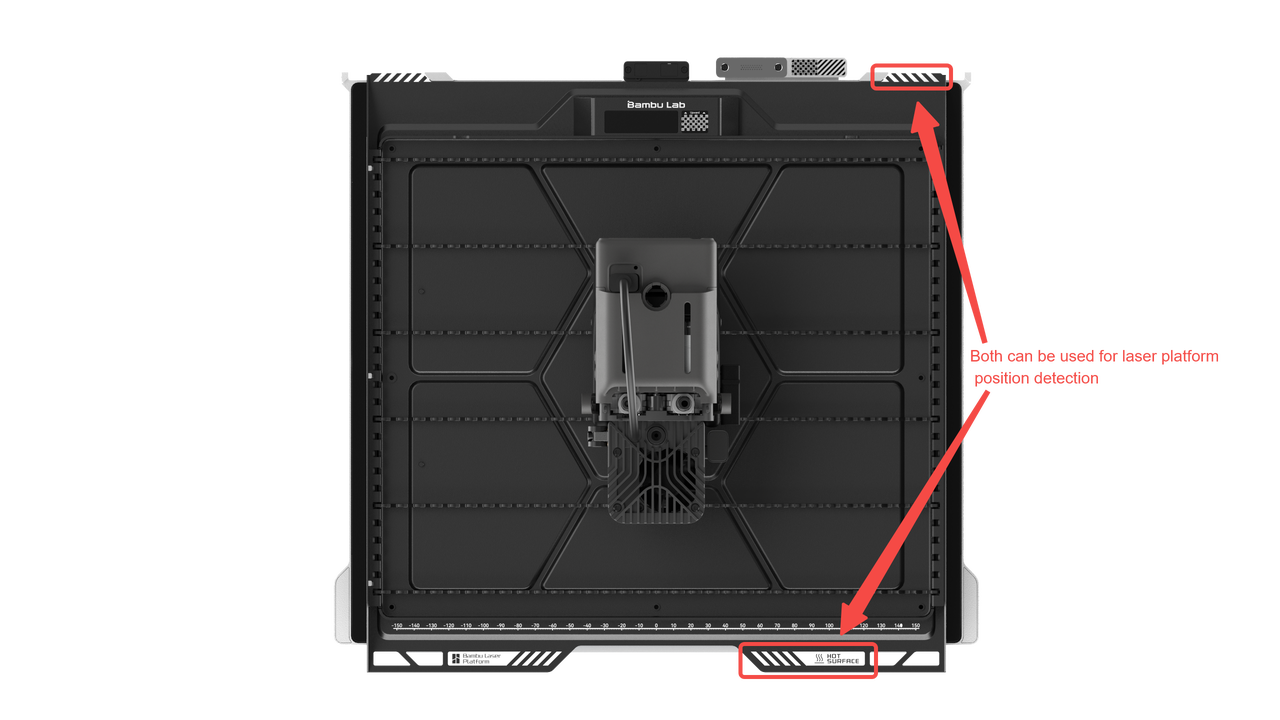

¶ Laser Platform Position Detection

By raising or lowering the heatbed to a specific height, the Birdseye Camera identifies markers on the laser platform to determine if the laser platform has been placed.

Timing of Detection: During mount calibration, after opening or closing the front door of the machine, when taking photos and initiating production in Bambu Suite.

¶ Related error codes

| Error code | Copywriting |

|---|---|

| 05008063 | The platform is not detected during calibration; please make sure the Laser Platform is properly placed. |

| 05008055 | Laser module is installed, but a Cutting Platform is detected. Please place a Laser Platform and perform laser calibration. |

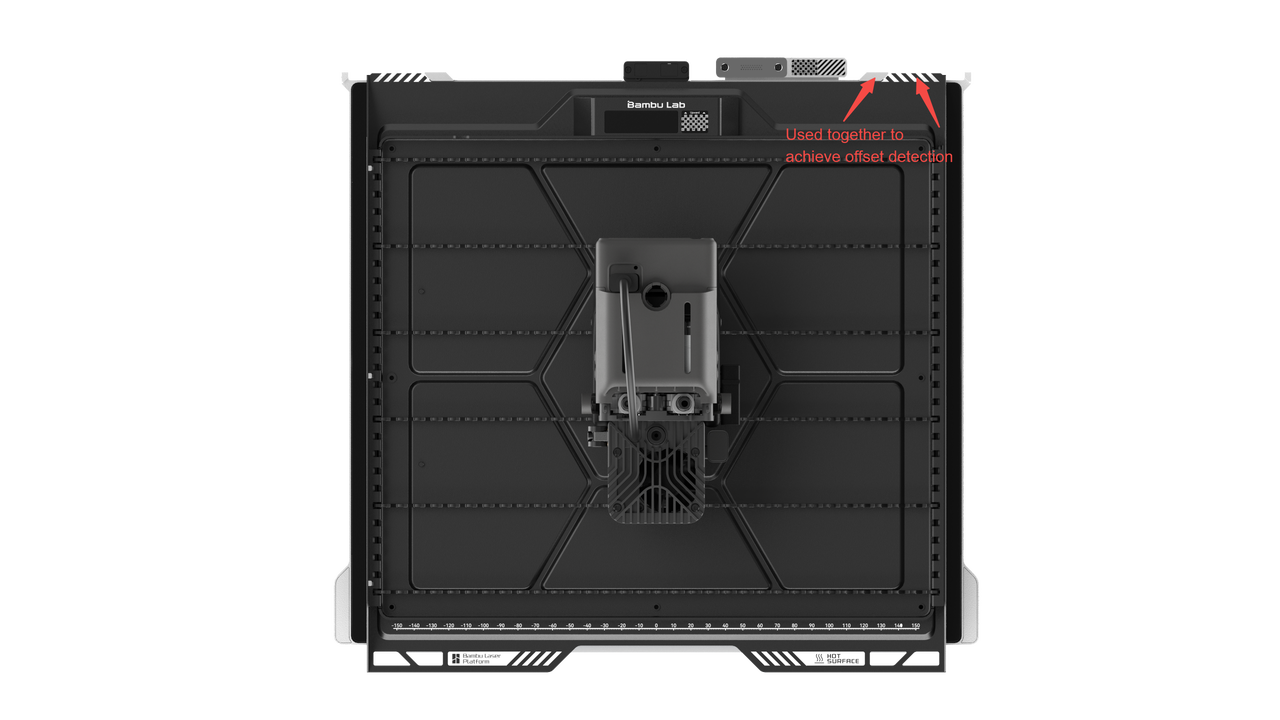

¶ Laser Platform Offset Detection

The birdseye camera can also detect whether the laser platform is offset based on the markers and the limit block inside the heatbed.

Timing of Detection: During mount calibration, after opening or closing the front door of the machine, when taking photos and initiating production in Bambu Suite.

¶ Related error code

| Error code | Copywriting |

|---|---|

| 05008074 | The Laser Platform is offset. Please ensure that the four corners of the platform are aligned with the heatbed, and the marker is not obstructed. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!