Brittle or improperly stored filament can break inside the AMS 2 Pro and H2D PTFE tubes, causing feeding failures or AMS errors. This step-by-step guide walks you through the process of removing broken filament from the filament tubes.

¶ When to Use this Guide?

-

Use this guide when you encounter error code [0700 8004], which indicates that the AMS is unable to retract the filament, assuming you’ve already ruled out other possible causes, such as improper filament insertion.

-

Unusual clicking or grinding noises. These sounds from the feeder may suggest that AMS 2 Pro is having difficulty pushing the filament through.

-

Visible filament remnants in the AMS 2 Pro tubes or in the PTFE tube from AMS 2 Pro to H2D.

¶ Tools Required

- H2.0 Hex Key

- Flat Tweezers

- Replacement PTFE Tube. You can buy it from the Bambu Lab store.

- A small piece of filament

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.When you perform maintenance or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Troubleshooting Guide

The first step is to identify the specific section where the filament is stuck. Check the printer’s screen or Bambu Studio for errors, such as “filament broken in the path” or HMS codes, specifically 0700-2000-0002-0003 or [0700 8004]. Note the AMS 2 Pro slot (1–4) with a red LED and inspect the PTFE tube from the AMS outlet to the H2D filament buffer or toolhead for visible filament fragments. The possible positions where the filament can break include:

- PTFE Tube running from AMS 2 Pro to H2D Printer

- AMS 2 Pro Tubes

¶ Removing Filament Stuck Inside the PTFE Tube from the AMS 2 Pro to the H2D Printer

If the filament is broken inside the PTFE tube that runs from the AMS 2 Pro to the H2D printer, you need to remove and clean the tube.

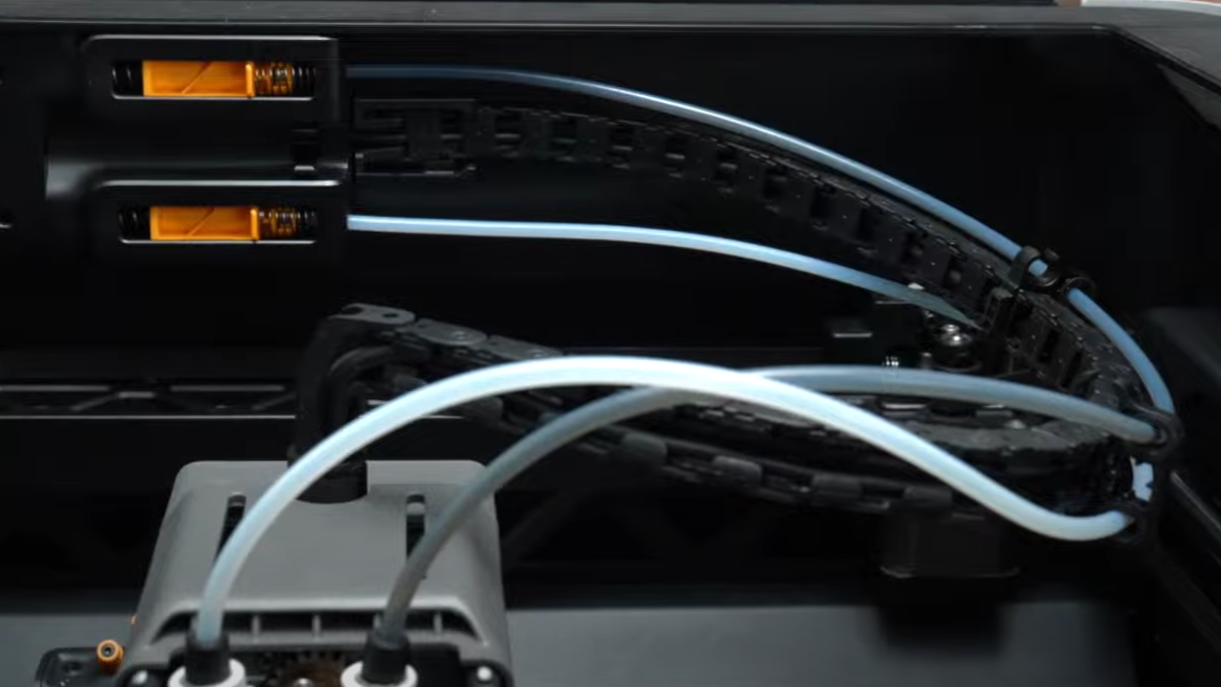

¶ Step 1: Remove the Tubes

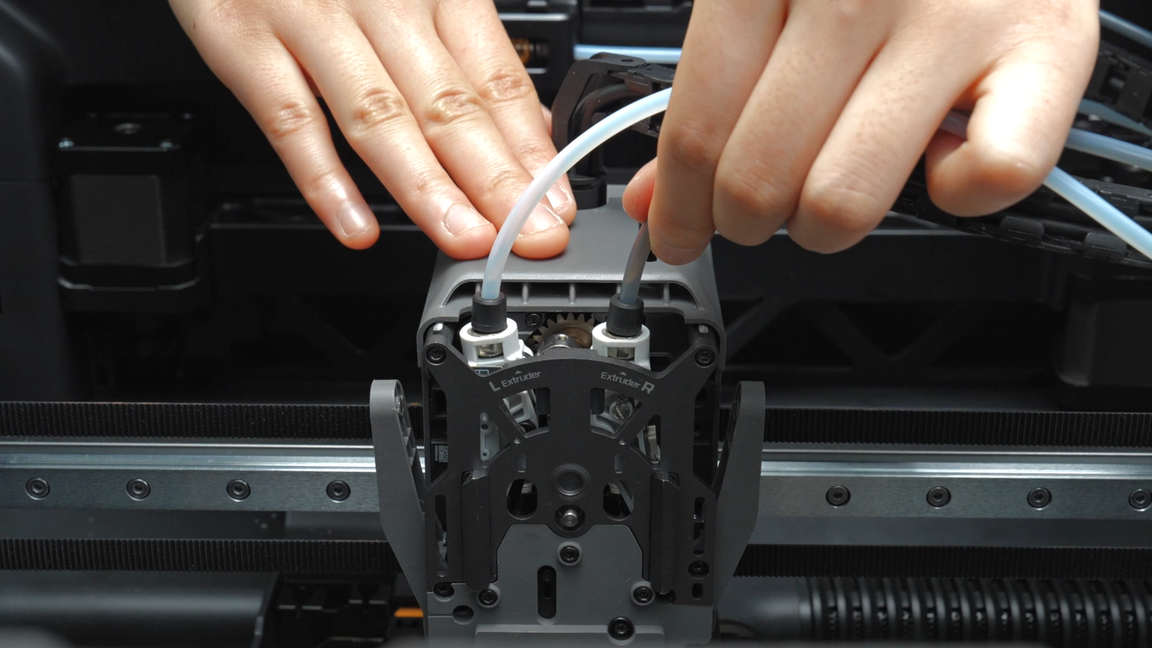

Press the black outer ring of the pneumatic connector, then unlock and pull the PTFE tube out.

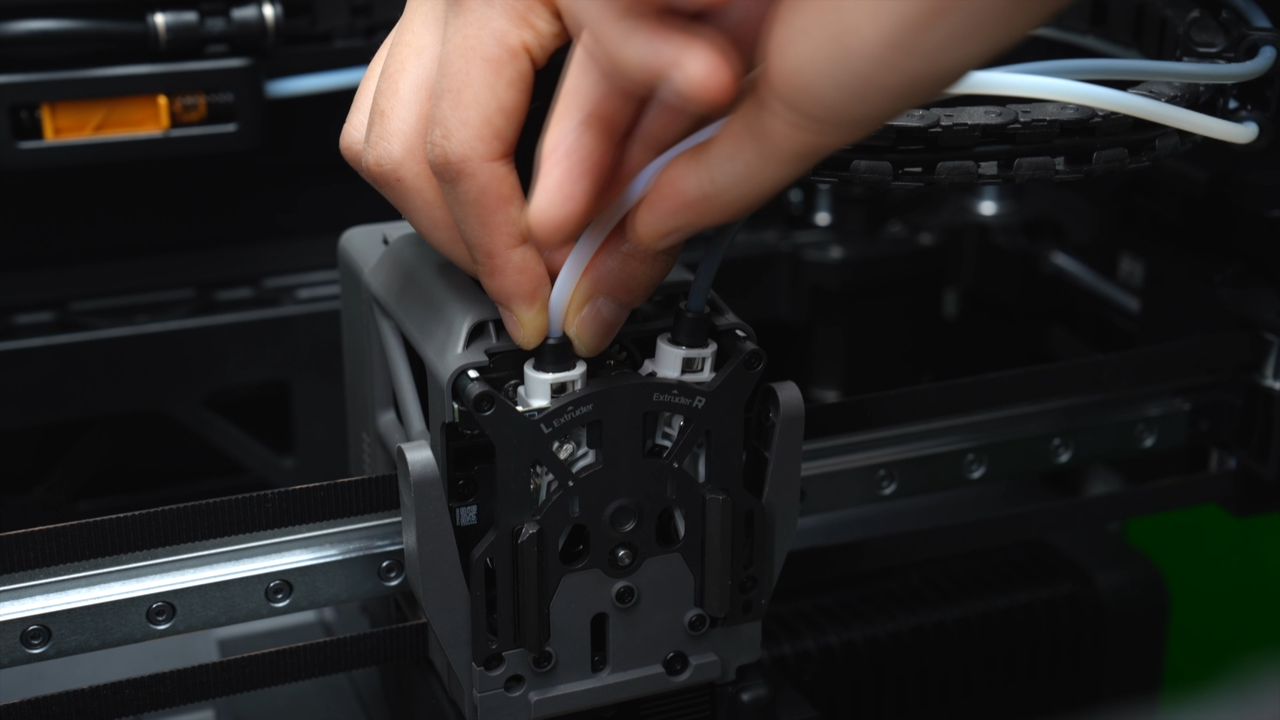

¶ Step 2: Disconnect the PTFE Tubes Inside the Chamber

Press the black outer ring to unlock the two connectors above the extruder.

¶ Step 3: Disconnect the Tubes from the Buffer

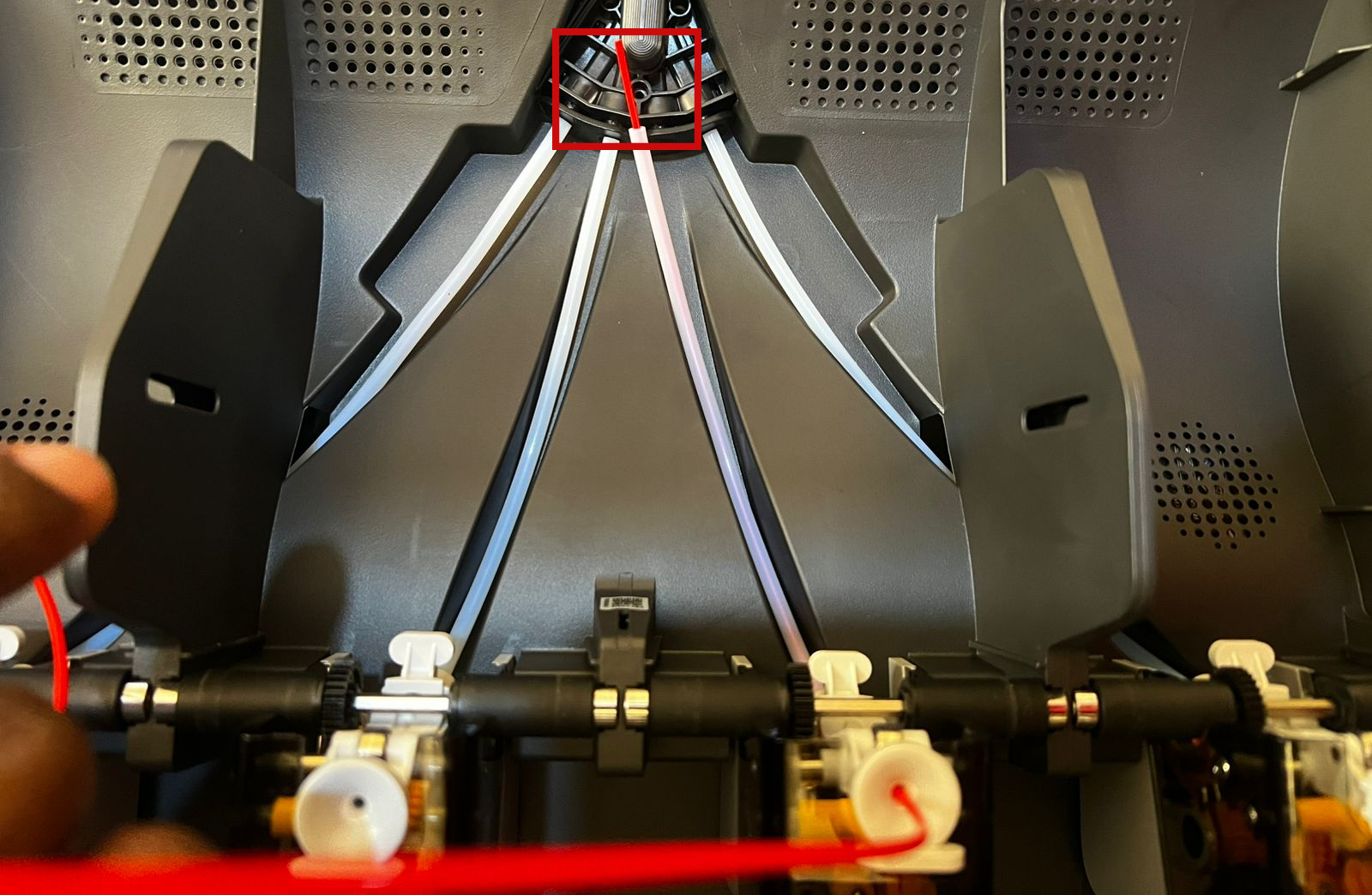

Press the black outer ring to unlock the two connectors at the upper and lower ends of the buffer. The upper connector can be pushed to the right to facilitate easier unlocking. Then, pull out the two PTFE tubes on the left and right.

¶ Step 4: Eject the Broken Filament

Use a long piece of filament to push the broken filament out of the tube from one end to the other.

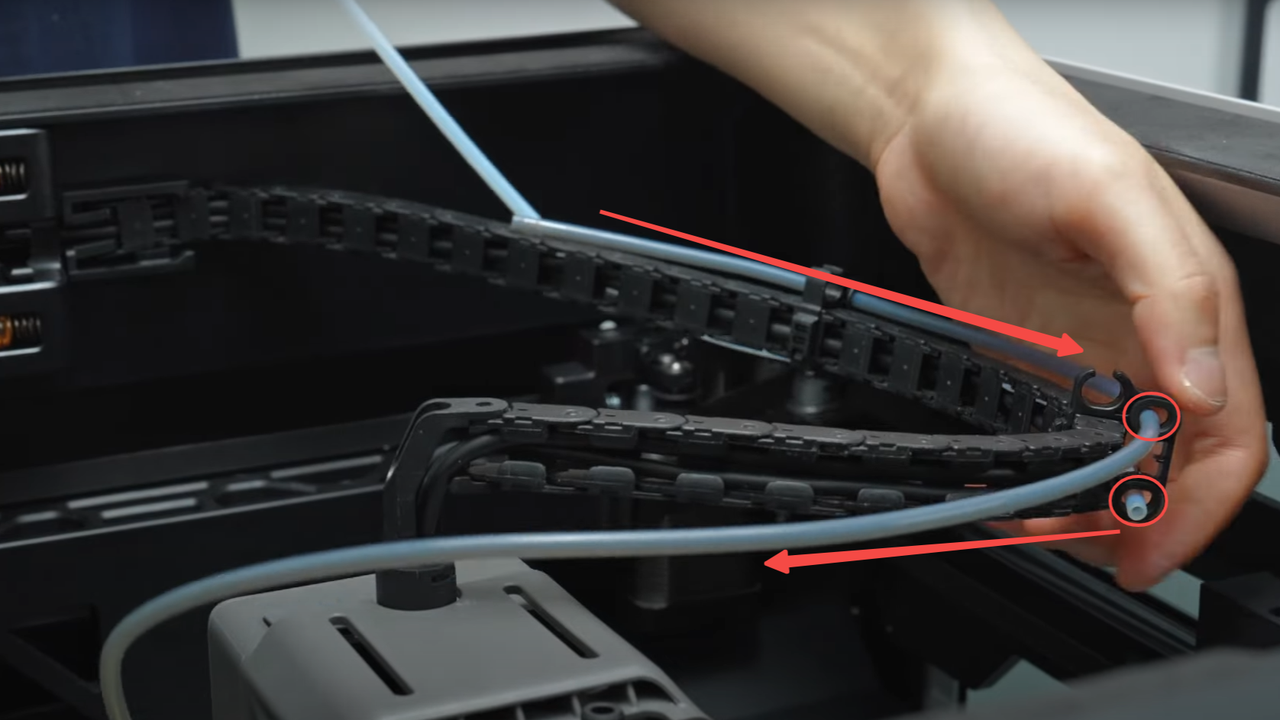

¶ Step 5: Reconnect the Tubes

After removing the broken filament, reconnect the PTFE tubes back. Put the two PTFE tubes through the holes on the side of the cable chain buckle.

Reconnect PTFE tubes to the AMS 2 Pro, filament buffer, and H2D toolhead, ensuring secure fittings (push until they click). Load a new filament and test feeding.

|

|

Note: The PTFE tube above the cable chain must be connected to the right extruder, and the PTFE tube below the cable chain must be connected to the left extruder.

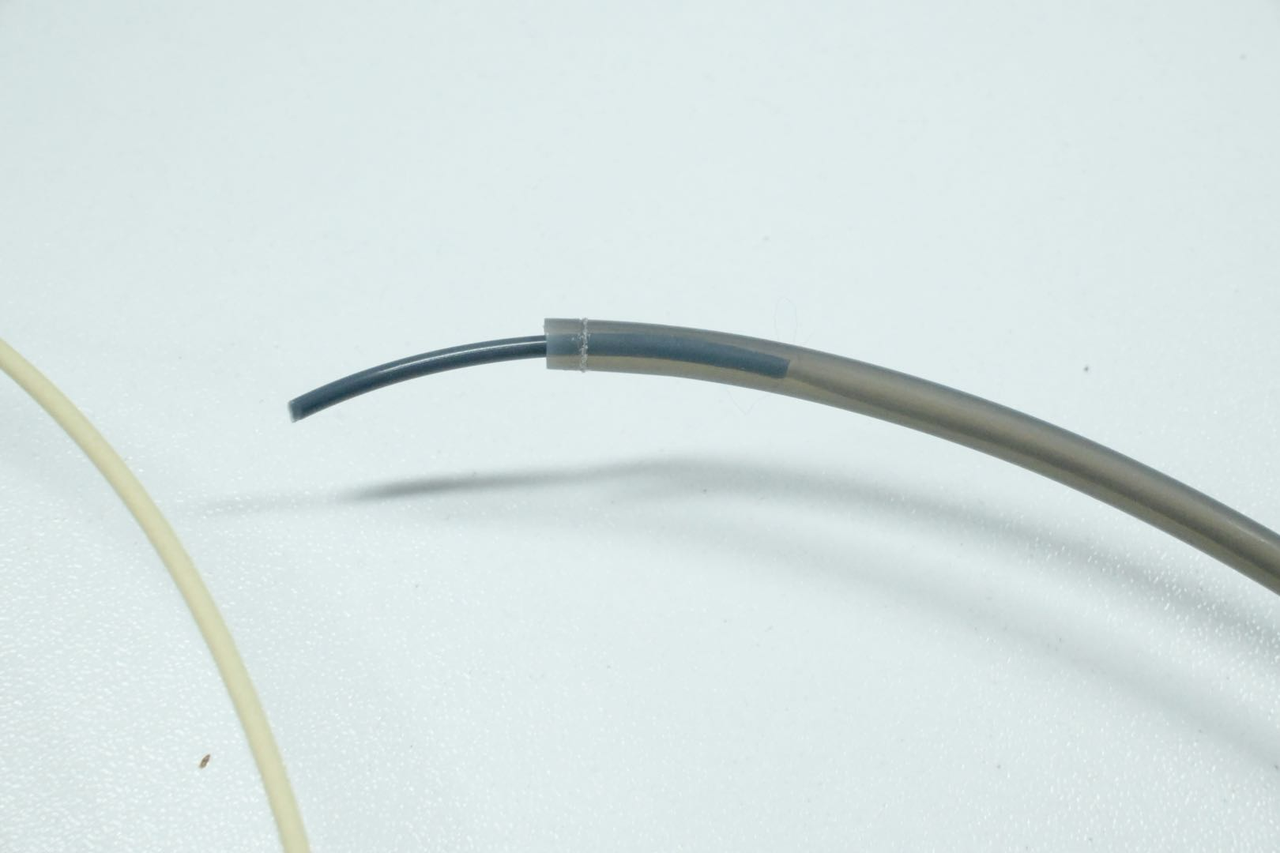

These tubes can experience wear and tear over time, potentially leading to increased friction and an increased risk of filament breakage inside. You need to inspect them properly. If they are worn out, you can buy them from the Bambu Lab store.

If the filament is broken inside the extruder, you will need to disassemble and remove the stuck filament, then reassemble it. Check out the disassembly and assembly of the H2D extruder wiki to learn how to do it. How to check which part is clogged in the H2D wiki is also a great resource.

¶ Removing the Filament Stuck Inside the AMS 2 Pro

¶ Step 1: Remove the Tubes

Unlock the filament tubes by pushing the black buttons with one hand, and use the other one to pull the tube out.

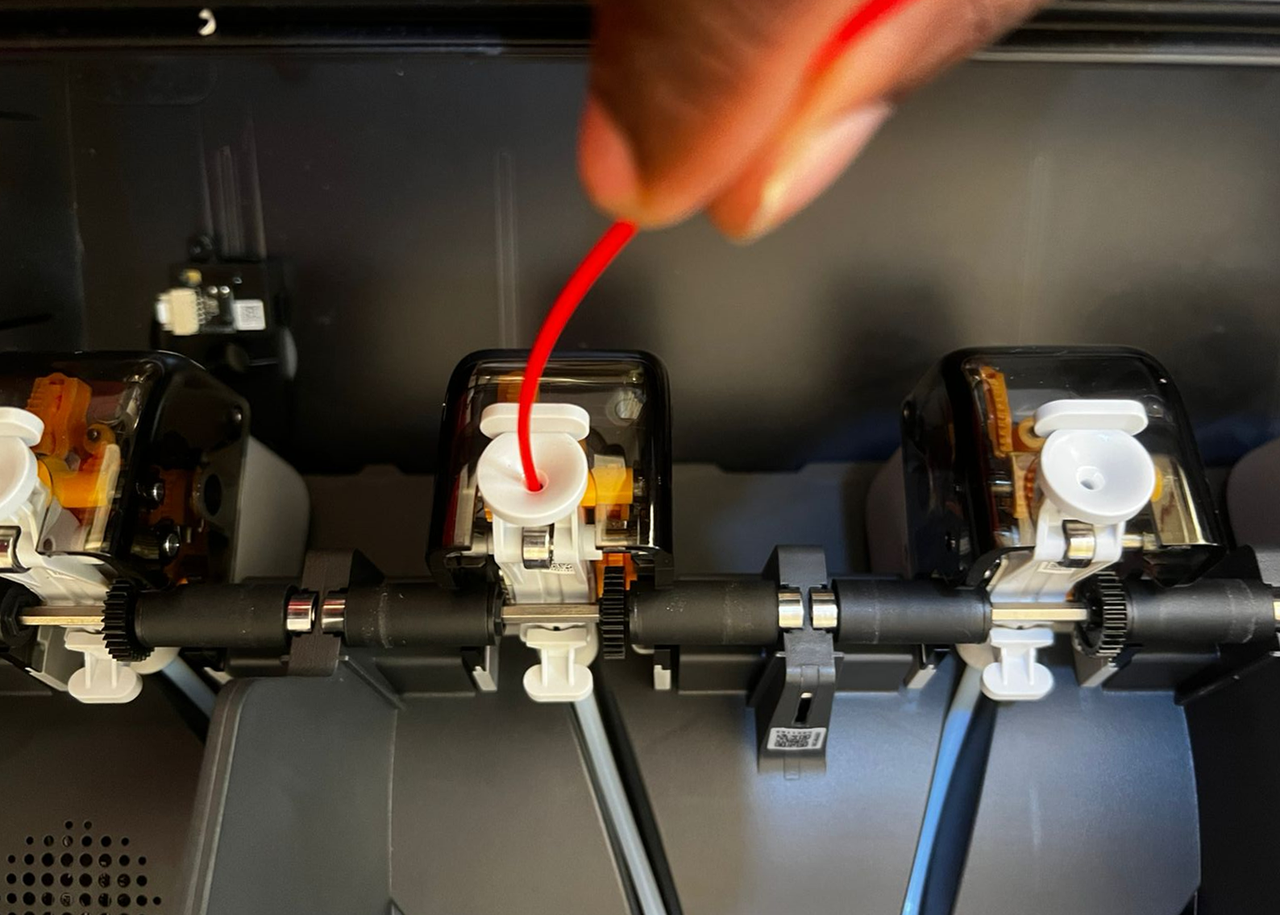

¶ Step 2: Insert the Filament Through the Feeder

Insert a small filmanent into the feeder until it goes through the tube, as shown below.

|

|

Any stuck filament should be removed through the PTFE tube opening. You may need to make several attempts to ensure all of it is cleared. Be gentle during the process to avoid breaking the filament again. Once the filament is fully removed, you can proceed with reassembling the parts.

¶ Step 3: Insert the Tubes Back

Insert the tubes back to their original slots.

If the filament breaks inside the internal hub, it is necessary to disassemble, inspect, and clean it.

¶ Removing the Filament Stuck Inside the Internal Hub

¶ Step 1: Disassemble the AMS 2 Pro

To access the internal hub, you need to disassemble the AMS 2 Pro. Check out the AMS 2 Pro disassembly and assembly wiki to learn how to do it.

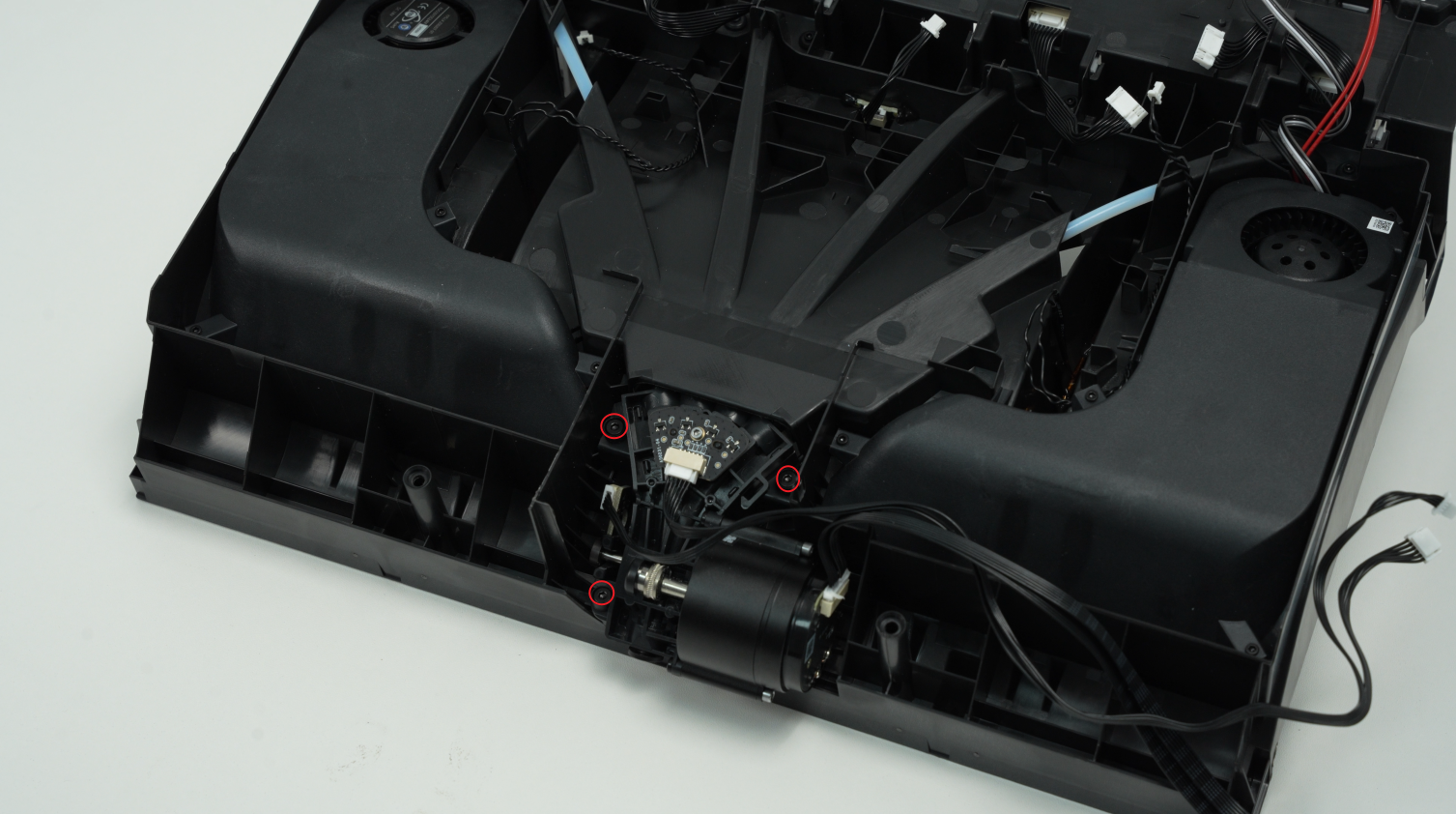

¶ Step 2: Remove the Internal Hub

Release the three cables from the filament hub by pulling them out of the clips. Then, unscrew the three screws and remove the filament hub. Carefully store the shock-proof silicone strip of the filament hub to avoid losing it.

|

|

¶ Step 3: Clean the Internal Hub

Disassemble the internal hub and clean it for any stuck filament. Check the clean the filaments hub wiki to learn how to do it. If there is no material inside the Internal Hub but it is still detected as having material (usually indicated by the feeder of the corresponding slot not having material inserted while the red light remains constantly on), it is possible that the internal magnet is not rebounding smoothly.

¶ Step 4: Check the Internal Magnet

Check to ensure that all the four internal magnets are rebounding smoothly.

If they are not, you will need to replace the filament hub. You can buy it from Bambu Lab store.

You should also check their direction and ensure they are facing the correct way.

If they are not facing the correct direction, you should remove and reorient them. Check the installing magnets in filament hub wiki to how to do it.

If other components are damaged, you may want to consider replacing the filament hub. You can buy it from Bambu Lab store.

Once you have addressed the above issues, reassemble the components by following the internal hub replacement wiki.

¶ Verify Functionality

Ensure the filament can be loaded again and the printer resumes printing without any error.

¶ End Notes

We hope our guide was helpful. If you have any questions or concerns about the process, please contact our customer service team. We're here to assist you.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.