¶ Issue Description

Nozzle temperature control mainly includes a heater and an NTC sensor. When the heater is operating at full power but fails to bring the nozzle up to the target temperature within time, the TH board will trigger a "heater over-temperature" error. This is a safety mechanism designed to prevent potential damage to the device or other risks in case of a temperature control failure.

The NTC is a temperature sensor that continuously monitors the actual nozzle temperature in real time. If there is a fault with the heater, the NTC itself, or a poor connection between components, the system may misread the temperature and trigger this error.

Common Scenarios Causing the Error

- The silicone sleeve is broken or improperly installed.

- The heater or NTC is not installed properly or is faulty.

- The connectors of the heater or NTC are in poor contact.

- The TH board is faulty.

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electrical damage and safety hazards.

When you perform maintenance or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electrical components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to power off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Troubleshooting guide

¶ X1 Series Troubleshooting

Quick Check: The easiest way to troubleshoot this issue is to try replacing the complete hotend with a new one to see if the error is resolved.

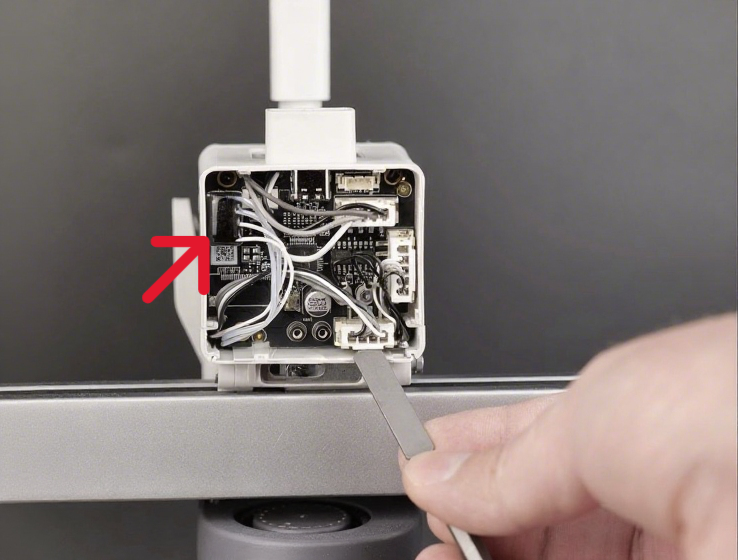

¶ Remove the Toolhead Front Cover

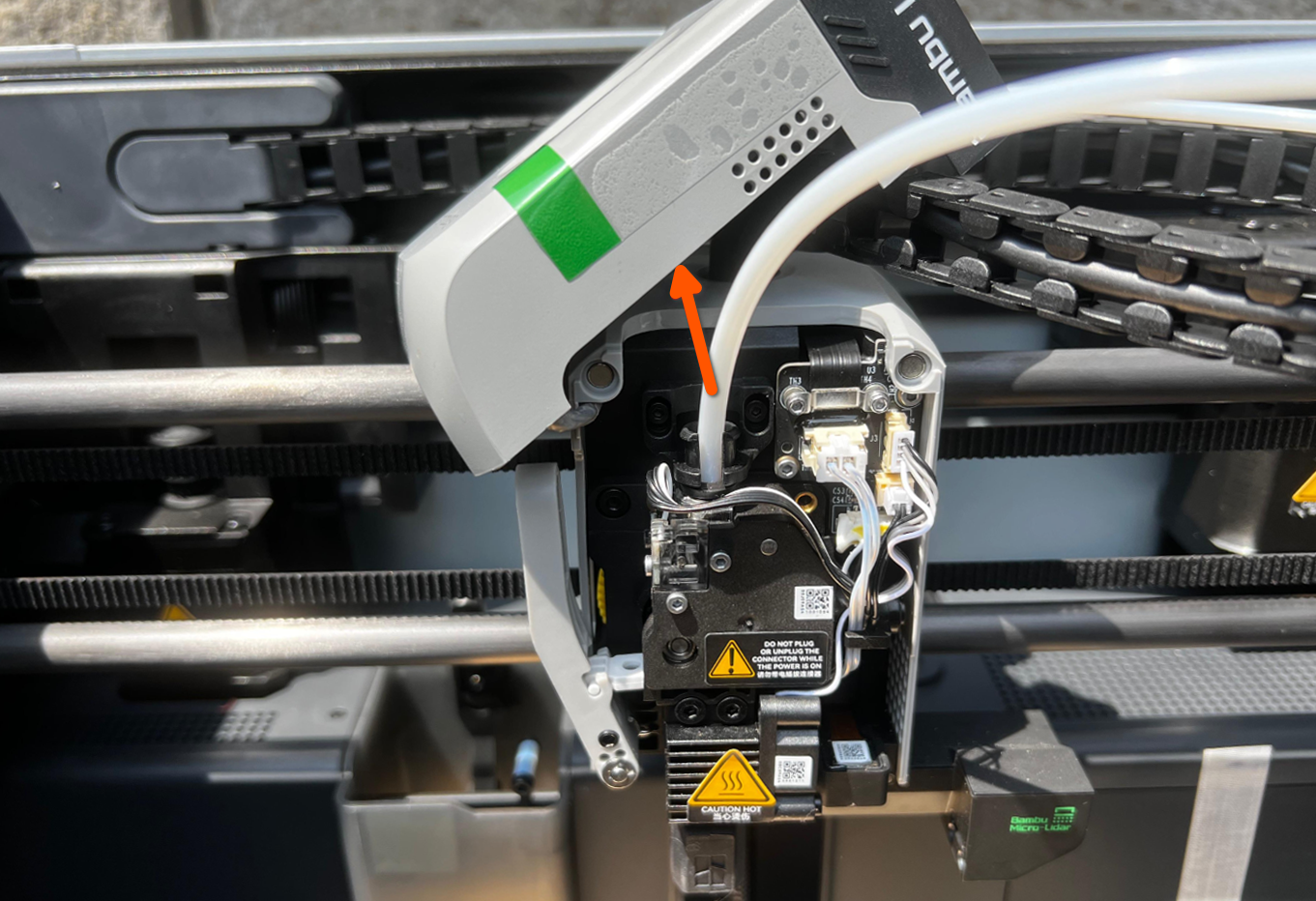

The X1 toolhead uses a magnetic front cover design, which can be removed directly by hand. Turn off the printer before operation. Gently open the front cover and rest it on the carbon rod as shown in the image. Handle with care to avoid damaging the connected cables.

¶ Reseat the cable of NTC

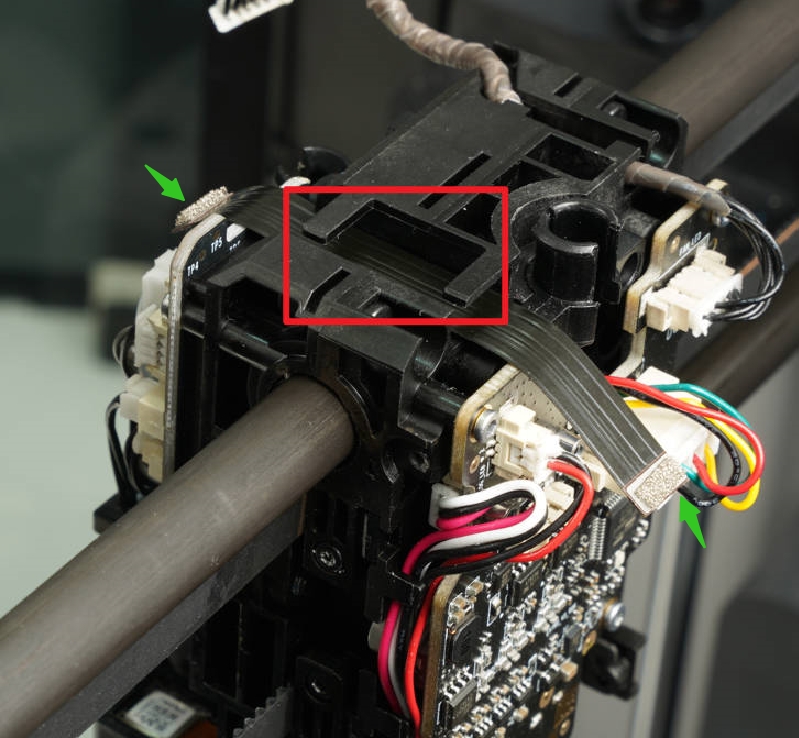

Reseat the cable of NTC and then check whether the error prompt disappears. The NTC for X1 series printers is located on the extrusion interface board.

¶ Disassemble the hotend

Please refer to this wiki to disassemble the hotend and check if the NTC sensor or wire is broken.

¶ Measure with a multimeter

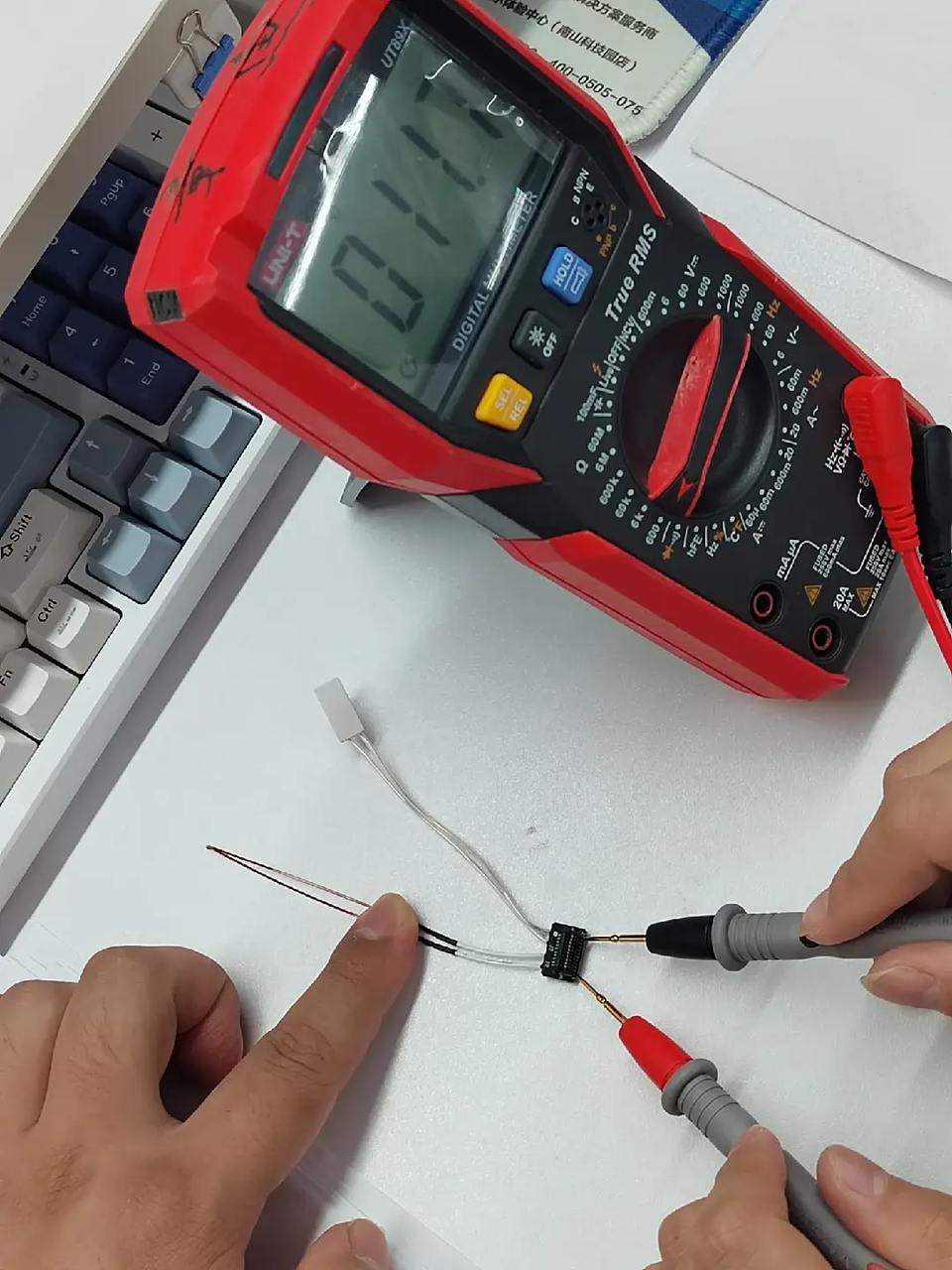

If you have a multimeter available, you can try measuring the resistance of the hotend component and follow the steps below to determine if there is a hotend malfunction.

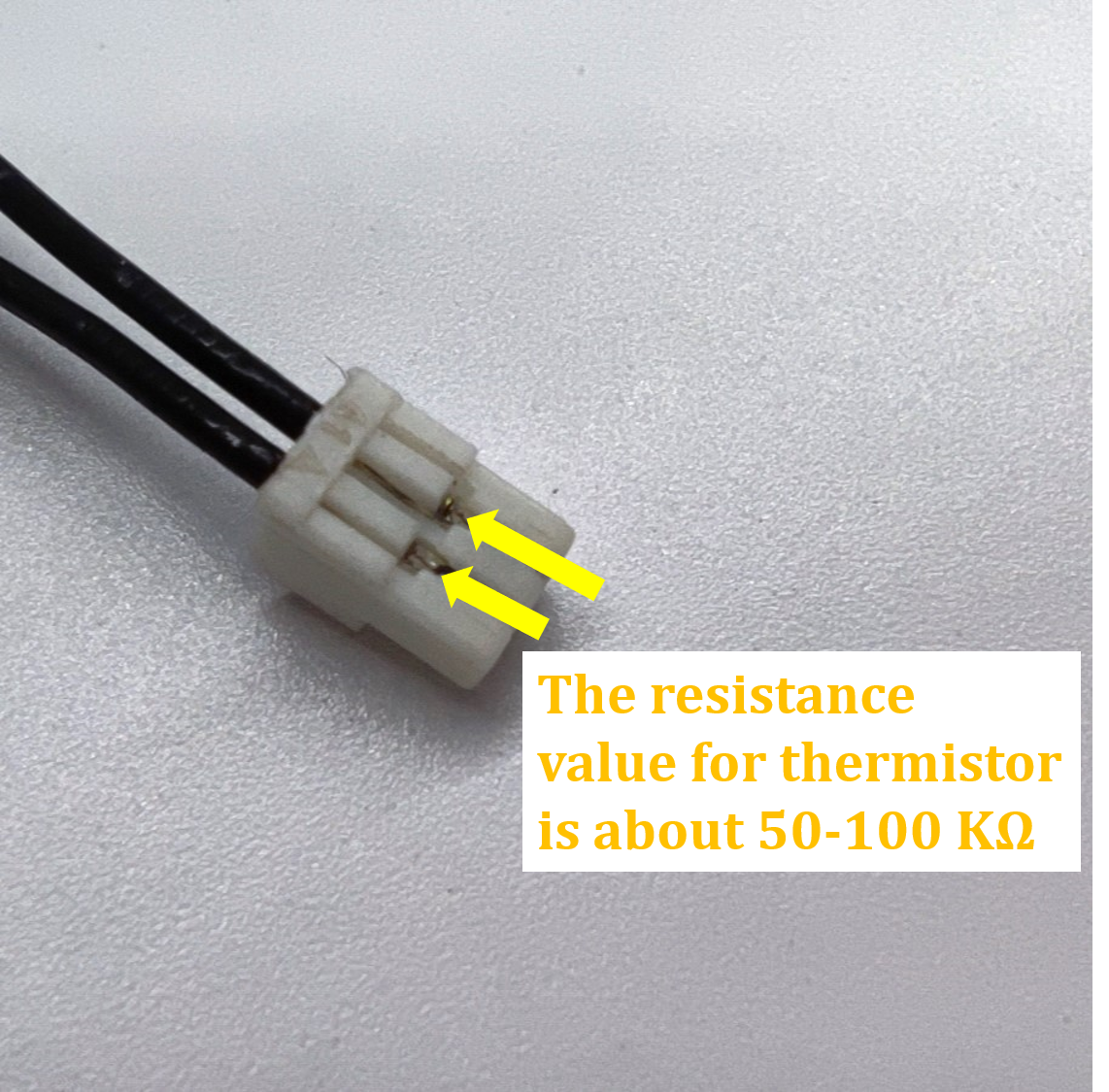

The resistance of the ceramic heater at room temperature is typically around 12Ω, while the resistance of the NTC is around 50-100 KΩ:

|

|

|

|

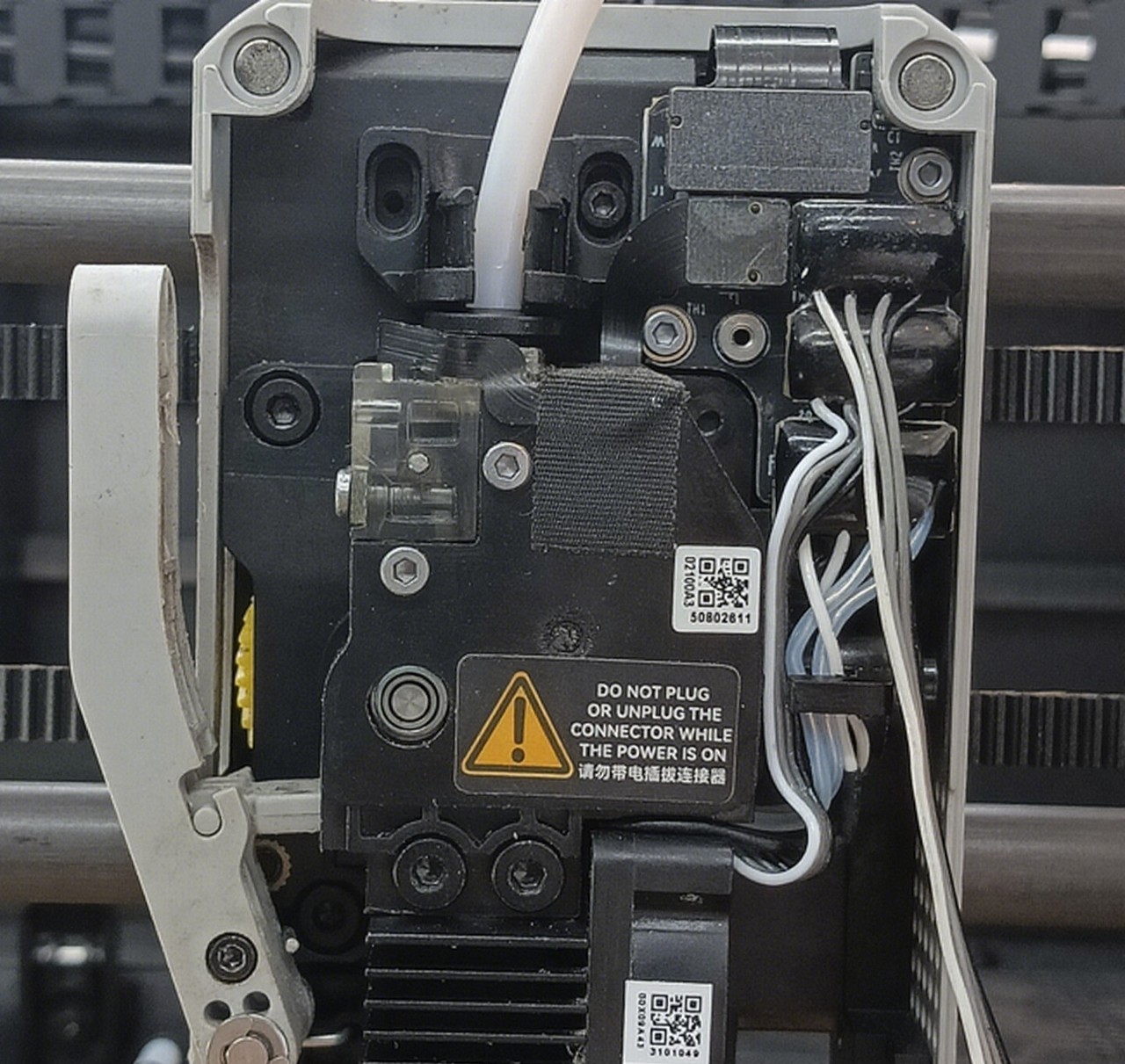

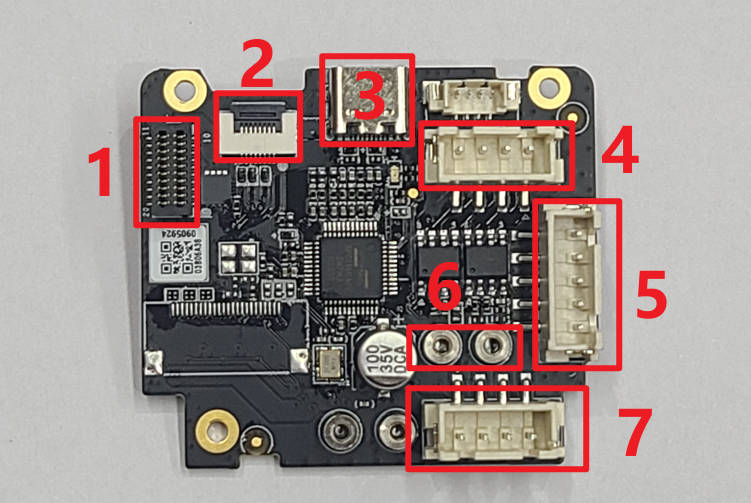

¶ Replug the 10Pin connector

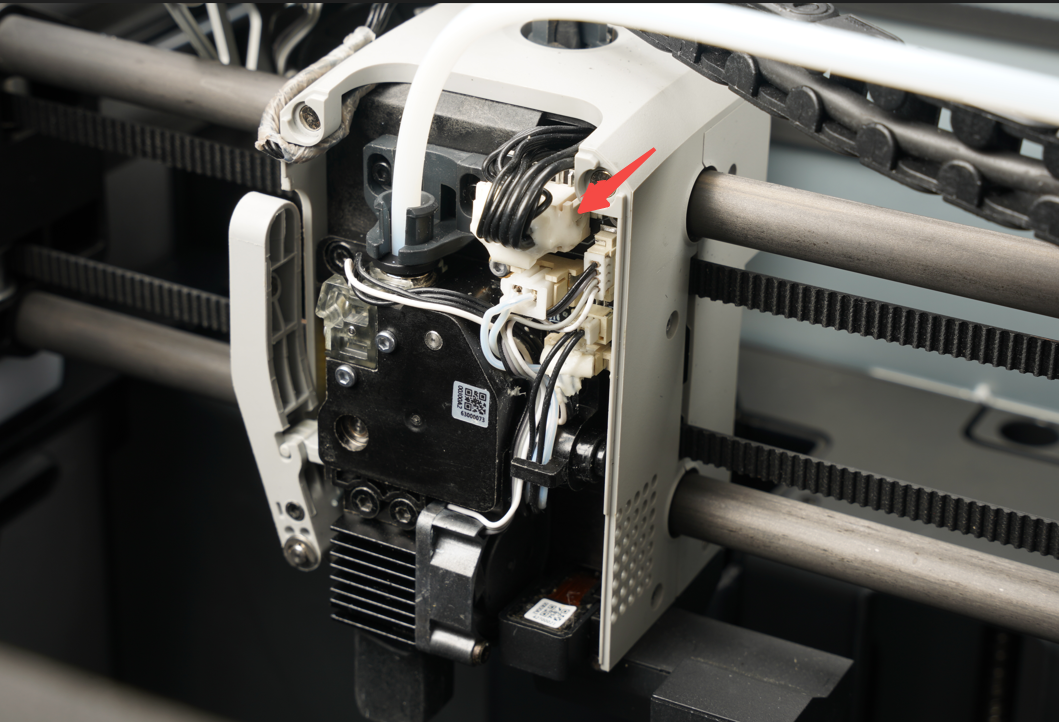

If you have a V8 TH board, replug the 10Pin connector (sometimes it needs to be replugged several times); also check for any signs of burnout on the 10-pin plug. You need to remove the silicone with tweezers before replugging it. Then try again.

If you have a V9 TH board, reseat both ends of the FPC.

V8 TH board |

V9 TH board |

Please refer to the following wiki for more information:

¶ P1 Series Troubleshooting

Quick Check: The easiest way to troubleshoot this issue is to try replacing the complete hotend with a new one to see if the error is resolved.

¶ Remove the Toolhead Front Cover

Turn off the printer and then open the toolhead front cover.

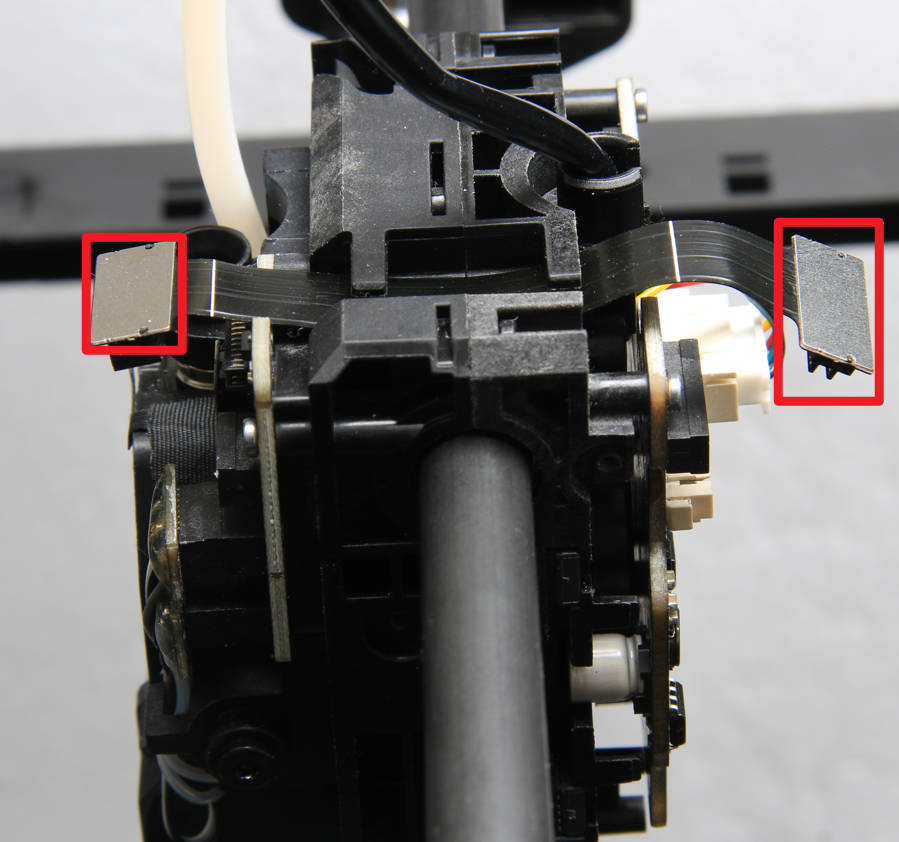

¶ Reseat the cable of NTC

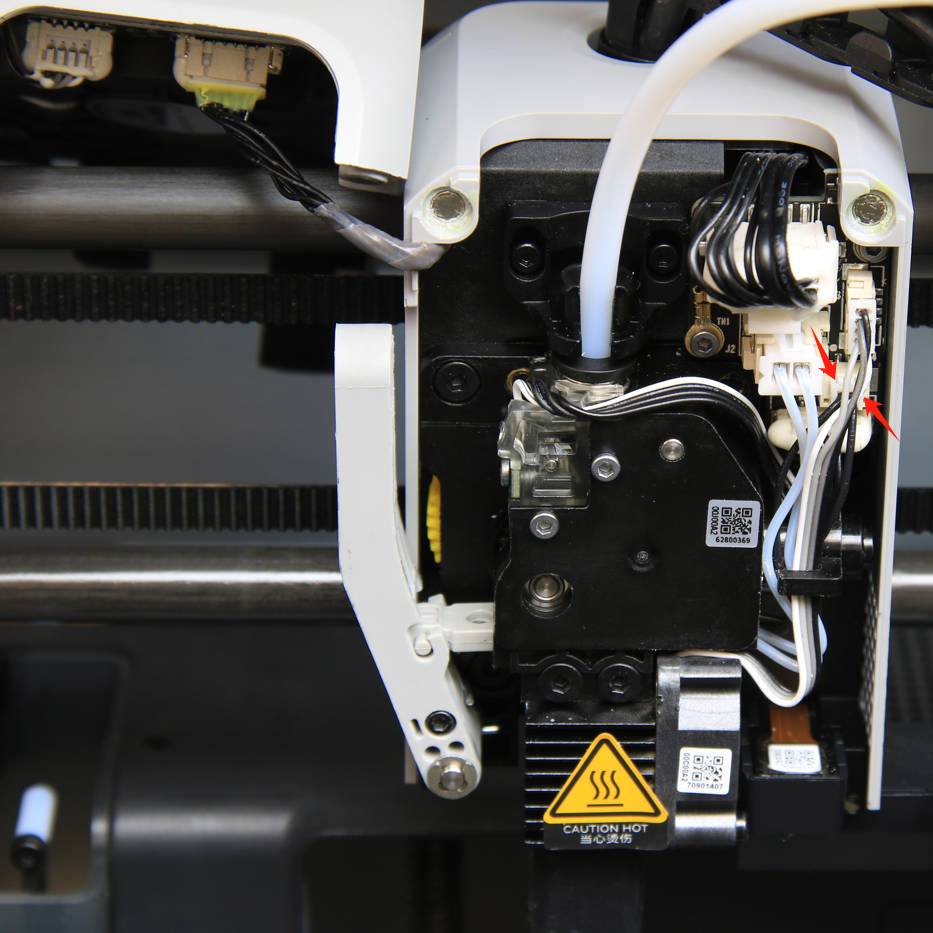

Reseat the cable of NTC as shown below and then check whether the error prompt disappears.

¶ Disassemble the hotend

Please refer to this wiki to disassemble the hotend and check if the NTC sensor or wire is broken. For the P1 series, the ceramic heater and the NTC are integrated into a single module through a combined terminal connector.

¶ Measure with a multimeter

If you have a multimeter available, you can try measuring the resistance of the hotend component and follow the steps below to determine if there is a hotend malfunction.

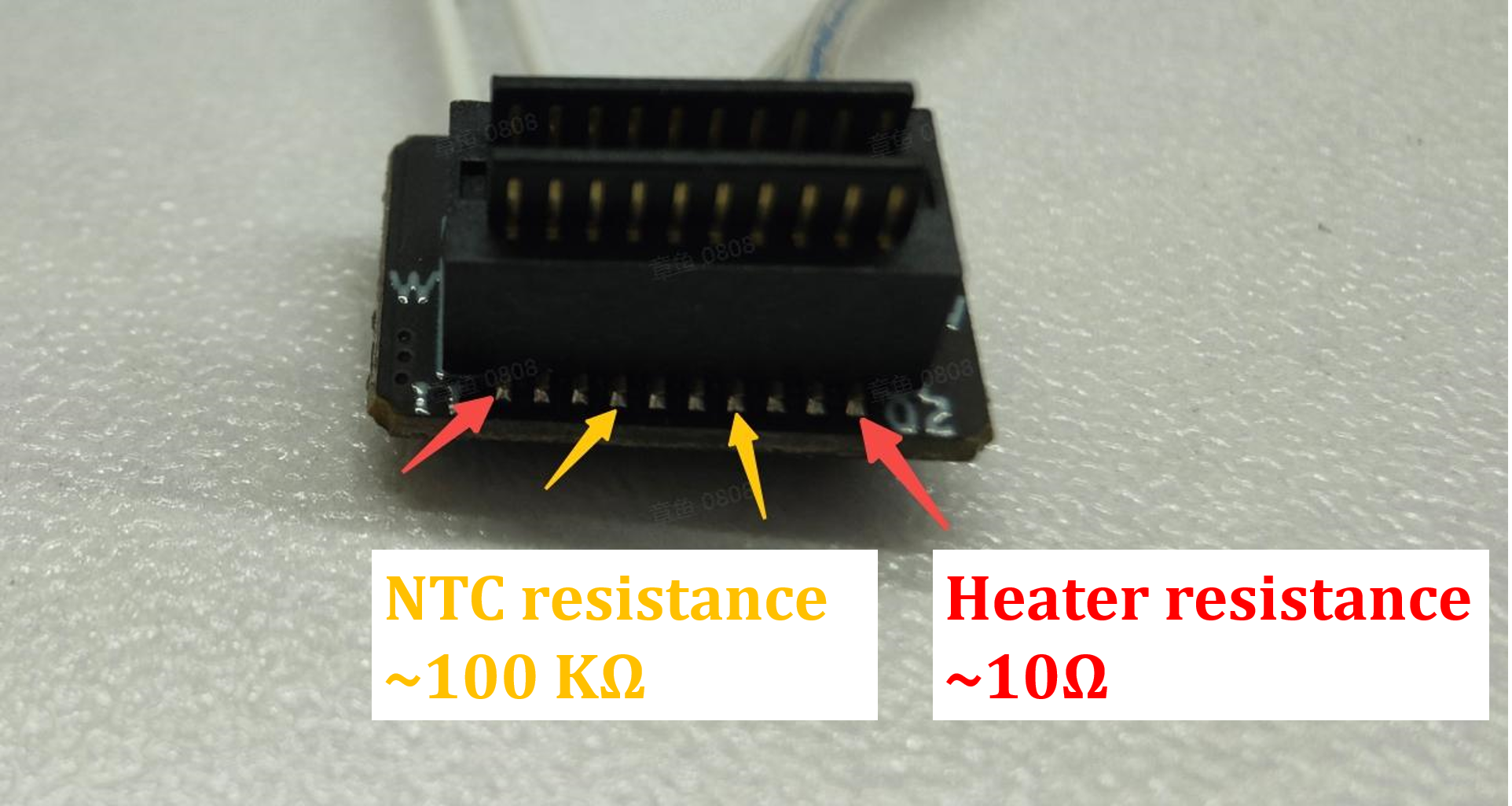

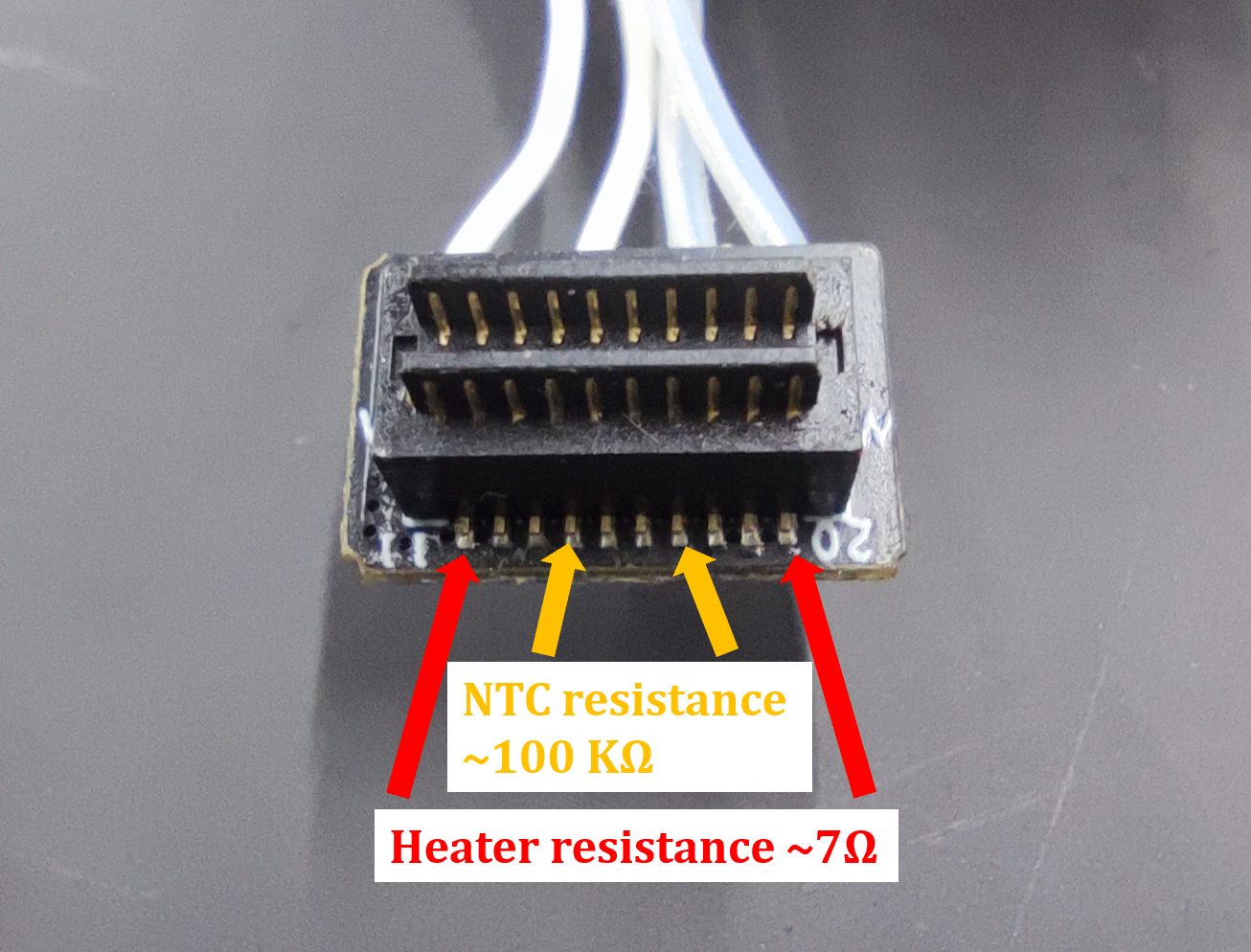

The resistance of the ceramic heater at room temperature is typically around 10Ω (two pins indicated by the red arrows in the image below), while the resistance of the NTC is around 100 KΩ (two pins indicated by the orange arrows ):

|

|

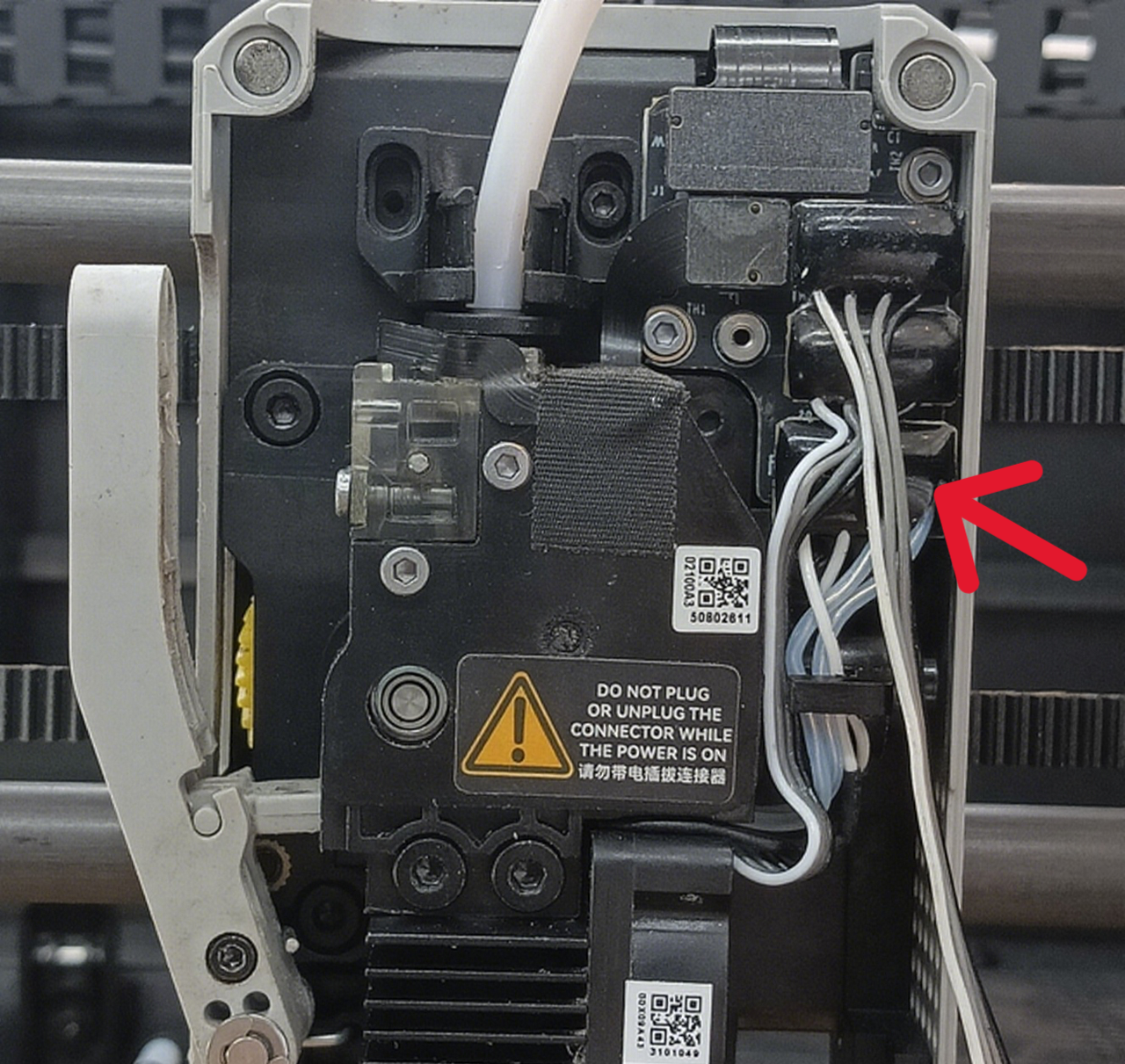

¶ Reseat the FPC

If the problem persists, reseat both ends of the FPC (sometimes you need to reseat it several times).

Please refer to the following wiki for more information:

PCBs on the toolhead of P1P | Bambu Lab Wiki

¶ A1 Series Troubleshooting

Quick Check: The easiest way to troubleshoot this issue is to try replacing the complete hotend with a new one to see if the error is resolved.

¶ Remove the Toolhead Rear Cover

Pull outward on the bottom of the rear cover as shown below, and open it.

¶ Reseat the cable of NTC

Reseat the cable of NTC as shown below and then check whether the error prompt disappears.

¶ Disassemble the hotend

Please refer to the wikis below to disassemble the hotend and check if the NTC sensor or wire is broken:

¶ Measure with a multimeter

If you have a multimeter available, you can try measuring the resistance of the hotend component and follow the steps below to determine if there is a hotend malfunction.

Typically, the error message for A1 series printers is 'Nozzle Temperature Malfunction'. To measure the resistance of the heating component, please remove the rear cover of the toolhead. The plug to be measured is the number 1 plug on the TH board.

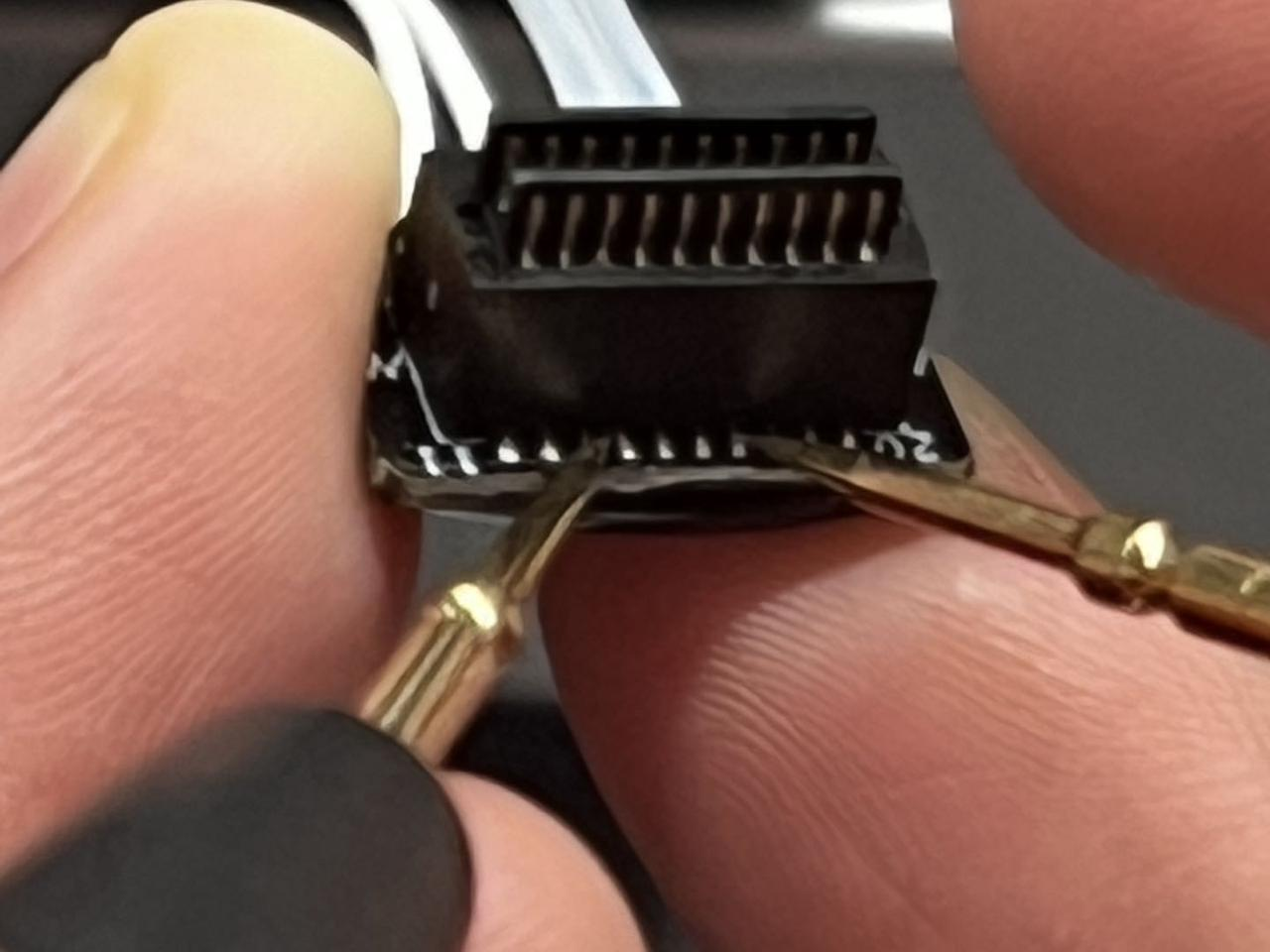

The resistance of the ceramic heater at room temperature is typically around 7Ω (two pins indicated by the red arrows in the image below), while the resistance of the NTC is around 100 KΩ (two pins indicated by the orange arrows, the resistance of NTC varies widely with temperature fluctuations):

|

|

¶ Contact the after-sales

If the message still shows up, please contact the after-sales team for further assistance.

¶ Error message

HMS_0300-0200-0001-0007: The nozzle temperature is abnormal, the sensor may be open circuit.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.