¶ Filament Selection and Management

¶ Material Quality Check and Selection Recommendations

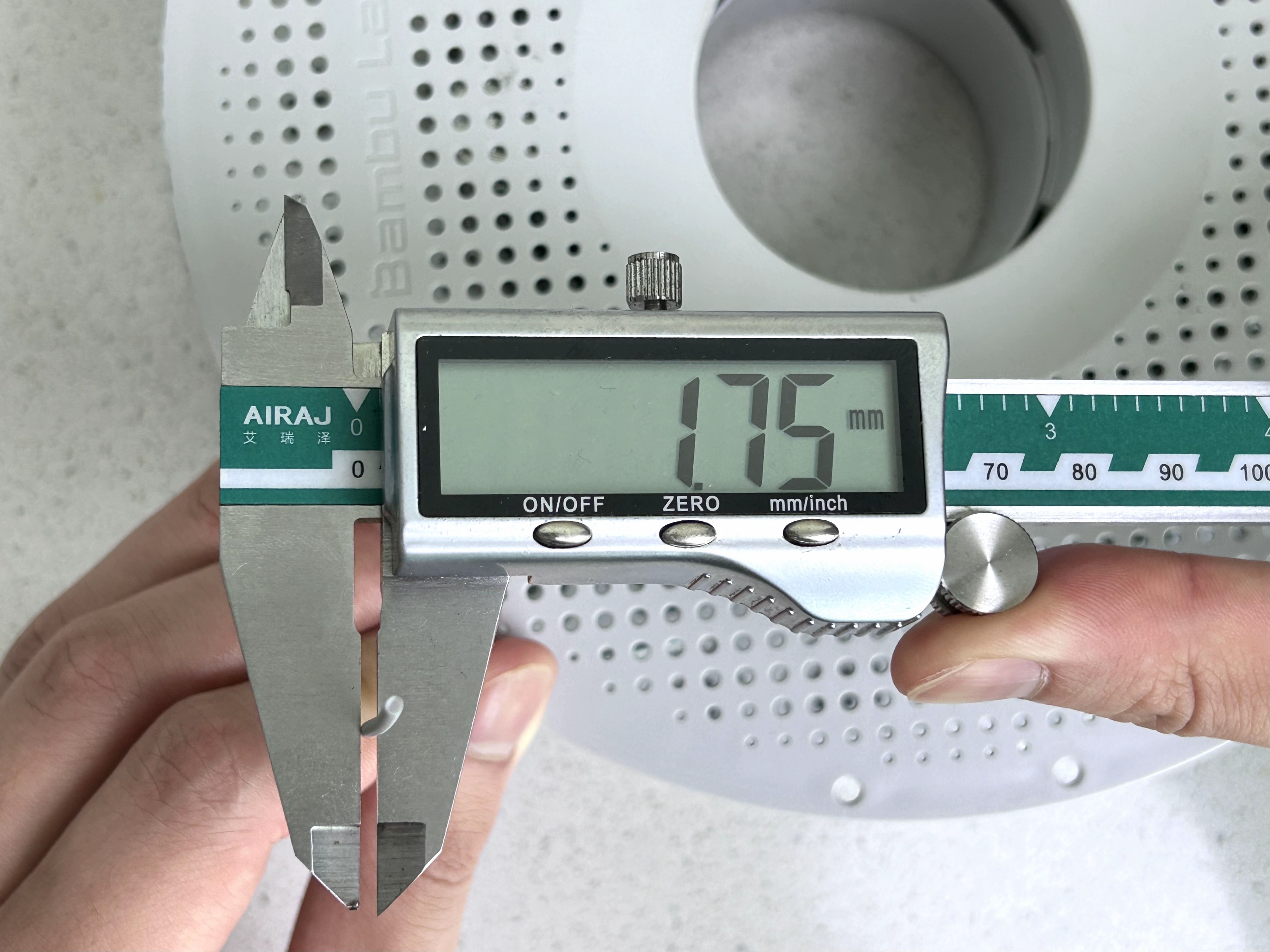

Common issues with low-quality filaments include inconsistent diameter and excessive impurities, both of which can lead to nozzle clogging. To avoid these problems, it is recommended to use high-quality filaments, such as Bambu Lab official filaments, which have better control over diameter and impurities. To verify the quality of your filament, you can measure the diameter using a caliper, ensuring it is within the 1.75±0.03mm range. Additionally, check the filament's surface and cross-section for impurities to ensure it is clean and free of contaminants.

Filament Diameter Measurement Diagram

¶ Proper Storage and Drying of Filament

Filament absorbs moisture, which is bad news for printing. Absorbed water vaporizes inside the nozzle, causing bubbles, stringing, poor flow, or rough surfaces. Engineering materials like PA, PC, CF, and GF are especially sensitive and prone to warping or clogging when damp.

Best practice:

-

Store filament in a sealed container or dry box when not in use.

-

For hygroscopic materials, dry them before printing for the best results.

Check out the links below for more information on filament drying:

| Link | What You’ll Find |

|---|---|

| Filament Drying Recommendations | Why drying matters and recommended drying temperatures/times for different materials. |

| How to Dry Filament on the X1, P1, and H2 Series Heatbed | Step-by-step guide to using built-in drying features on Bambu printers. |

| How to Use the AMS 2 Pro for Filament Drying With a Bambu Lab X1 and P1 Series | Learn the steps for using AMS 2 Pro for filament drying in Bambu X1/P1 series. |

| Introduction to AMS HT Workflow and Features | High-temperature drying features for advanced materials. |

¶ Switching Between High and Low-Temperature Materials

After printing with high-temperature materials such as PAHT-CF, PET-CF, PPA-CF, PPA-GF, PPS, or PPS-CF, you may want to switch to lower-temperature, softer filaments like PLA, TPU, or PETG. To avoid nozzle clogging and ensure smooth extrusion, follow this transition process:

- Set the nozzle temperature to 250–300 °C.

- Unload the high-temperature filament manually.

- Load the new low-temperature filament and let it push out the remaining high-temperature residue while gradually cooling down.

- Lower the nozzle temperature to 220–240 °C, continuing extrusion during cooldown until the new filament flows smoothly.

- Once the nozzle is stable and clean, you are ready for the next print.

¶ Printing Guidelines and Parameter Settings

¶ Set Temperatures According to Material

Each filament has specific nozzle and bed temperature requirements. Printing too cold can cause under-melting and clogs. Always check the recommended settings before printing.

Check out the links below for detailed filament guides and recommendations:

| Link | What You’ll Find |

|---|---|

| Filament guide - Compatibility to printer, nozzle, AMS, build plate, glue and required parametes | This article is a filament guide to help you choose the right filaments and materials with nozzle and plate compatibility, printing settings and storage info |

| TPU printing guide | Optimization techniques and parameter suggestions for TPU. |

| Printing guide for TPU 85A and 90A | Introduces the printing guides for TPU 85A and 90A. |

| Select the filaments you want to compare | Official filament overview, including compatibility, parameters, and precautions. |

| FDM 3D Printing Filament guide for Beginners | An introduction to common materials, their characteristics, and ideal use cases. |

¶ Control Chamber Temperature to Prevent Jamming

For softer filaments such as PLA and PETG, reduce the bed temperature when possible, and open the door or remove the top cover to help dissipate heat. This prevents soft filament from buckling or jamming inside the extruder.

Check out the links below for more information on filament compatibility and heat creep:

| Link | What You’ll Find |

|---|---|

| Filament guide - Compatibility to printer, nozzle, AMS, build plate, glue and required parametes | This article is a filament guide to help you choose the right filaments and materials with nozzle and plate compatibility, printing settings and storage info |

| What is heat creep? | This article describes the definition of heat creep, its main causes, common troubles, and avoidance measures, and adds other considerations. |

¶ Adjust Printing Speed Properly

If extrusion fails, first check that the nozzle temperature is set correctly. Persistent extrusion issues may indicate a worn-out or damaged heater cartridge.

Printing too fast (e.g., in Ludicrous Mode) may not allow enough time for proper melting, leading to partial clogs. Clean the nozzle, then either reduce speed or slightly increase temperature before resuming.

For more detailed guides on filament settings and TPU printing, check out the links below:

| Link | What You’ll Find |

|---|---|

| Filament guide - Compatibility to printer, nozzle, AMS, build plate, glue and required parametes | This article is a filament guide to help you choose the right filaments and materials with nozzle and plate compatibility, printing settings and storage info |

| TPU printing guide | Optimization techniques and parameter suggestions for TPU. |

| Printing guide for TPU 85A and 90A | Introduces the printing guides for TPU 85A and 90A. |

¶ Clear Residues from Fiber-Reinforced Filaments

When printing with filaments containing fibers or other particulate matter (e.g., PAHT-CF, PA-GF), there is a risk of residual particles accumulating inside the nozzle, which can lead to partial blockages. To prevent print failures and ensure consistent extrusion quality, it is essential to regularly clean and unclog the nozzle. For cleaning methods, please refer to the cold-pull technique.

¶ Avoid Frequent Start/Stop Printing

Repeated short prints with constant heating/cooling cycles accelerate residue buildup. Where possible, combine smaller jobs into a single print.

¶ Maintenance and Care

¶ Perform Regular Cold Pulls

Cold pull cleaning helps remove debris and reduce extrusion resistance. The process works by softening filament inside the nozzle, cooling it until partially solid, then pulling it out along with burnt residue or dust.

Routine cold pulls extend nozzle life and ensure consistent flow. We recommend performing one at least once a month, especially when switching between different filament types.

Check out the links below for detailed cold pull procedures for different printer series:

| Link | What You’ll Find |

|---|---|

| X1 Series Nozzle Cold Pull Maintenance and Cleaning | Step-by-step cold pull procedure for the X1 series. |

| P1 Series Nozzle Cold Pull Maintenance and Cleaning | Step-by-step cold pull procedure for the P1 series. |

| H2D Nozzle Cold Pull Maintenance and Cleaning | Step-by-step cold pull procedure for the H2D series. |

| H2S Nozzle Cold Pull Maintenance and Cleaning | Step-by-step cold pull procedure for the H2S series. |

¶ Install the Silicone Sock

Ensure the silicone nozzle cover is properly installed. It stabilizes nozzle temperature and reduces filament buildup. Missing or loose covers can affect detection accuracy and print quality.

¶ Nozzle Clog Troubleshooting

Even with proper maintenance, occasional clogs are normal and not a sign of serious malfunction.

The symptoms are fairly easy to diagnose as these will show themselves through:

- Under extrusion: not enough plastic is being extruded, resulting in gaps around the printed model

- No extrusion: the printer is doing the right moves, but no filament is coming out of the nozzle

💡 Tip

Nozzle clogs are a common, minor issue in 3D printing. With regular care and correct operation, your printer will continue delivering high-quality results.

For more detailed guides on unclogging the nozzle for different printer, check out the links below:

| Link | What You’ll Find |

|---|---|

| Nozzle/Hotend Unclogging Procedure for X1/P1 | This guide shows a few examples of how to remove a clog on the X1/P1 hotend/nozzle |

| H2D Nozzle/Hotend Unclogging Procedure | This guide shows a few examples of how to remove a clog on the H2D nozzle/hotend. |

| H2S Hotend Unclogging Procedure | This article will systematically introduce the troubleshooting methods and detailed operation steps when the H2S hotend is clogged. |

| A1 series Nozzle Unclogging Guide | A guide showing how to unclog the A1 hotend / nozzle |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!