This guide explains the troubleshooting process recommended when the filament stops extruding.

Most of the time, this problem is located around the print head, but in rare cases it could also be related to external factors like AMS, filament path or PTFE tubes.

¶ When to use?

This guide should be used when the extruder is clicking and/or not extruding filament.

Common issues that cause this problem for X1 and P1 Series printers

- Nozzle has a clog and needs to be unclogged

- Nozzle temperature is too low

- The extruder is clogged

- The filament sensor on the extruder is damaged/clogged

- The extruder motor is faulty

- The TH board is faulty / USB C cable for TH board has a bad connection

¶ Tools and materials needed

- H2.0 hex wrench

- 20 minutes of your time

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenance or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Potential clog locations

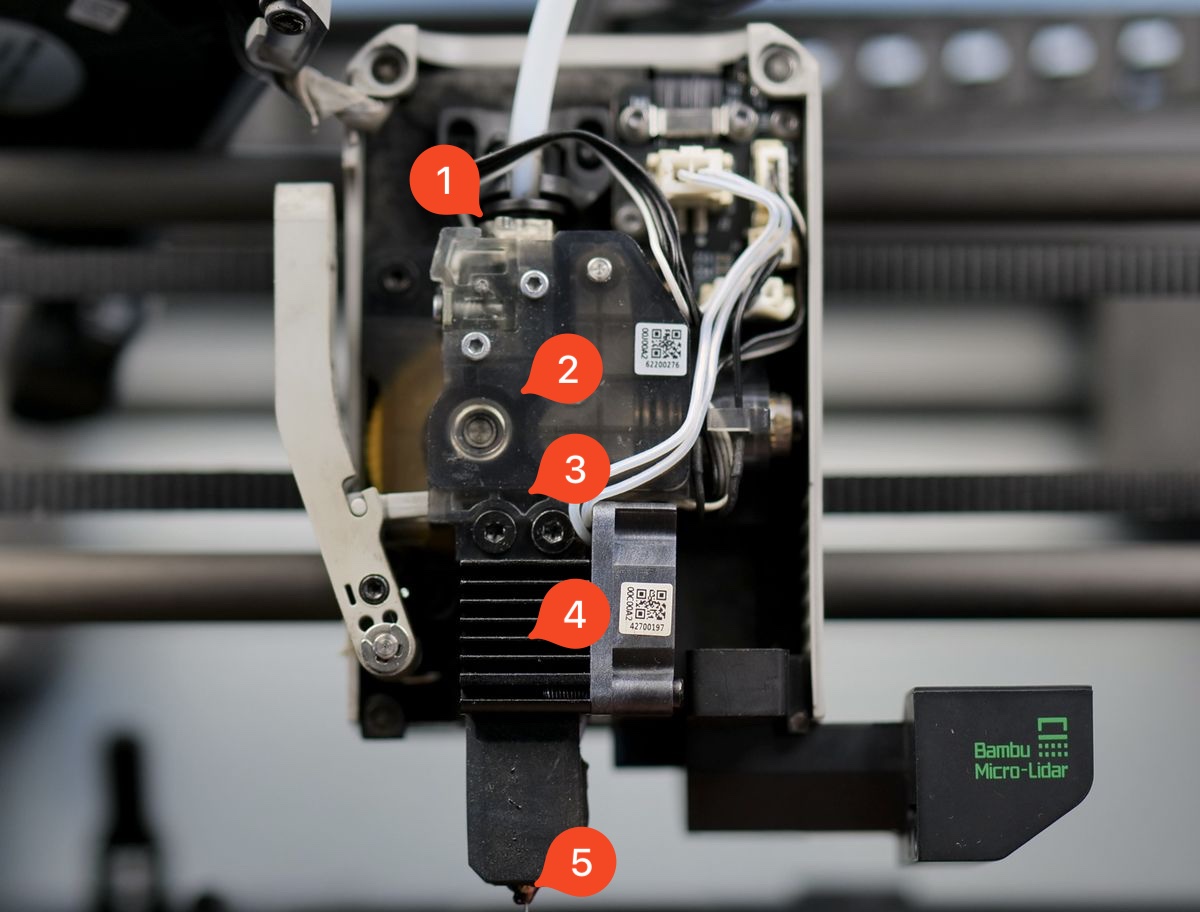

In the image below, you can see a few potential clog locations.

¶ 1. Filament sensor

The filament sensor could have filament dust / debris inside which “locks” the magnet in place and does not allow the filament to be fed to the extruder gears

To solve the problem, please follow this guide to clean the Filament Sensor before moving to the other step.

¶ 2. Extruder gears

Inside the extruder there could be filament debris which causes the gears of the extruder to get stuck. This is more common for printers that have not been regularly maintained as expected.

Another possibility is to have an extruder clog caused by filament which has become softer inside the extruder, due to heat creep. This guide explains the problem in more detail and we recommend reading it to learn more about this problem.

The best way to solve an issue related to the extruder gears is to remove the extruder, clean it thoroughly and also grease the extruder gears according to the Extruder Maintenance Guide.

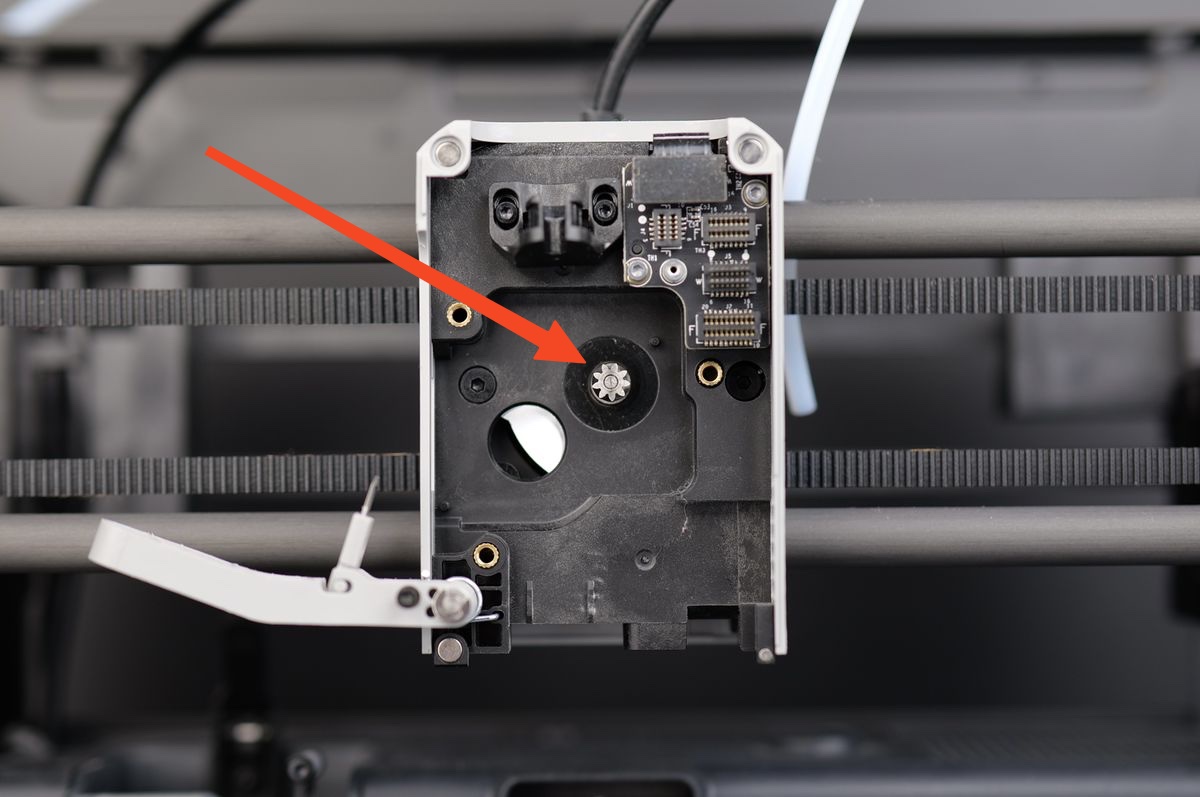

When the extruder is removed from the printer, you should be able to easily spin the yellow gear without feeling any restriction in the motion.

¶ 3. Filament Cutter

If the filament cutter has not been replaced in a long time, it might not cut the filament cleanly. When this happens, the filament could get stuck during retraction.

Lack of regular maintenance could also lead to debris and dust reaching inside the filament cutter path, making it harder move. If the filament cutter gets stuck in a less ideal position it could block the filament path and make the extruder skip steps.

The easiest solution for this is to perform the extruder maintenance and replace the filament cutter blade at the same time.

¶ 4. Heat Creep with filament stuck in the cold end

If you print filaments with a low glass transition temperature (PLA, PETG, TPU) in an enclosed printer (X1 series and P1S) the chamber temperature will get higher which can lead to the filament getting stuck in the cold end of the hotend.

The solution in this case would be to follow our wiki on how to unclog the hotend. In specific cases, you might not be able to unclog the hotend, and in that case you will need to install a new one.

We also recommend reading this wiki article to learn more about heat creep and how to avoid it in the future.

¶ 5. Nozzle tip getting clogged

This problem is quite common when printing with filaments that contain different types of particulates inside. CF filament has small carbon fiber particulates added to the nozzle that could lead to clogs in some situations.

When this problem occurs, the extruder might start clicking and filament will stop extruding.

The solution in this case would be to follow our wiki on how to unclog the hotend. In specific cases, you might not be able to unclog the hotend, and in that case you will need to install a new one.

We also recommend using a 0.6 mm nozzle when printing filaments that have different particulates in it to avoid clogs.

¶ Motor related issues

There is also a very low chance for the Extruder motor to fail. When this happens, the motor does not have enough power to turn the extruder gears leading to skipped steps.

The best way to test the extruder motor is to follow these steps:

¶ 1. Remove the extruder from the print head

The first step is to remove the extruder from the print head.

¶ 2. Use the extrude buttons on the printer screen to turn the extruder motor gear

Tap the load filament button a few times to turn the extruder motor gear

¶ 3. Try to stop the extruder motor

The purpose of this test is to try and grab the extruder motor gear while it is spinning, and stop it.

If the extruder motor works as expected, you should not be able to easily stop the motor from spinning. This would confirm that the extruder motor is working as expected.

But if the extruder motor can be stopped easily during extrusion, then the extruder motor might be faulty and will need to be replaced.

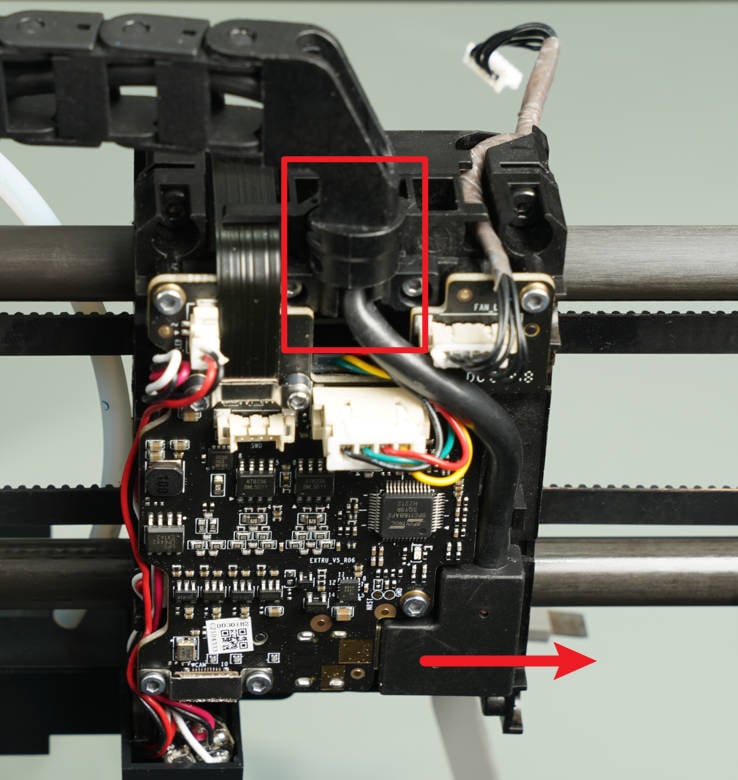

Before replacing the extruder, we recommend double-checking the extruder motor cable connection on the TH board and re-connecting it.

We also recommend to re-connect the main USB cable on the TH board (step 4 in this guide).

If the problem persists, the issue could be related to the Extruder Motor or the TH board / USB C cable and our Customer Support team can offer more insight into this issue.

Make sure to provide them the log file of the printer, and the information about the tests you have done.

¶ Calibration step after the operation

We recommend performing a bed leveling procedure to ensure everything is working as expected.

We also strongly recommend washing the PEI textured plate before use, as it might have been contaminated during this procedure.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.